Rock wool fiber-reinforced silicon oxide-based high-strength thermal-insulation composite material and preparation method thereof

A technology of rock wool fiber and composite materials, which is applied in the field of high-strength thermal insulation composite materials and its preparation, can solve the problems of low strength of thermal insulation materials and complicated preparation processes, and achieve low cost, safe preparation process and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

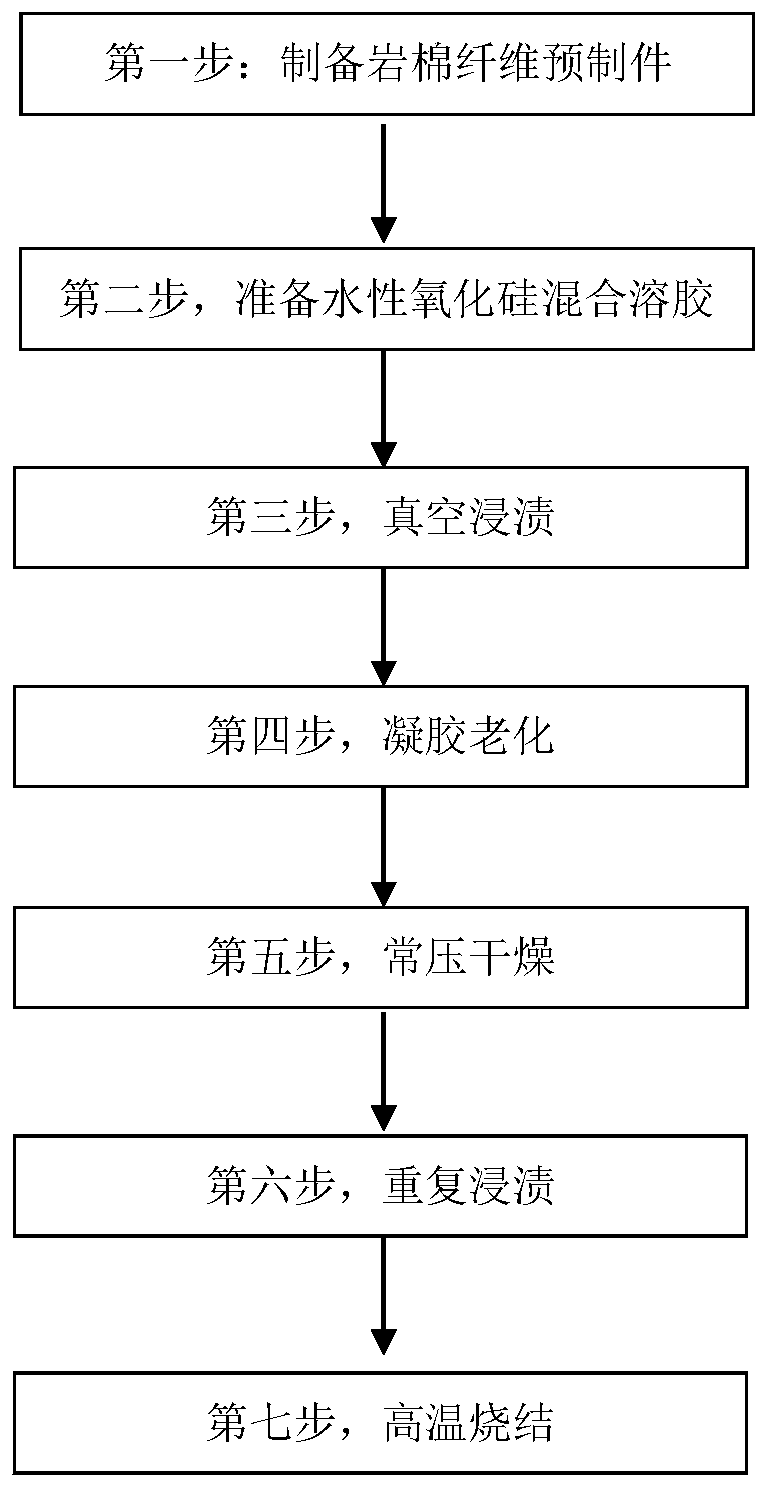

[0041] Embodiment 1: as figure 1 Shown, the present invention comprises the following steps

[0042] (1) Forming of rock wool fiber prefabricated parts: the apparent density of the designed fiber prefabricated parts is 0.26g / cm 3 , the size is 210×210×20mm 3 , use mass = density × volume to calculate the required rock wool fiber quality, weigh 229.32g of rock wool fiber, clamp and fix the weighed rock wool fiber with a mold, and make the fiber arrangement direction perpendicular to the heat flow during heat insulation direction, to obtain rock wool fiber preforms.

[0043] (2) Preparation of silica mixed sol: use aqueous silica sol (solid content 20%) as the silicon source, add ammonium nitrate and ammonia water (0.5mol / L), stir for 10 minutes to obtain mixed silica sol, configure silica mixture Sol 2L spare. Among them, the molar ratio of aqueous silica sol: ammonium nitrate: ammonia water is 1:1.78×10 -3 :9.82×10 -2 .

[0044] (3) Vacuum impregnation: Put the prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com