Preparation method of polypyrrole ppy nanocellulose nccs composite membrane electrode material

A nanocellulose and composite technology is applied in the field of preparation of polypyrrole PPy nanocellulose NCCs composite membrane electrode materials, which can solve the problems of difficult processing, poor mechanical properties, working voltage and energy storage density to be improved, etc. The effect of enhanced electrochemical properties, low cost, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

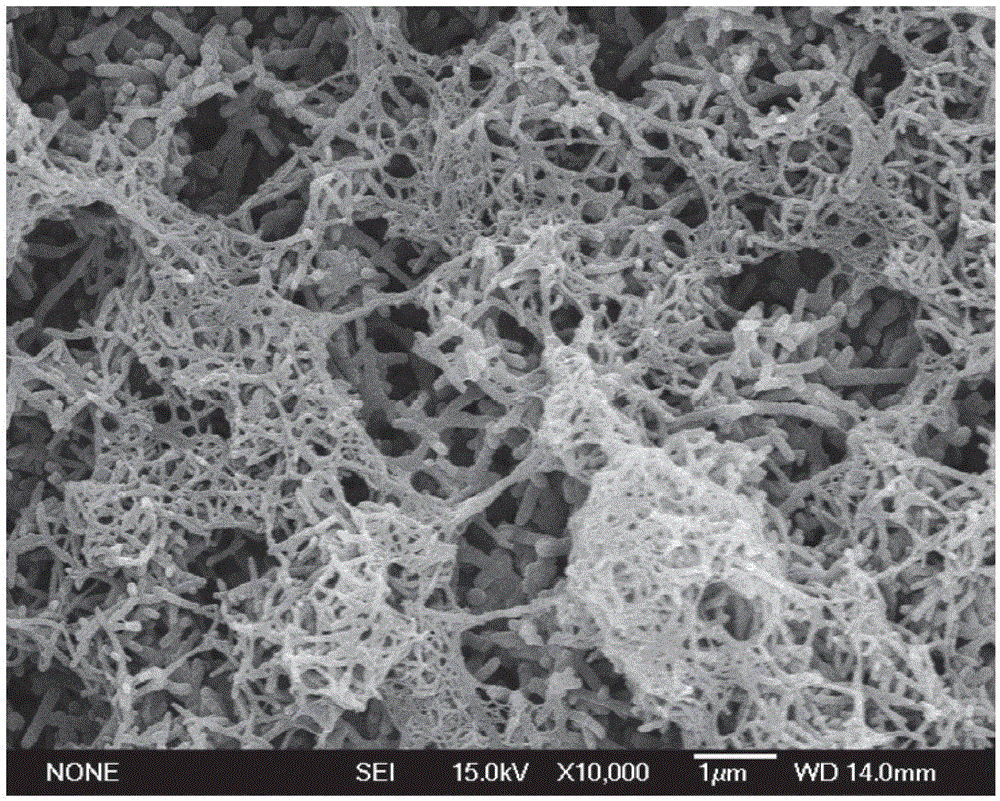

[0020] Embodiment 1: The preparation method of the polypyrrole PPy nanocellulose NCCs composite membrane electrode material that this embodiment provides, it comprises the following steps: to plant raw material pretreatment and hydrolysis, obtain NCCs from plant raw material, the NCCs that will obtain and The pyrrole monomers are mixed to form an electrolyte, and the polypyrrole PPy nanocellulose NCCs composite membrane electrode material is prepared by an electrochemical method.

[0021] Described preparation method specifically comprises the following steps:

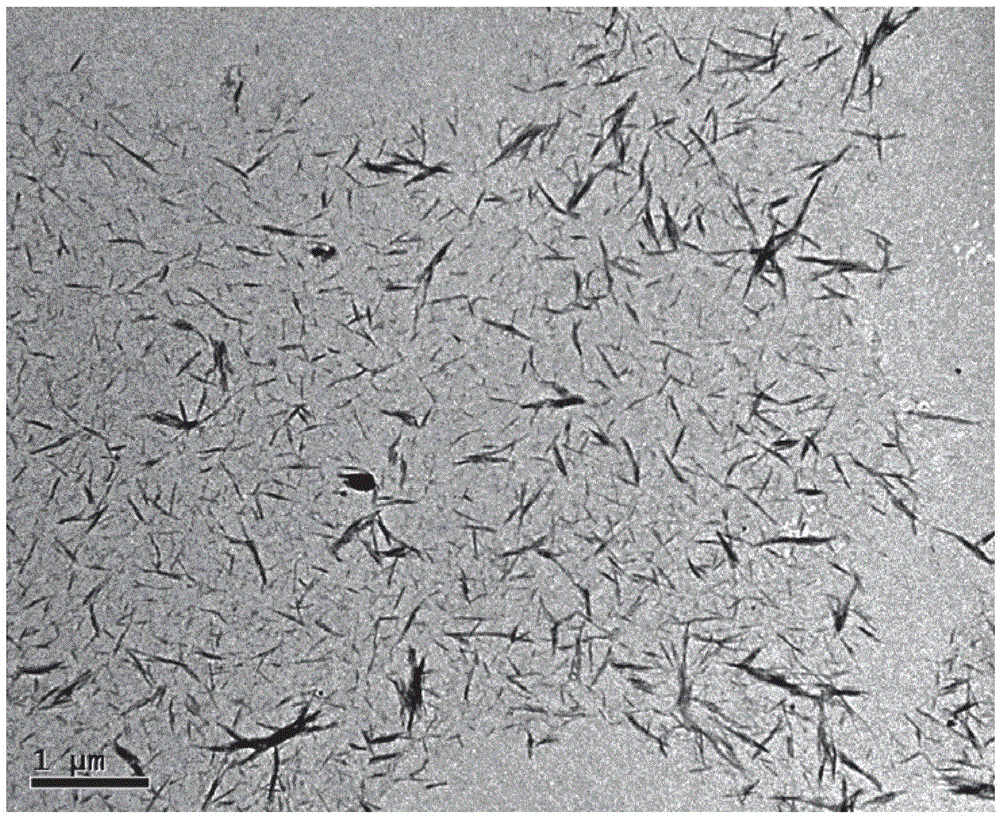

[0022] (1) For the pretreatment and hydrolysis of the plant raw material, the plant raw material is added to 2% NaOH aqueous solution, heated and reacted for 1h and then washed by suction filtration, then heated and reacted in the NaClO solution for 30min, after suction filtered and washed, rinse with 55% H 2 SO 4 Heating and hydrolysis reaction in aqueous solution for 30mins, and finally centrifuging and washing to o...

Embodiment 2

[0029] Example 2: The preparation method of the polypyrrole PPy nanocellulose NCCs composite membrane electrode material provided in this example, the steps are basically the same as in Example 1, except that:

[0030] (1) For the pretreatment and hydrolysis of ramie, ramie is added to 2% NaOH aqueous solution, heated and reacted for 1 hour, then filtered and washed by suction, then heated and reacted in NaClO solution for 30 minutes, after suction filtered and washed, rinse with 55% H 2 SO 4 Heating and hydrolysis reaction in aqueous solution for 30mins, and finally centrifuging and washing to obtain nanocellulose NCCs;

[0031] (2) The nanocellulose NCCs prepared in step (1) is mixed with deionized aqueous solution of 5.0 mg / mL pyrrole monomer by 0.1 mg / mL to obtain an electrolyte;

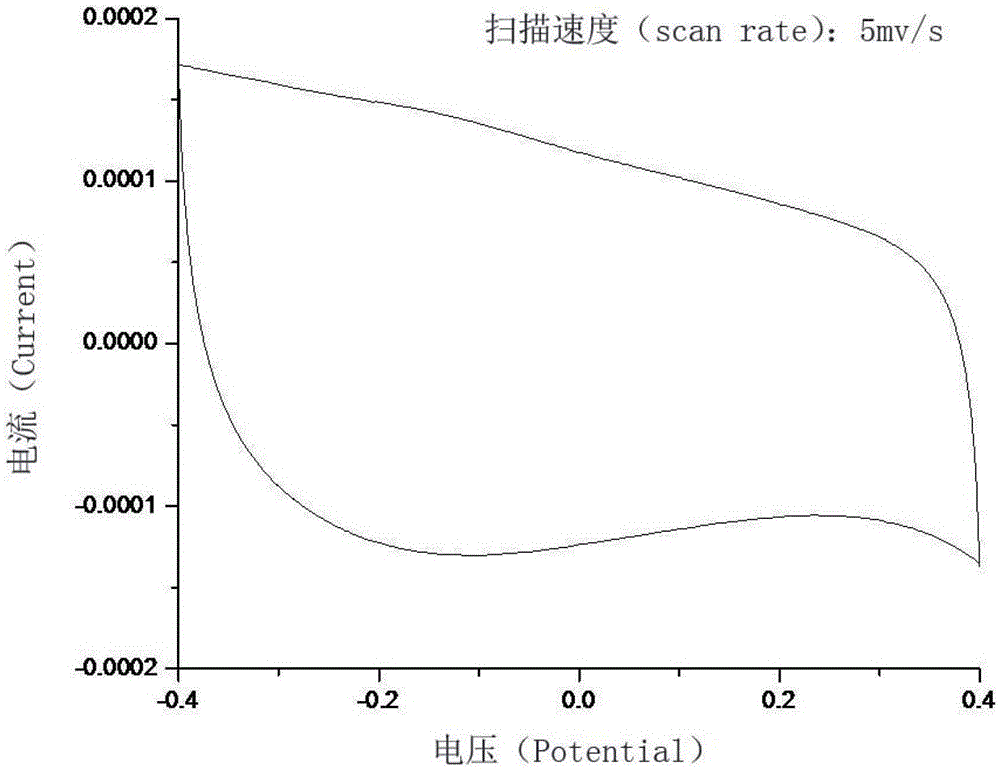

[0032] (3) A three-electrode system is adopted, with conductive glass ITO / FTO as the working electrode, the reference electrode and the counter electrode are respectively a saturated calomel el...

Embodiment 3

[0033] Example 3: The preparation method of the polypyrrole PPy nanocellulose NCCs composite membrane electrode material provided in this example, its steps are basically the same as those in Example 1 and 2, the difference is:

[0034] (1) For the pretreatment and hydrolysis of sisal, sisal is added to 2% NaOH aqueous solution, heated and reacted for 1h and then washed by suction filtration, then heated and reacted in NaClO solution for 30min, after suction filtered and washed, rinse with 55% H 2 SO 4 Heating and hydrolysis reaction in aqueous solution for 30mins, and finally centrifuging and washing to obtain nanocellulose NCCs;

[0035] (2) The nanocellulose NCCs prepared in step (1) is mixed with a deionized aqueous solution of 15.0 mg / mL pyrrole monomer at 5.0 mg / mL to obtain an electrolyte;

[0036] (3) A three-electrode system is adopted, the glassy carbon electrode GC is used as the working electrode, the reference electrode and the counter electrode are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com