Graphene and nickel diselenide composite and preparation method thereof

A technology of nickel diselenide and composite materials, which is applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, and achieves the effects of simple preparation process, rich source of raw materials and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Mix 5 mL of hydrazine hydrate with 10 mL of graphene oxide aqueous solution with a concentration of 0.1 mg / ml, stir evenly to form a brown solution, and then add it to a polytetrafluoro-lined stainless steel reactor. Fill 1 mmol sodium selenite and 0.5 mmol nickel sulfate In the above reaction kettle, close and tighten the reaction kettle to make it airtight; put it in an oven, set the temperature at 100℃, take out the reaction kettle after 0.5h reaction, let it cool naturally, filter the mixture in the reaction kettle, and use distilled water Repeated washing and suction filtration with absolute ethanol, and finally drying in a vacuum oven at 40°C for 0.5h, collecting samples and storing them in a desiccator.

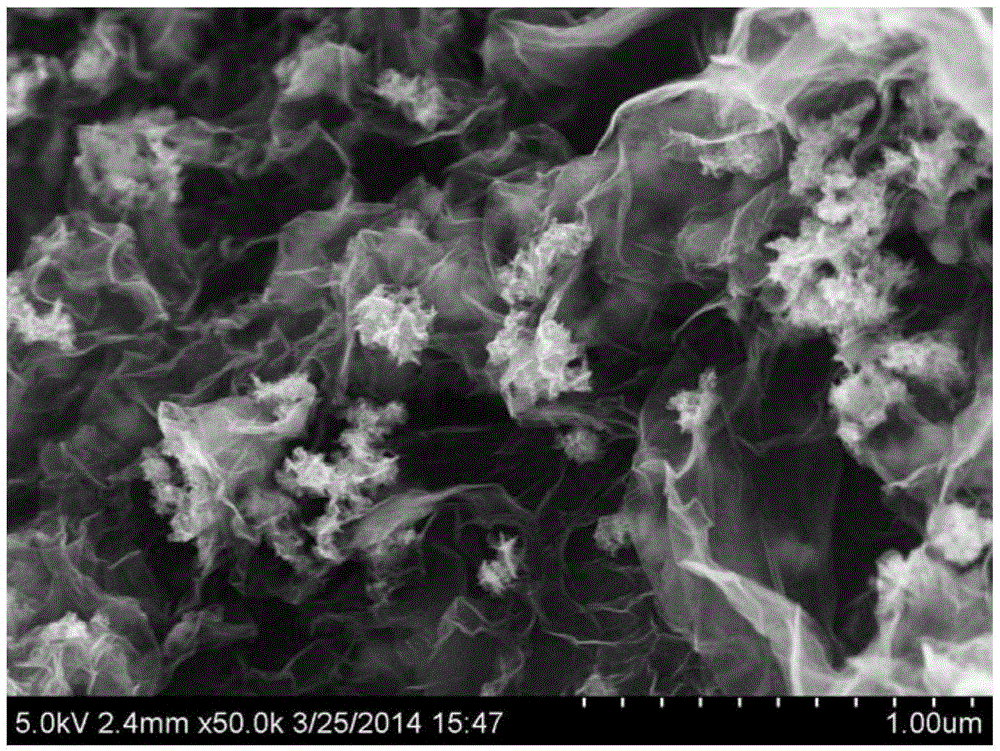

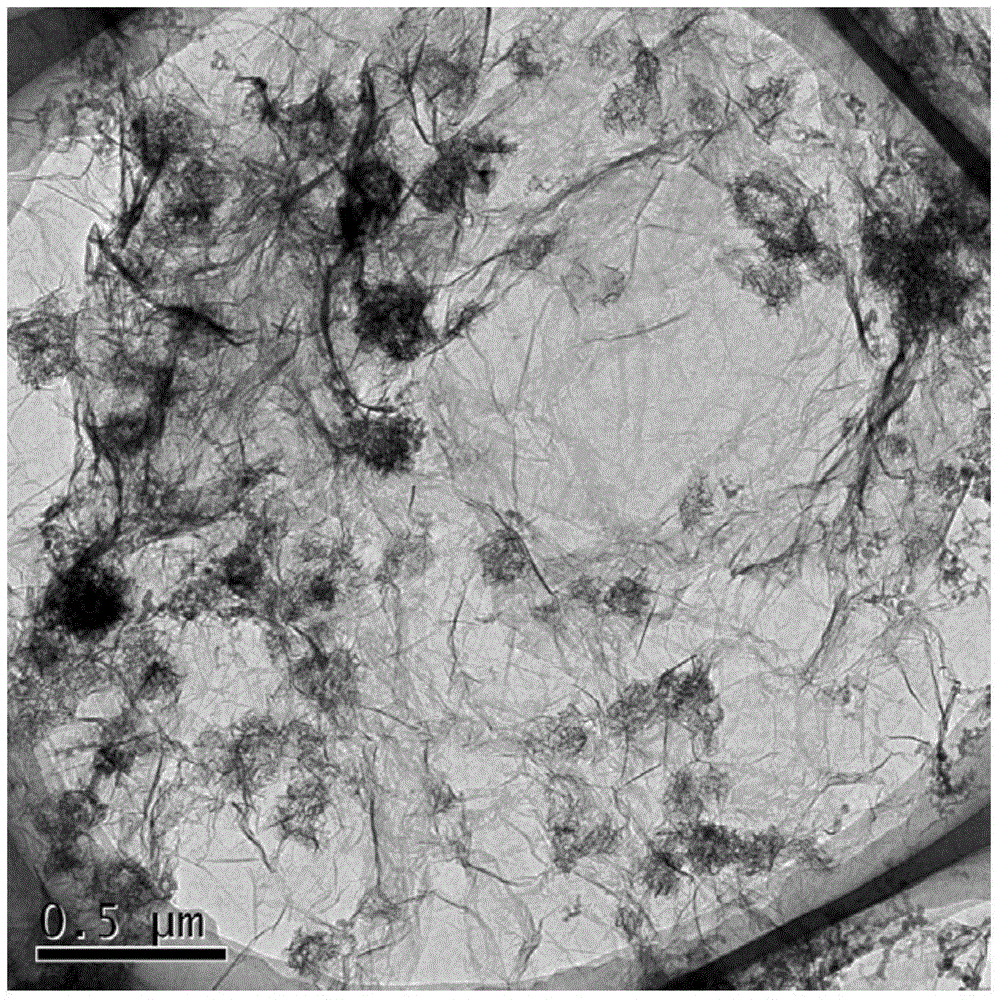

[0043] figure 1 with figure 2 SEM and TEM images of the samples prepared in this example. It can be seen from the figure that the prepared nickel diselenide is spherical particles, which are relatively uniformly distributed on the graphene sheet, with an average p...

Embodiment 2

[0045] Mix 1mL of hydrazine, 1mL of dimethylhydrazine, 1mL of vitamin C, 2mL of hydrogen iodide with 50mL of graphene oxide aqueous solution with a concentration of 20mg / ml, stir evenly to form a dark brown solution, and then add it to a Teflon-lined stainless steel reactor. Put 1mmol potassium selenite, 0.2mmol nickel nitrate, 0.3mmol nickel perchlorate into the above reaction kettle, close and tighten the reaction kettle to make it airtight; put it in the oven, set the temperature at 250℃, react for 72h Take out the reaction kettle and let it cool naturally. The mixture in the reaction kettle is suction filtered, washed and filtered repeatedly with distilled water and absolute ethanol, and finally dried in a vacuum oven at 100°C for 24 hours. The samples are collected and stored in a desiccator.

Embodiment 3

[0047] Mix 2mL sodium borohydride, 2mL formaldehyde, 2mL acetaldehyde, 2mL hydroquinone, 2mL p-phenylenediamine and 10mL graphene oxide aqueous solution with a concentration of 1mg / ml, stir evenly to form a dark brown solution, and then add to the polytetrafluoroethylene In a stainless steel reactor lining, put 1.5mmol elemental selenium and 0.5mmol nickel oxalate into the above reactor, close and tighten the reactor to make it sealed; put it in the oven, set the temperature at 150℃, take it out after reacting for 24h The reaction kettle was allowed to cool naturally, the mixture in the reaction kettle was suction filtered, washed and filtered repeatedly with distilled water and absolute ethanol, and finally dried in a vacuum oven at 60°C for 12 hours. The samples were collected and stored in a desiccator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com