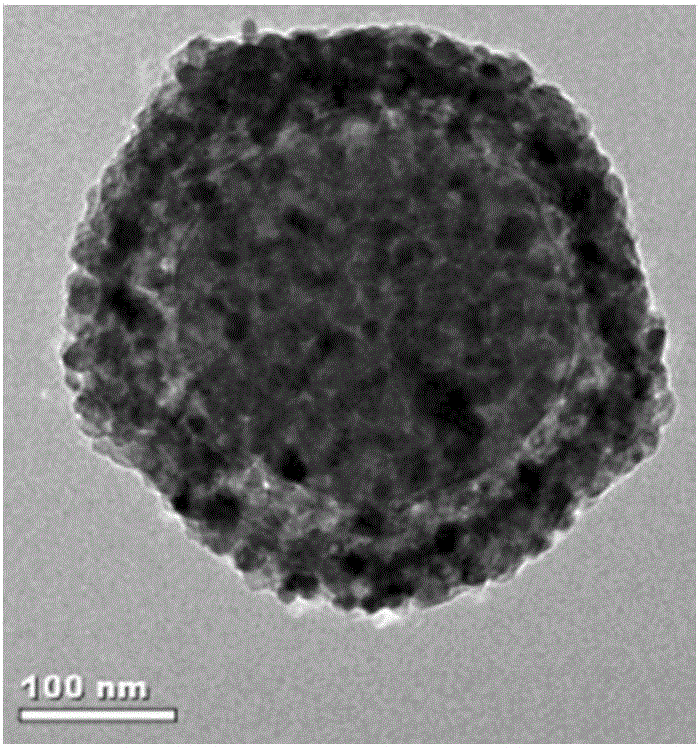

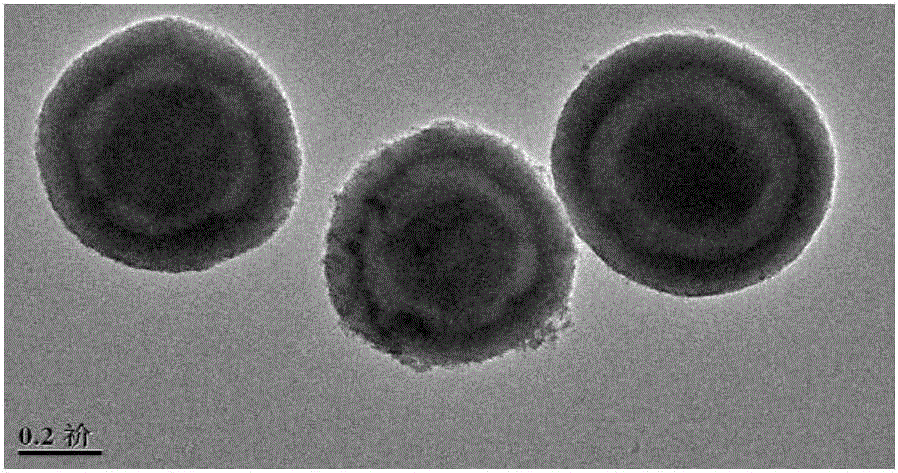

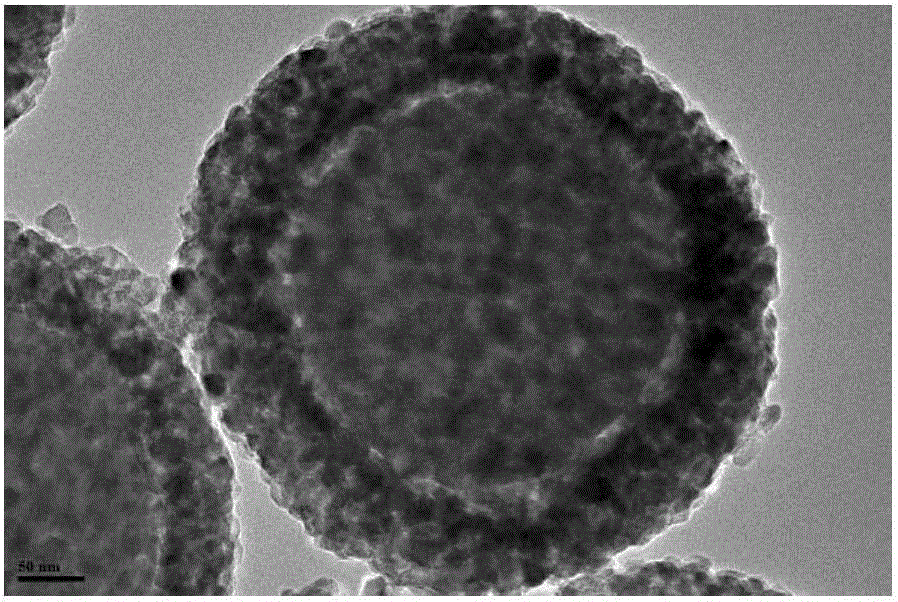

Zeolite molecular sieve-mesoporous titanium oxide composite material with egg yolk-eggshell structure and preparation method thereof

A technology of zeolite molecular sieve and mesoporous titanium oxide, which can be used in molecular sieve catalysts, chemical instruments and methods, silicon compounds, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (I) Add 0.5g of ZSM-5 zeolite (Si / Al=100) into 280mL of deionized water, add 0.3mL of ammonia water, then add 0.4g of resorcinol and 0.6mL of formaldehyde, stir at 30°C for 24h, and then Stir at 80°C for 5 hours, the reaction solution turns brick red, centrifuge, and the solid product obtained is washed three times with ethanol and deionized water respectively, to obtain ZSM-5PF with a core-shell structure;

[0044] (II) Disperse the ZSM-5PF obtained in step (I) into 600mL of ethanol, sonicate for 1h, then add 1.8mL of concentrated ammonia water, and then slowly add 12mL of tetrabutyl titanate dropwise with a syringe (the dropwise addition is completed in 1 hour), 25 Stir at ℃ for 24 hours, the color of the reaction solution turns from brick red to light, centrifuge, and the solid product obtained is washed 3 times with ethanol and deionized water, dried at 80℃ for 12h, and finally calcined at 500℃ for 2 hours in an air atmosphere to obtain a high specific surface area ...

Embodiment 2

[0047] (I) Add 0.5g of ZSM-5 zeolite (Si / Al=40) into 280mL of deionized water, add 0.3mL of ammonia water, then add 0.4g of phenol and 0.6mL of formaldehyde, stir at 30°C for 24h, then stir at 80°C After 24 hours, the reaction solution turned yellow and was centrifuged, and the obtained solid product was washed three times with ethanol and deionized water respectively to obtain ZSM-5PF with a core-shell structure;

[0048] (II) Disperse the ZSM-5PF obtained in step (I) into 600mL of ethanol, sonicate for 1h, then add 1.8mL of concentrated ammonia water, then slowly add 6mL of tetrabutyl titanate dropwise with a syringe (0.5 hours to complete), 25 Stir at ℃ for 24 hours, the color of the reaction solution turns from yellow to lighter, and centrifuge to separate the obtained solid product, which is washed three times with ethanol and deionized water, dried at 80℃ for 12 hours, and finally roasted at 450℃ for 3 hours in an air atmosphere to obtain egg yolk with high specific surfa...

Embodiment 3

[0051] (I) Add 0.5g of ZSM-5 zeolite (Si / Al=200) into 280mL of deionized water, add 0.3mL of ammonia water, then add 0.4g of resorcinol and 0.6mL of formaldehyde, stir at 30°C for 24h, and then Stir at 80°C for 24 hours, the reaction solution turns brick red, centrifuge, and the obtained solid product is washed three times with ethanol and deionized water respectively, to obtain ZSM-5PF with a core-shell structure;

[0052] (II) Disperse the ZSM-5PF obtained in step (I) into 600mL ethanol, sonicate for 1h, then add 1.8mL concentrated ammonia water, and then slowly add 18mL tetrabutyl titanate dropwise with a syringe (1.5 hours to complete), 25 Stir at ℃ for 24 hours, the color of the reaction solution turns from brick red to lighter, and centrifuge to separate the obtained solid product, which is washed three times with ethanol and deionized water, dried at 80℃ for 12 hours, and finally calcined at 450℃ for 3 hours in an air atmosphere to obtain a high specific surface area ZS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com