Plastic oil and gas separator with labyrinth type and screw type combined

An oil-gas separator and spiral technology, which is applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve the problems of unoptimized oil-gas separation efficiency, single structure, rough inner wall, etc., and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

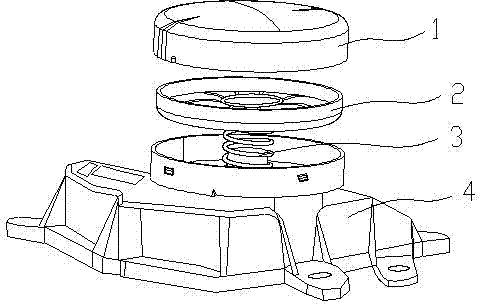

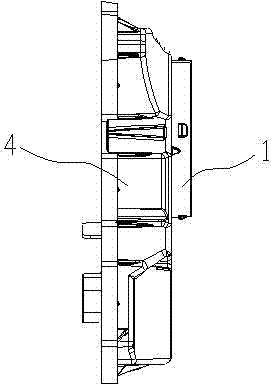

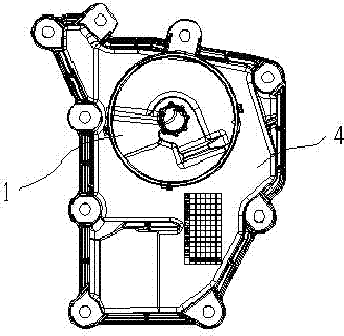

[0031] This example figure 1 , figure 2 , image 3 As shown, a plastic oil-gas separator combining a labyrinth type and a spiral type, the shell 4 is a flat box structure formed by one-time injection molding, the inside of the shell 4 has a smooth surface, and the surface roughness value Ra≤0.08μm (The smooth surfaces mentioned in this technical solution are all the same). The circular card cover 1 on the outer end surface of the housing, the oil-gas separation membrane 2 is installed at the joint between the card cover 1 and the housing 4, and the oil-gas separation membrane 2 is also a one-time injection-molded disc-shaped structure, and there are distribution points on its width. Around the center of the circle, there are 12 long strip-shaped geometric protrusions with a semicircular cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com