Method and device for preparing antifouling and drag-reducing material by laser treatment

A laser treatment and antifouling technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high environmental pollution, inability to achieve superhydrophilic-superhydrophobic composite wettability, etc., and achieve high flexibility, High-resolution, material-adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

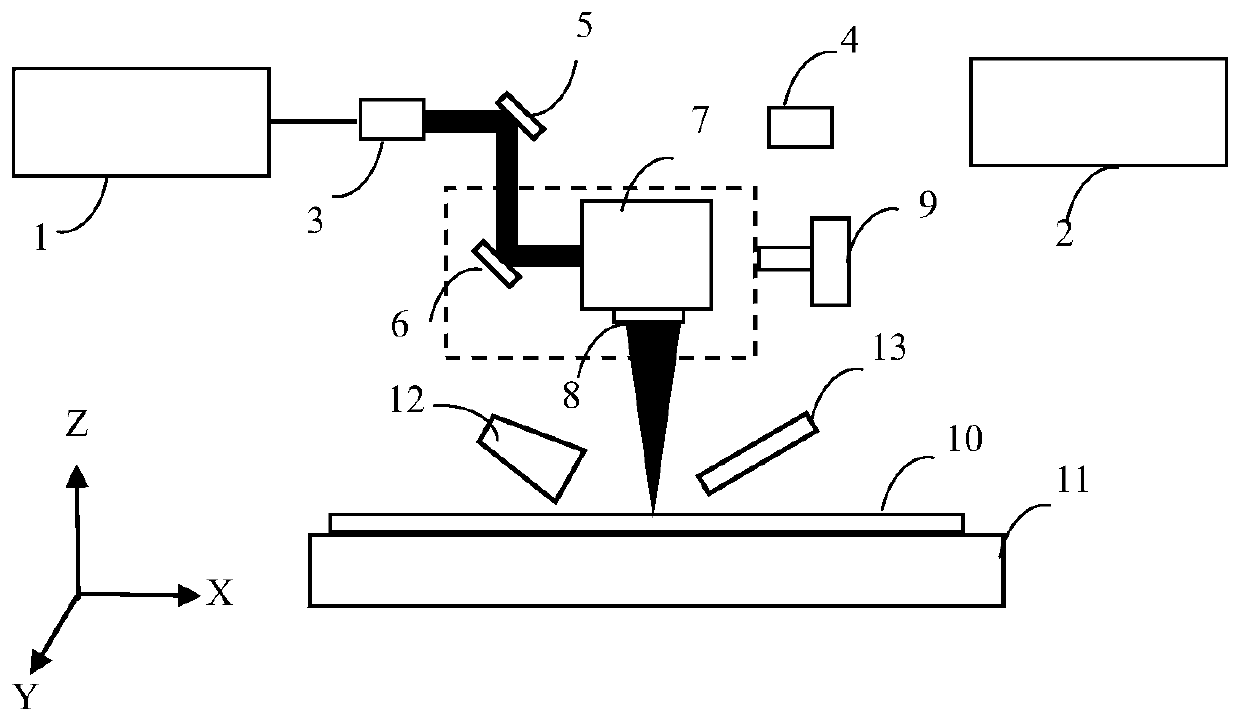

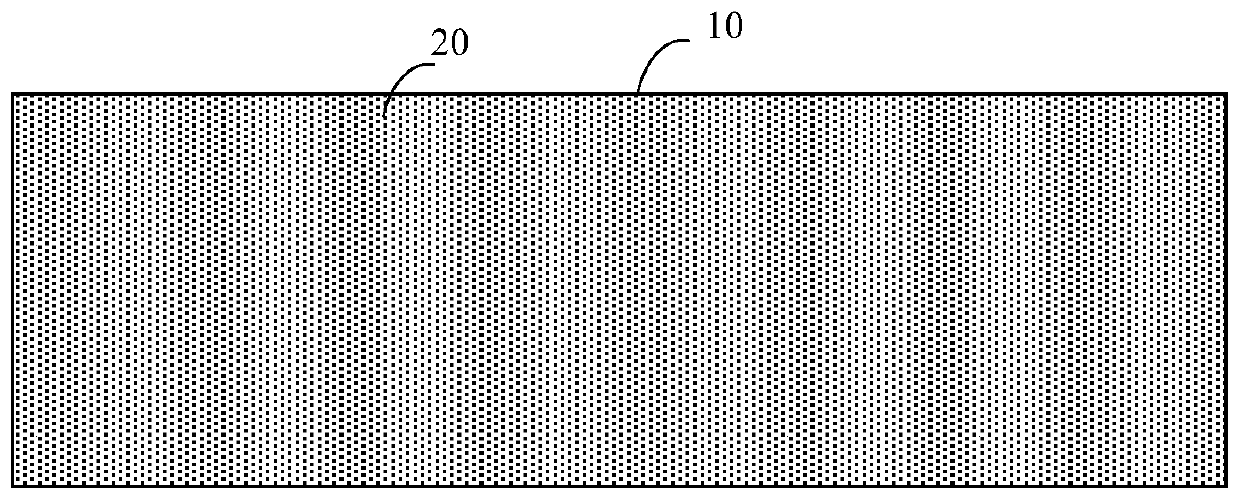

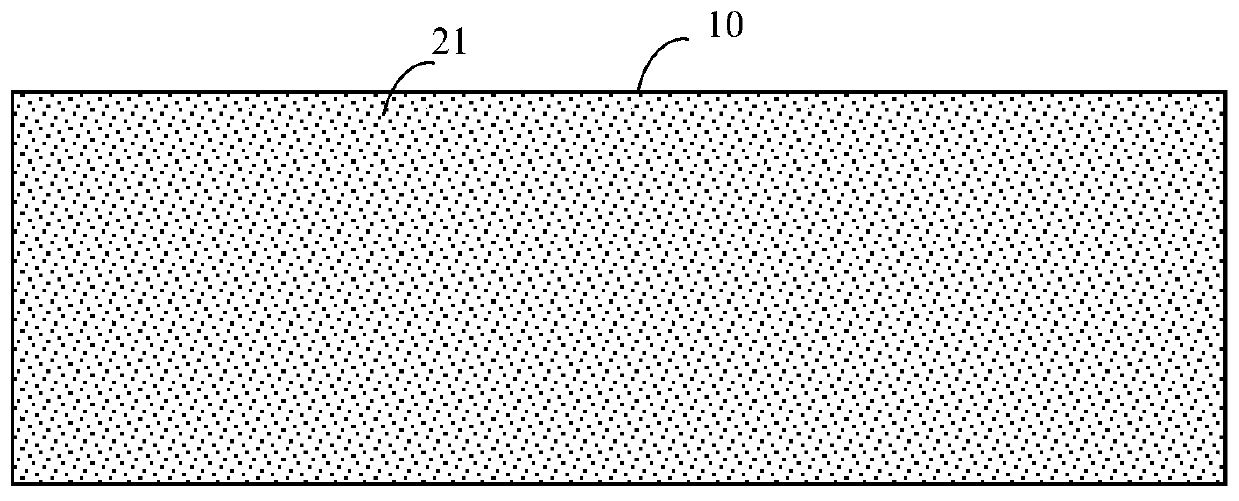

[0067] Example 1: Preparation of a composite wettable structure on the surface of a copper material

[0068] First use a femtosecond laser with a wavelength of 1030nm, set the power to 80W, the frequency to 2MH, and the scan rate to 5000mm / s, focus on the surface of the copper material, open the dust suction pipe and the protective gas nozzle, and perform high-speed femtosecond laser on the copper surface Etching processing to obtain a micro / nano mixed rough surface; then deposit a layer of low surface energy chemical reagent PFOTS (perfluorodecyltrimethylsilane) on the surface of the micro / nano mixed rough surface area, and deposit it in an oven after deposition Cured at 300°C to obtain a super-hydrophobic surface; finally, a picosecond laser with a wavelength of 532nm was used with a power of 5W, a frequency of 1MH, and a scan rate of 1000mm / s to open the dust suction pipe and the protective gas nozzle to super-hydrophobize the copper material. The hydrophobic surface is sel...

example 2

[0069] Example 2: Fabrication of Composite Wettable Structures on PTFE Surfaces

[0070] First use a femtosecond laser with a wavelength of 355nm, set the power to 50W, the frequency to 1MH, and the scan rate to 1000mm / s, focus on the surface of PTFE, open the dust suction pipe and the protective gas nozzle, and conduct rapid Femtosecond laser etching process to obtain micro / nano hybrid rough surface. Since PTFE itself has a low surface energy, it does not require low surface energy treatment and can be directly processed in the next step. Directly carry out superhydrophilic modification on the surface of PTFE, switch to a 1064nm picosecond laser, set the power to 30W, the frequency to 2MH, and the scanning rate to 2000mm / s. The hydrophobic surface is selectively hydrophilic modified with a linear pattern with a line width of 30 microns and a period ratio of 1:150, and super-hydrophilic regions with specific arrangement and distribution are obtained on the micron scale, final...

example 3

[0071] Example 3: Fabrication of Composite Wetting Structures on Glass Surfaces

[0072] First use a femtosecond laser with a wavelength of 355nm, set the power to 10W, the frequency to 500kHz, and the scanning rate to 200mm / s, focus on the glass surface, turn on the dust suction pipe and the protective gas nozzle, and perform fast femtosecond laser etching on the glass surface to obtain Micro / nano hybrid rough surface. Then deposit a layer of low surface energy chemical agent PDMS (polydimethylsiloxane) on the surface of the processing area, and then cure it in an oven at 300°C to obtain a super-hydrophobic surface. Finally, using a 355nm picosecond laser with a power of 5W, a frequency of 1MH, and a scan rate of 1000mm / s, the superhydrophobic surface of the glass is patterned with a line width of 400 microns and a period ratio of 1 to 200 for selective hydrophilicity. Modification, the specific arrangement and distribution of hydrophilic regions are obtained on the micron s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com