Fabrication method of large-area highly ordered porous oxide films based on soft nanoimprinting

A porous oxide film, highly ordered technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, coating, etc., can solve the problems of long operation time, cumbersome operation, high cost, etc., and achieve the goal of convenient method and high tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a large-area highly ordered porous oxide film based on nano soft imprinting, the preparation method at least includes the following steps:

[0050] First, step 1 is performed, providing a master template with an ordered structure of micro-nano size, copying the ordered structure of micro-nano size onto a silica gel soft template, and obtaining a soft silica gel template with an ordered structure of micro-nano size.

[0051] The said master template has no special limitation on the material, it can be metals such as nickel, copper, chromium or alloys thereof, and it can also be an inorganic template such as silicon, glass, quartz, sapphire, titanium dioxide (TiO 2 ), iron oxide (Fe 2 o 3 ), indium oxide (In 2 o 3 ), zinc oxide (ZnO), tungsten oxide (WO 3 ), bismuth vanadate (BiVO 4 ) Silicon nitride (Si 3 N 4 ), boron nitride (BN), titanium nitride (TiN), silicon carbide (SiC), titanium carbide (TiC), zirconium carbide...

Embodiment 1

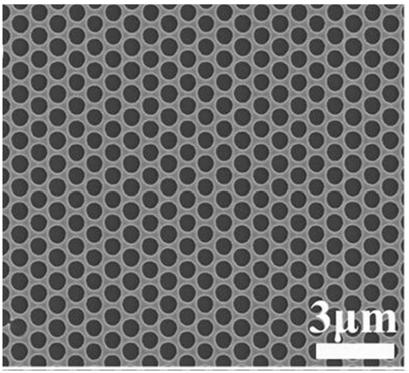

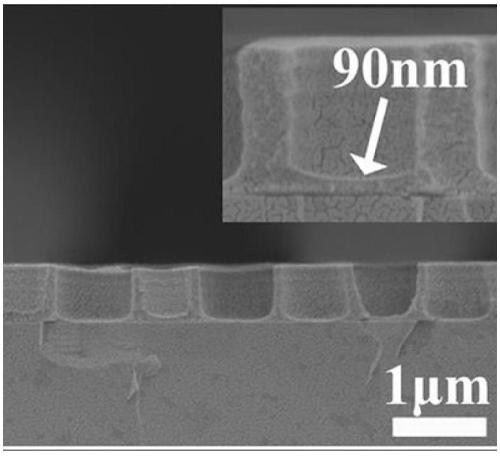

[0082] In this example, a large-size HOAAO based on nano-soft imprinting is prepared, and the preparation process is as follows:

[0083] 1. Coat the well-mixed PDMS precursor and curing agent (10:1) on the master template with micro-nano pillars, the thickness is about 0.2cm, remove air bubbles in vacuum, and then place at 60°C Cured in an oven for 3 hours, cooled to room temperature and uncovered to obtain a PDMS soft mold.

[0084] 2. Place the Al sheet in acetone, ethanol, and water for ultrasonic cleaning for 15 minutes. Using the Al sheet as the anode and the graphite sheet as the cathode, perform electrochemical polishing treatment in a mixed solution of chromic acid and ethanol (volume ratio 3:1) at 5°C, with a voltage of 10V and a treatment time of 8 minutes, to obtain a smooth and even surface of the Al sheet .

[0085] 3. Coating UV-curable glue on the Al sheet obtained in step 2 by means of spin coating at a speed of 3000 r / min for 50 s, and the thickness of the ...

Embodiment 2

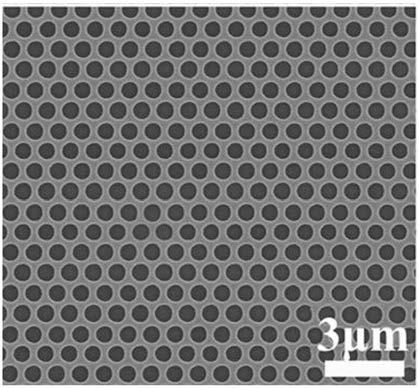

[0091] In this example, a large-size inverted tapered HOAAO based on nano soft imprinting is prepared, and the preparation process is as follows:

[0092] 1. Coat the well-mixed PDMS precursor and curing agent (10:1) on the master template with micro-nano pillars, the thickness is about 0.2cm, remove air bubbles in a vacuum, and then place it in a certain 60 ℃ in an oven for 3 hours, and then peel off after cooling to room temperature to obtain a PDMS soft mold.

[0093] 2. Place the Al sheet in acetone, ethanol, and water for 15 minutes for ultrasonic cleaning. Using the Al sheet as the anode and the graphite sheet as the cathode, perform electrochemical polishing treatment in a mixed solution of chromic acid and ethanol (volume ratio 3:1) at 5°C, with a voltage of 10V and a treatment time of 8 minutes, to obtain a smooth and even surface of the Al sheet .

[0094] 3. Coating UV-curable glue on the Al obtained in step 2 by spin coating at a speed of 3000r / min for 50s, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com