Patents

Literature

337 results about "Laser treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser resurfacing is a treatment to reduce facial wrinkles and skin irregularities, such as blemishes or acne scars. The technique directs short, concentrated pulsating beams of light at irregular skin, precisely removing skin layer by layer.

Precision spray processes for direct write electronic components

InactiveUS6251488B1Keep for a long timeIncrease probabilityMolten spray coatingVacuum evaporation coatingElectrical resistance and conductanceElectronic component

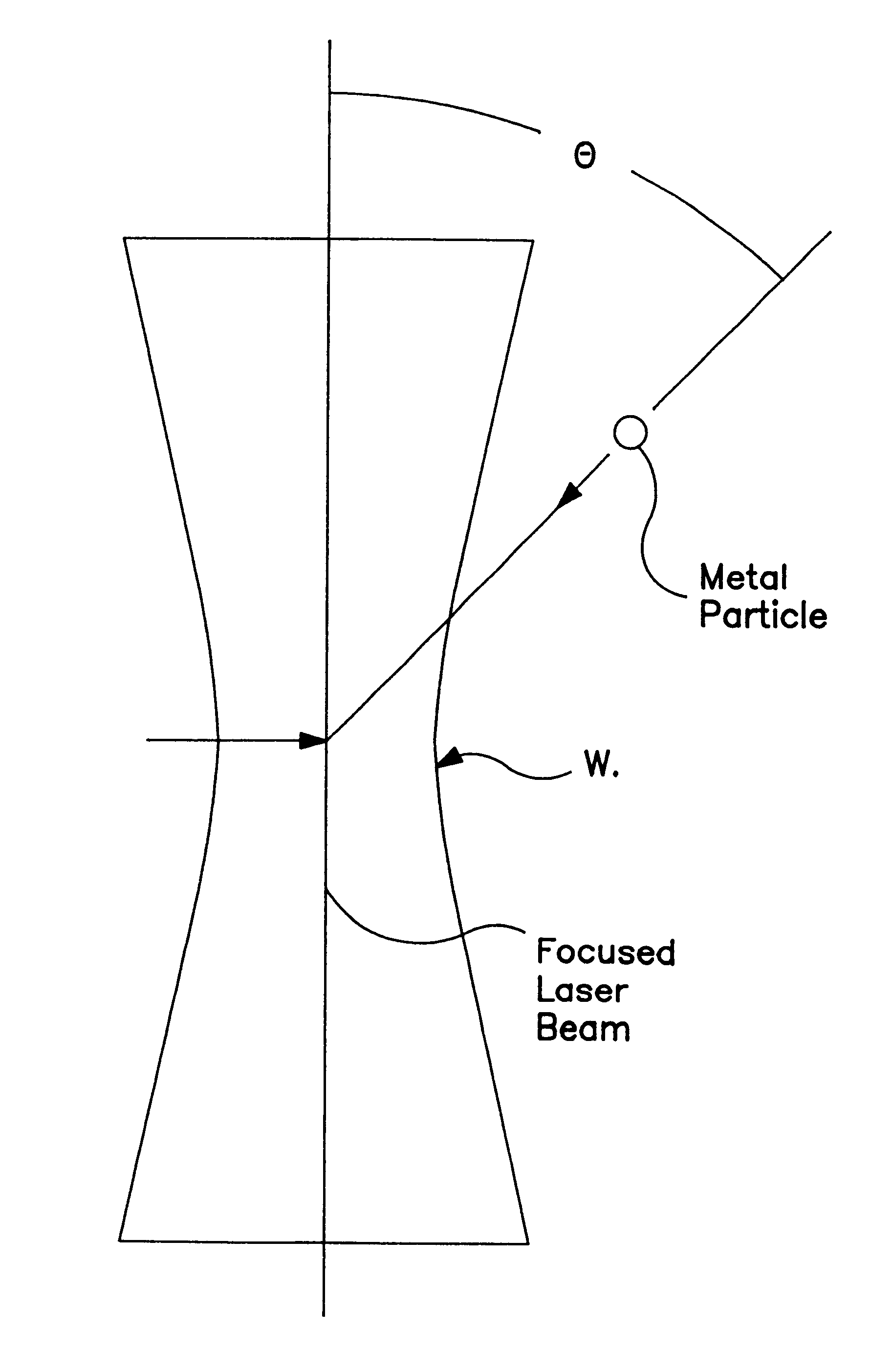

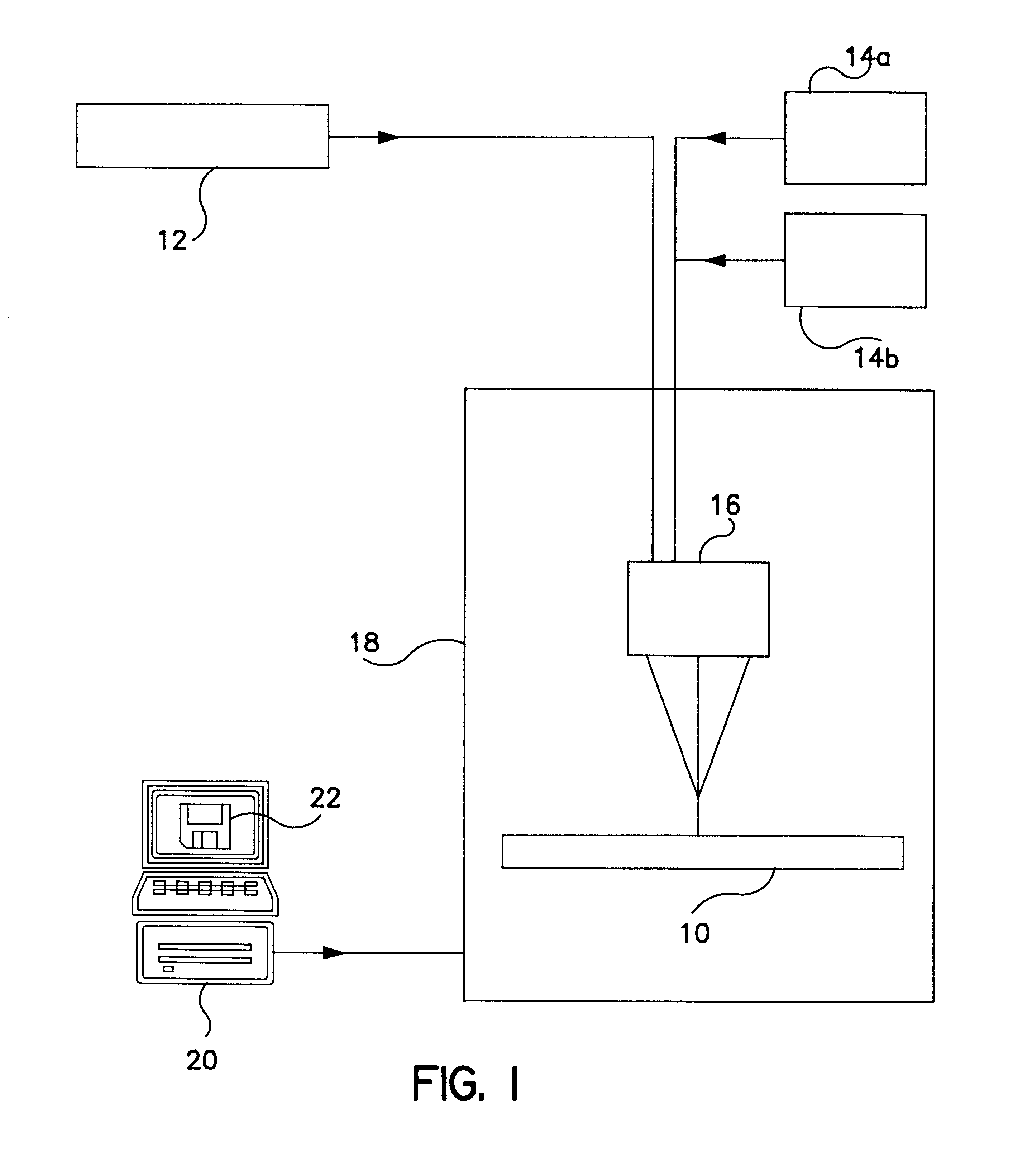

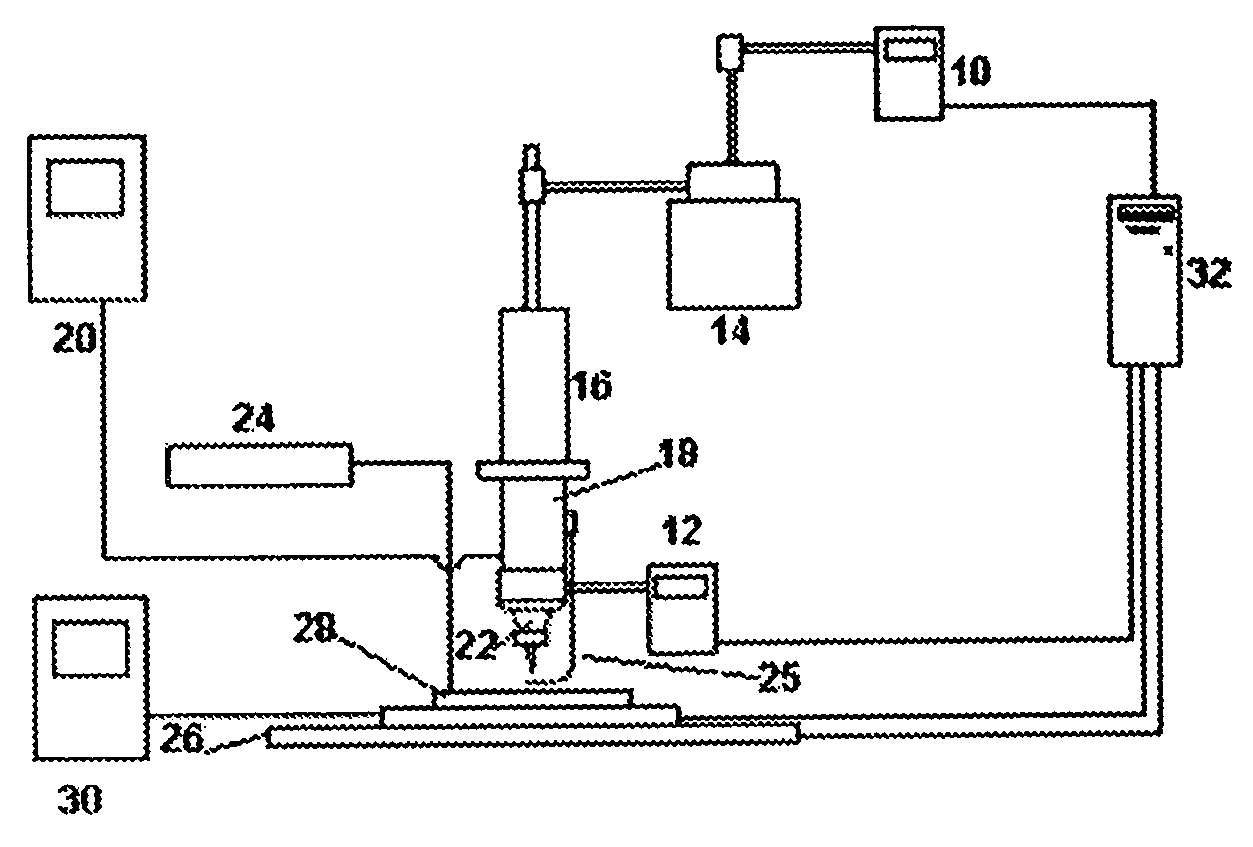

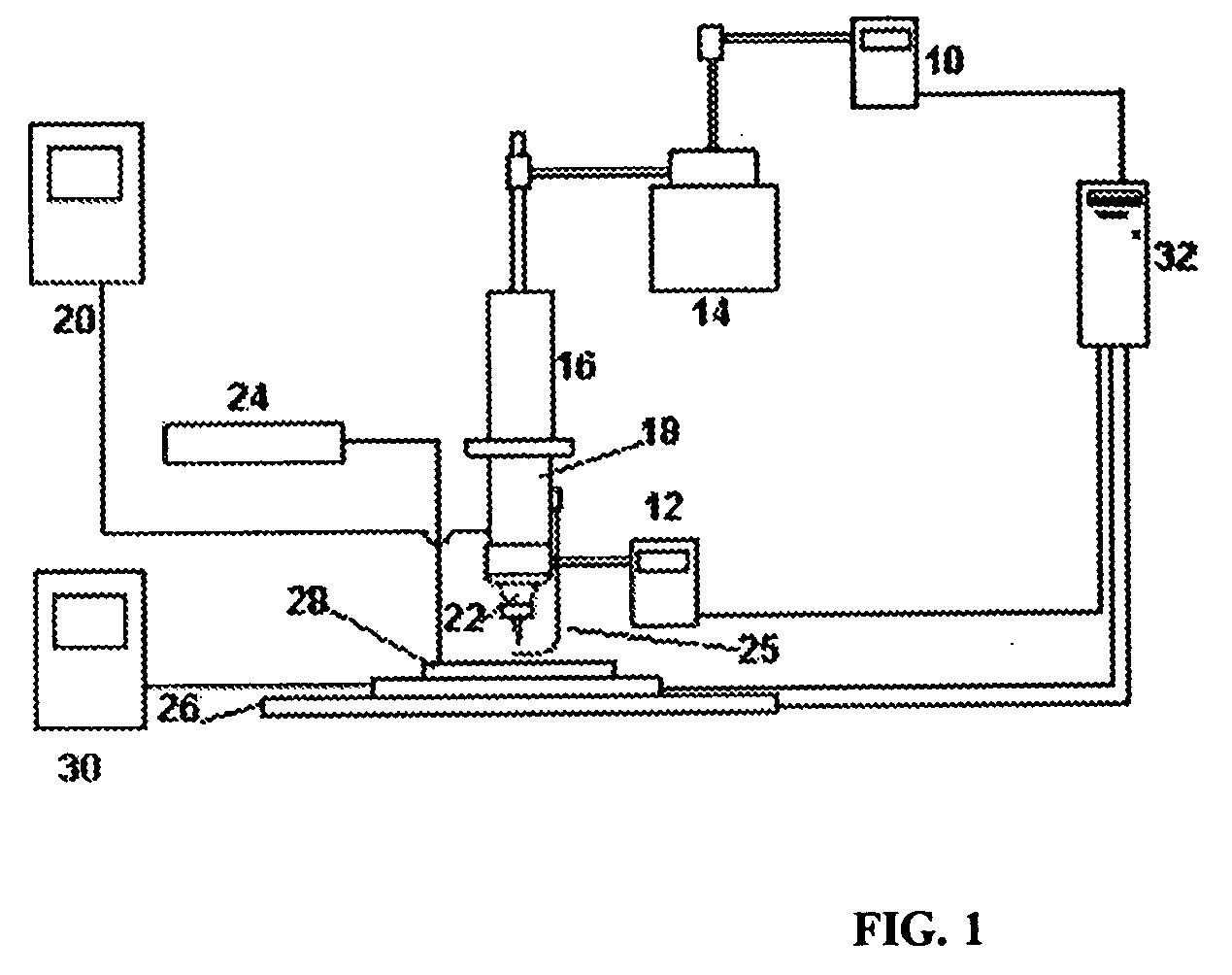

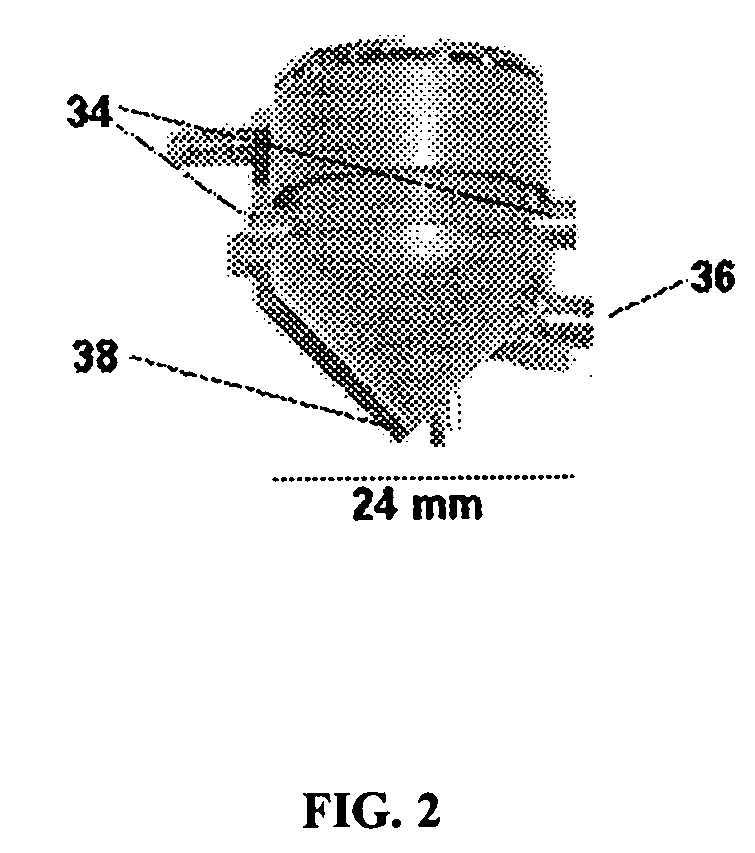

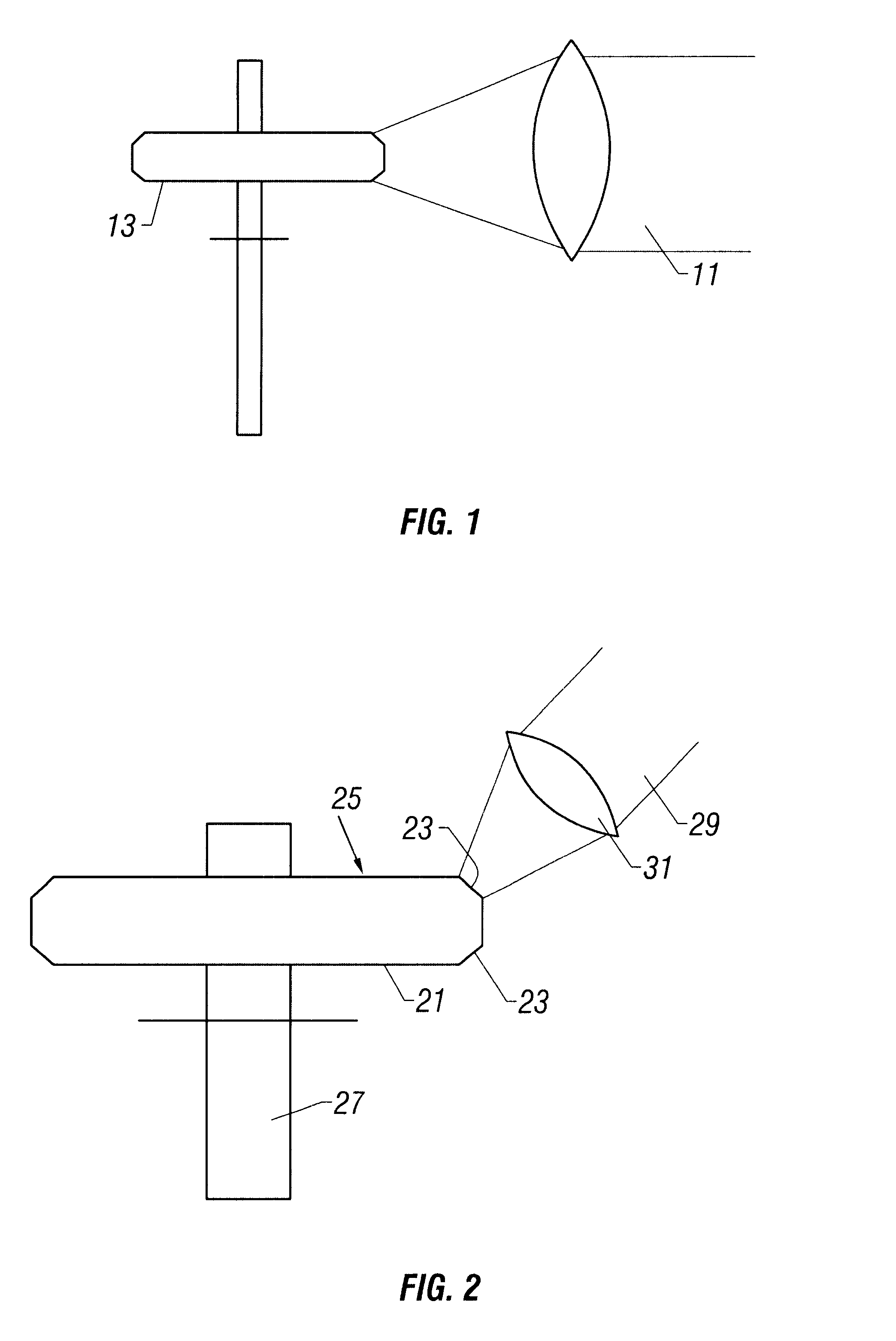

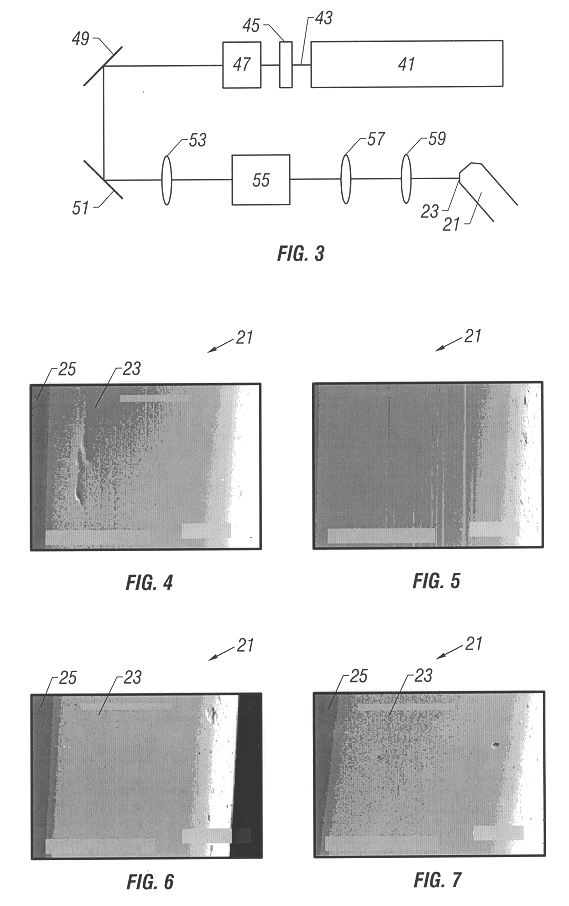

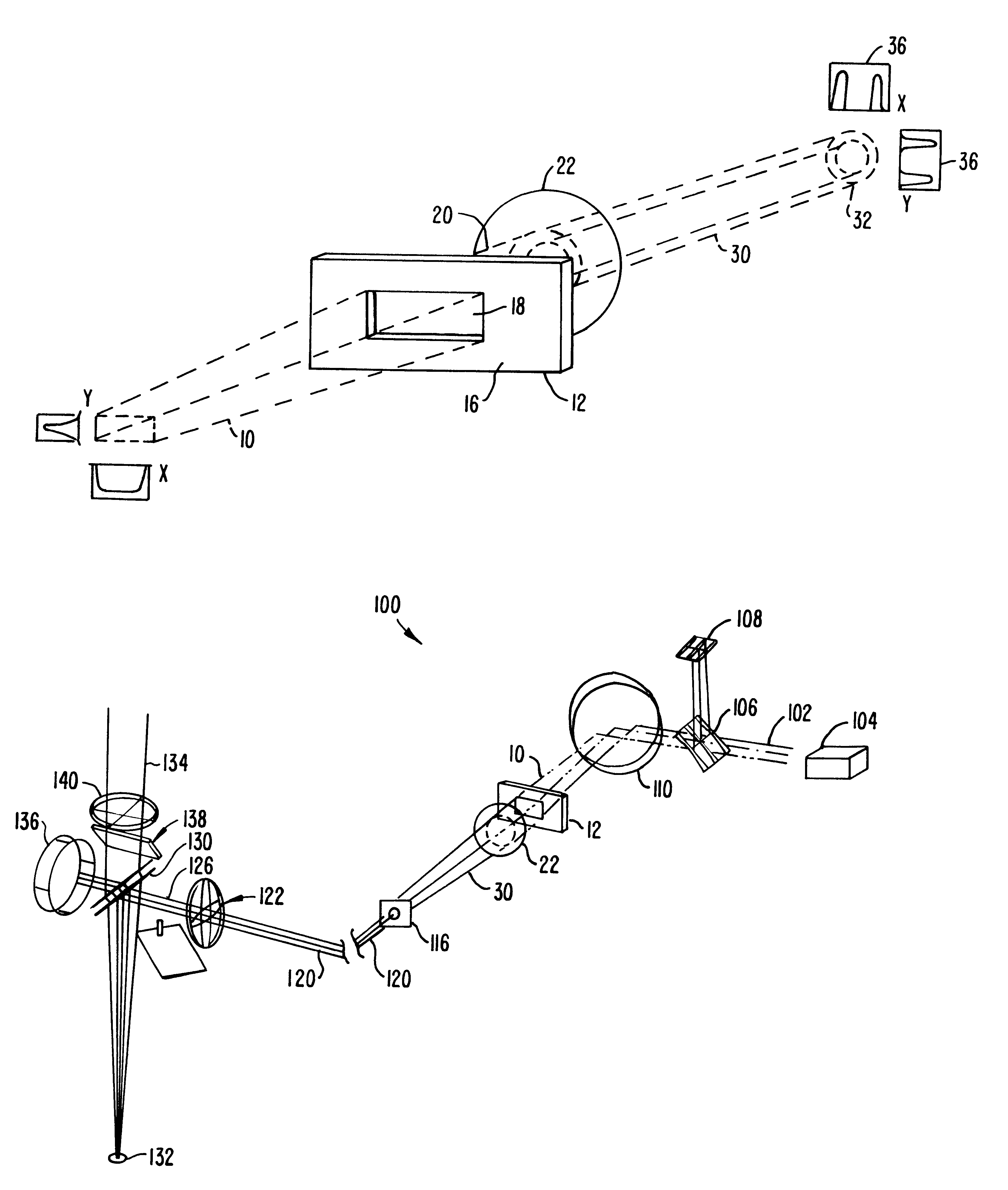

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

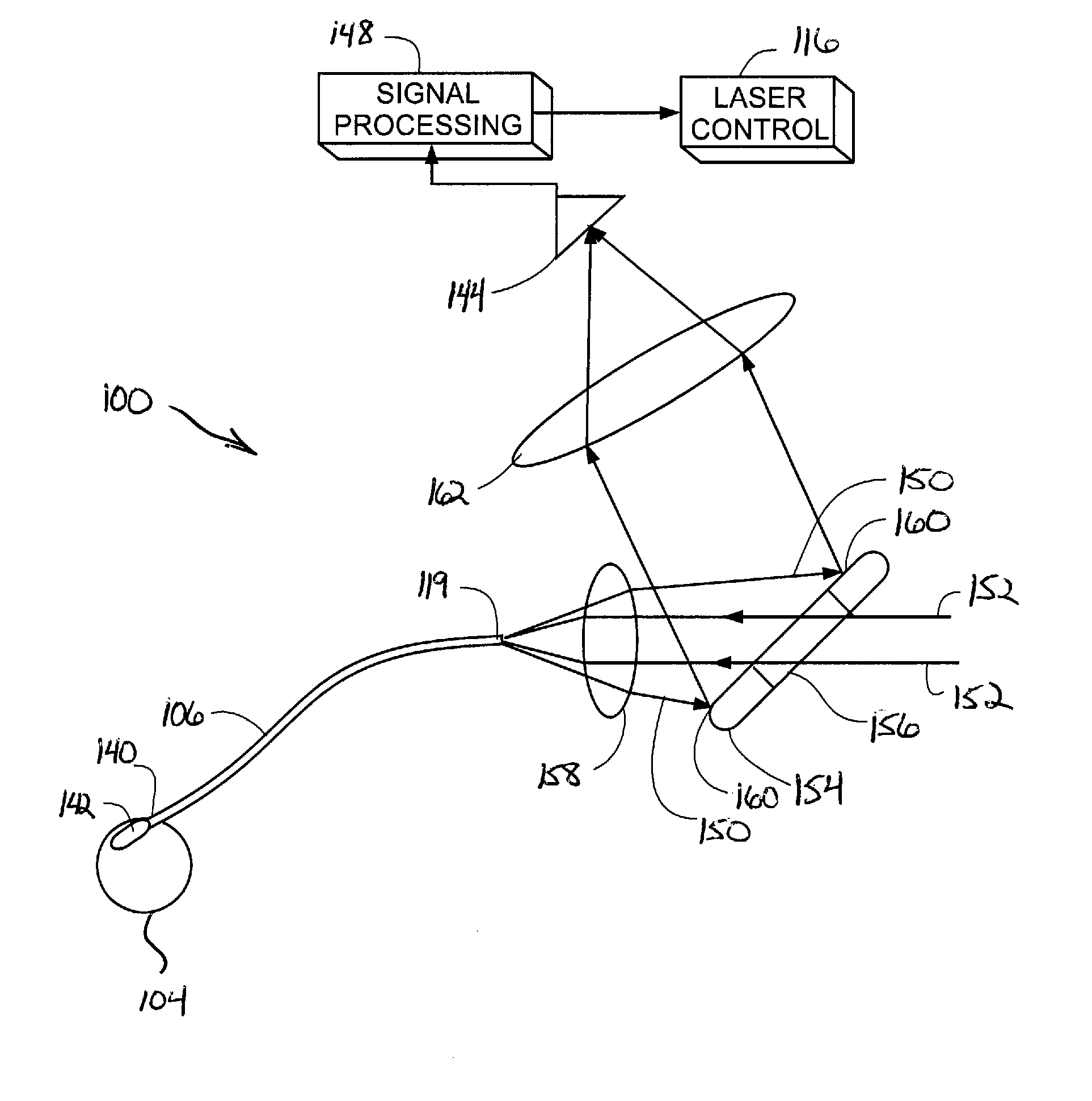

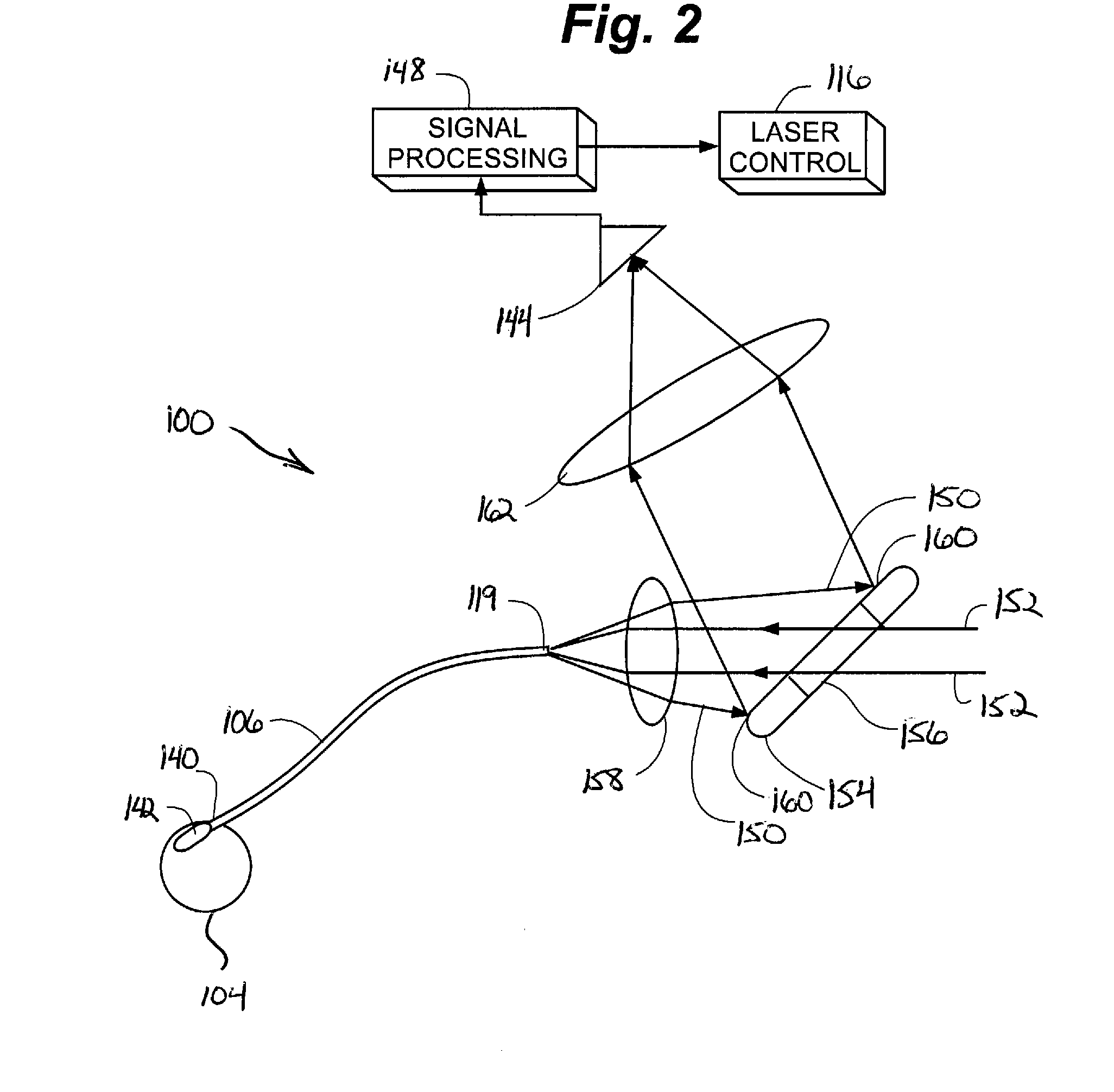

Laser ablation process and apparatus

InactiveUS20020045811A1Reduce Fresnel reflectionMaximize transmitted lightControlling energy of instrumentDiagnostics using spectroscopyFiberLaser light

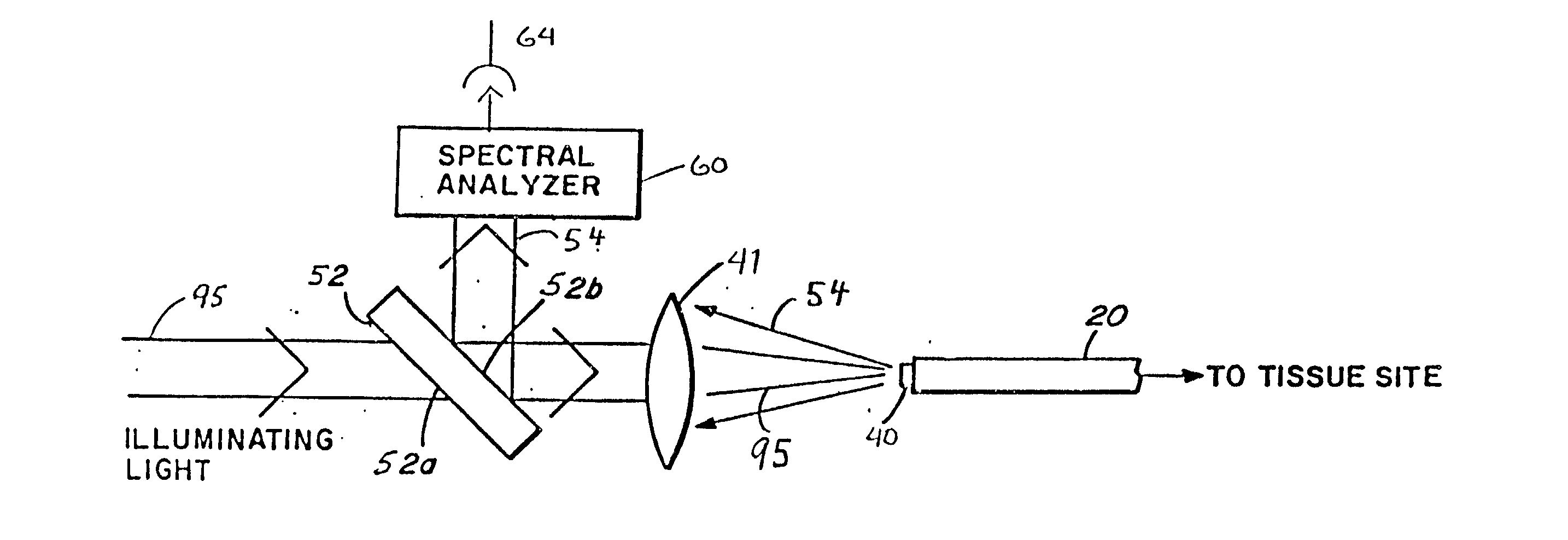

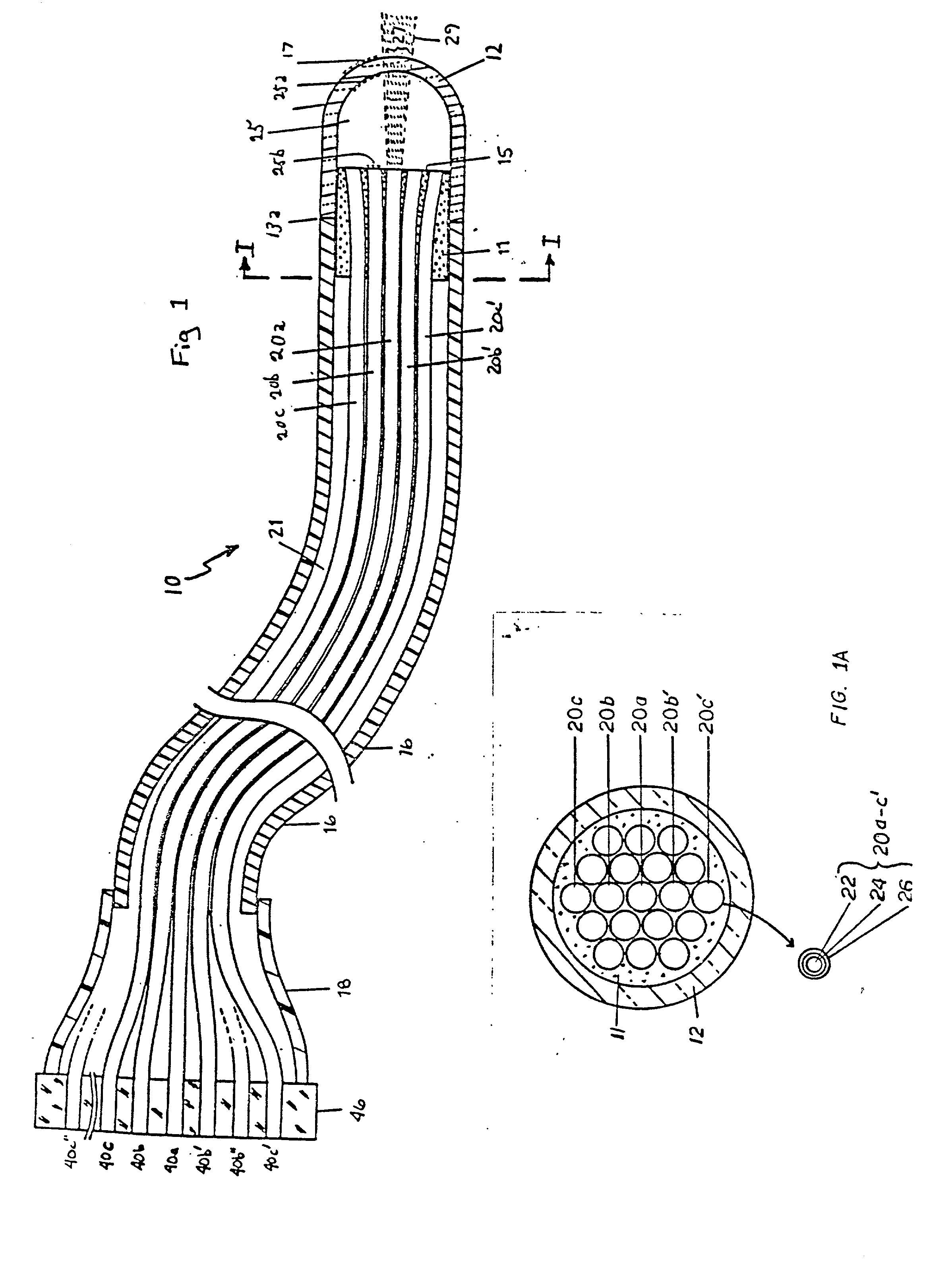

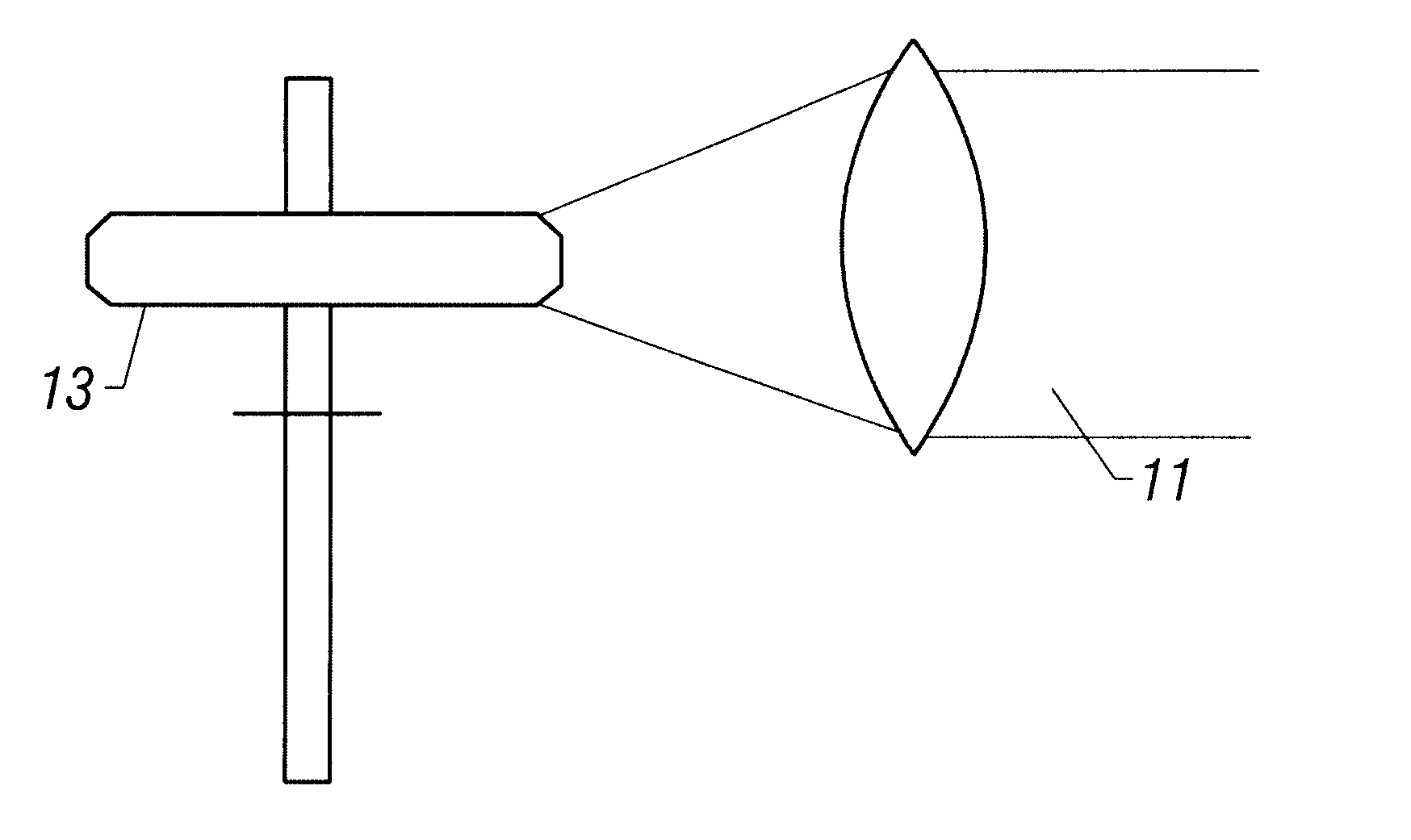

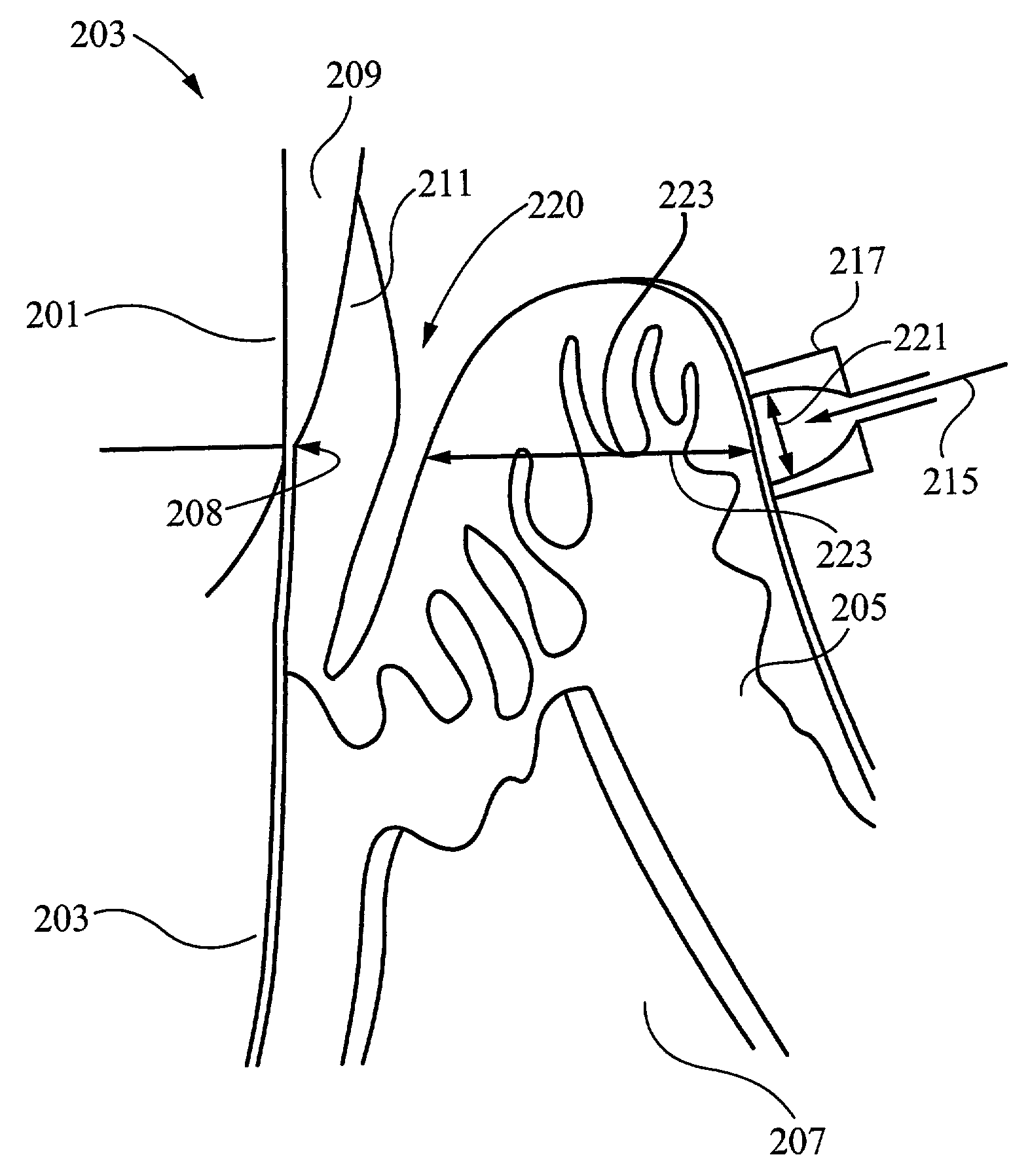

A laser catheter is disclosed wherein optical fibers carrying laser light are mounted in a catheter for insertion into an artery to provide controlled delivery of a laser beam for percutaneous intravascular laser treatment of atherosclerotic disease. A transparent protective shield is provided at the distal end of the catheter for mechanically diplacing intravascular blood and protecting the fibers from the intravascular contents, as well as protecting the patient in the event of failure of the fiber optics. Multiple optical fibers allow the selection of tissue that is to be removed. A computer controlled system automatically aligns fibers with the laser and controls exposure time. Spectroscopic diagnostics determine what tissue is to be removed.

Owner:KITTRELL CARTER +2

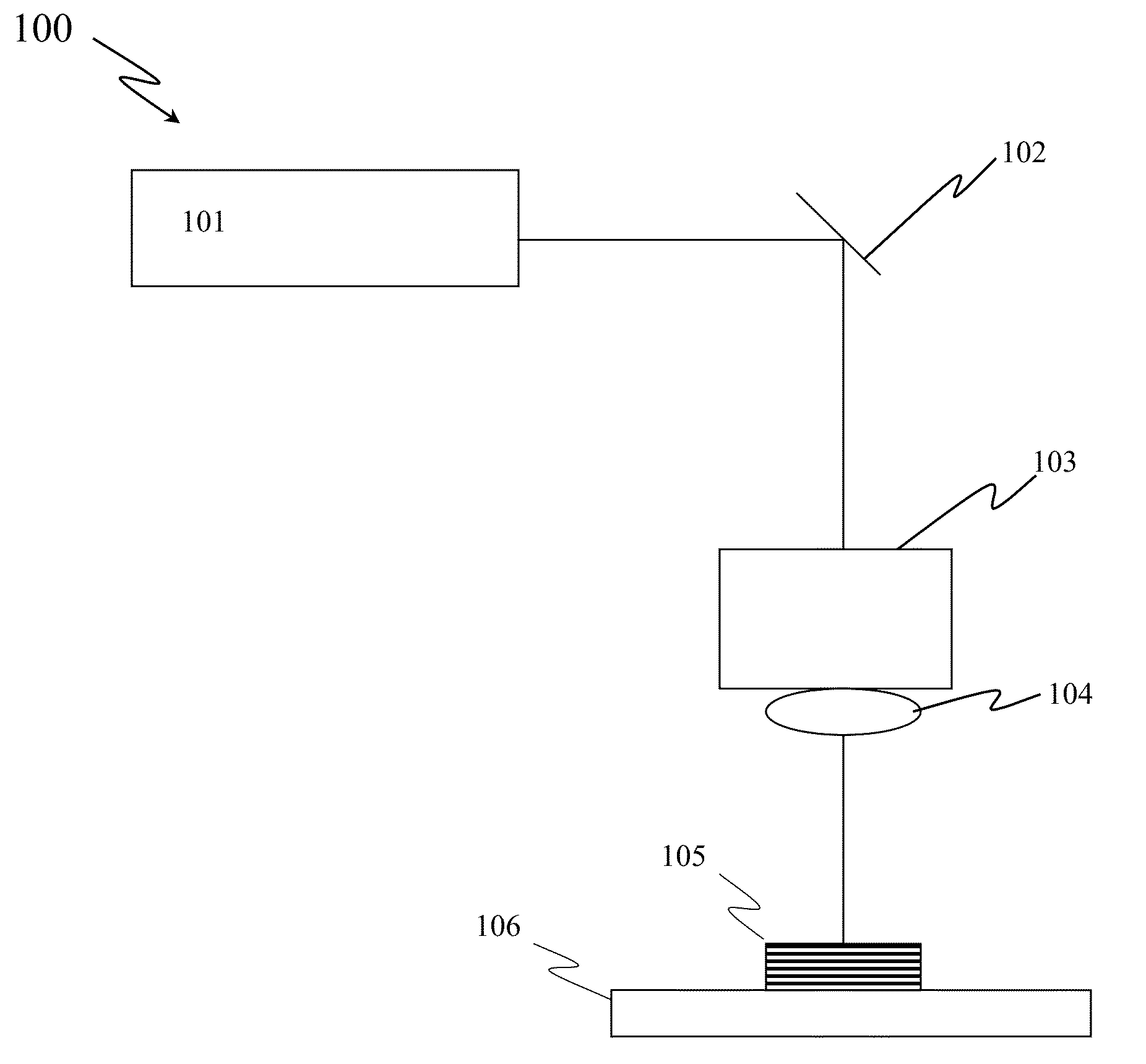

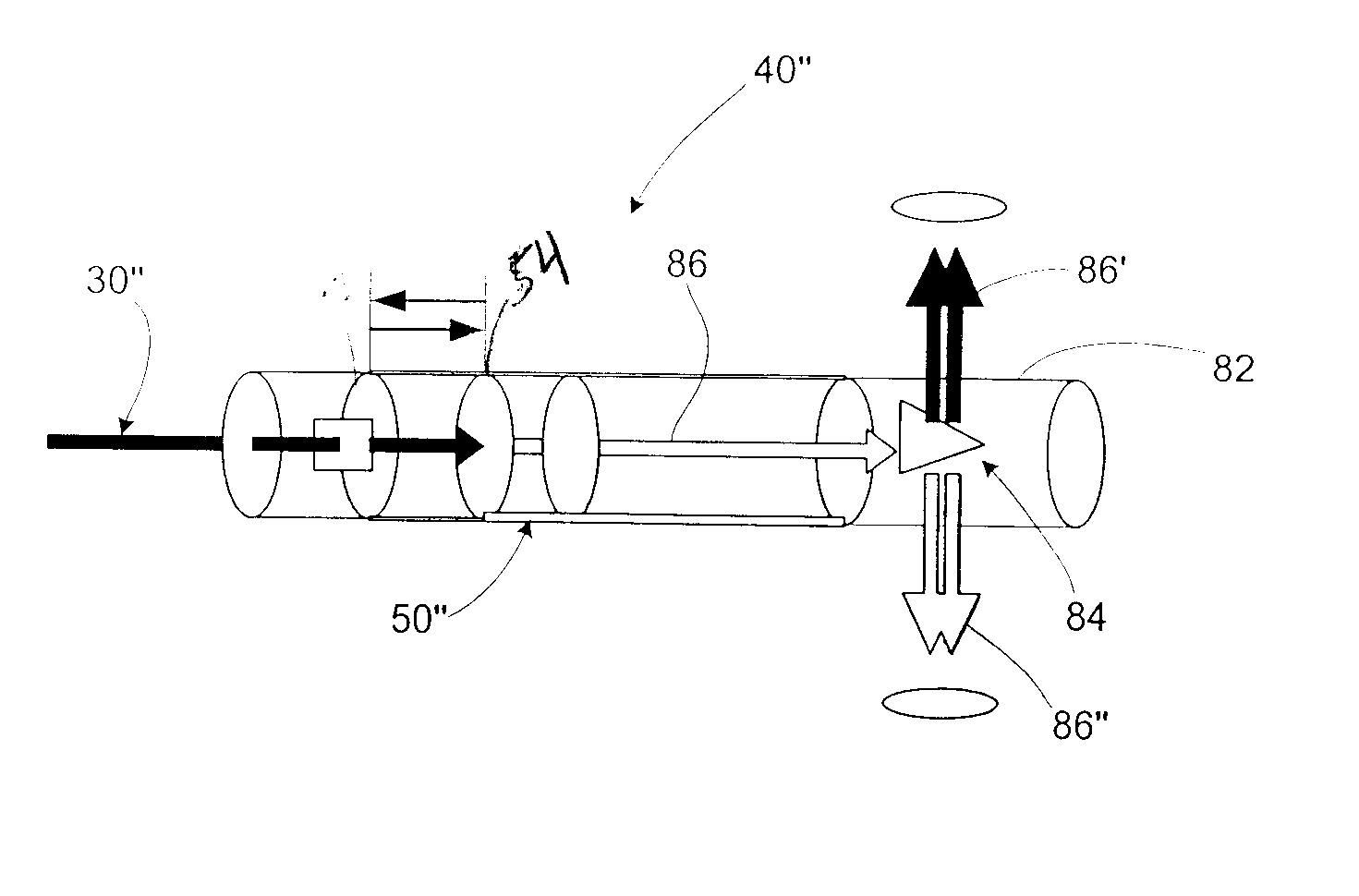

Power regulated medical underskin irradiation treament system

InactiveUS20040199151A1Procedure is limitedEasy to controlControlling energy of instrumentCatheterVeinVascular lumen

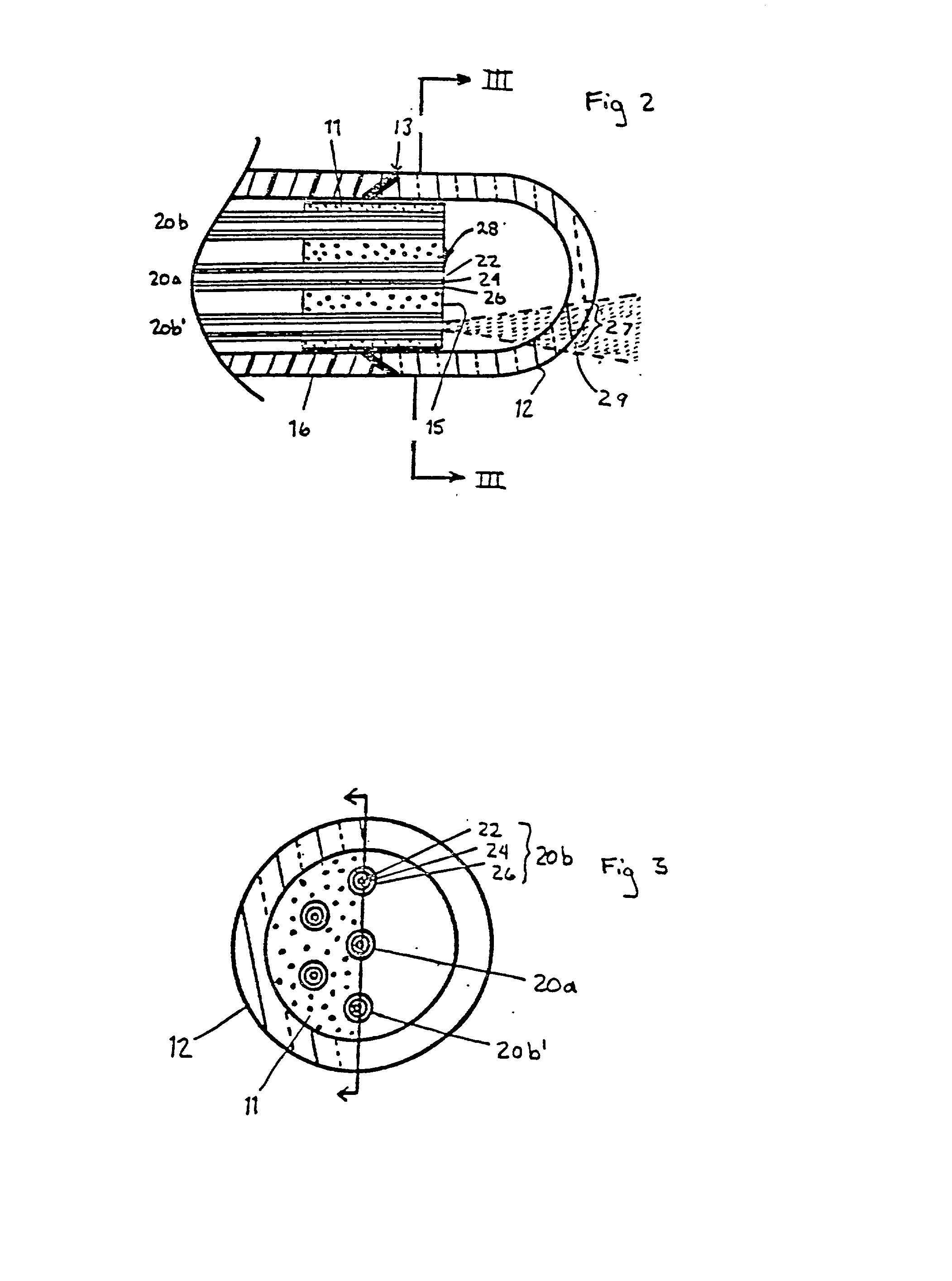

A system and method for controllably releasing laser radiation in percutaneous laser treatment is disclosed. In a preferred embodiment, an optical fiber is inserted below the skin or into a vascular lumen to a predetermined point. The fiber is connected to a source of electromagnetic radiation such as a laser. Radiation is then delivered to the treatment site while the fiber is simultaneously drawn out to the entry point. The fiber is manually withdrawn at a predetermined rate and radiation is administered in a constant power or energy level. To maintain a constant proper energy density, the speed of withdrawal is measured and sent to a controlling mechanism. The controlling mechanism modifies the power emitted, pulse length or pulse rate to ensure that the vein or tissue receives a consistent dose of energy. In one preferred embodiment, an imaging device provides the controlling device with speed information based on fiber surface textural properties or based on a series of bar code like markings. In another embodiment, additional information is collected, such as vein diameter prior to treatment, position of the distal end of the fiber, and / or impact measurements such as vibration or temperature during treatment, and the controlling mechanism adjusts output power or pulse rate in response to measurements to maintain a desired power density.

Owner:CERAMOPTEC IND INC

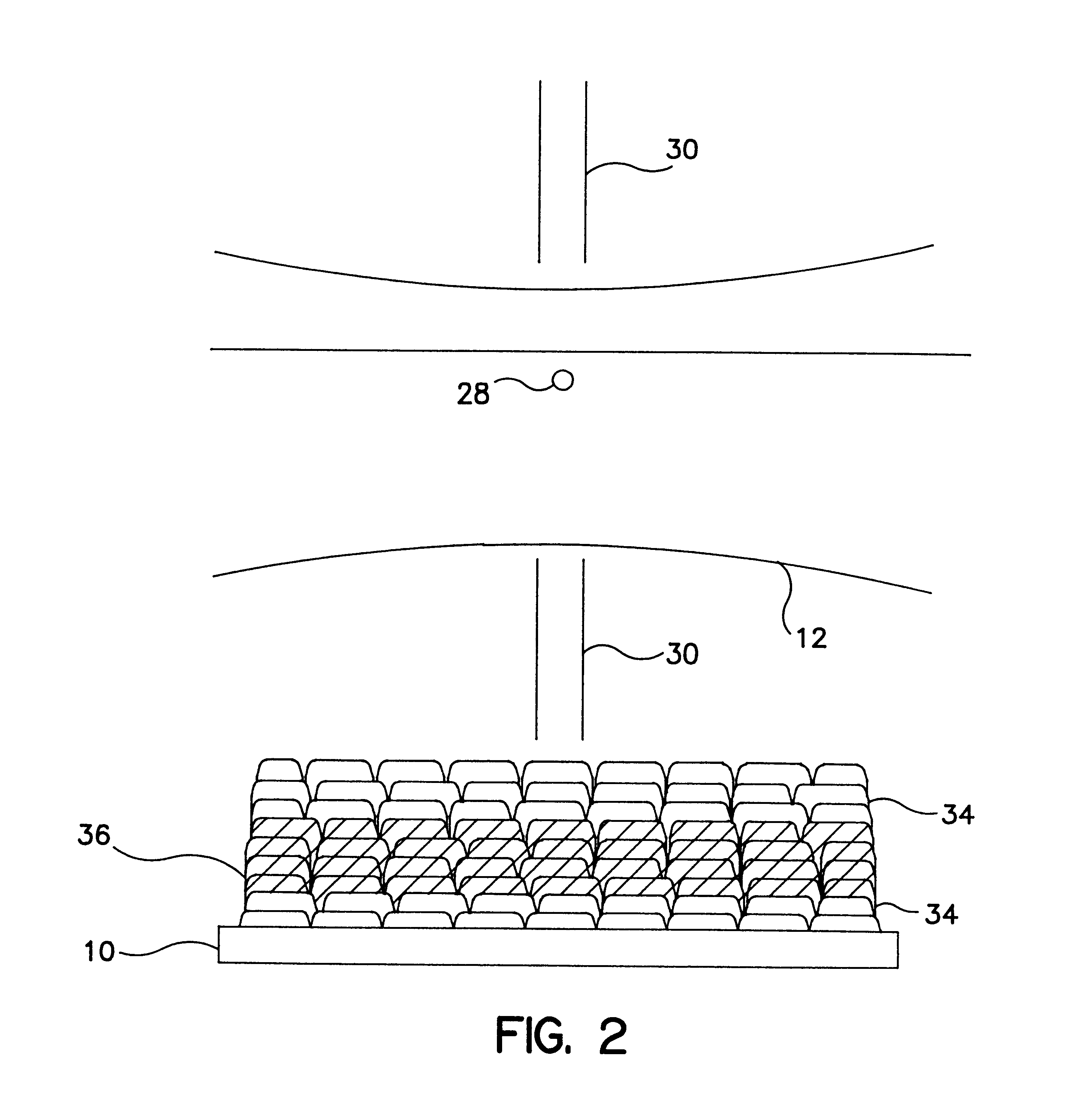

Apparatus, methods and precision spray processes for direct write and maskless mesoscale material deposition

InactiveUS20040197493A1Reduce package sizeElectric discharge heatingVacuum evaporation coatingOptoelectronicsBiological materials

Apparatuses and processes for maskless deposition of electronic and biological materials. The process is capable of direct deposition of features with linewidths varying from the micron range up to a fraction of a millimeter, and may be used to deposit features on substrates with damage thresholds near 100° C. Deposition and subsequent processing may be carried out under ambient conditions, eliminating the need for a vacuum atmosphere. The process may also be performed in an inert gas environment. Deposition of and subsequent laser post processing produces linewidths as low as 1 micron, with sub-micron edge definition. The apparatus nozzle has a large working distance-the orifice to substrate distance may be several millimeters-and direct write onto non-planar surfaces is possible. This invention is also of combinations of precision spray processes with in-flight laser treatment in order to produce direct write electronic components, and additionally lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

Apparatus and method for improving chamfer quality of disk edge surfaces with laser treatment

A carbon dioxide laser is used as a non-mechanical means for smoothing and polishing the as-cut chamfer surface at the edge of the disk. Applying laser radiation to the glass surface causes transient melting and resolidification. Due to surface tension effects, the glass resolidifies to produce a surface that is significantly smoother than it was before irradiation. If scratches or abrasive marks are present on the glass surface prior to irradiation, the irradiation process "polishes out" these defects as long as they are not too deep. At a wavelength near 10 mum, the penetration depth of the radiation into the glass is approximately 1 mum. Therefore, scratches and defects of this order of magnitude are eliminated. The quality of the resulting modified chamfer surface is far superior to the original mechanically ground and polished surface.

Owner:WESTERN DIGITAL TECH INC

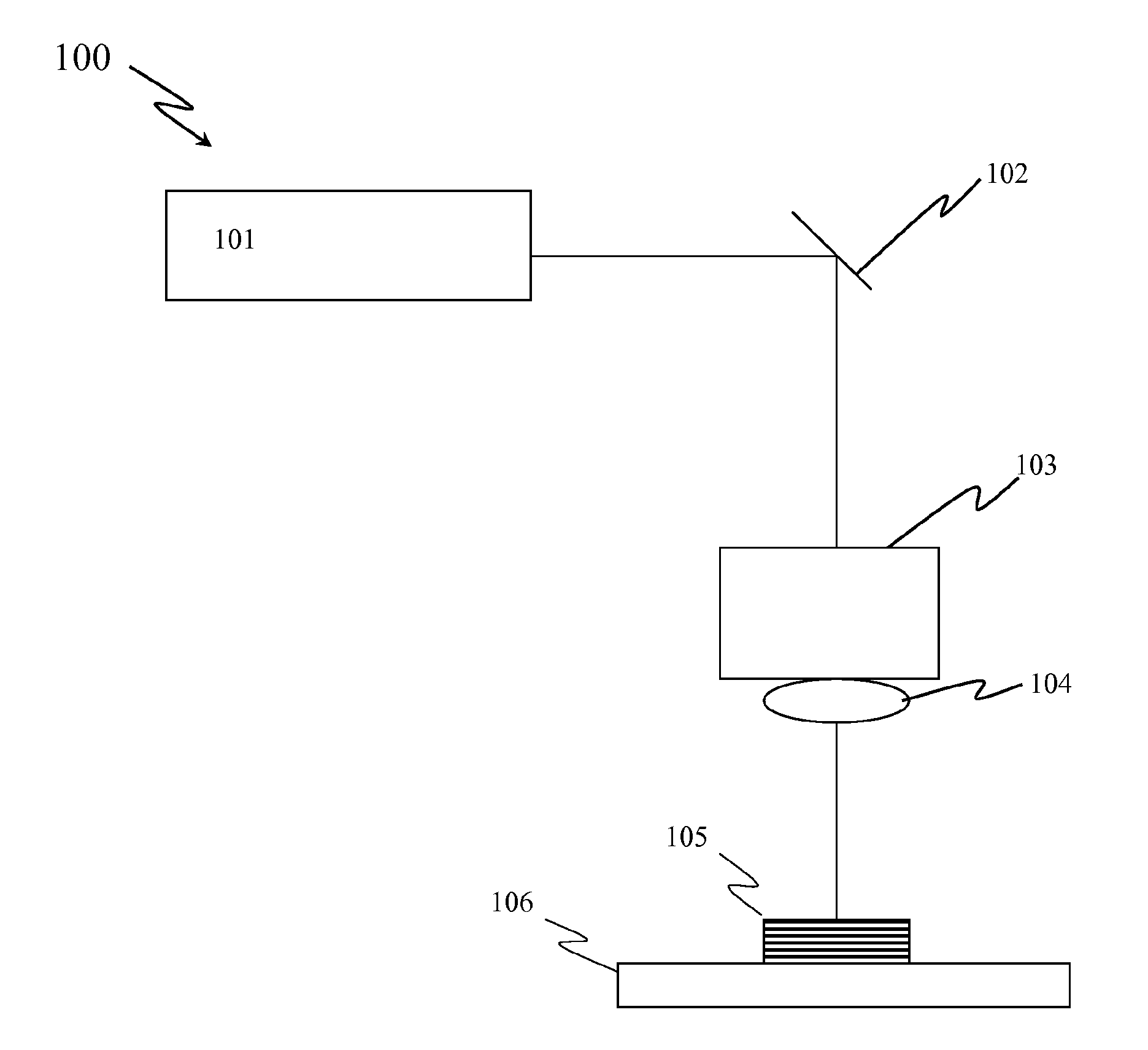

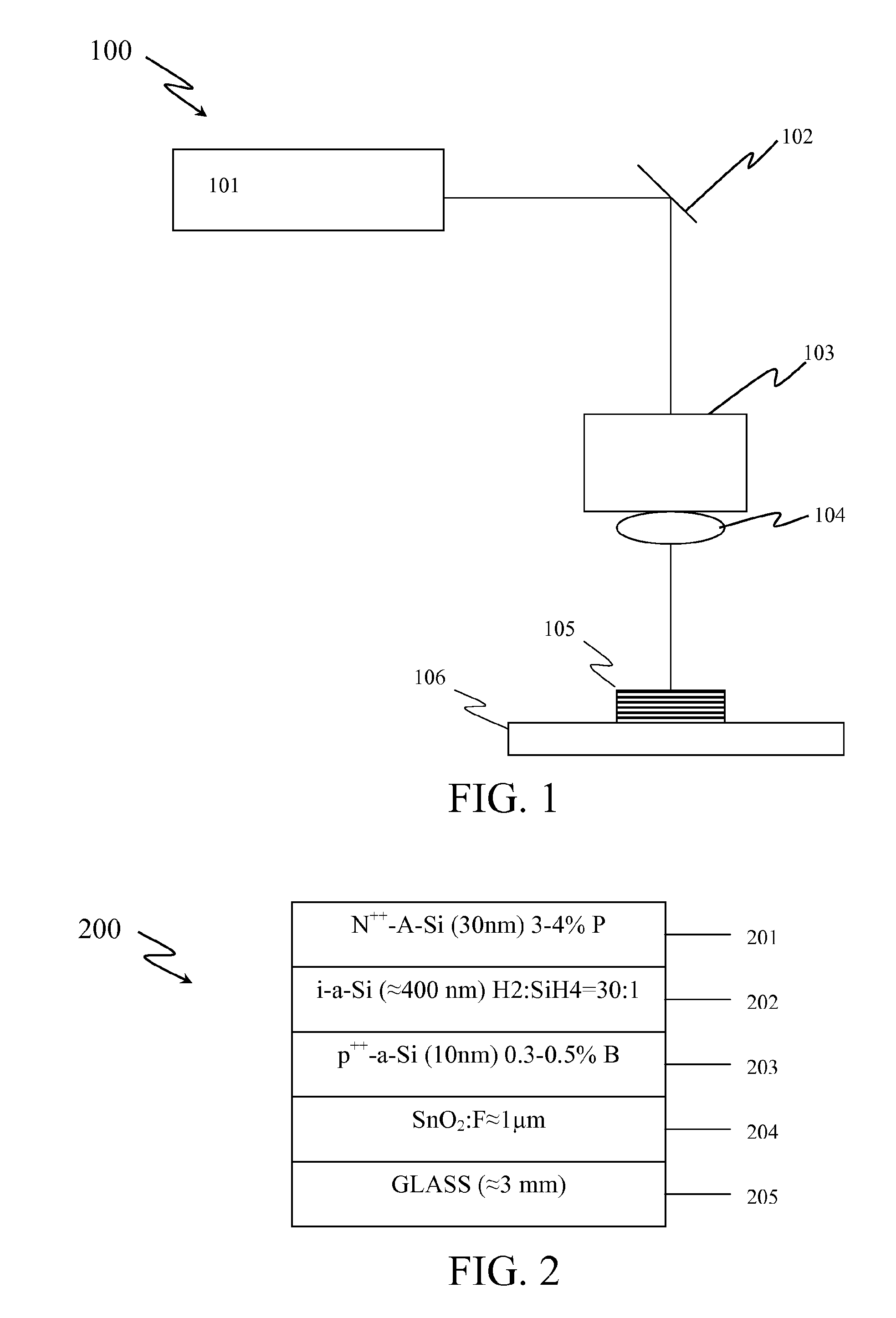

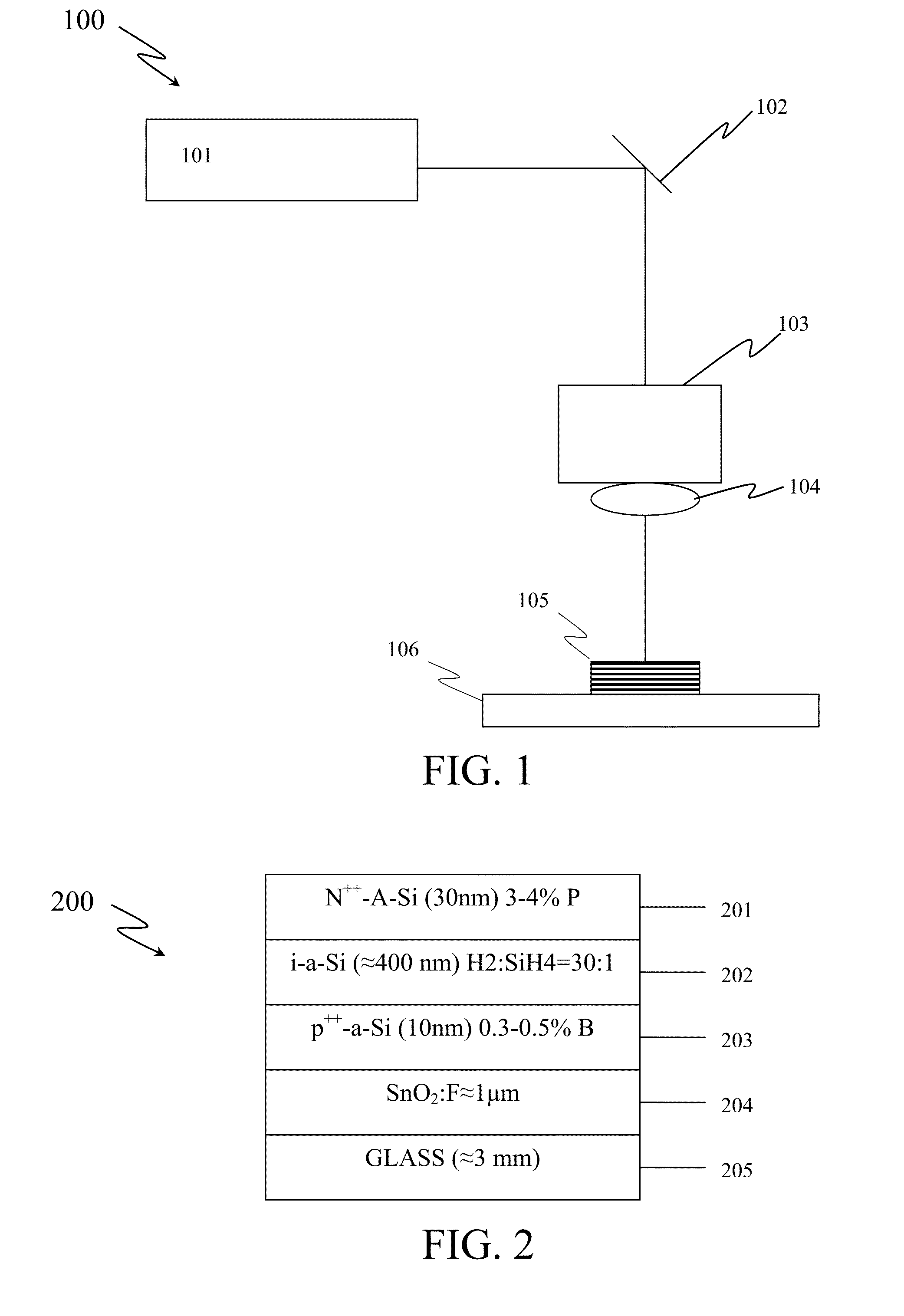

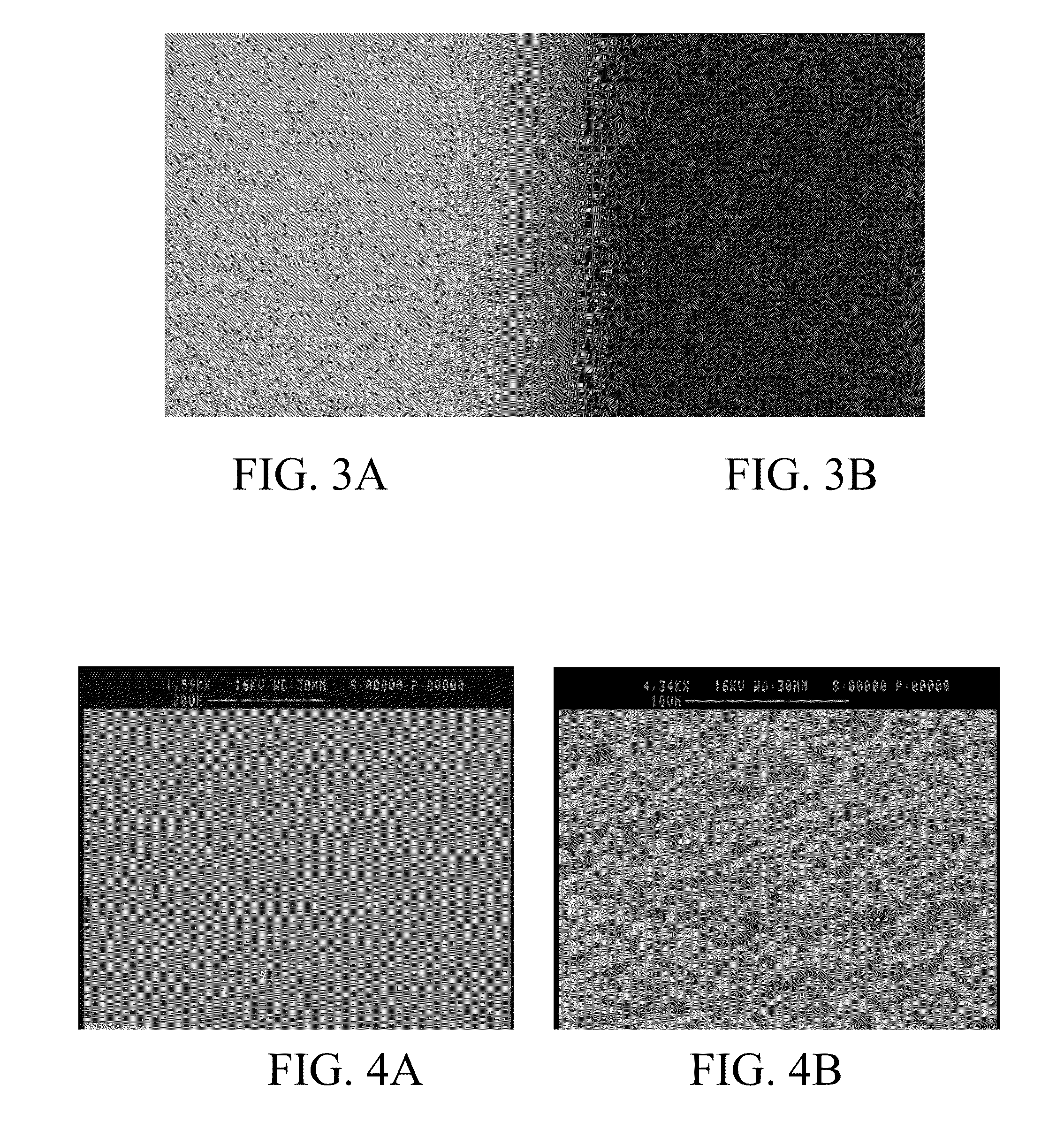

Systems and Methods of Laser Texturing of Material Surfaces and their Applications

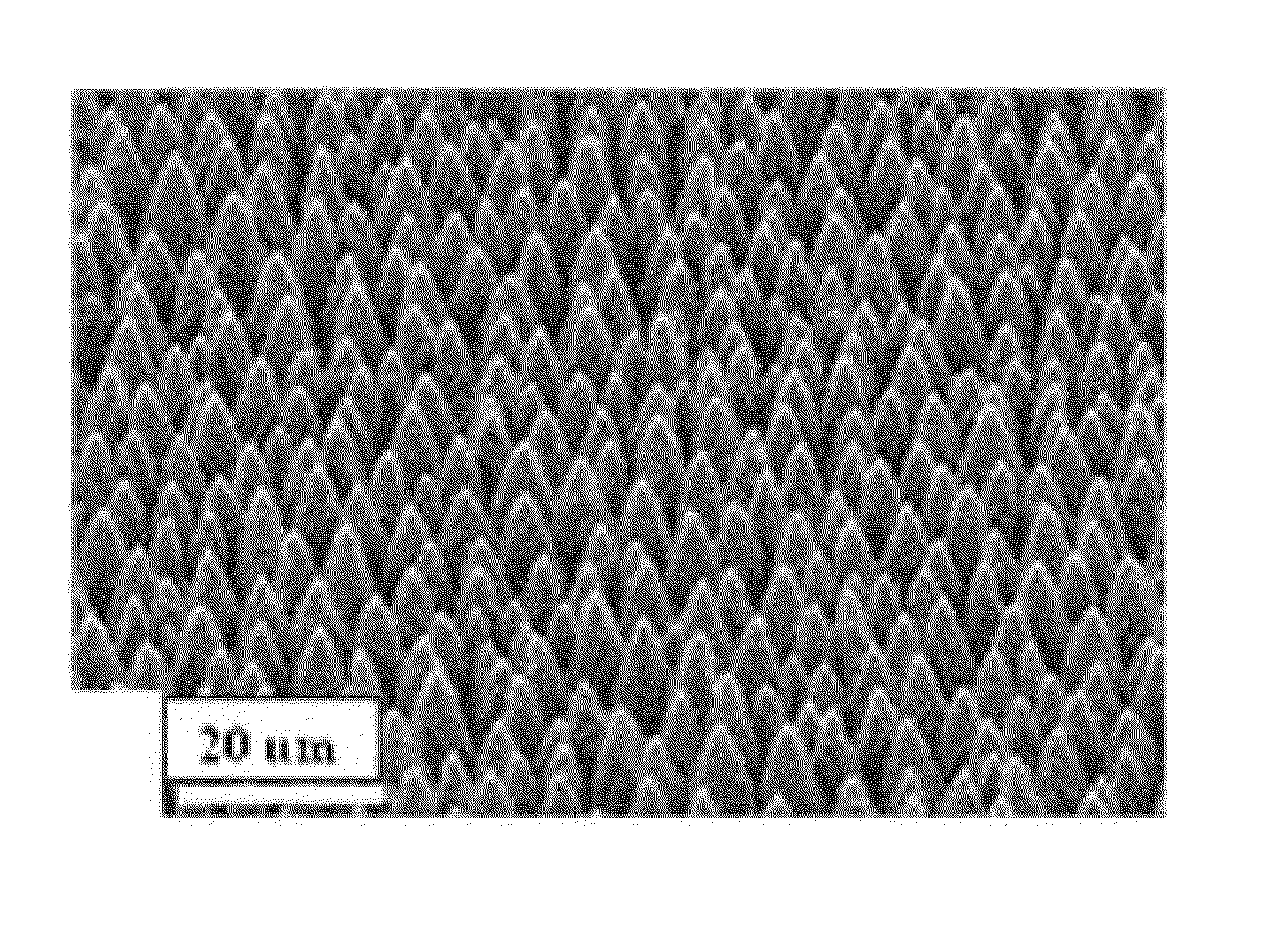

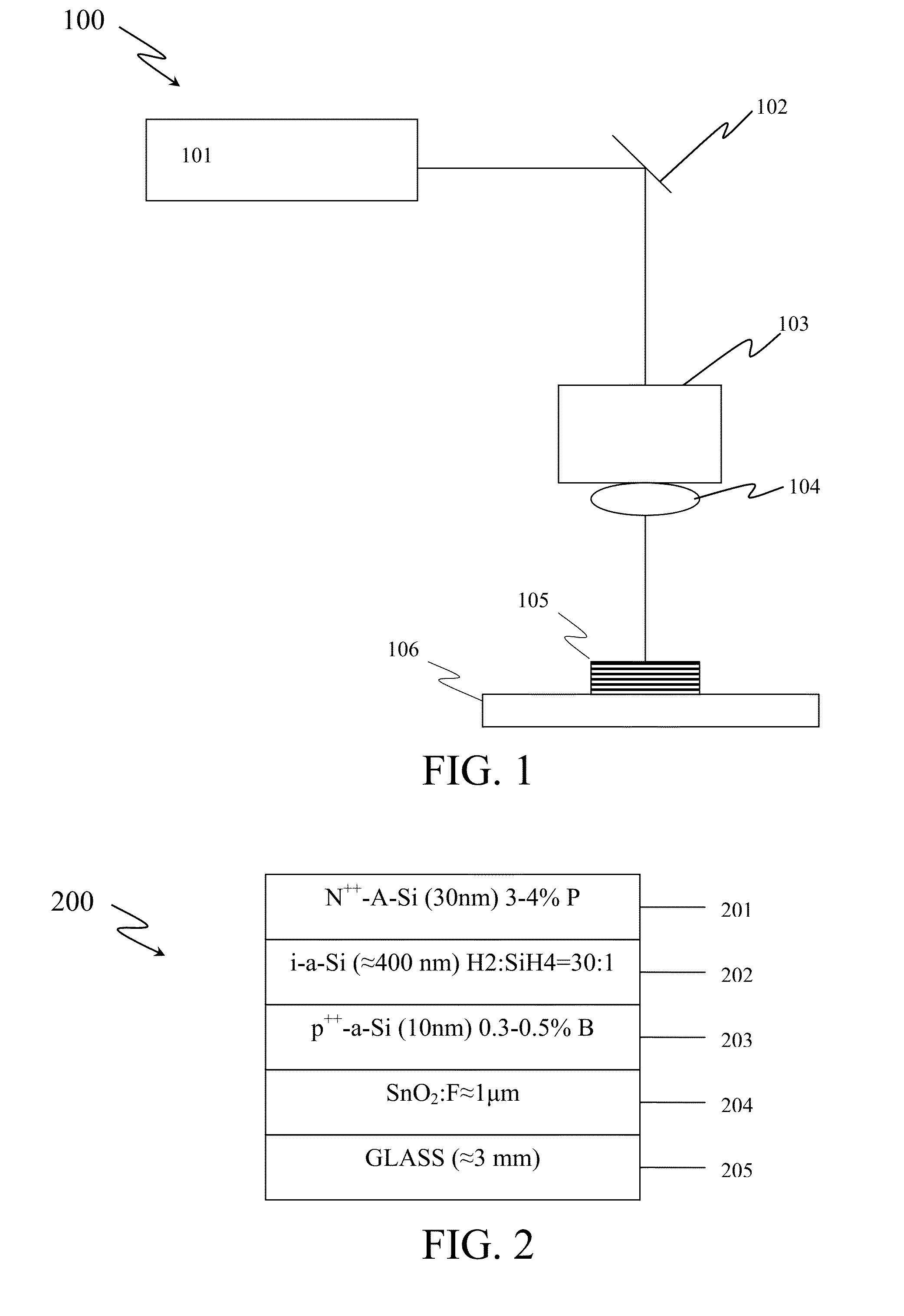

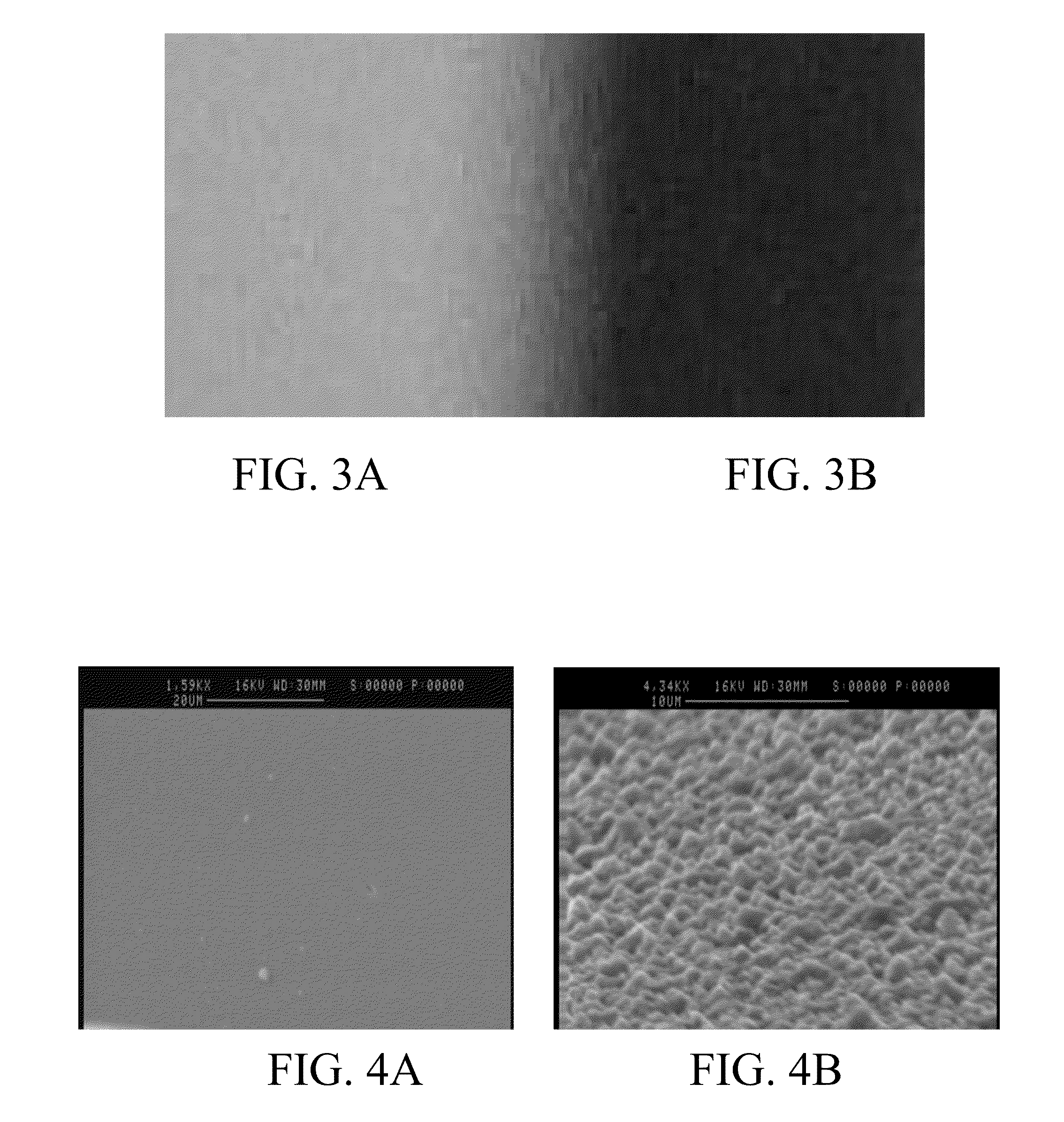

InactiveUS20100143744A1Enhance light absorptionImprove conductivityDecorative surface effectsSemiconductor/solid-state device manufacturingAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

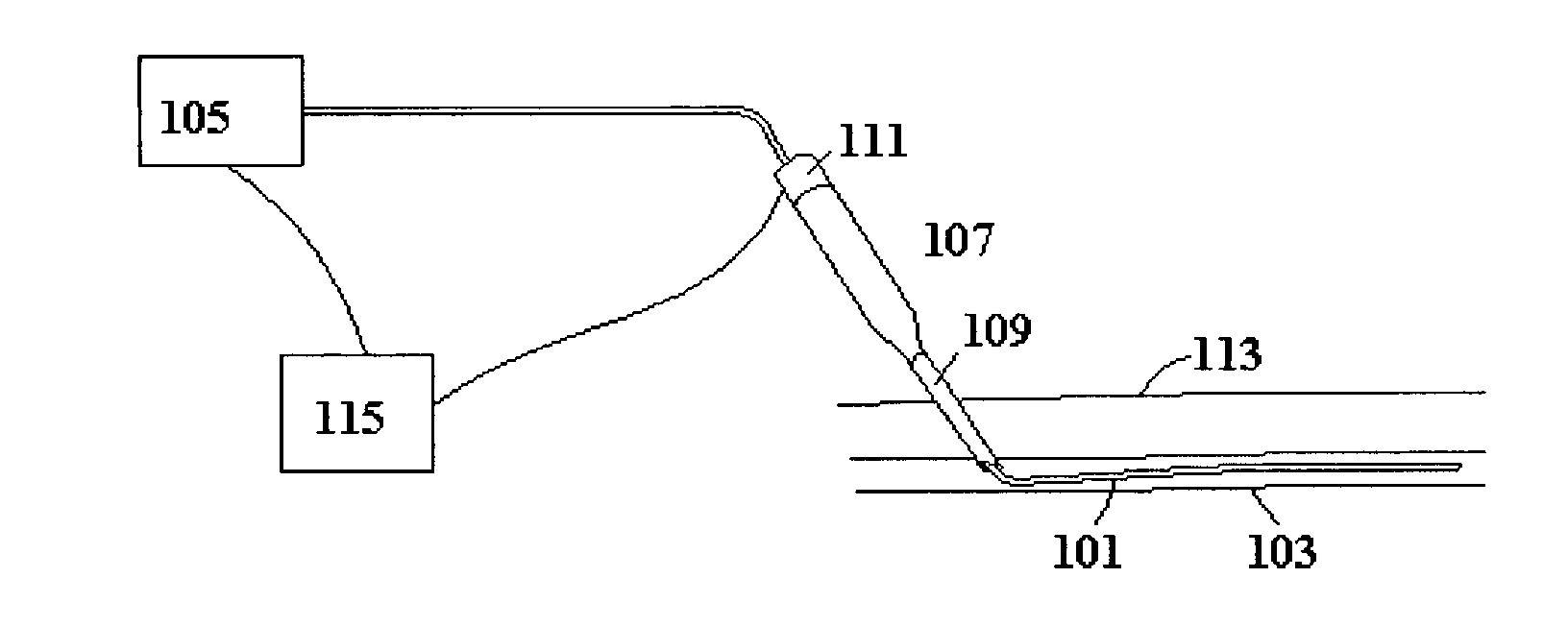

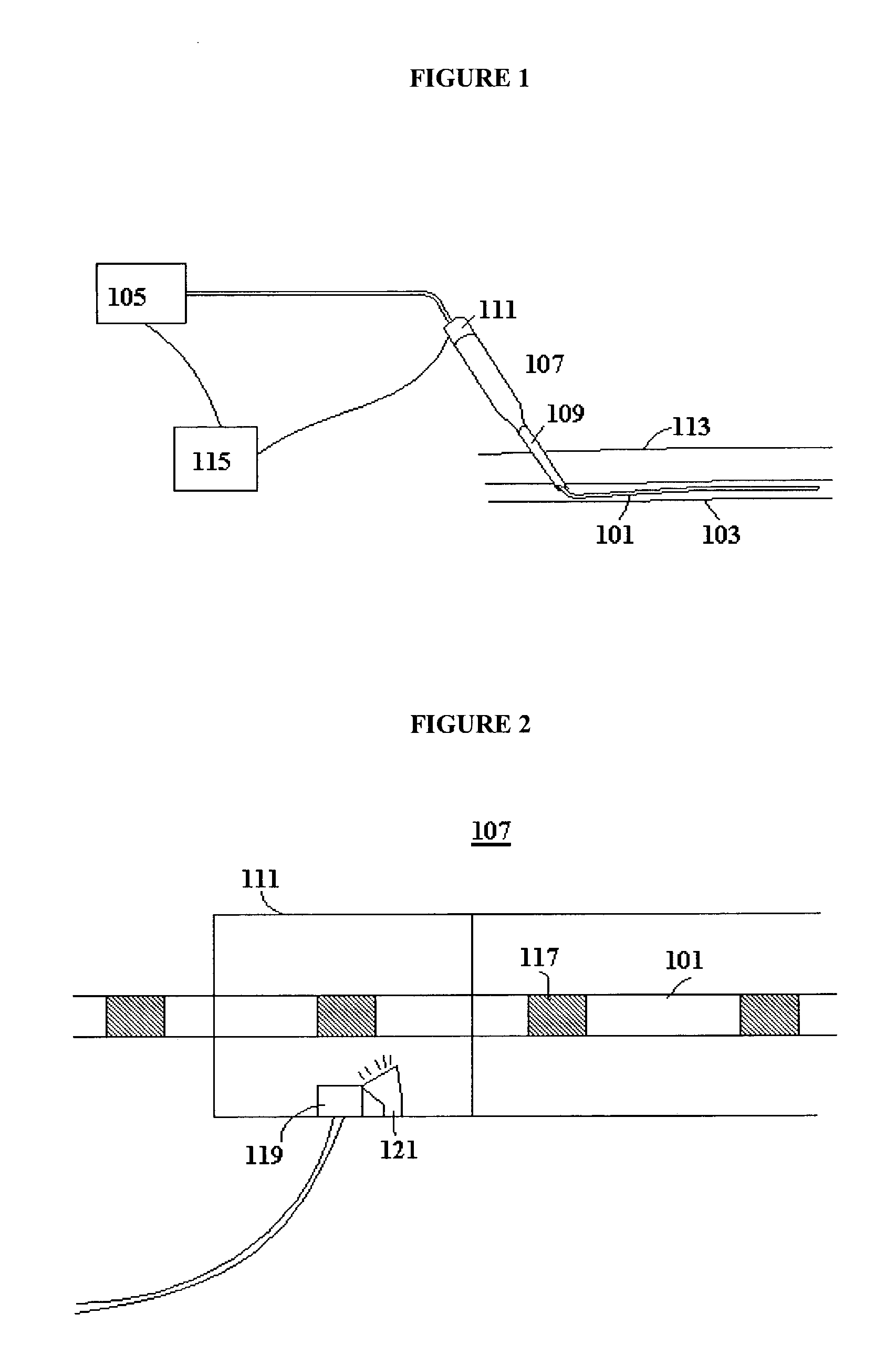

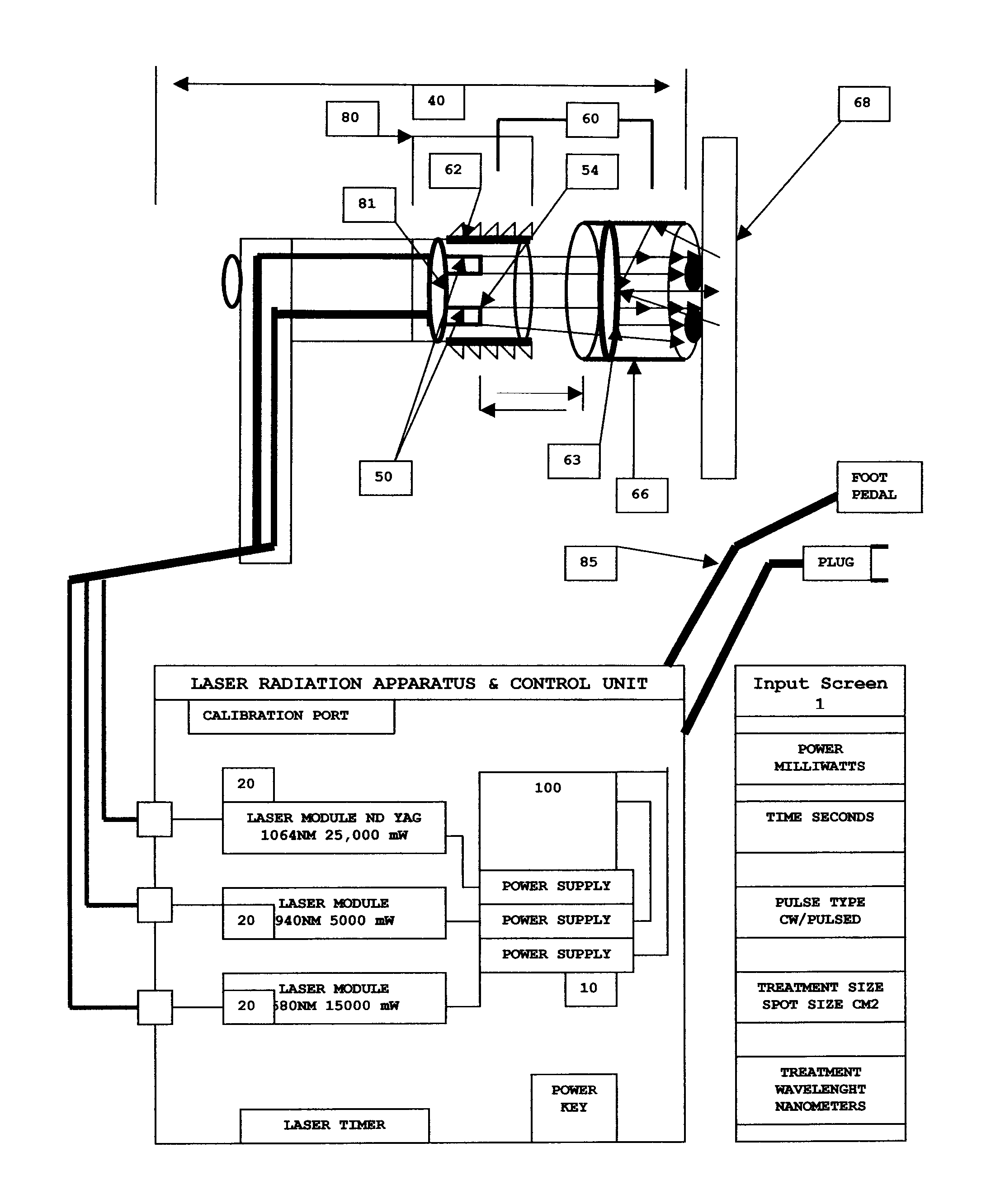

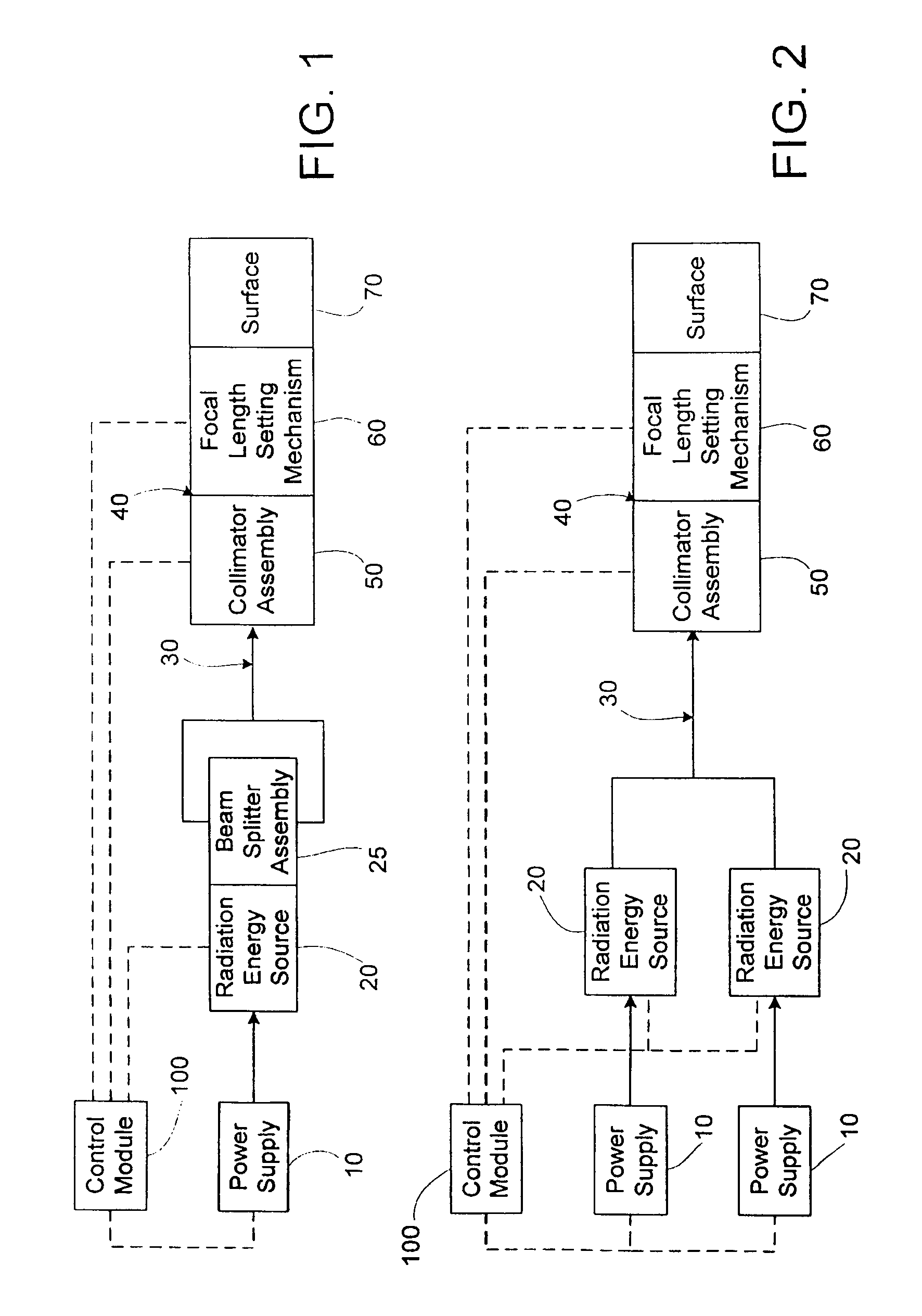

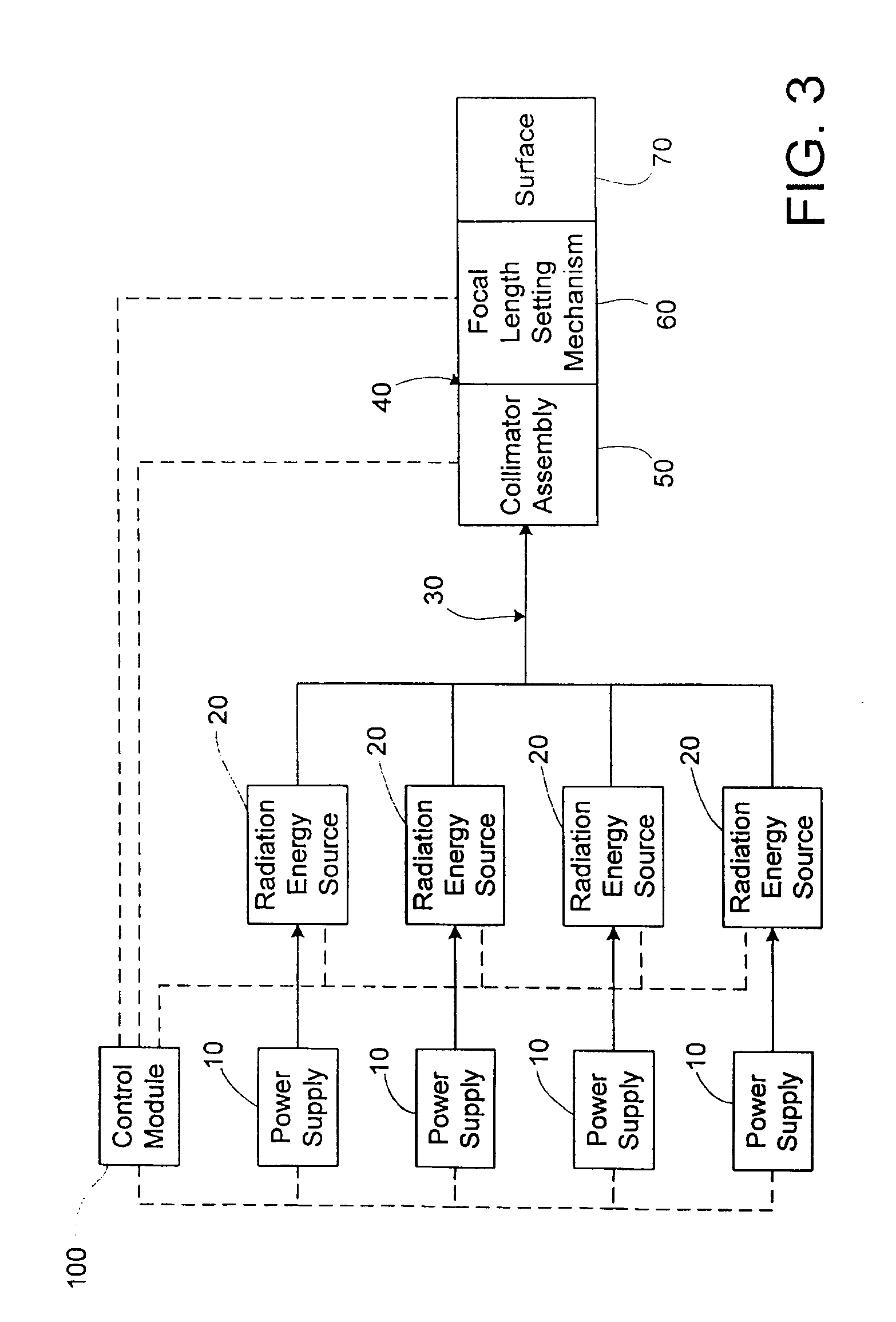

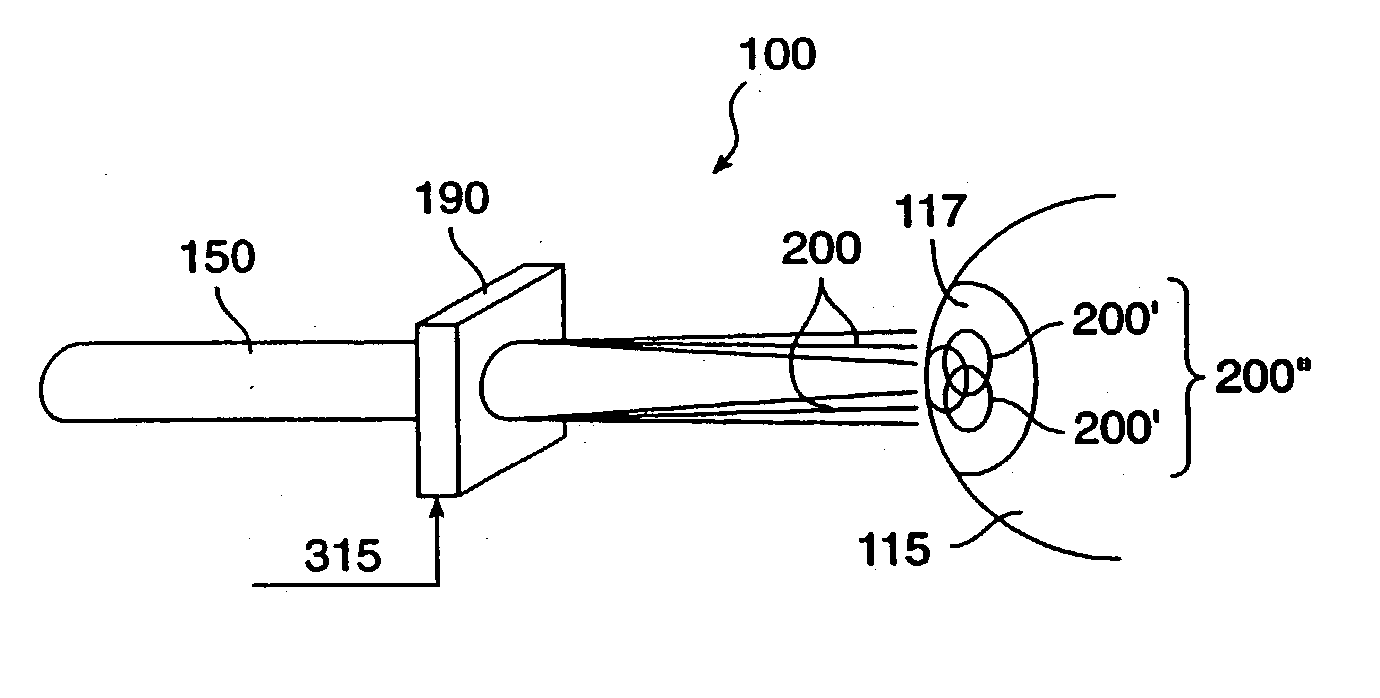

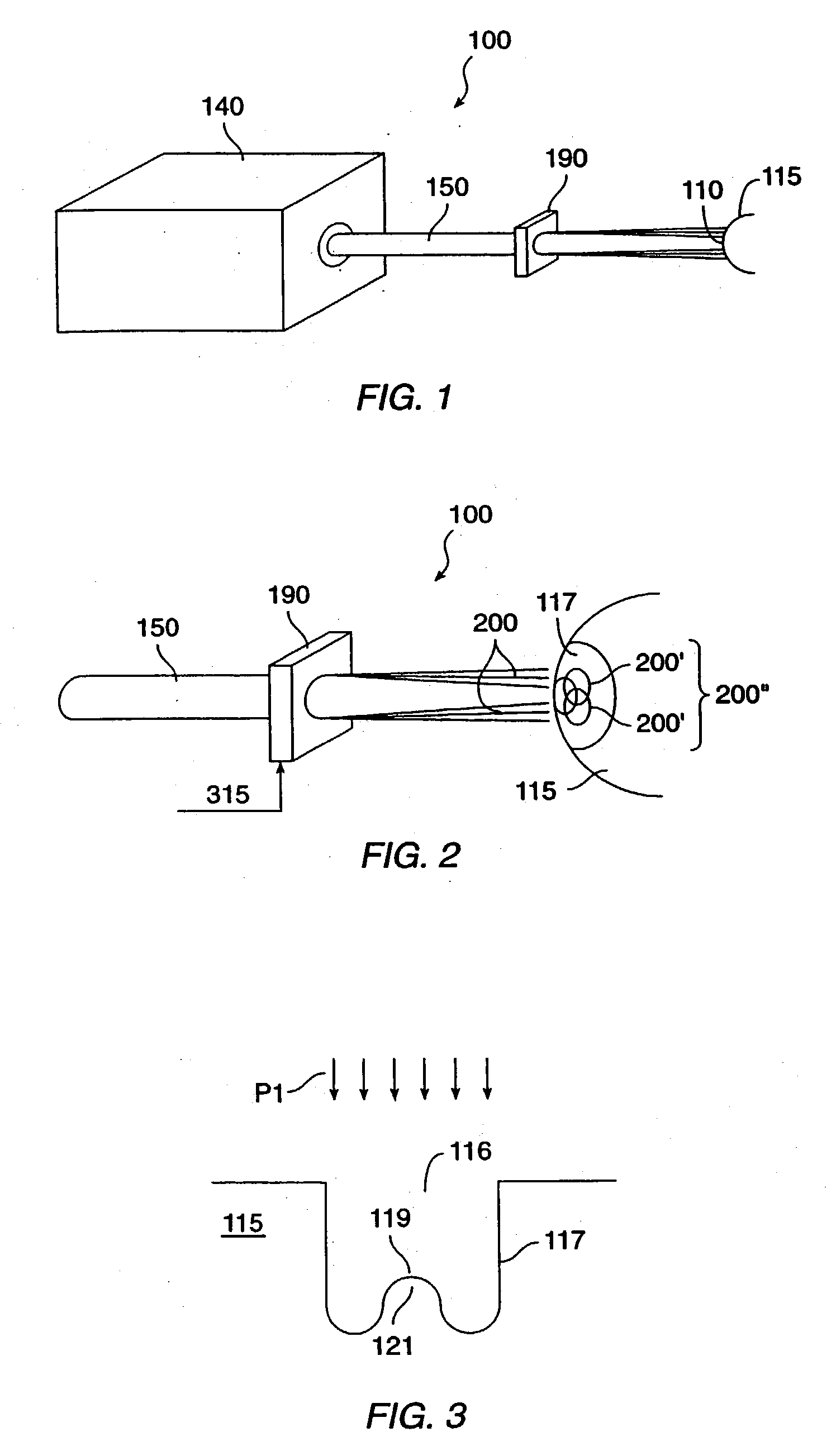

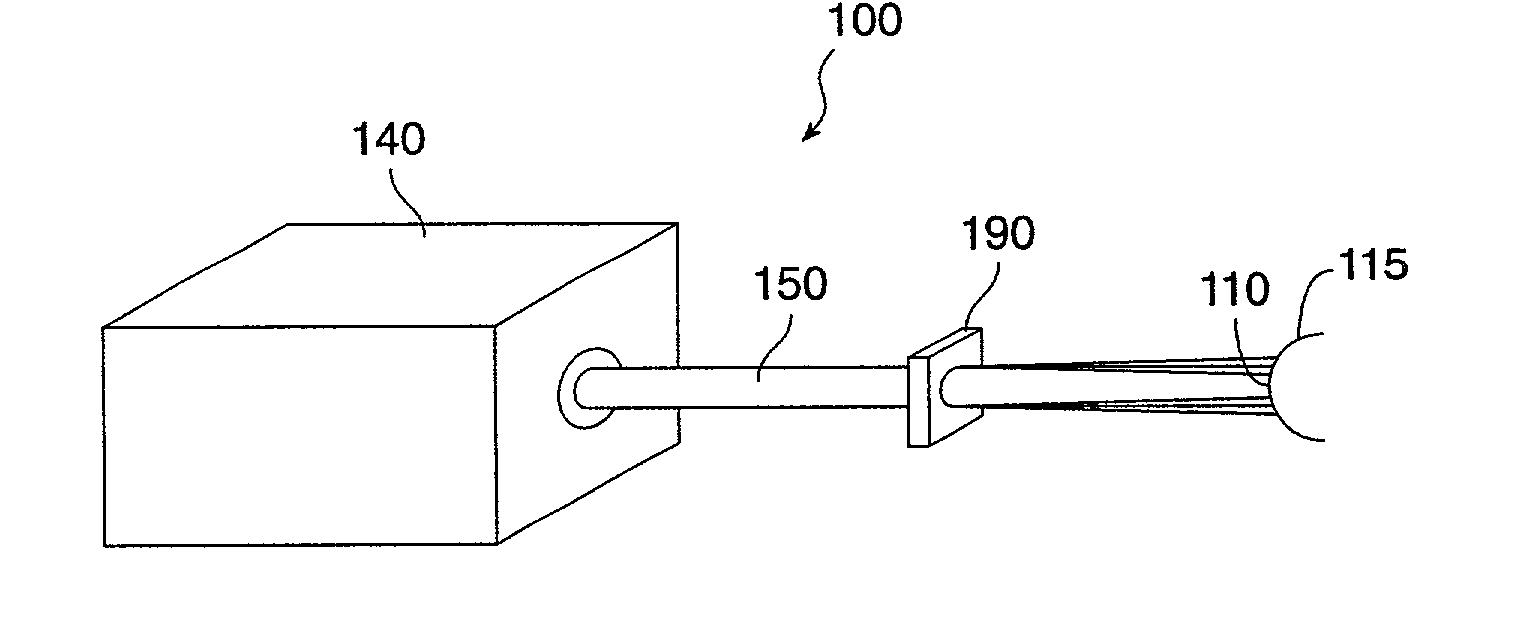

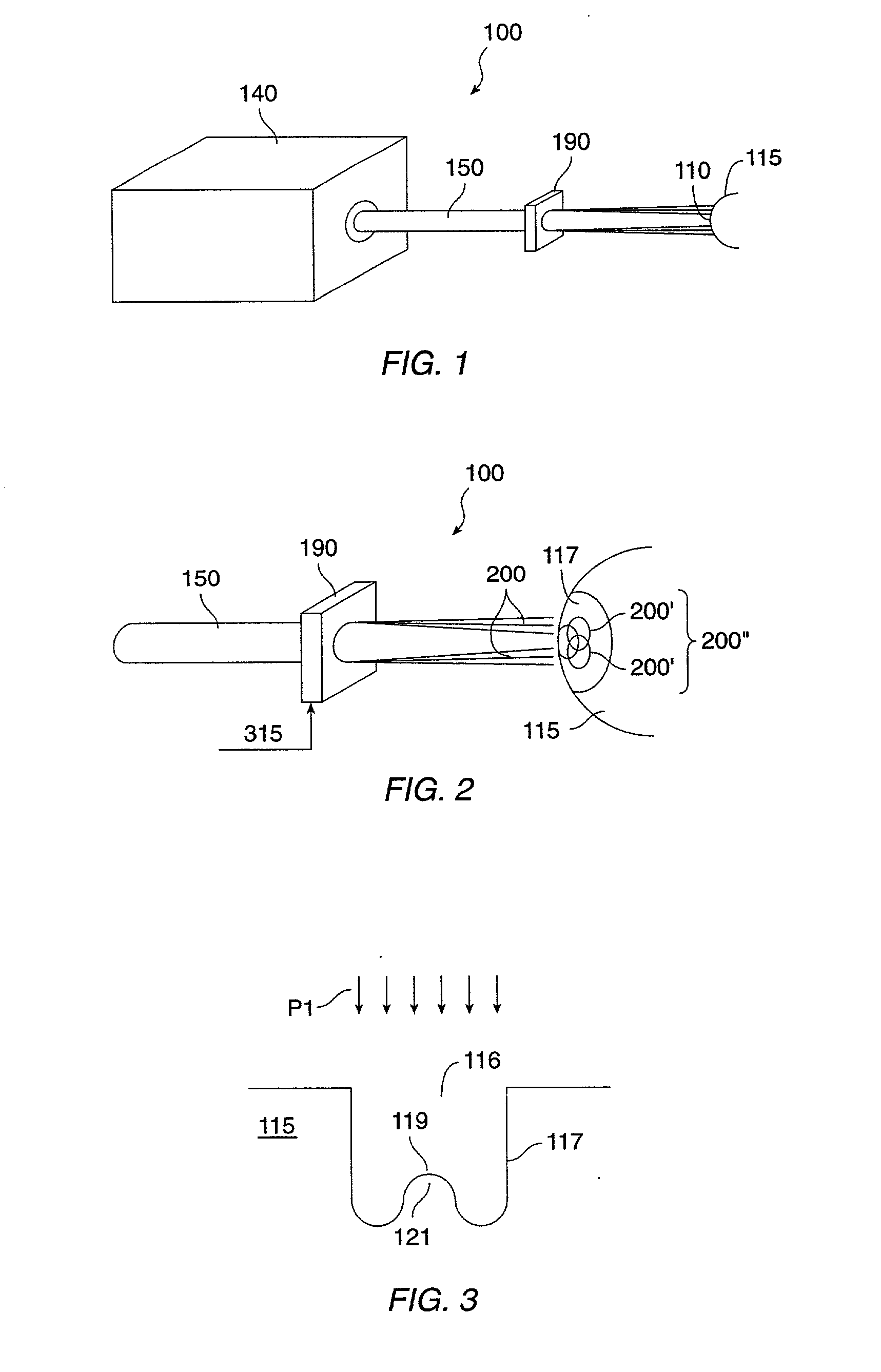

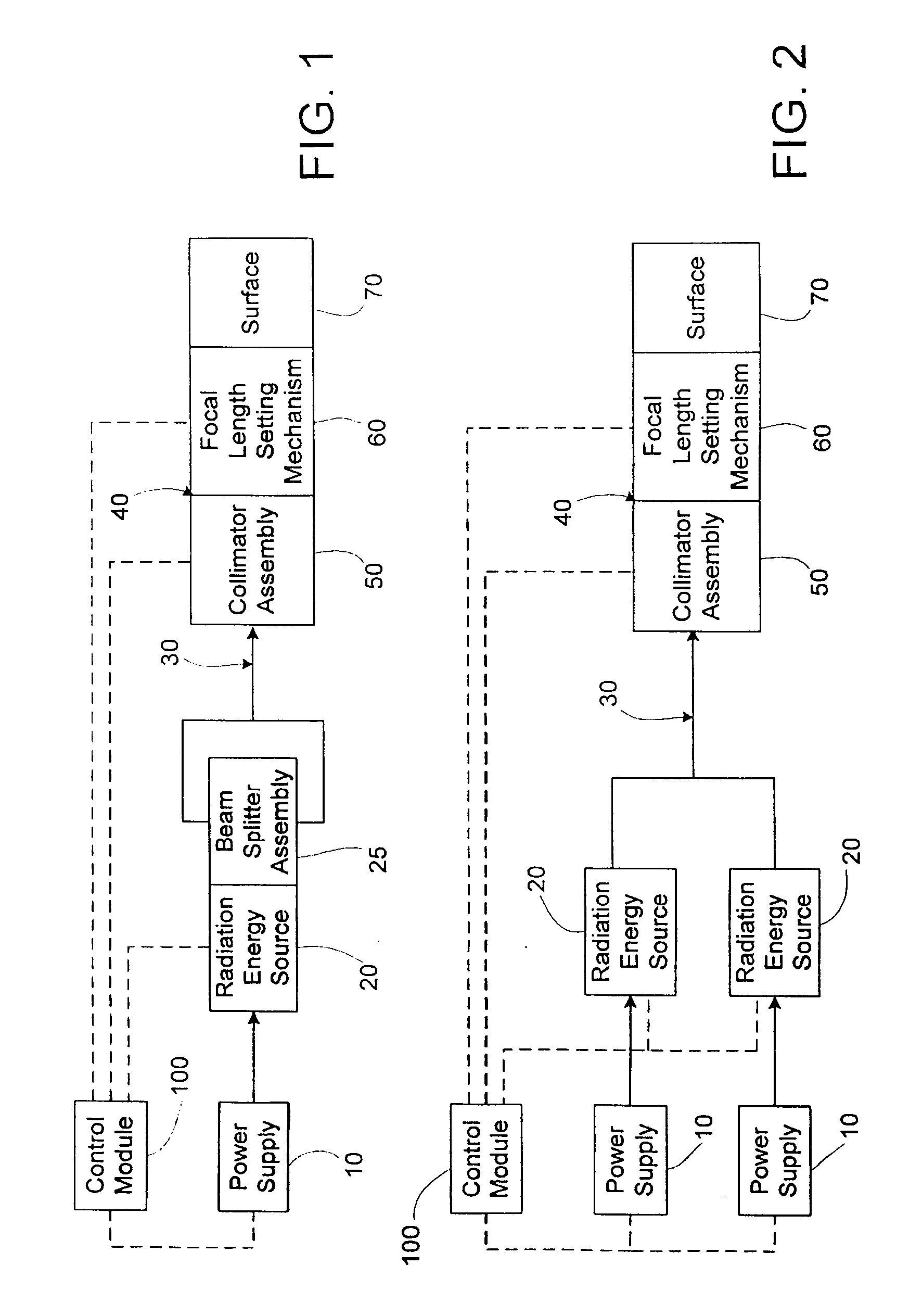

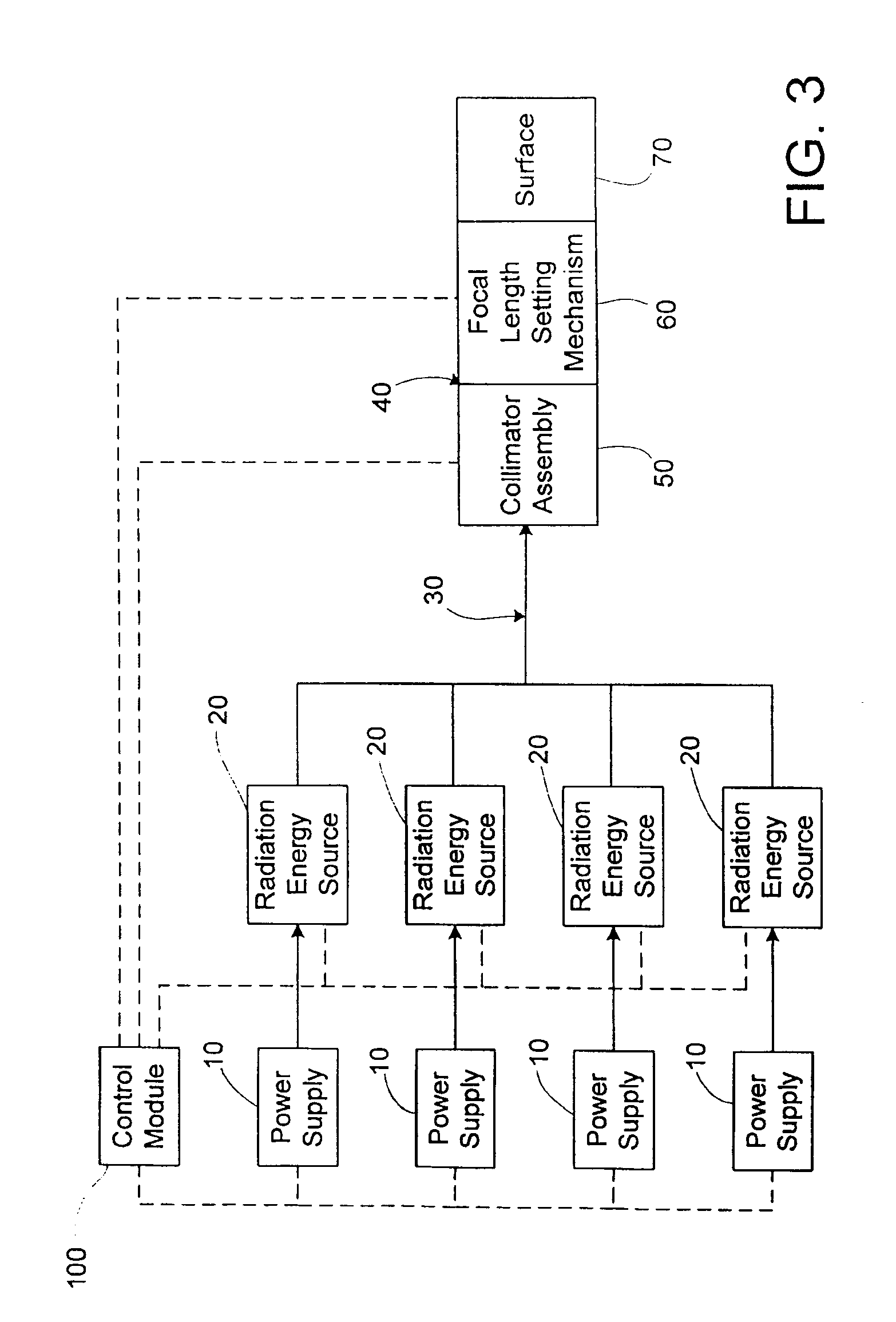

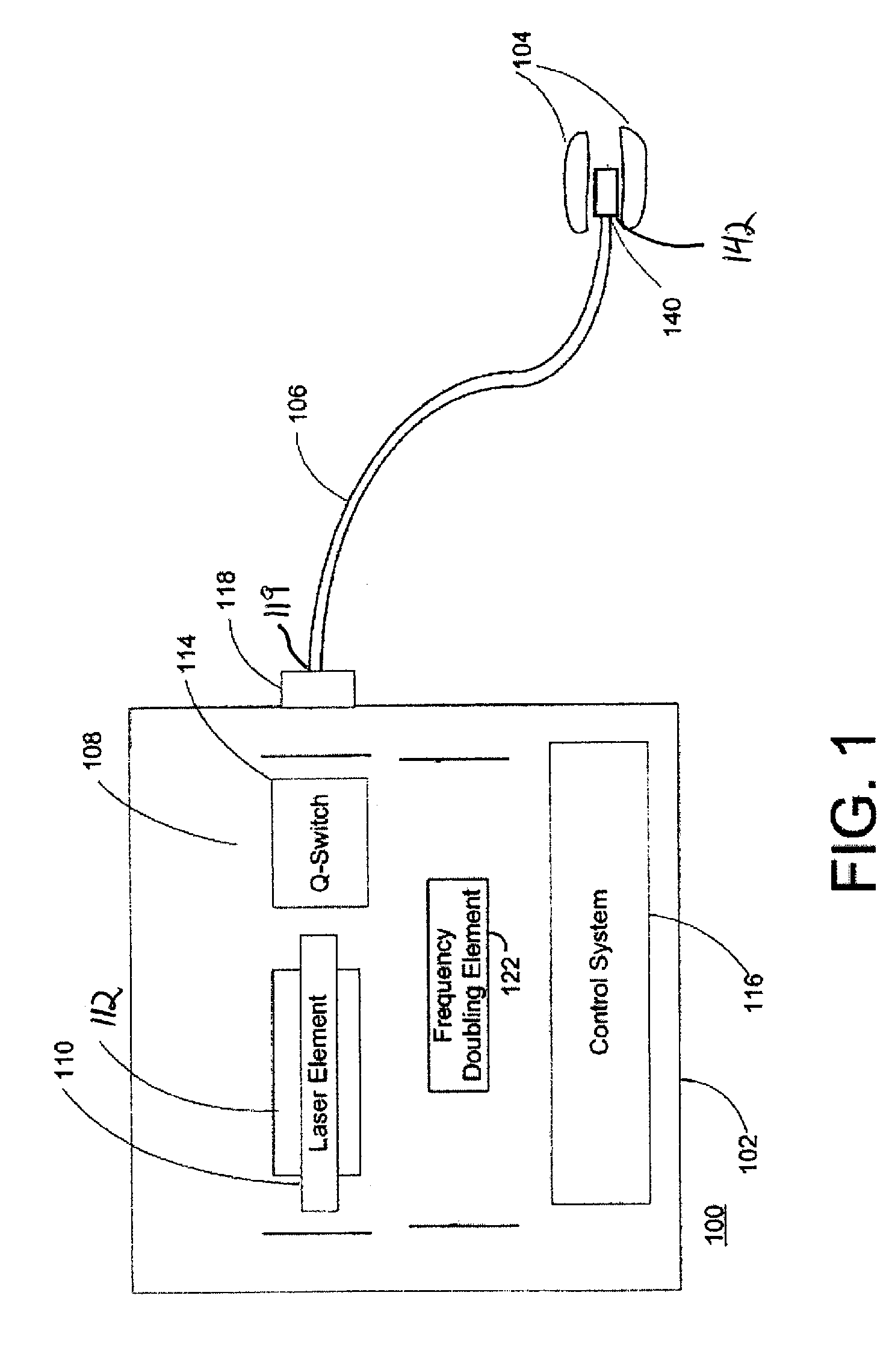

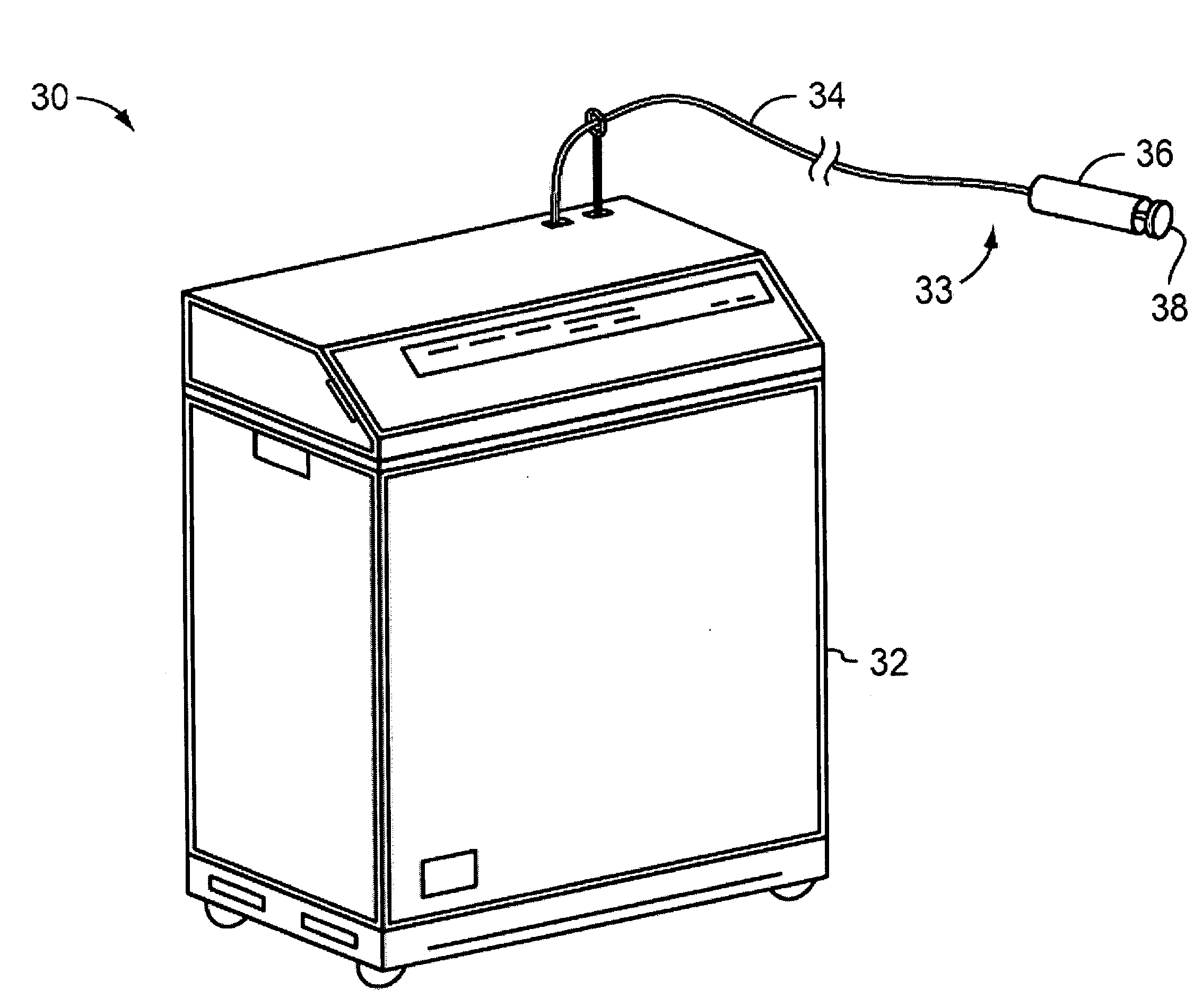

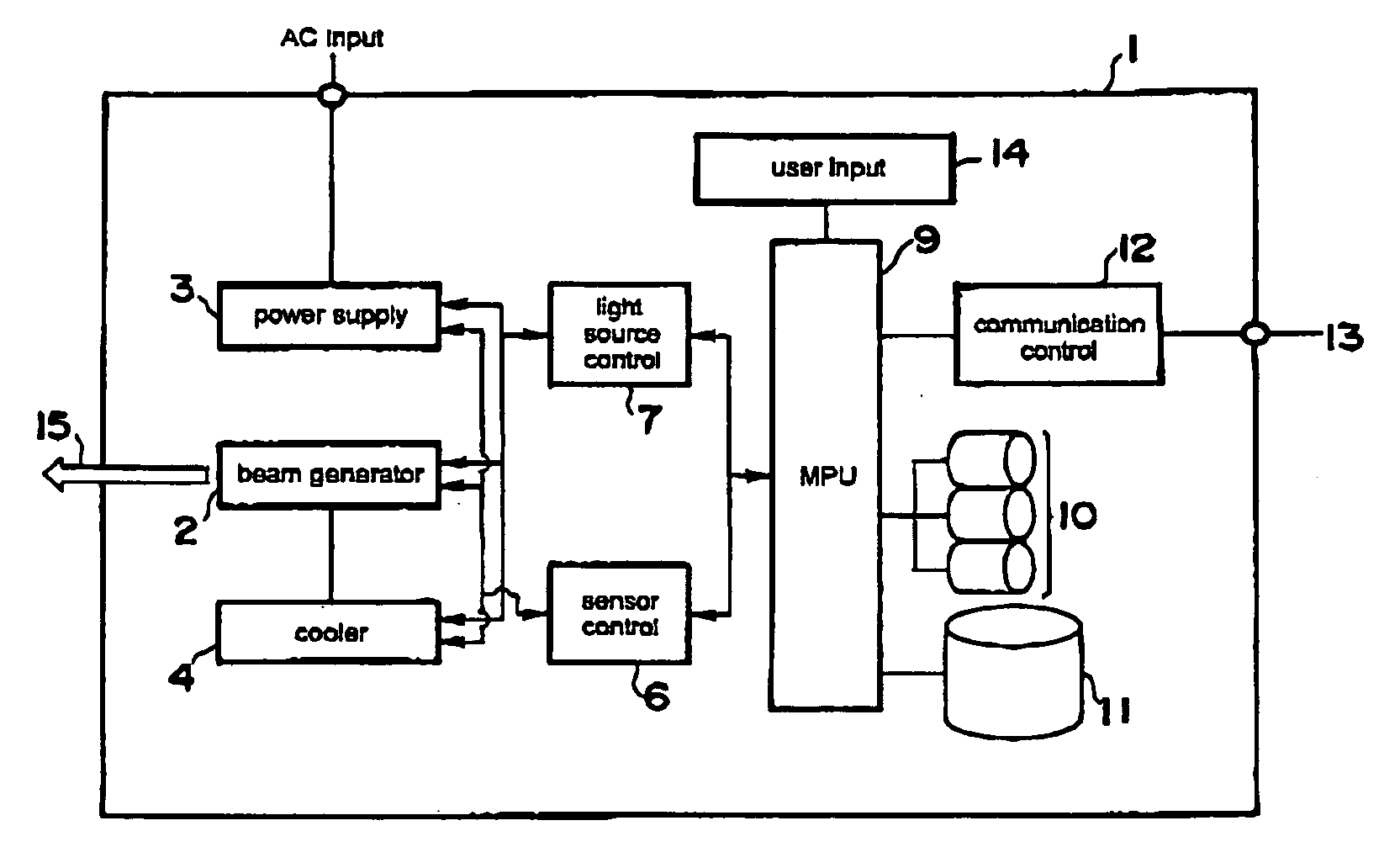

Apparatus and method for performing radiation energy treatments

InactiveUS8287524B2Improve efficiencyImprove securitySurgical instrument detailsLight therapyFiberTherapeutic effect

An apparatus and method to apply photo-stimulation, photo-dynamic therapy and / or ablation laser treatment to biological tissue. The apparatus includes a plurality of radiation energy sources, preferably laser beams. Additionally, the apparatus allows either a single wavelength or a combination of various wavelengths, either coincidentally or adjacently, to be utilized to achieve a desired treatment effect. Laser beams are transmitted to the treatment area by one or more fiber optic cables which terminate at an assembly structured to collimate the emitted radiation prior to application to the tissue. In addition, the apparatus includes a focal length setting mechanism which assures that a constant, fixed distance exists between the point of discharge of the laser beam and the biological tissue, thus assuring a constant energy density at the point of application. A method is presented for applying photo-stimulation, photocollagen stimulation and / or ablation laser treatment utilizing the above apparatus.

Owner:SIEGEL JERRY

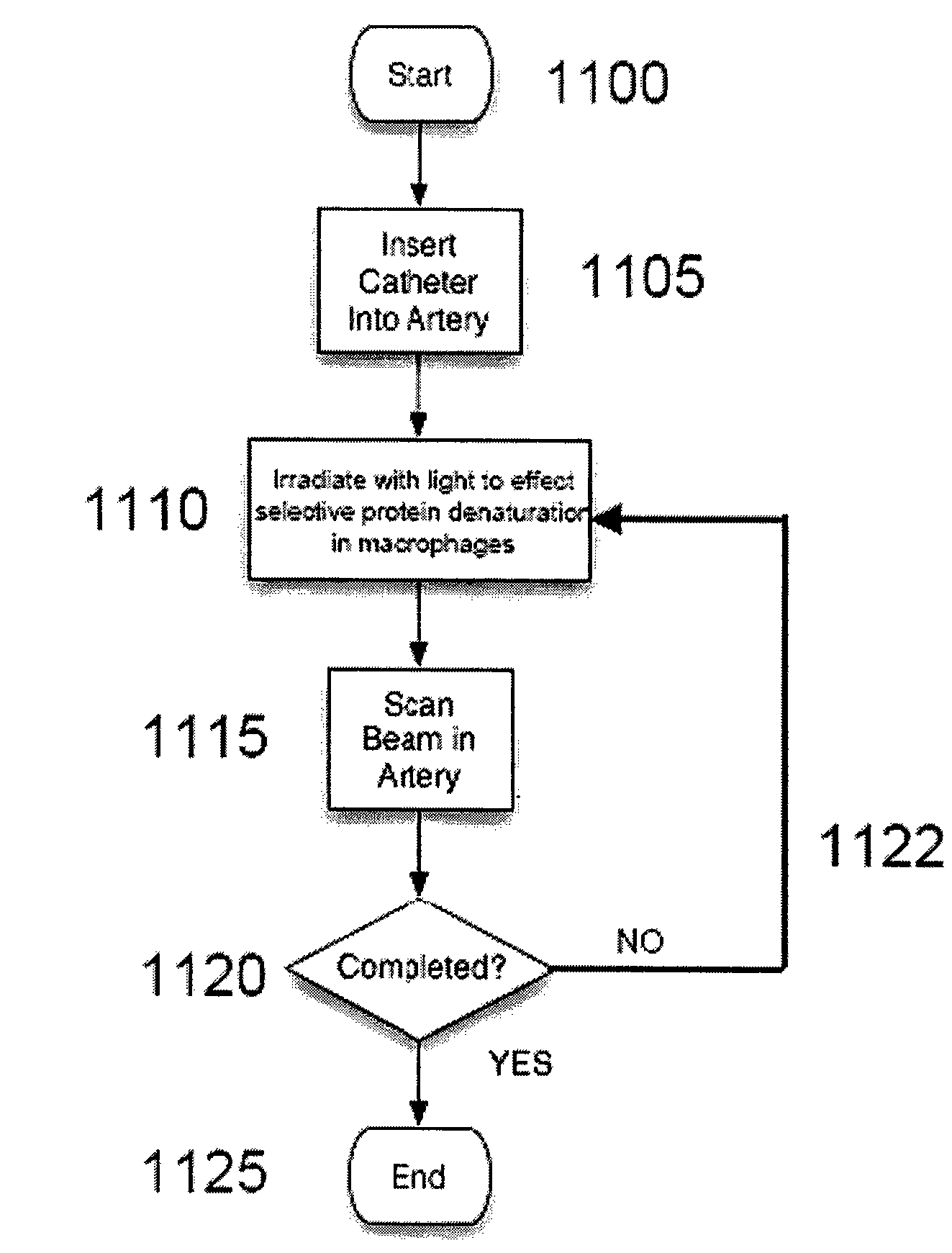

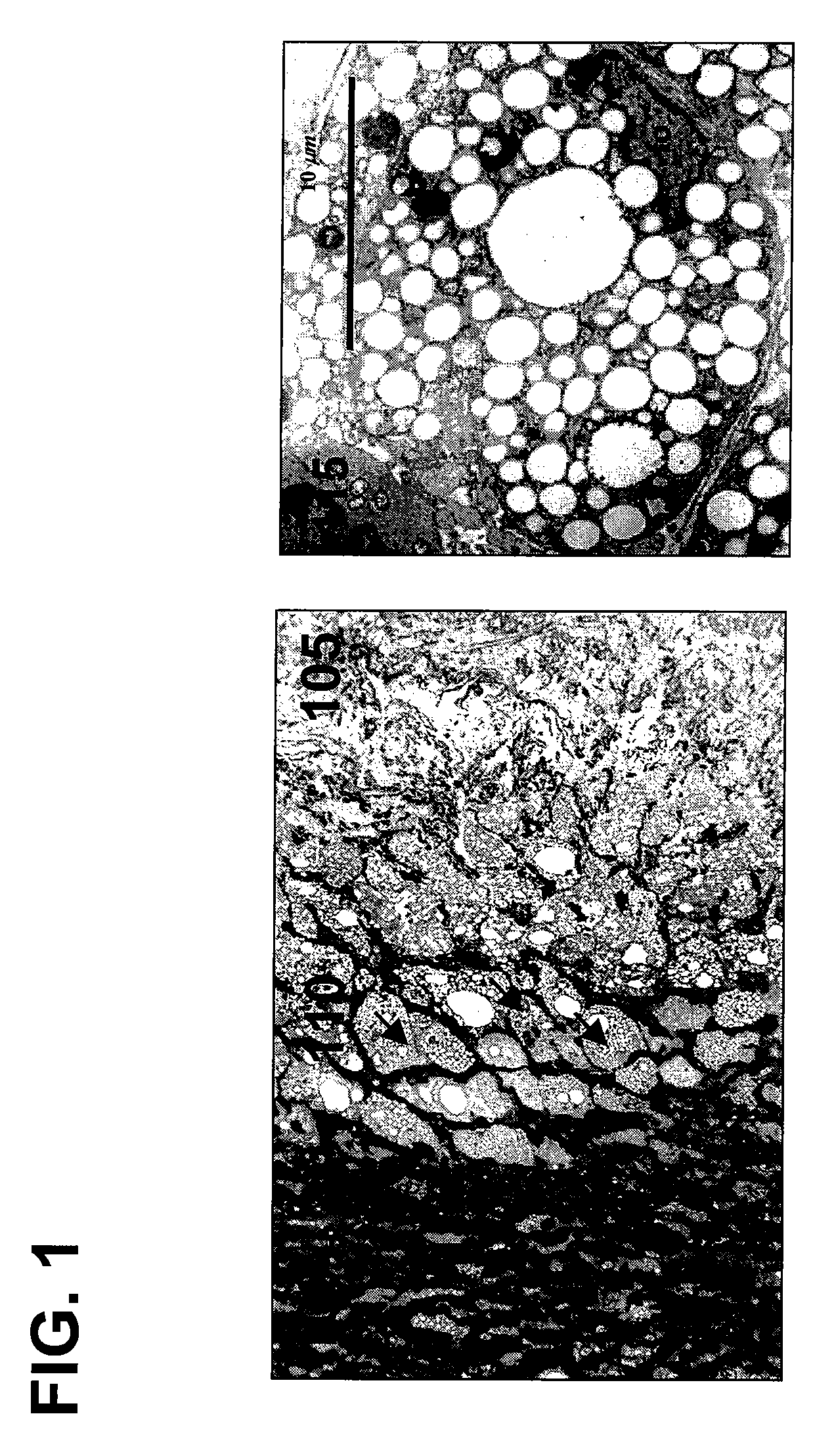

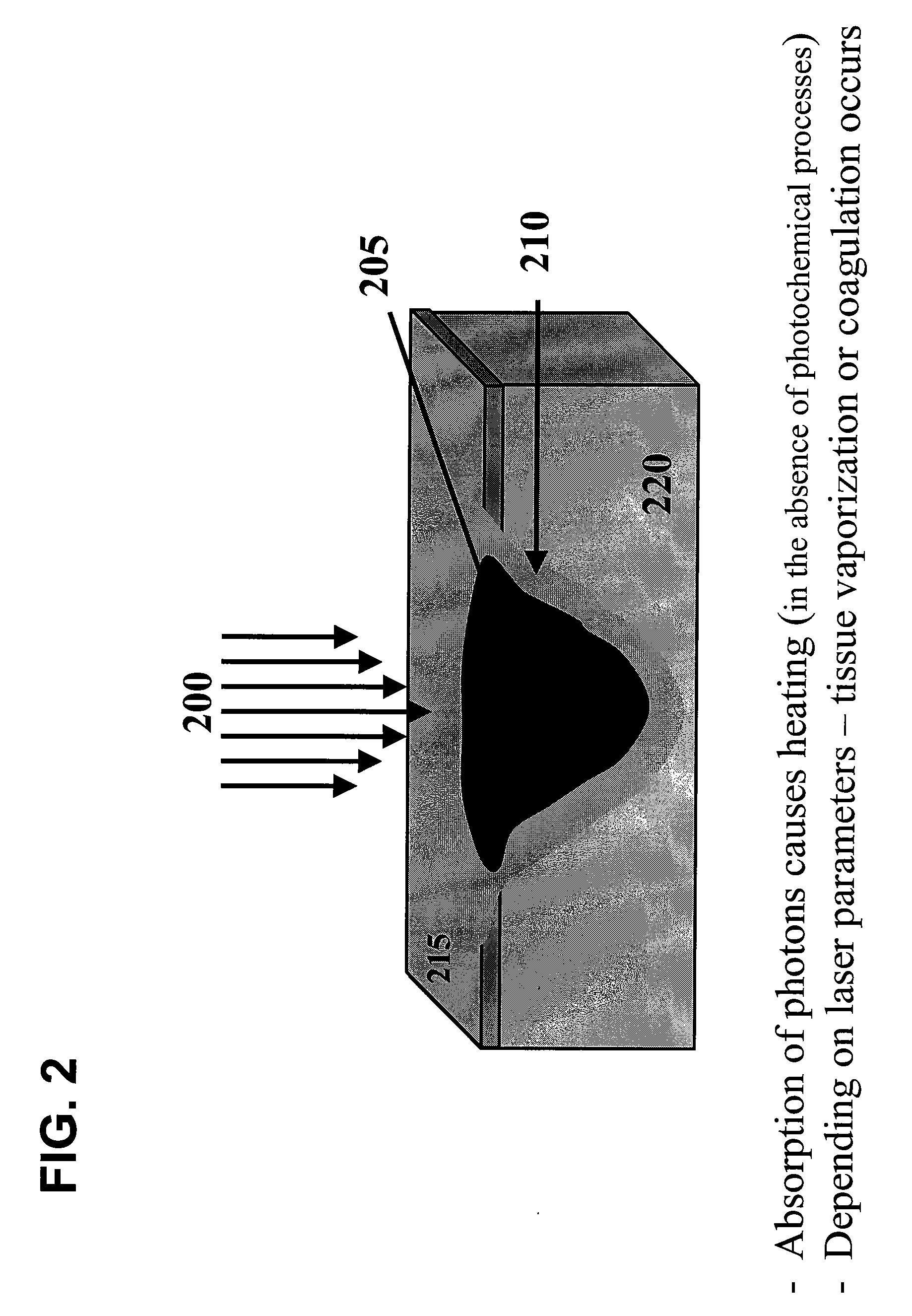

System and method for providing cell specific laser therapy of atherosclerotic plaques by targeting light absorbers in macrophages

An apparatus and method according to the present invention can be provided, e.g., for a cell specific laser therapy of atherosclerotic plaques, particularly to systems and methods for targeting endogenous light absorbers present within plaque macrophages and exogenous nanoparticle targeting. In one exemplary embodiment, an electro-magnetic radiation can be forwarded to an anatomical structure. The electromagnetic radiation may have at least one property configured to (a) modify at least one characteristic of at least one first cell, and (b) minimize any modification of and / or modify at least one characteristic of at least second cell. The first and second cells may be different from one another, the characteristics of the first and second cells can be different from one another, and the first cell and / or the second cell may have at least one macrophage feature, and the characteristic of the at least one first cell and / or the at least one second cell can be temperature. According to still another exemplary embodiment, a location associated with the first cell and the second cell can be determined. For example, the electromagnetic radiation can be forwarded in a vicinity of the location.

Owner:THE GENERAL HOSPITAL CORP

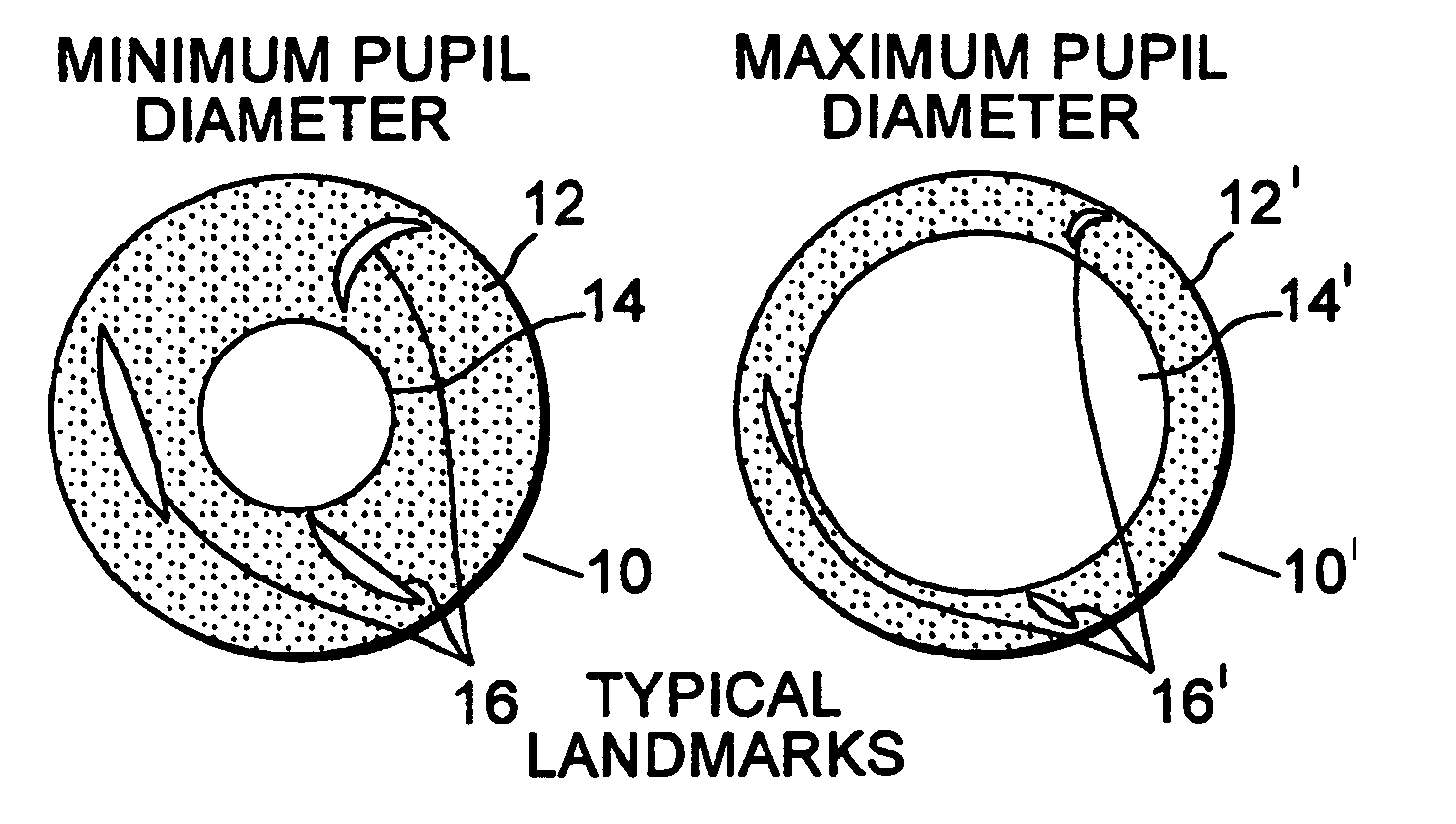

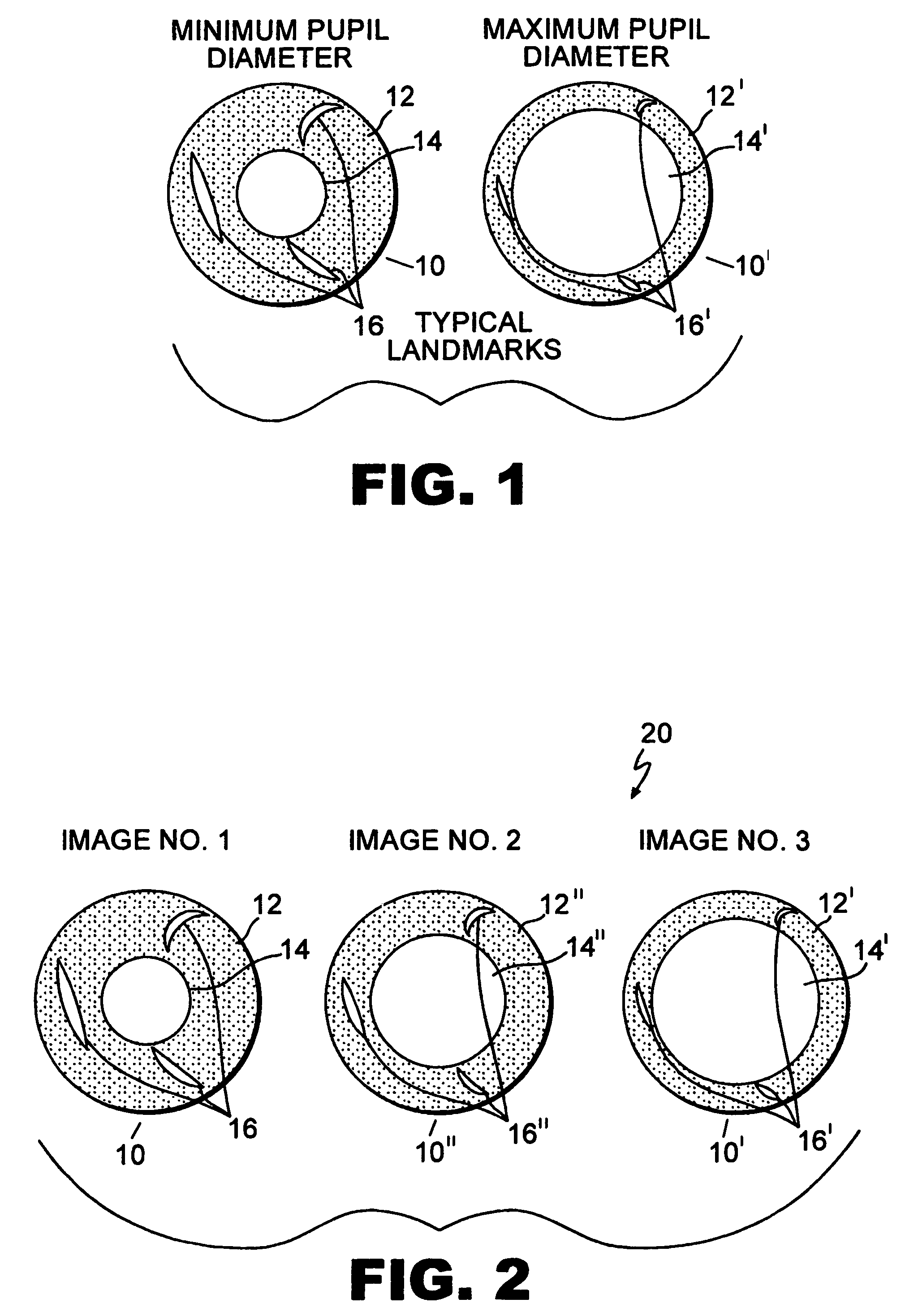

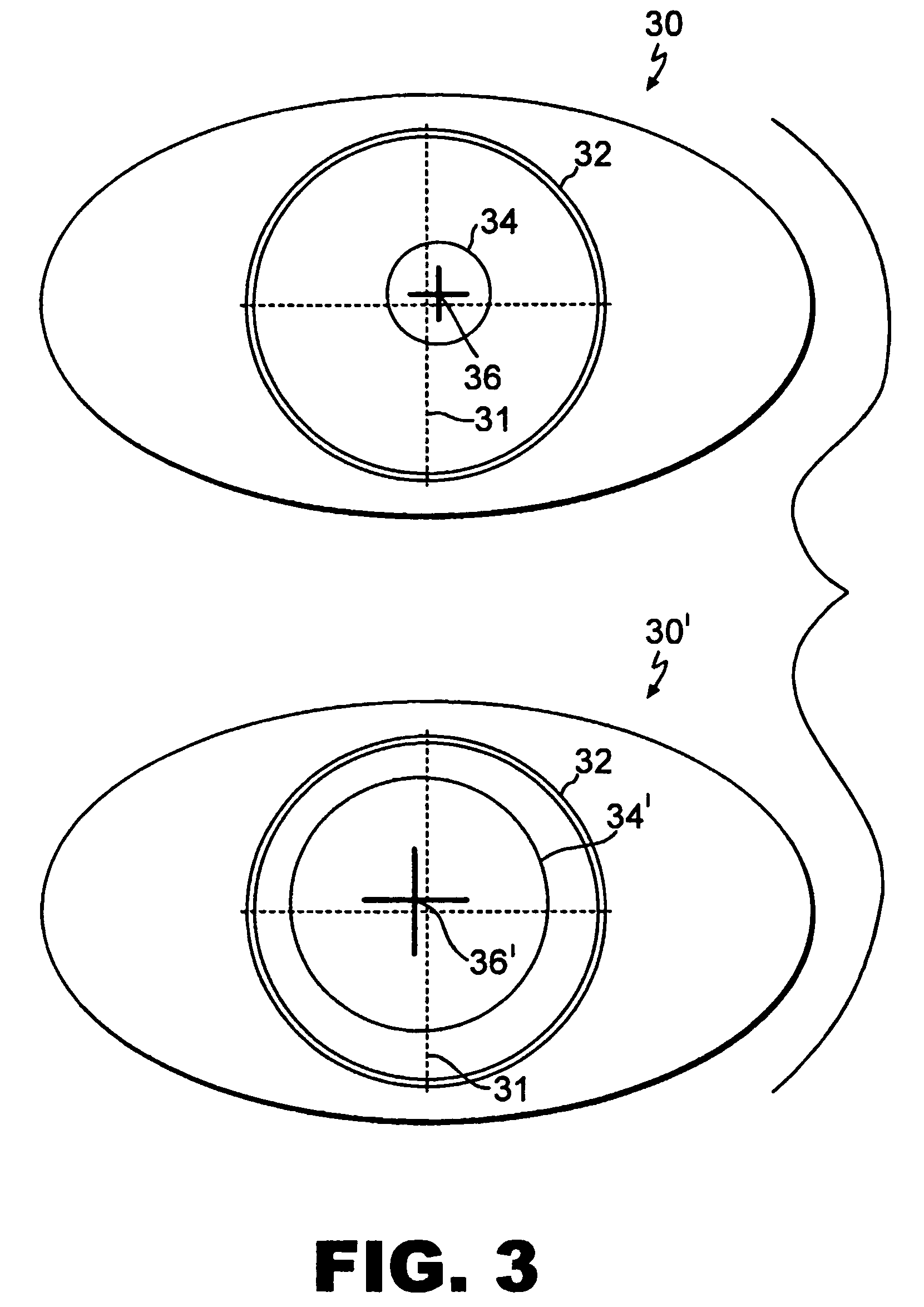

Iris pattern recognition and alignment

Apparatus and methods are described for aligning diagnostic and therapeutic iris images, via iris pattern recognition, for effecting more accurate laser treatment of the eye. A method for aligning a dilated pupil diagnostic iris image associated with a diagnostic measurement for calculating a laser treatment, with a constricted pupil diagnostic iris image, by identifying an iris landmark that is not identifiable solely between the two images, includes a sequential plurality of diagnostic iris images of varying pupil size such that the iris landmark can be tracked between the two images. The aligned, constricted pupil diagnostic image can then be aligned with a constricted pupil treatment image and the ablation pattern rotated accordingly. Limbal edge detection is used in the diagnostic images to provide pupil center translation information for translational alignment of the laser treatment. An improved aberrometer is disclosed having a variable visible illumination fixation target for controlling pupil size for the diagnostic images. A diagnostic and therapeutic laser eye treatment system is described incorporating the apparatus and method embodiments of the invention.

Owner:BAUSCH & LOMB INC +1

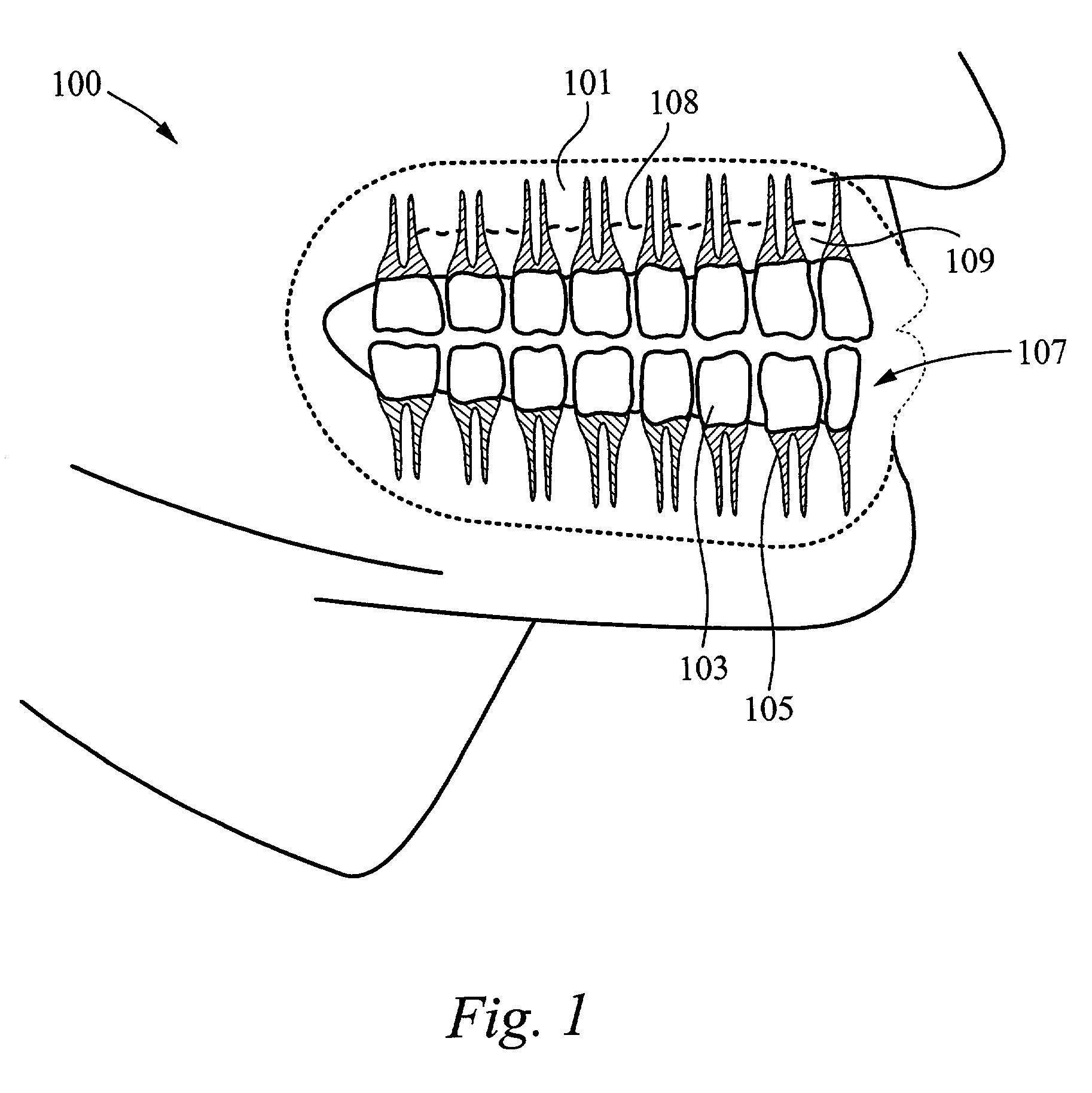

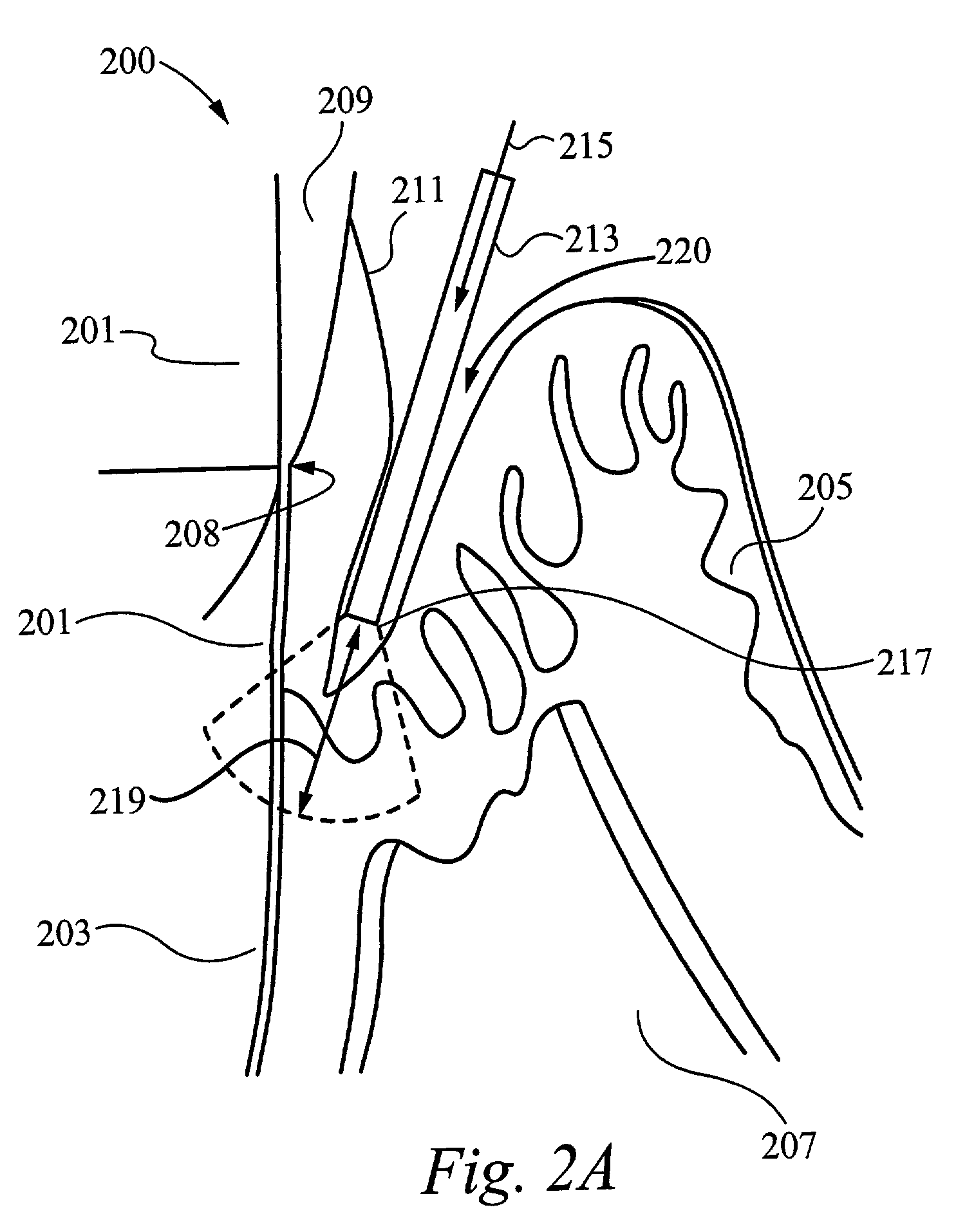

Method of periodontal laser treatment

A method of selectively treating microbiological pathogens which are implicated in the advancement of periodontitis is disclosed. Preferably, the microbiological pathogens are phorphyromonas gingivalis (Pg) and prevotella intermedia (Pi) which are known to colonize in dental plaque, cementum, gingival sulcus epithelium and surrounding periodontal tissues. The microbiological pathogens can also include pigmented fungi such as Histoplasma and Aspirgillus Niger. The microbiological pathogens are selectively irradiated with high-energy antiseptic laser pulses which are strongly absorbed by the microbiological pathogens and which are substantially transparent to the periodontal tissues. Preferably, high-energy antiseptic laser pulses eradicate a portion of the microbiological pathogens within the periodontal tissues without requiring aggressive debridement procedures.

Owner:PINPOINTE US

Systems and methods of laser texturing of material surfaces and their applications

ActiveUS20130020297A1Enhance light absorptionImprove conductivityNanotechLaser beam welding apparatusAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

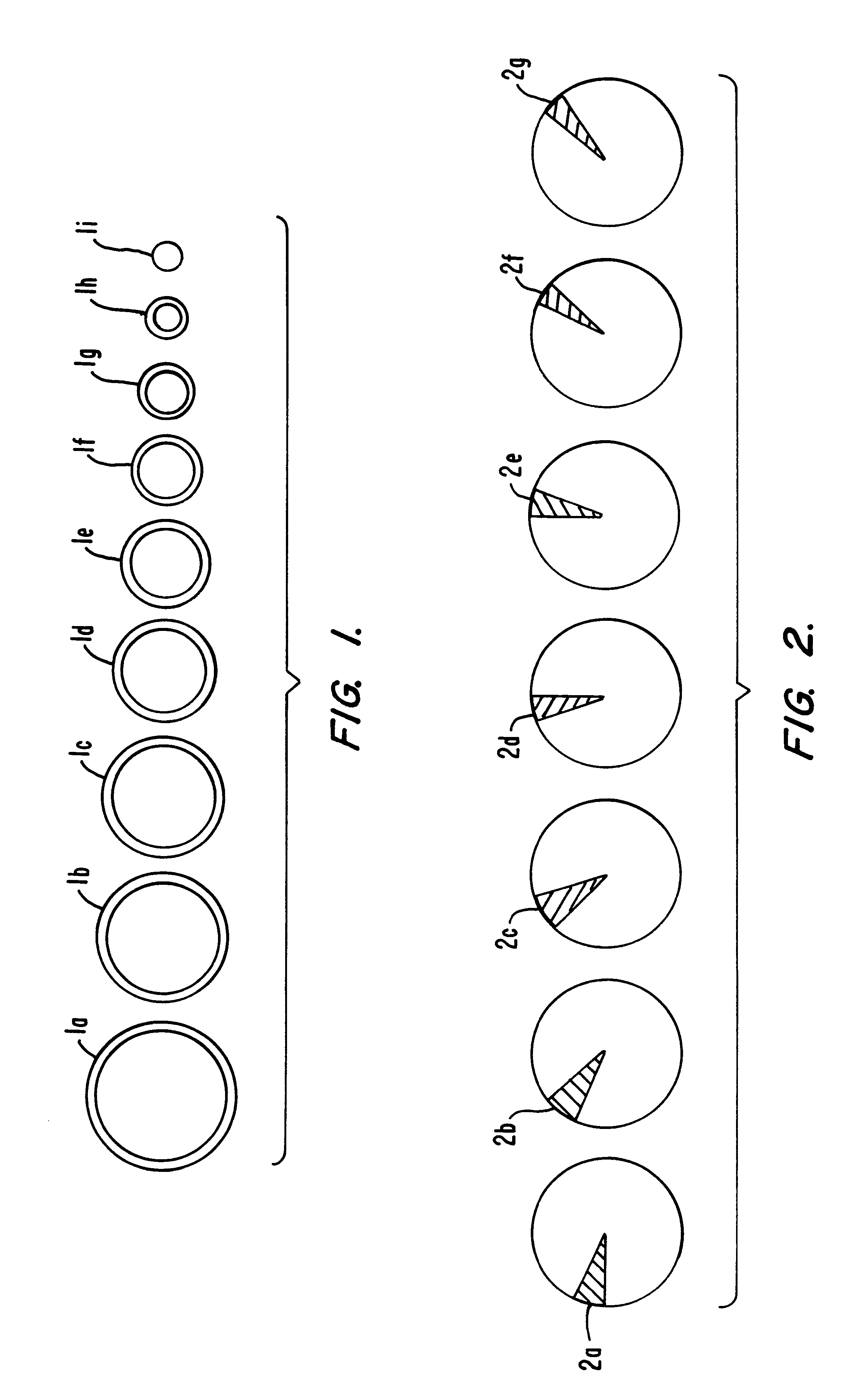

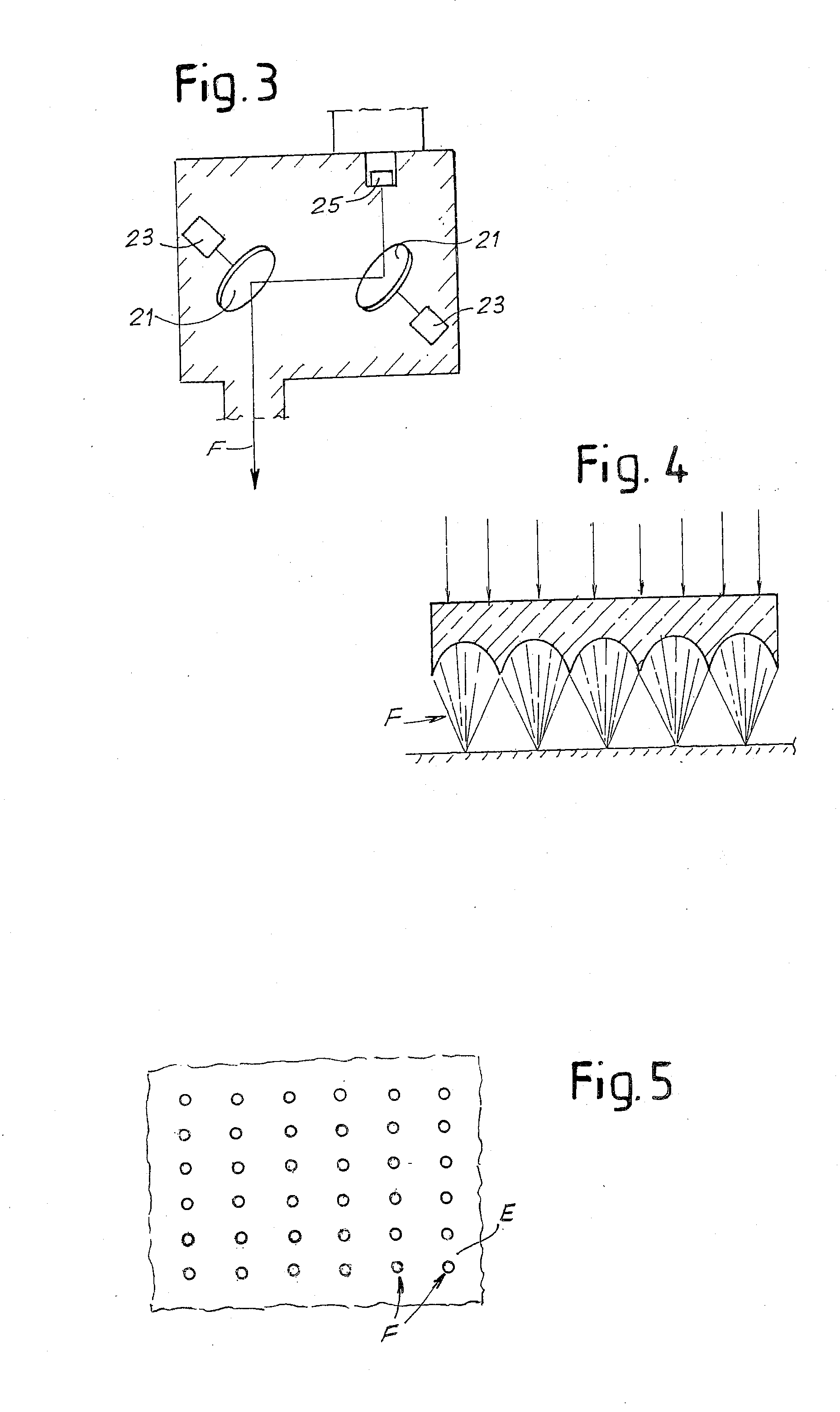

Method for scanning non-overlapping patterns of laser energy with diffractive optics

InactiveUS6193710B1Improve uniformityFacilitates dosage controlLaser surgerySurgical instrument detailsBeam expanderLight beam

A method for laser treatment of the eye using one or more diffractive optical elements for producing unique treatment segments within an ablation zone on the eye. The treatment segments may be annular, pie-shaped, or have other geometries or patterns selected to apply energy in a particular manner, usually in a non-overlapping manner so that energy dosages can be precisely controlled. In a first embodiment of the method, a single diffractive optical element is used and a beam expander expands or converges the beam to achieve the different treatment segments. In a second embodiment, a plurality of diffractive optical elements are used, each of which produces a single treatment segment.

Owner:AMO MFG USA INC

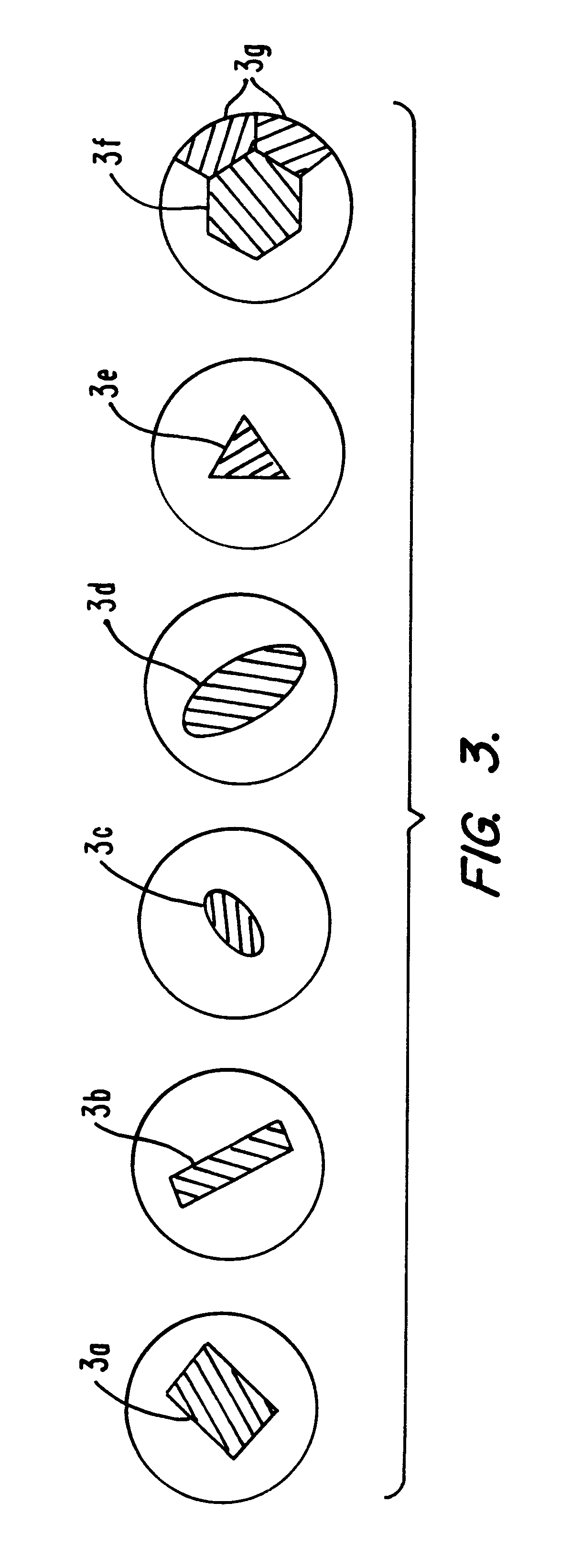

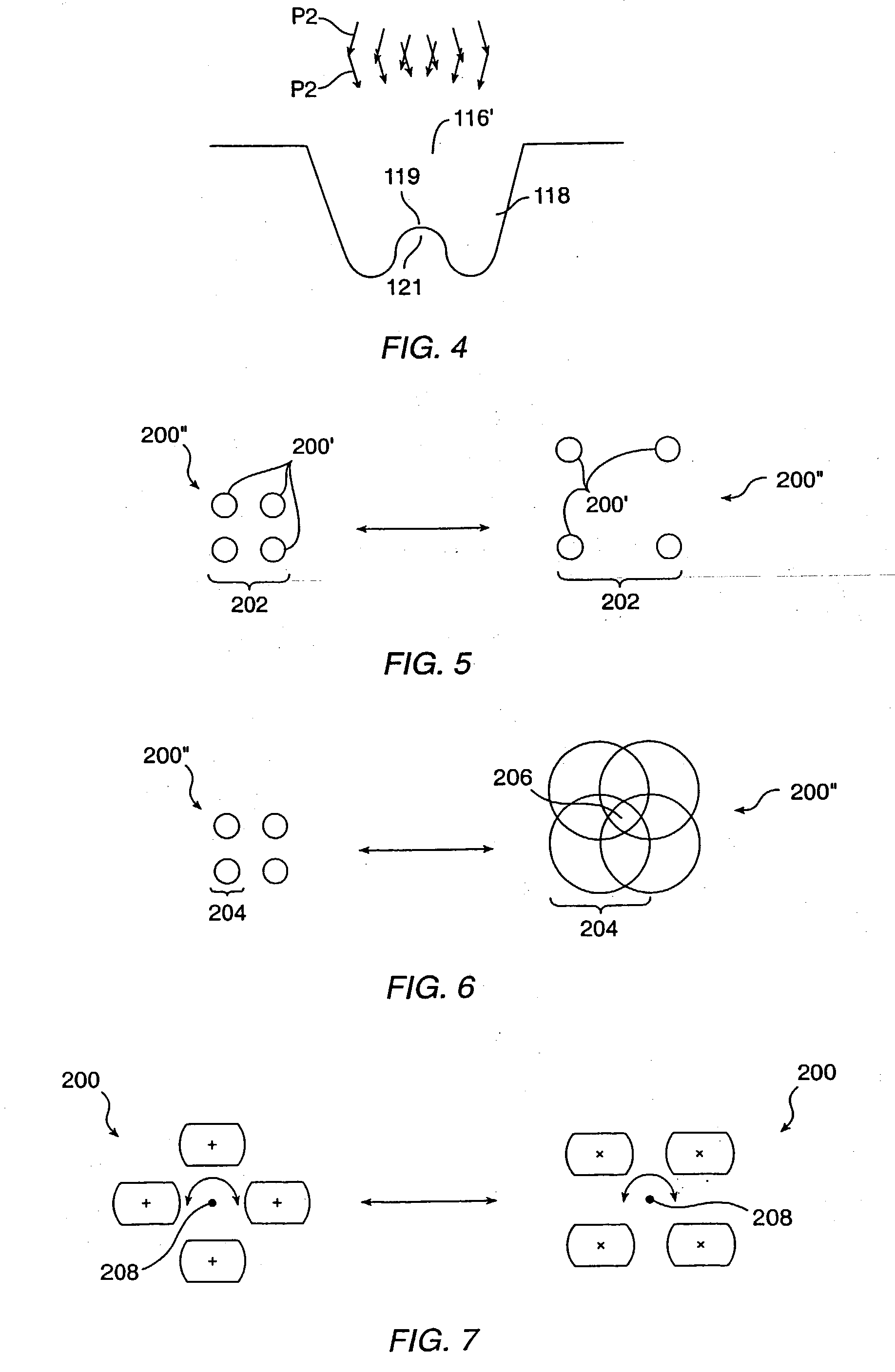

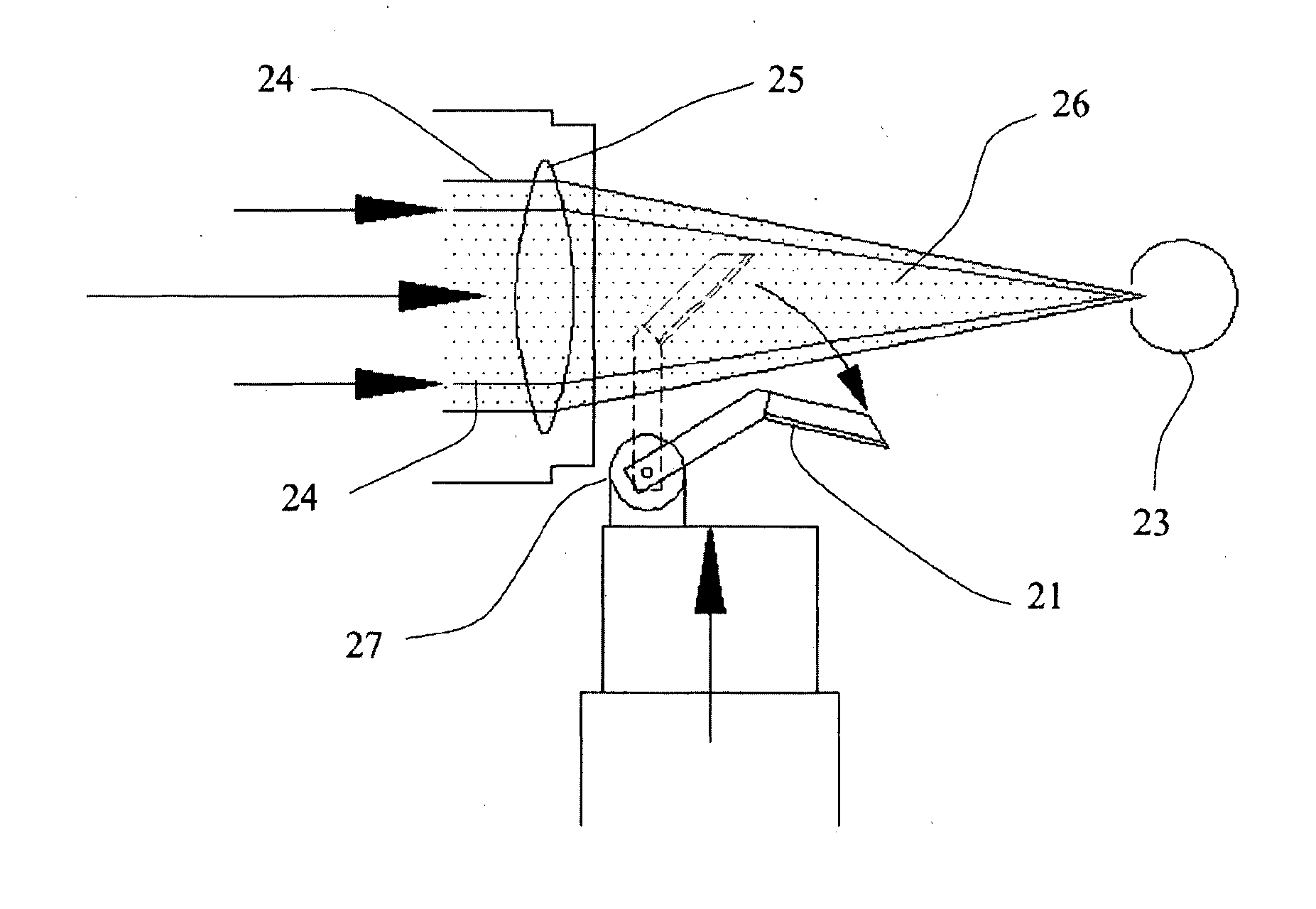

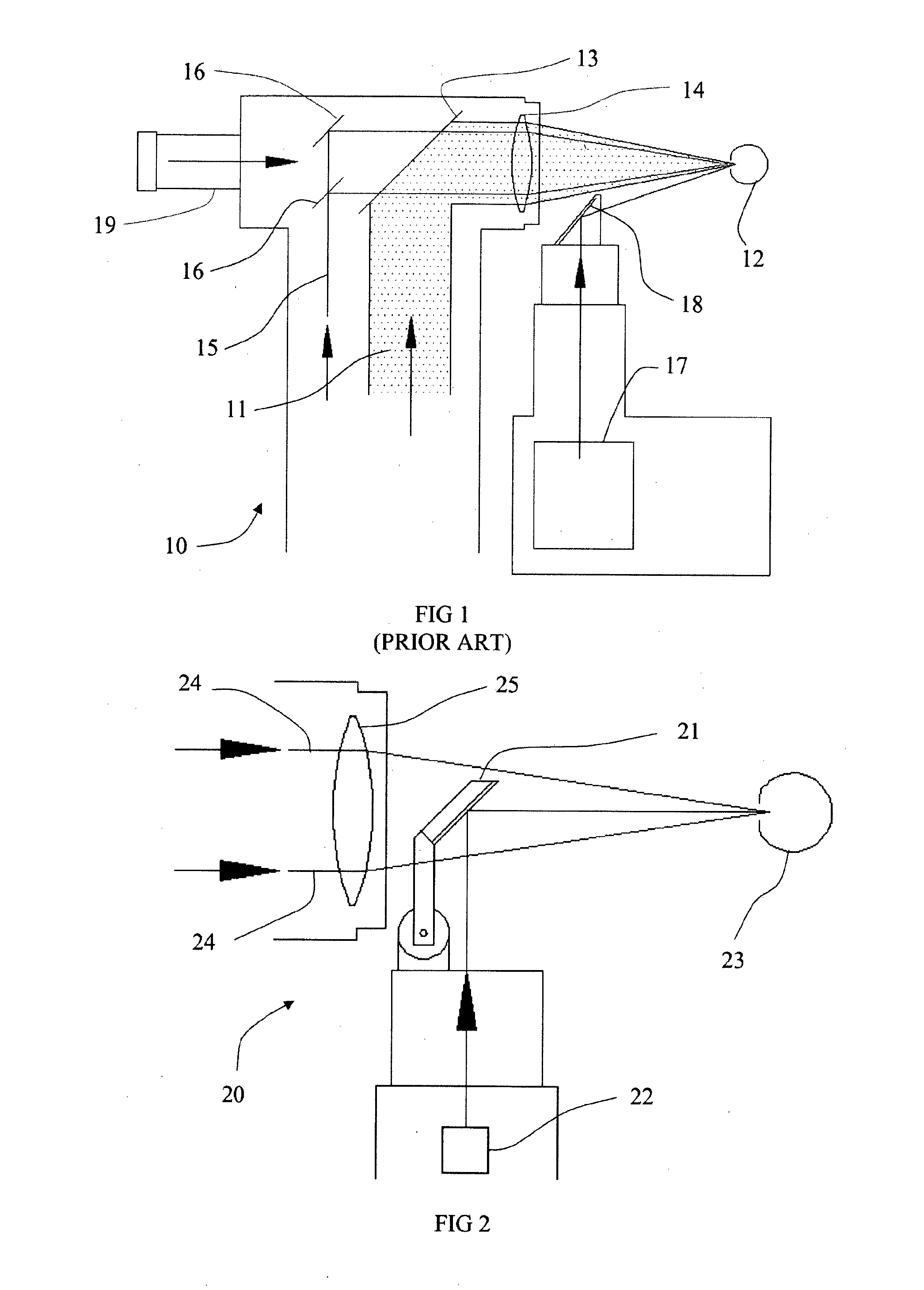

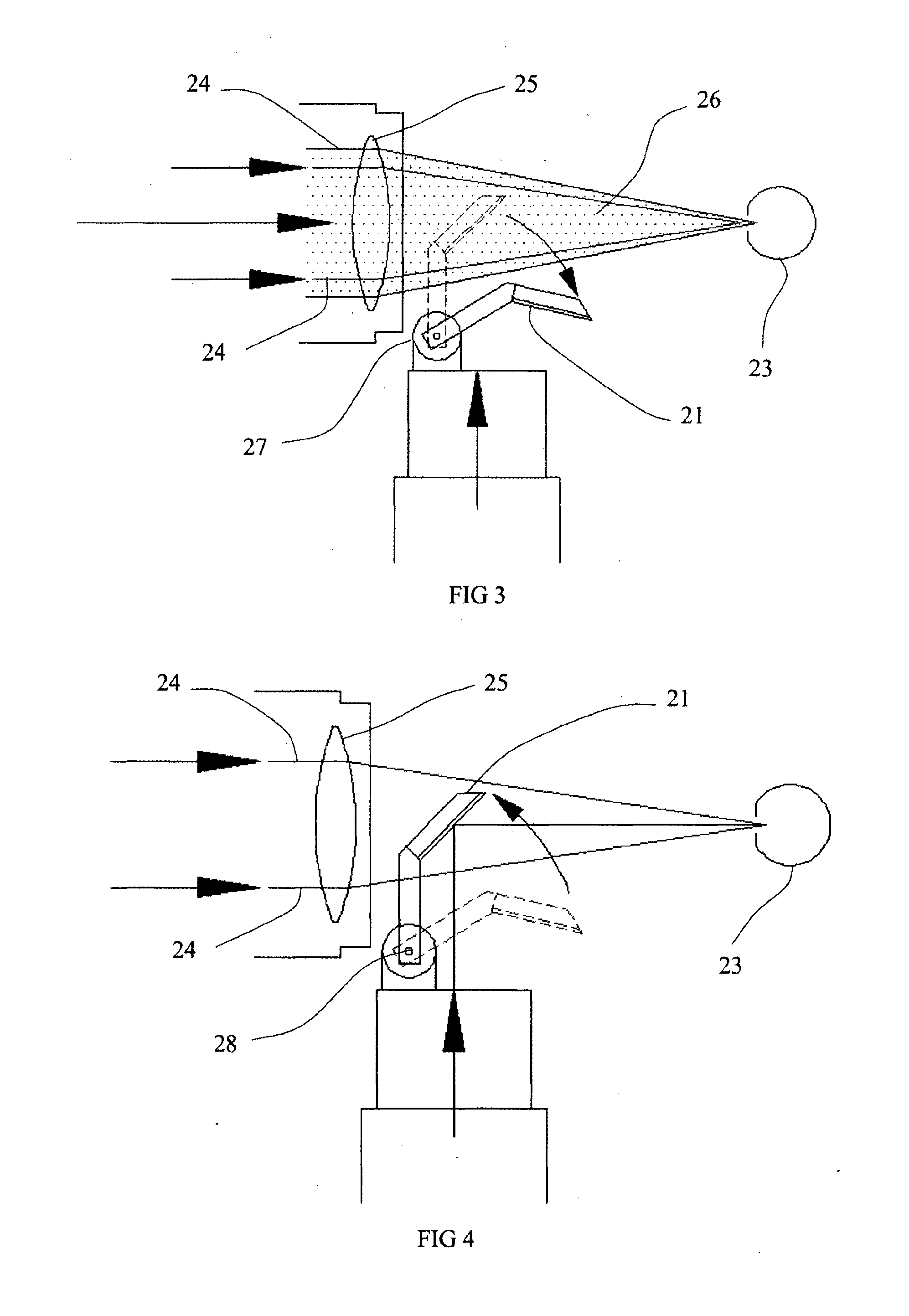

Multiple beam laser sculpting system and method

The invention improves the laser sculpting of a region of a material to a predetermined shape by improving the smoothness and accuracy of surfaces formed by the sculpting technique. The technique includes projecting plurality of partially overlapping beams toward the region. The invention includes blurring an edge of an ablation to smooth an internal portion of the ablation that is separate from the edge. The blurred edge may be formed by the partially overlapping beams. Using a computer controlled laser delivery system, the position and shape of the overlapping beams may be precisely controlled to sculpt the material to a desired shape according to a laser treatment table.

Owner:AMO MFG USA INC

Multiple beam laser sculpting system and method

The invention improves the laser sculpting of a region of a material to a predetermined shape by improving the smoothness and accuracy of surfaces formed by the sculpting technique. The technique includes projecting plurality of partially overlapping beams toward the region. The invention includes blurring an edge of an ablation to smooth an internal portion of the ablation that is separate from the edge. The blurred edge may be formed by the partially overlapping beams. Using a computer controlled laser delivery system, the position and shape of the overlapping beams may be precisely controlled to sculpt the material to a desired shape according to a laser treatment table.

Owner:AMO MFG USA INC

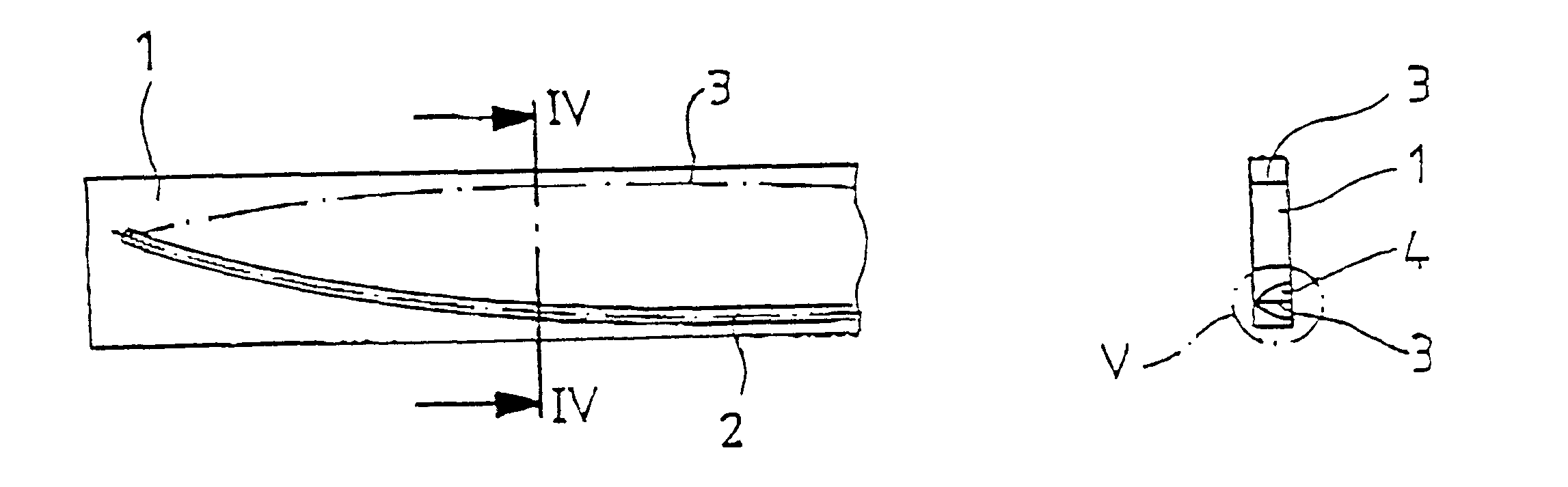

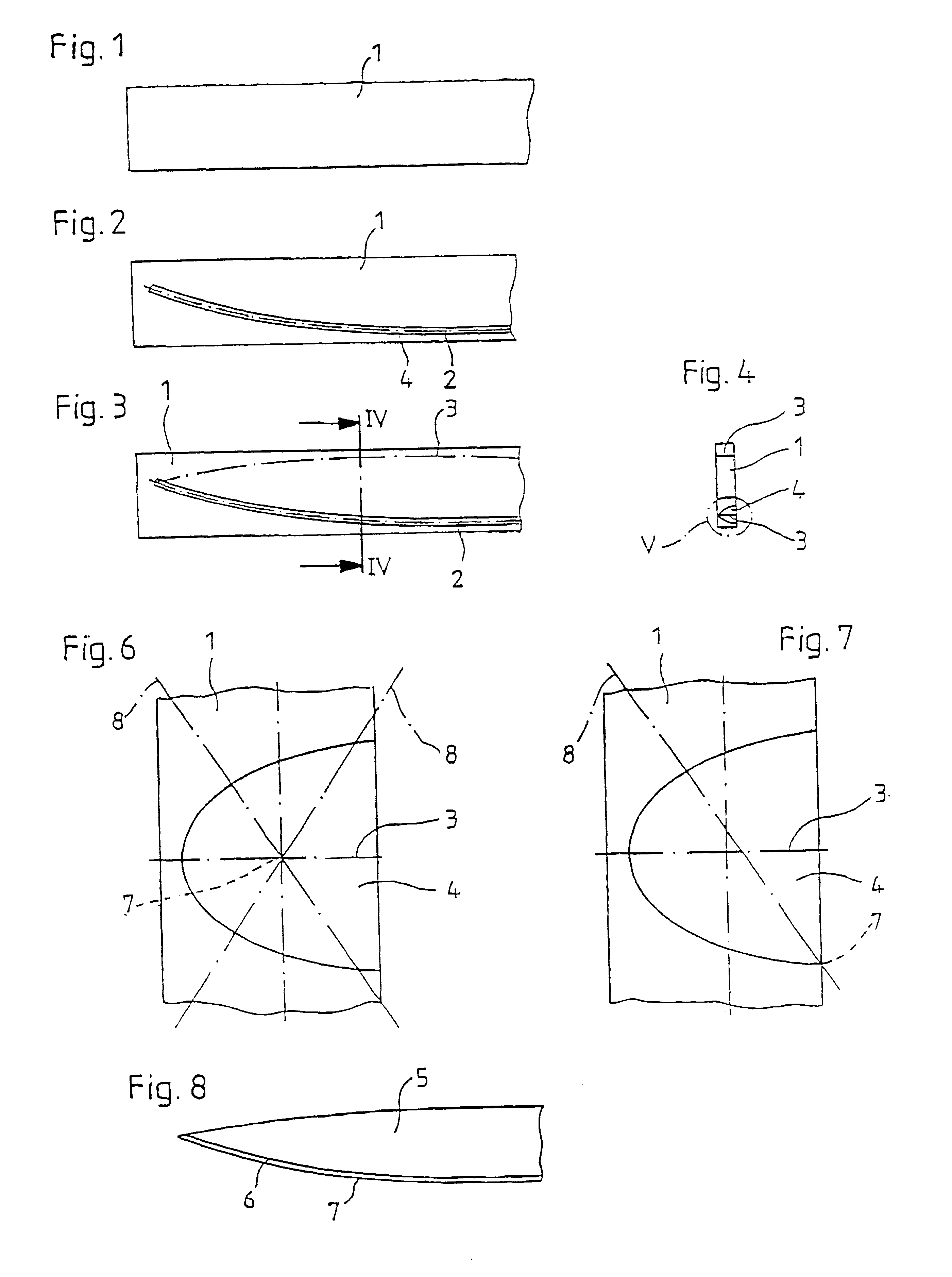

Process for manufacturing a blade of a cutting tool and product manufactured therewith

A method for manufacturing a blade of a cutting tool, in particular, a knife. In order to create a process with which influence is to be exerted in a targeted manner on the technological material properties of the blade and material chipping to be avoided, as well as permitting economical manufacturing, a process is carried out by treating a blade base material with a laser in a first process step along a curve contour determined by the final edge of the blade and, in a second process step, the edge of the blade is formed, in particular, cut to shape, along the curve contour determined by the final blade form inside the laser-treated area, or the blade base material is machined in a first process step by punching or trimming to form the final edge, subsequently the laser treatment is performed in a second process step on the narrow side forming the final edge and finally, in a third process step, the blade is formed, in particular, ground, inside the laser-treated area.

Owner:ZWILLING J A HENCKELS

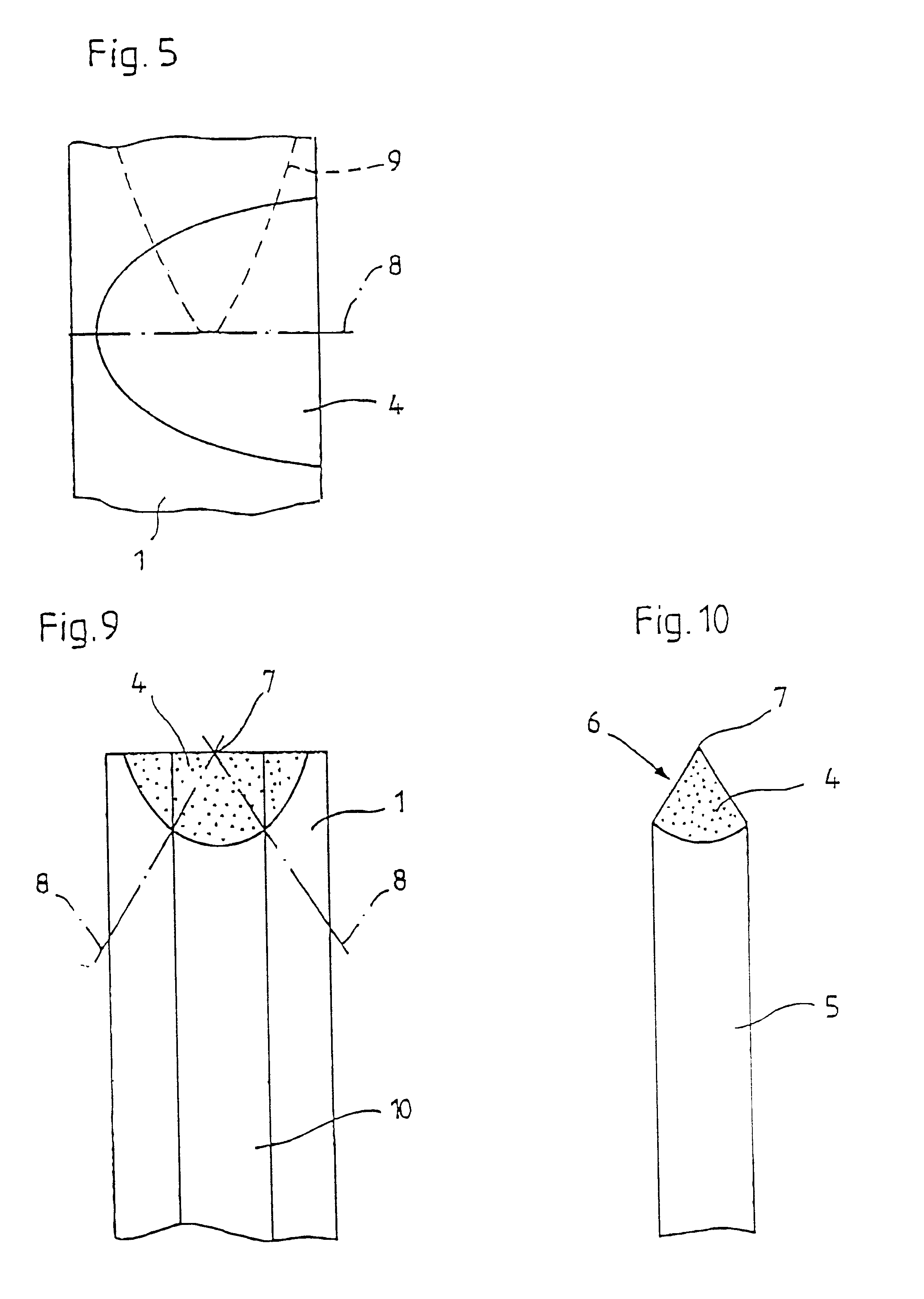

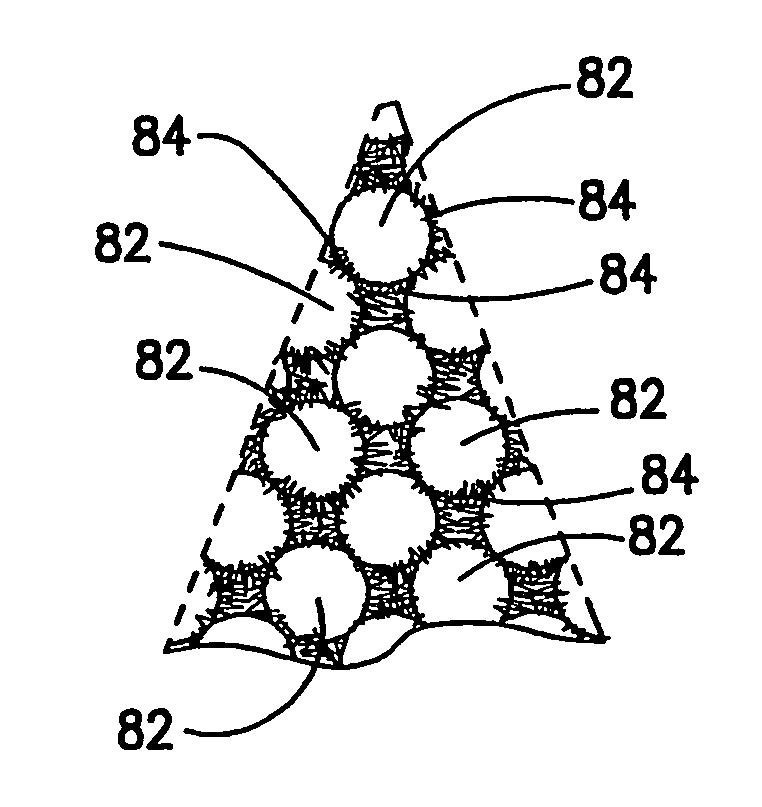

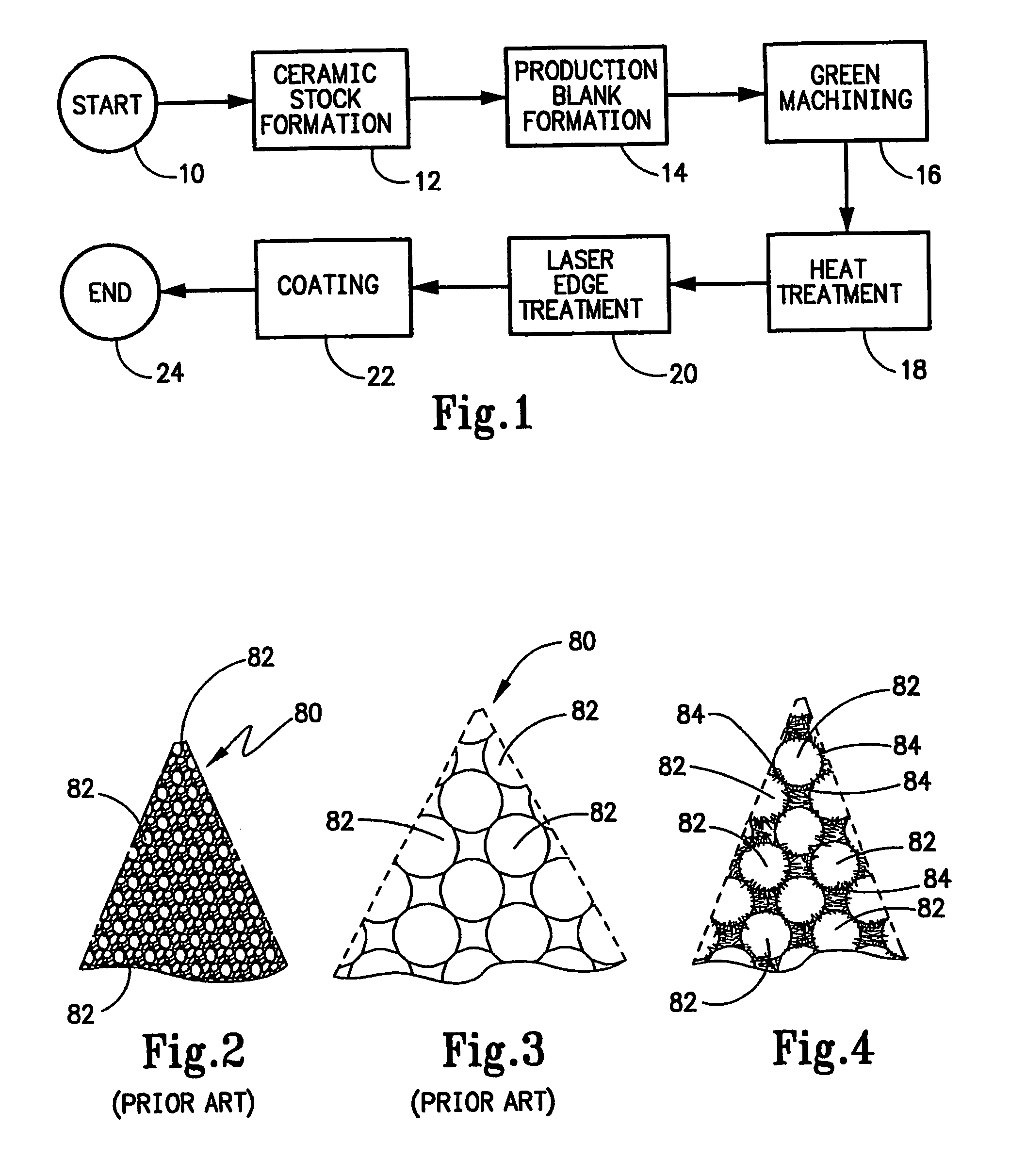

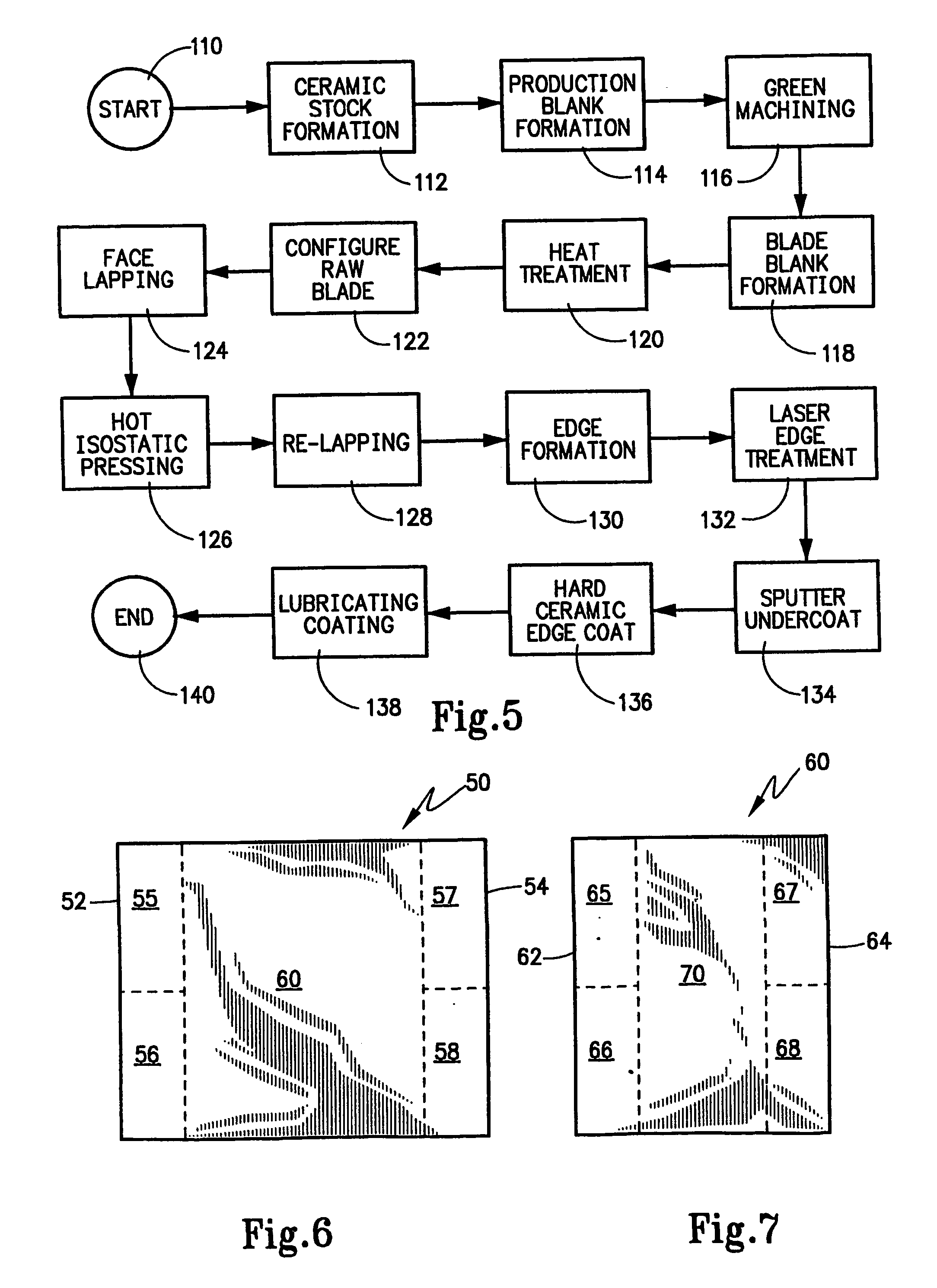

Ceramic blade and production method therefor

InactiveUS7140113B2Enhanced cutting edgeDurable edgeMetal working apparatusCutleryForming faceCeramic coating

A blade of ceramic material is treated to enhance the strength and sharpness of the cutting edge. In one embodiment, ceramic particles along at least one margin of an edge-forming face are fused, such as by a laser treatment. The edge mardin can have a hard ceramic coating of a different ceramic material such as a nitride of chromium, zirconium, titanium, titanium carbon or boron. The hard ceramic coating can be used alone or in conjunction with the laser treatment. The invention includes the methods of treating the edge, both to form the hard ceramic coating and to fuse the particles by scanning with laser, such as an ultraviolet laser.

Owner:LAZORBLADES

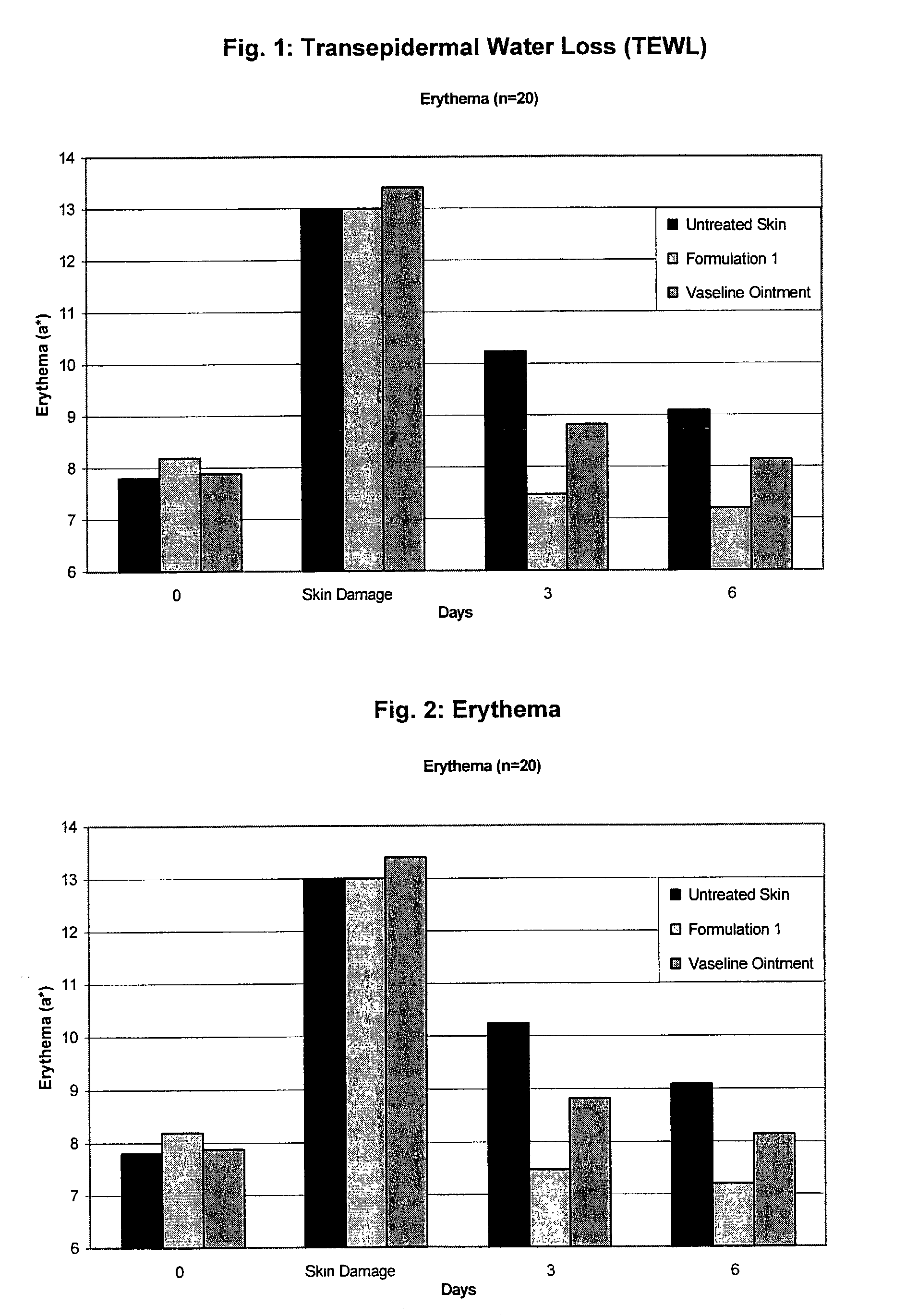

Methods for treatment of human skin damaged by laser treatment or chemical peelings and compositions useful in such methods

InactiveUS20030012762A1Eliminate disadvantageEliminate disadvantagesCosmetic preparationsBiocideCompound (substance)Co enzyme q10

Methods for treatment of human skin damaged by laser treatment or chemical peelings, said method comprising topical application of a lamellar oil-in-water system, said lamellar oil-in-water system comprising at least one vegetable oil as the oily component and at least one hydrogenated phospholipid as emulsifier, said at least one hydrogenated phospholipid comprising not more than 10 percent by weight of negatively charged phospholipids the remainder being neutral phospholipids. Compositions useful in carrying out said methods are lamellar oil-in-water systems comprising at least one vegetable oil as the oily component and at least one hydrogenated phospholipid as emulsifier, said at least one hydrogenated phospholipid comprising not more than 10 percent by weight of negatively charged phospholipids the remainder being neutral phospholipids. Said lamellar oil-in-water system may further comprises sodium carboxymethyl beta-glucan (Sodium Carboxymethyl Betaglucan) as a compound for improving wound healing and / or coenzyme Q10 as a compound for improving skin regeneration.

Owner:MIBELLE COSMETICS

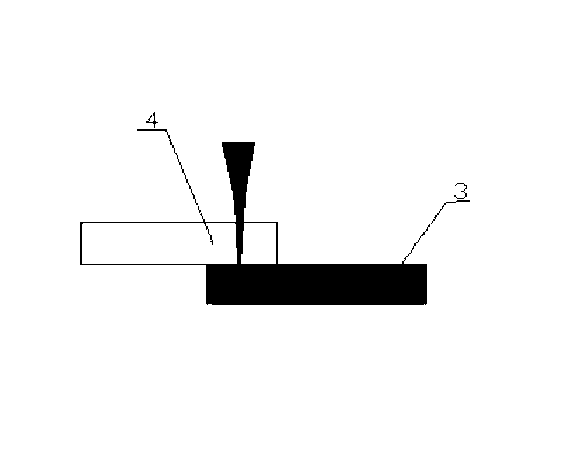

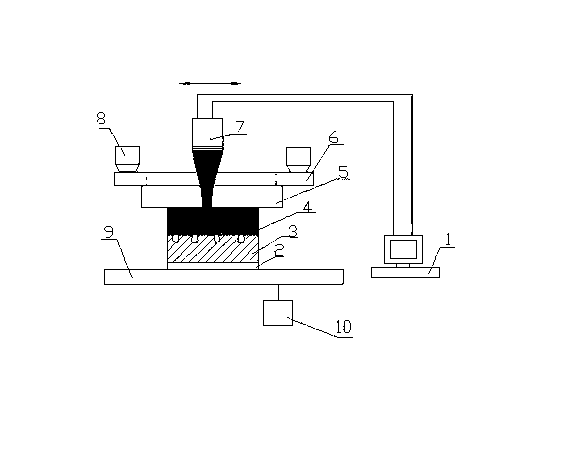

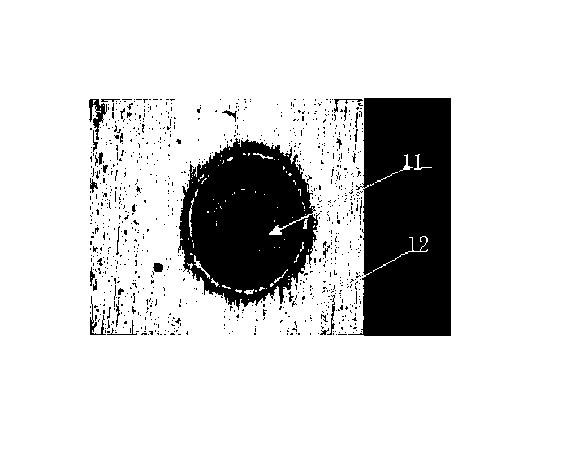

Method for improving laser transmission welding connection strength

The invention discloses a method for improving laser transmission welding connection strength, belonging to the field of laser transmission welding technology, and especially refers to laser transmission welding of metals and polymers. The method comprises pulsed laser treatment is performed to the surface of a metal material which needs welding to form pits on the surface; during the welding, the metal treated by pulsed laser is used as a lower layer light-absorbing material, and the polymer is used as a top layer light transmitting material, by adopting an overlapping connection type, a restrained layer is used for clamping tightly and the welding pressure is applied; a semiconductor laser with continuous energy is used for laser transmission welding to make a surface temperature quickly reaches the melting point of the top layer polymer, so the polymer surface is melted; because pits are formed on the lower metal surface after pulsed laser treatment, the melted polymer on the top surface flows into the pits by the action of the welding pressure to form an engaging interface with a riveting structure at a welding line, thereby improving laser transmission welding connection strength.

Owner:JIANGSU UNIV

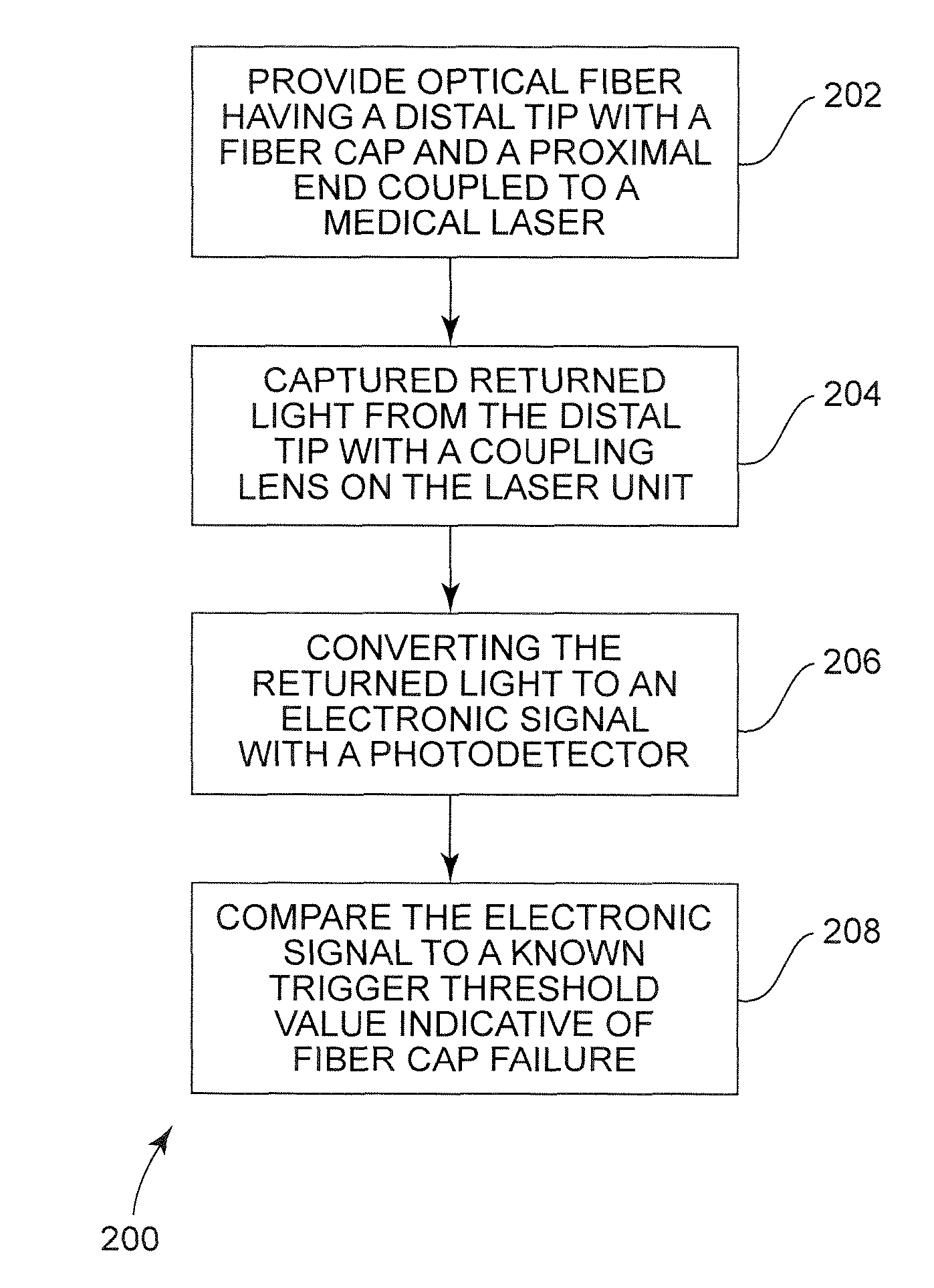

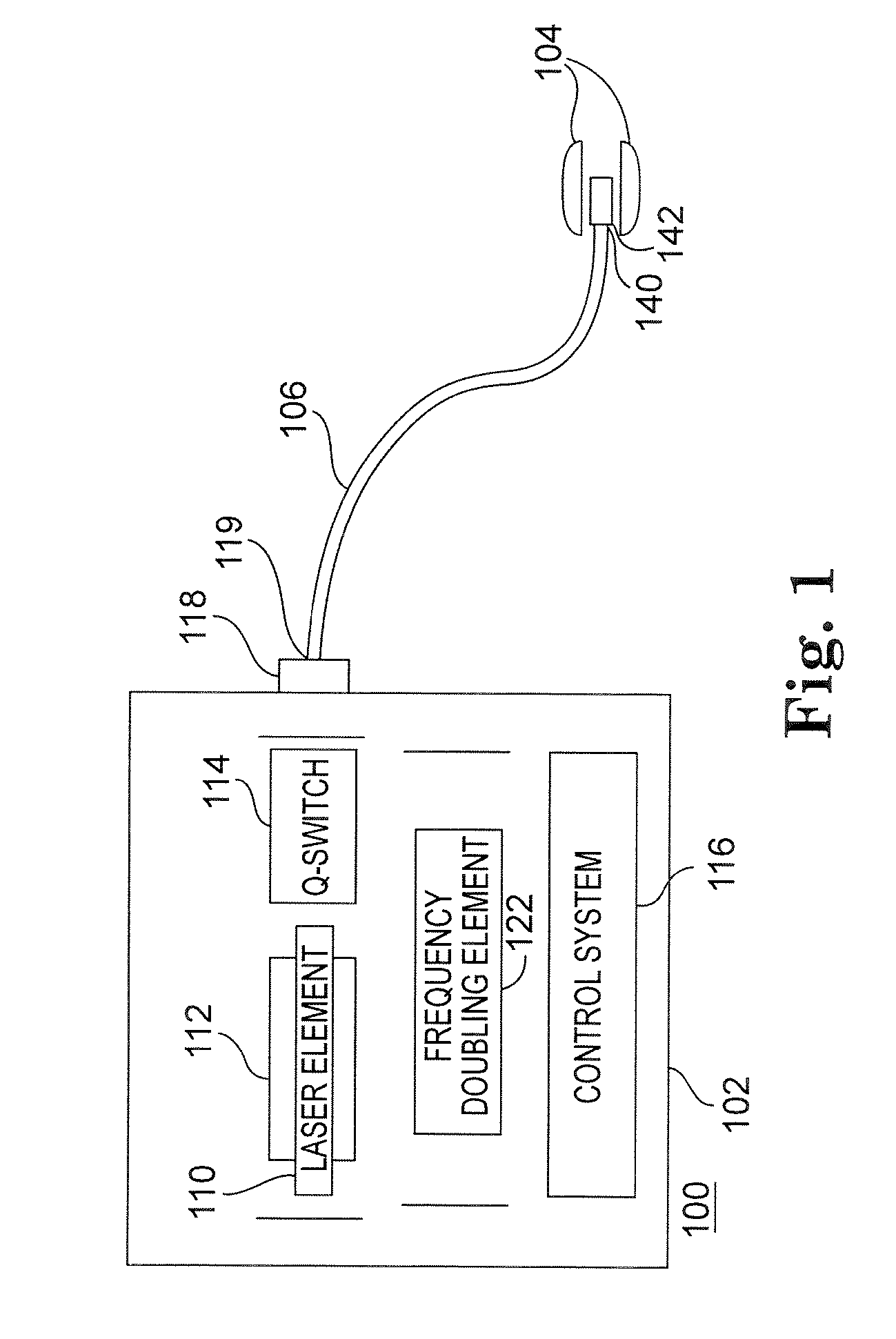

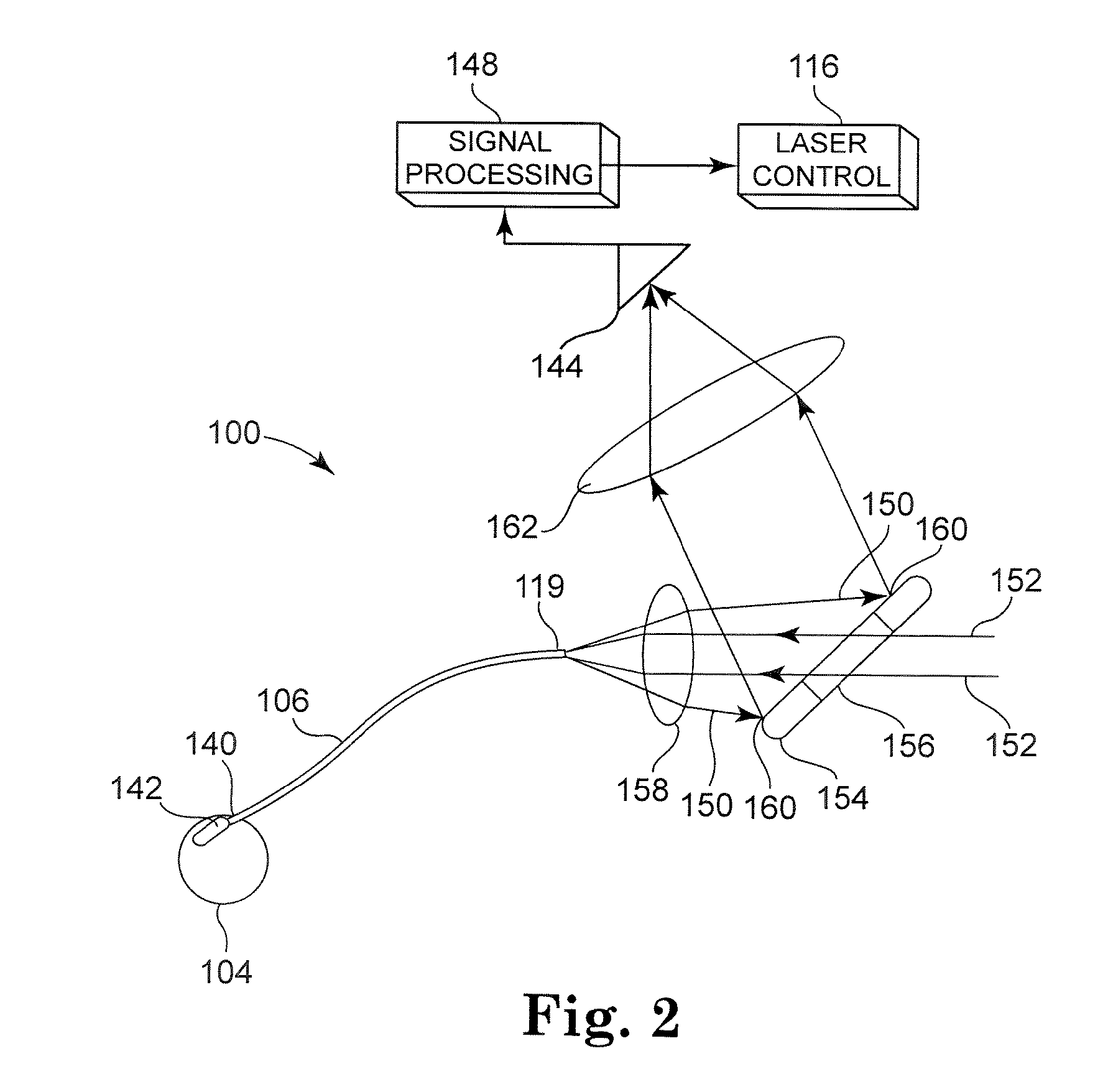

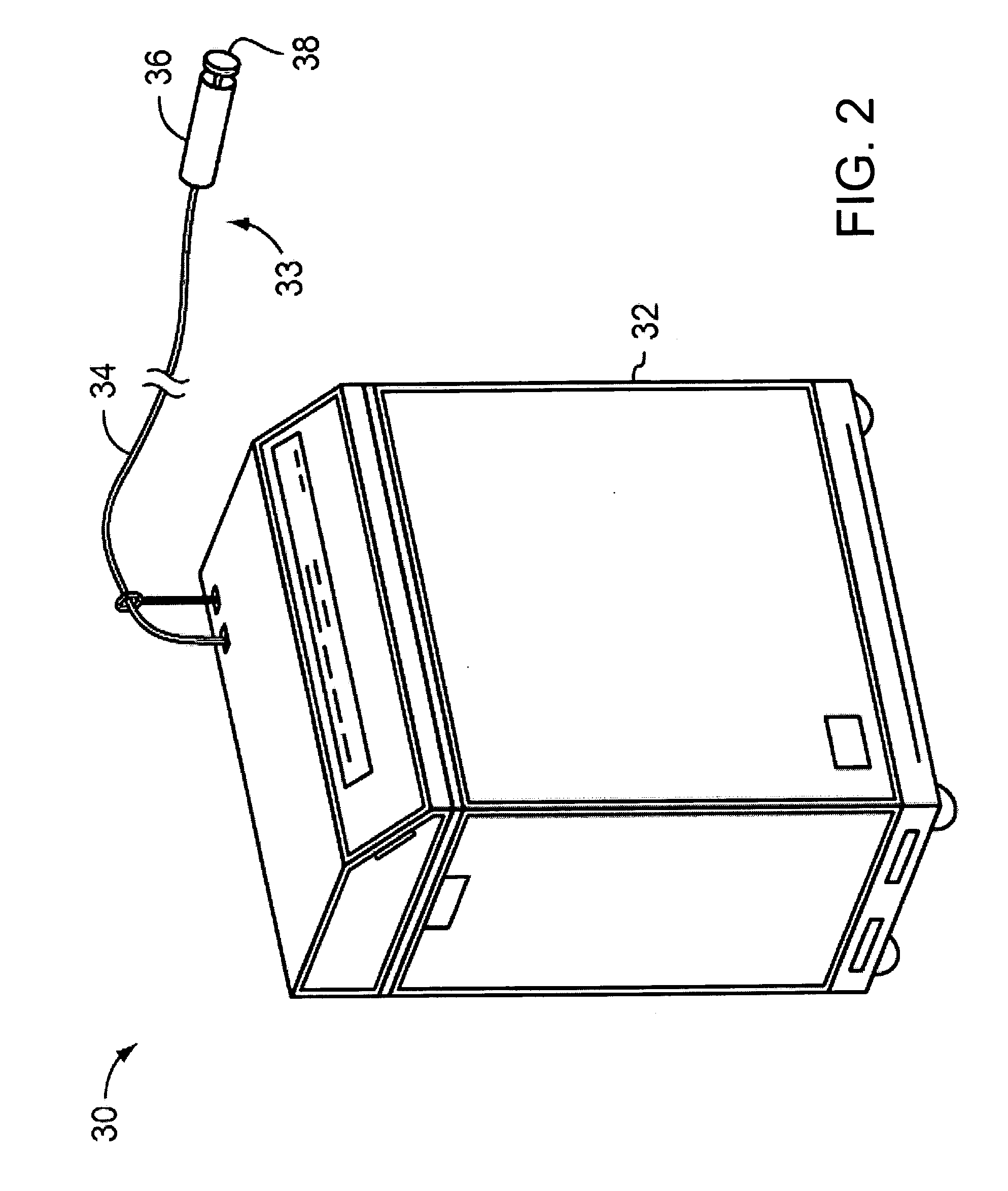

Fiber damage detection and protection device

InactiveUS7869016B2Reduce power outputAvoid failureMaterial analysis by optical meansEndoscopesFiberPhotodetector

A medical laser system and related methods of monitoring optical fibers to determine if an optical fiber cap on the optical fiber is in imminent danger of failure. The laser system includes a photodetector for converting returned light from the optical fiber cap to an electronic signal for comparison to a trigger threshold value known to be indicative imminent fiber cap failure. The returned light can be the main laser treatment wavelength, an auxiliary wavelength such as an aiming beam or infrared wavelengths generated by a temperature of the optical fiber cap. In the event the electronic signal reaches the trigger threshold value, the laser system can be temporarily shut-off or the power output can be reduced.

Owner:BOSTON SCI SCIMED INC

Apparatus and method for performing radiation energy treatments

InactiveUS20070106284A1Improve efficiencyImprove securitySurgical instrument detailsLight therapyFiberTreatment effect

An apparatus and method to apply photo-stimulation, photo-dynamic therapy and / or ablation laser treatment to biological tissue. The apparatus includes a plurality of radiation energy sources, preferably laser beams. Additionally, the apparatus allows either a single wavelength or a combination of various wavelengths, either coincidentally or adjacently, to be utilized to achieve a desired treatment effect. Laser beams are transmitted to the treatment area by one or more fiber optic cables which terminate at an assembly structured to collimate the emitted radiation prior to application to the tissue. In addition, the apparatus includes a focal length setting mechanism which assures that a constant, fixed distance exists between the point of discharge of the laser beam and the biological tissue, thus assuring a constant energy density at the point of application. A method is presented for applying photo-stimulation, photocollagen stimulation and / or ablation laser treatment utilizing the above apparatus.

Owner:SIEGEL JERRY

Fiber Damage Detection and Protection Device

InactiveUS20080285017A1Prevent optical fiber cap failureReduce power outputEndoscopesMaterial analysis by optical meansFiberPhotodetector

A medical laser system and related methods of monitoring optical fibers to determine if an optical fiber cap on the optical fiber is in imminent danger of failure. The laser system includes a photodetector for converting returned light from the optical fiber cap to an electronic signal for comparison to a trigger threshold value known to be indicative imminent fiber cap failure. The returned light can be the main laser treatment wavelength, an auxiliary wavelength such as an aiming beam or infrared wavelengths generated by a temperature of the optical fiber cap. In the event the electronic signal reaches the trigger threshold value, the laser system can be temporarily shut-off or the power output can be reduced.

Owner:BOSTON SCI SCIMED INC

Cutting method of semiconductor component containing metal back plating

ActiveCN102751400AImprove yieldOvercome the defect of splittingFine working devicesLaser beam welding apparatusMaterials scienceMetal

The invention provides a cutting method of a semiconductor component containing metal back plating, belonging to the field of semiconductors. The method comprises the following steps: firstly, manufacturing a plurality of semiconductor units on a semiconductor substrate; secondly, making the metal back plating layer at the back side of the semiconductor substrate; and removing metal layers corresponding to the semiconductor units by using out-of-focus type laser treatment so as to form cutting channels; carrying out the invisible cutting on the semiconductor substrate through the cutting channels so as to form deterioration layers; and finally, carrying out splintering so as to accomplish the cutting. The invention provides a cutting method through which the invisible cutting technology is applied to devices with metal back plating; the defect that a traditional cutting process easily causes the loss of the device area or the splitting of crystalline grains is overcome; and moreover, the yield of the cutting of the device is improved. The cutting method is simple in process and is applicable for industrial production.

Owner:宁波安芯美半导体有限公司

Systems and methods of laser texturing of material surfaces and their applications

ActiveUS8846551B2Enhance light absorptionImprove conductivityMaterial nanotechnologyDecorative surface effectsAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Treating dermatological conditions using an alexandrite laser

ActiveUS20070198003A1Effective treatmentSimpler and faster treatmentDiagnosticsSurgical instrument detailsAlexandrite LasersOphthalmology

A beam of radiation can be provided to treat a dermatological condition in a target region of skin. The beam of radiation can have a wavelength between about 700 nm and about 800 nm, a fluence greater than about 50 J / cm2, and a pulse duration between about 10 msec and about 300 msec. The beam of radiation is delivered to the target region of skin to affect (i) at least one pigmentary abnormality disposed in an epidermal region of the target region and (ii) at least one vascular abnormality disposed in a dermal region of the target region. A surface of the epidermal region of the target region of skin can be cooled to prevent substantial unwanted injury to at least a portion of the epidermal region.

Owner:UNITED STATES OF AMERICA +1

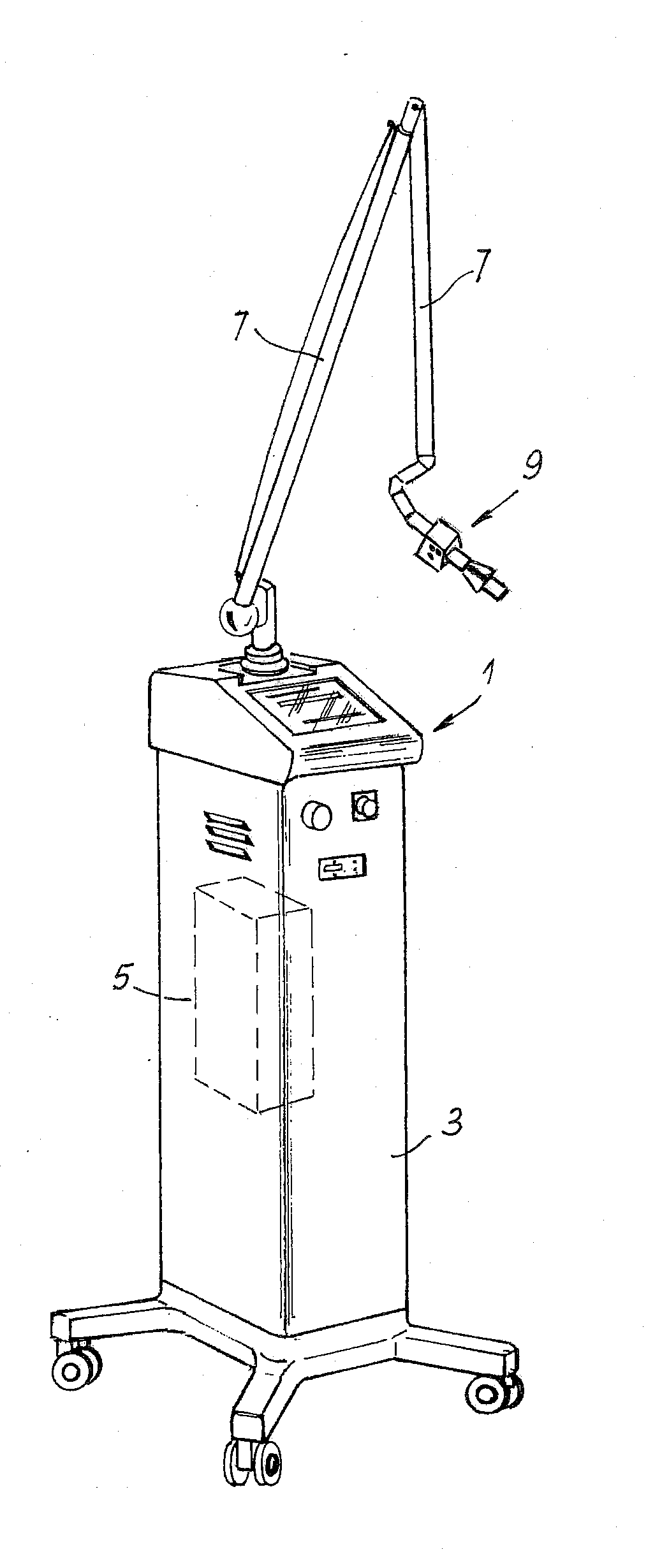

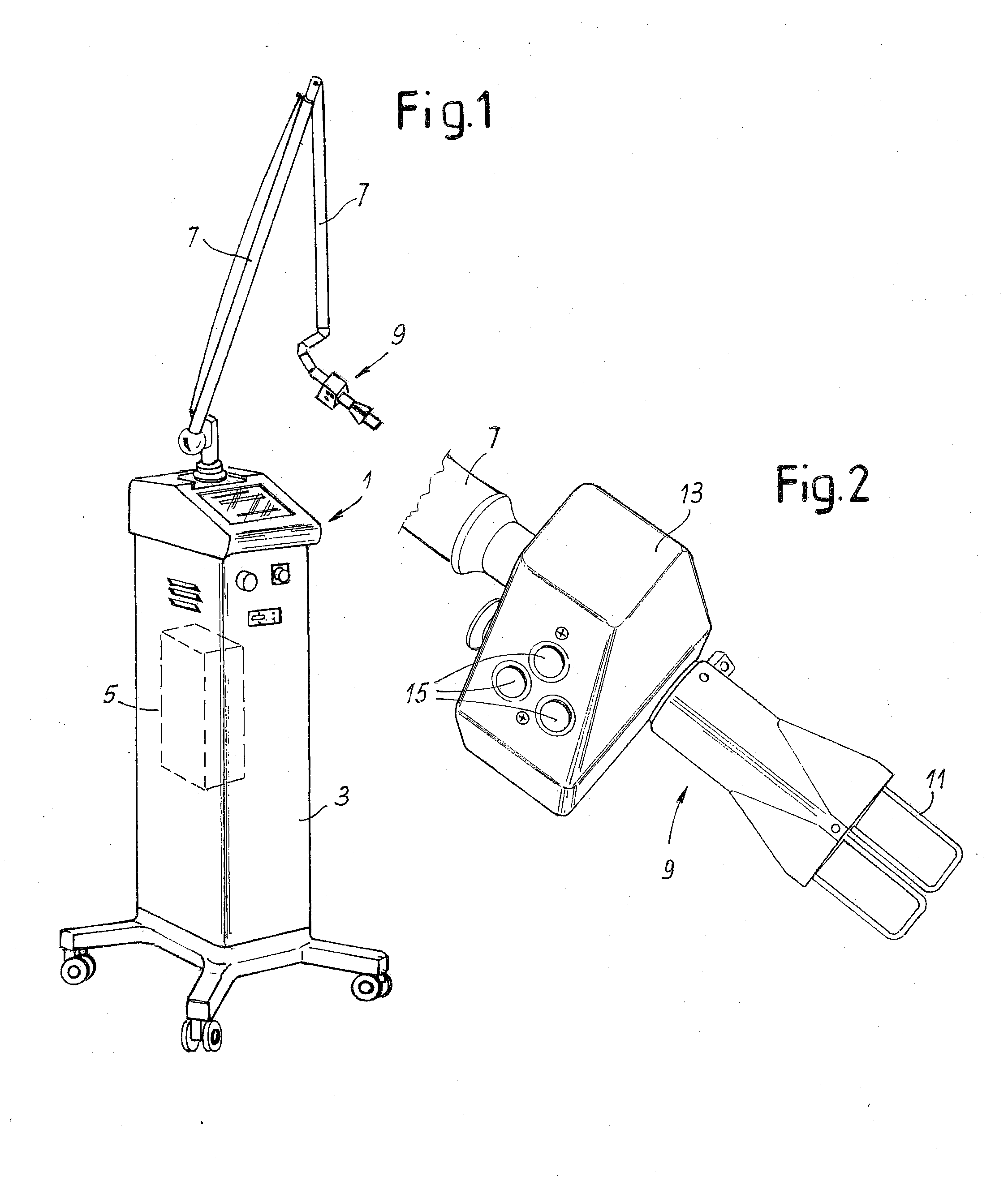

Device and method for skin laser treatment

ActiveUS20140018783A1Short timeNegligible effectElectrotherapySurgical instruments for heatingOptoelectronicsPulse sequence

The system for treating a region of the epidermis, comprising: —at least one laser energy source; —a time control device to generate a laser beam; —a laser energy focusing system arranged and produced to direct a laser beam on said region of the epidermis. The control device generates a laser beam comprising a plurality of composite pulses, emitted at a base frequency, each composite pulse comprising a sequence of sub-pulses at a higher frequency than said base frequency.

Owner:EL EN SPA

Reflex coaxial illuminator

A mirror for an ophthalmic laser treatment device that is movable on an axis from a position in a treatment laser beam path to a position out of the treatment laser beam path. The mirror reflects light from a light source into the eye of a patient. The mirror is biased towards a position in the path and is moved out of the path by an actuator just long enough for the laser treatment to be applied and without noticeable interruption to viewing by a user.

Owner:ELLEX MEDICAL

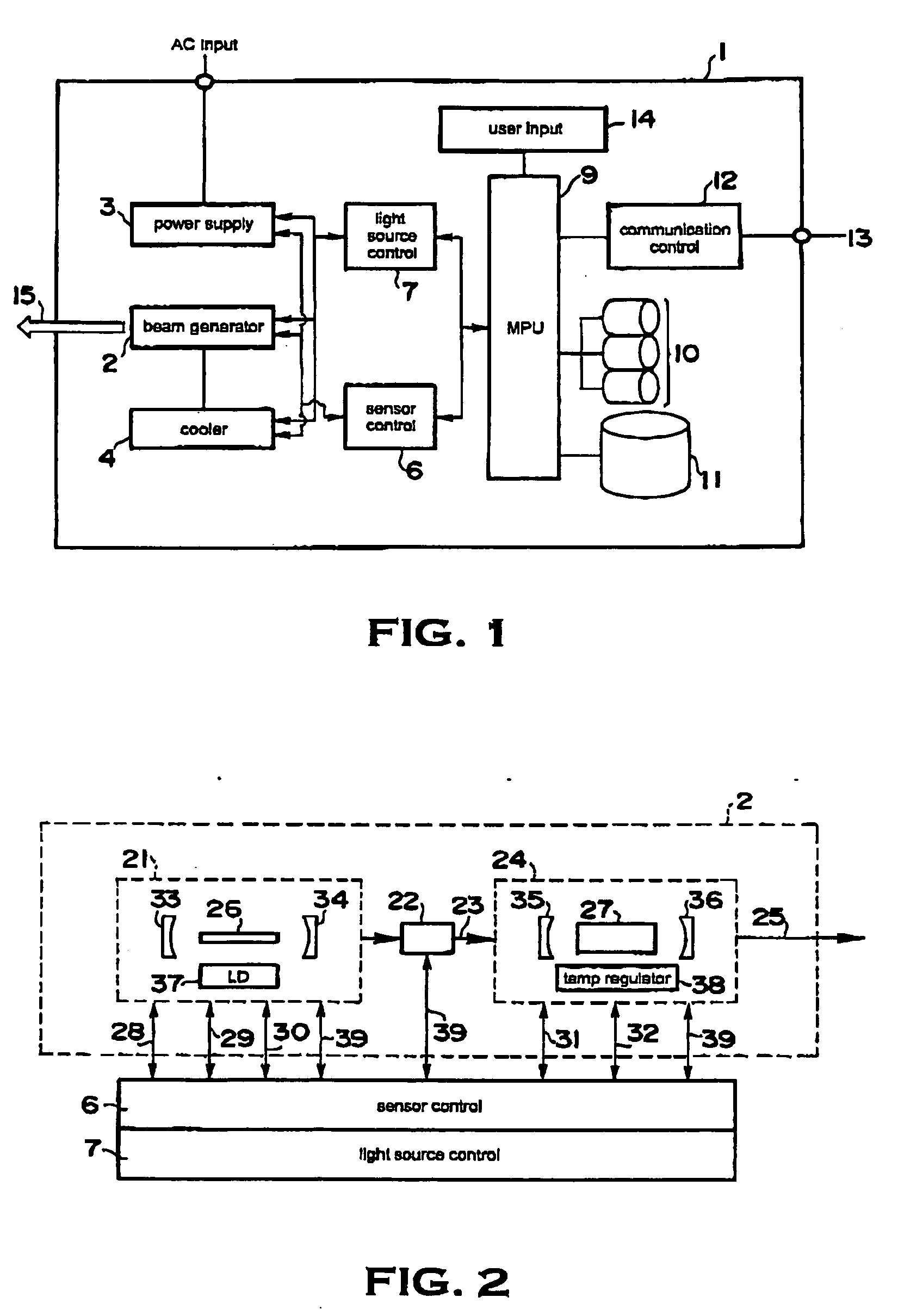

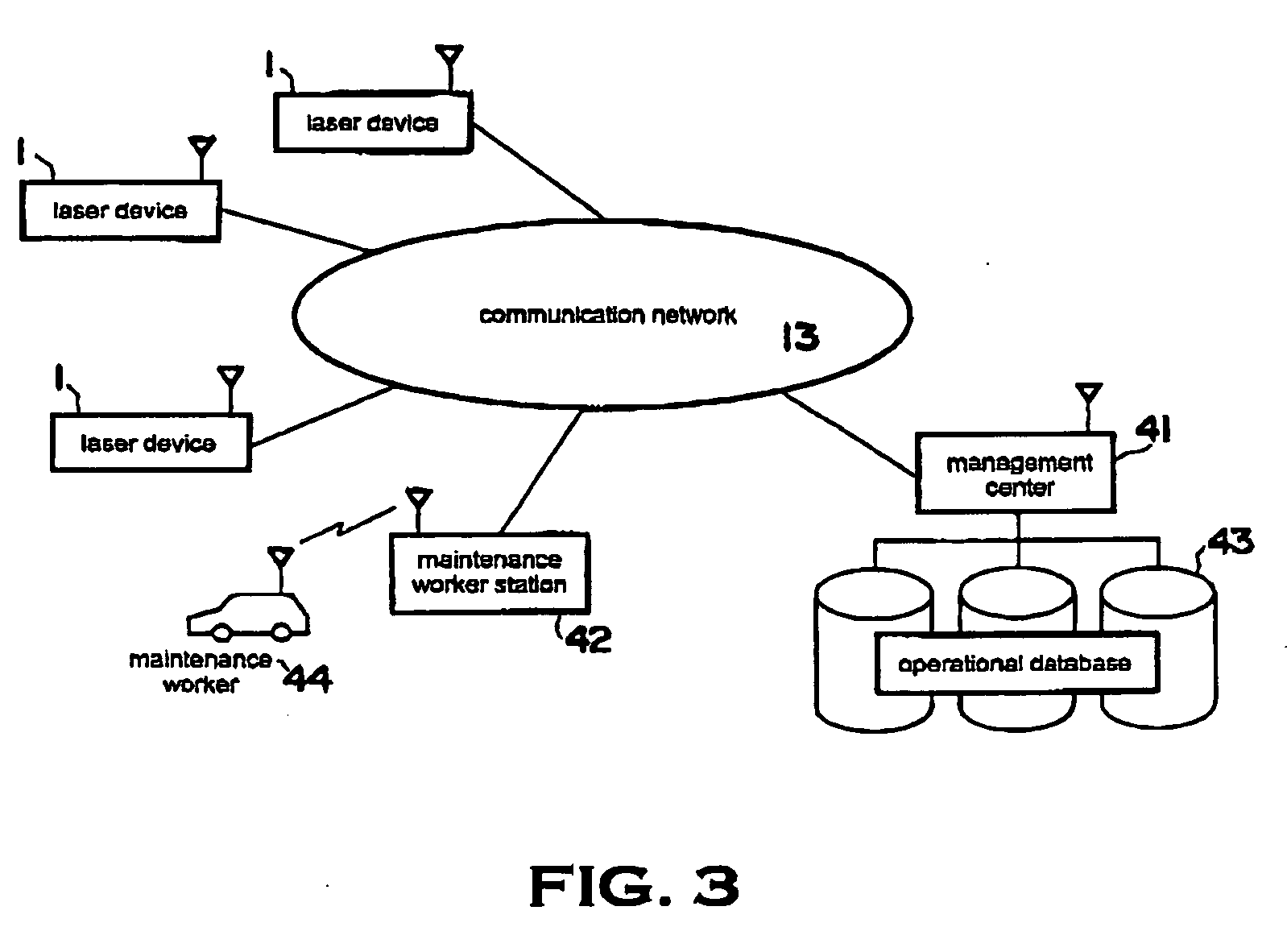

Problem diagnosis method and problem repair method for laser device

InactiveUS20060274794A1Accurate predictionImprove reliabilityLocal control/monitoringControlling energy of instrumentOperant conditioningMedical treatment

A problem diagnosis method and problem repair method for a laser device such as laser treatment devices used in the medical field and laser processing devices used in industrial fields, capable of detecting problems in laser devices early and reducing the time required for maintenance work on the laser devices are provided. The method comprises a step of measuring the intensity of scattered light generated by an optical part inside the laser device; a step of referring to data indicating a temporal change in the scattered light predicted under predetermined operating conditions of the laser device, and predicting the seriousness of the problem from the intensity of scattered light; and a step of determining what kind of maintenance work is necessary based on the seriousness of the problem. Additionally, the seriousness of the problem in the optical part can be predicted by executing fuzzy logic based on membership functions defining the relationship between scattered light intensity and the seriousness of problems of optical parts.

Owner:CYBER LASER

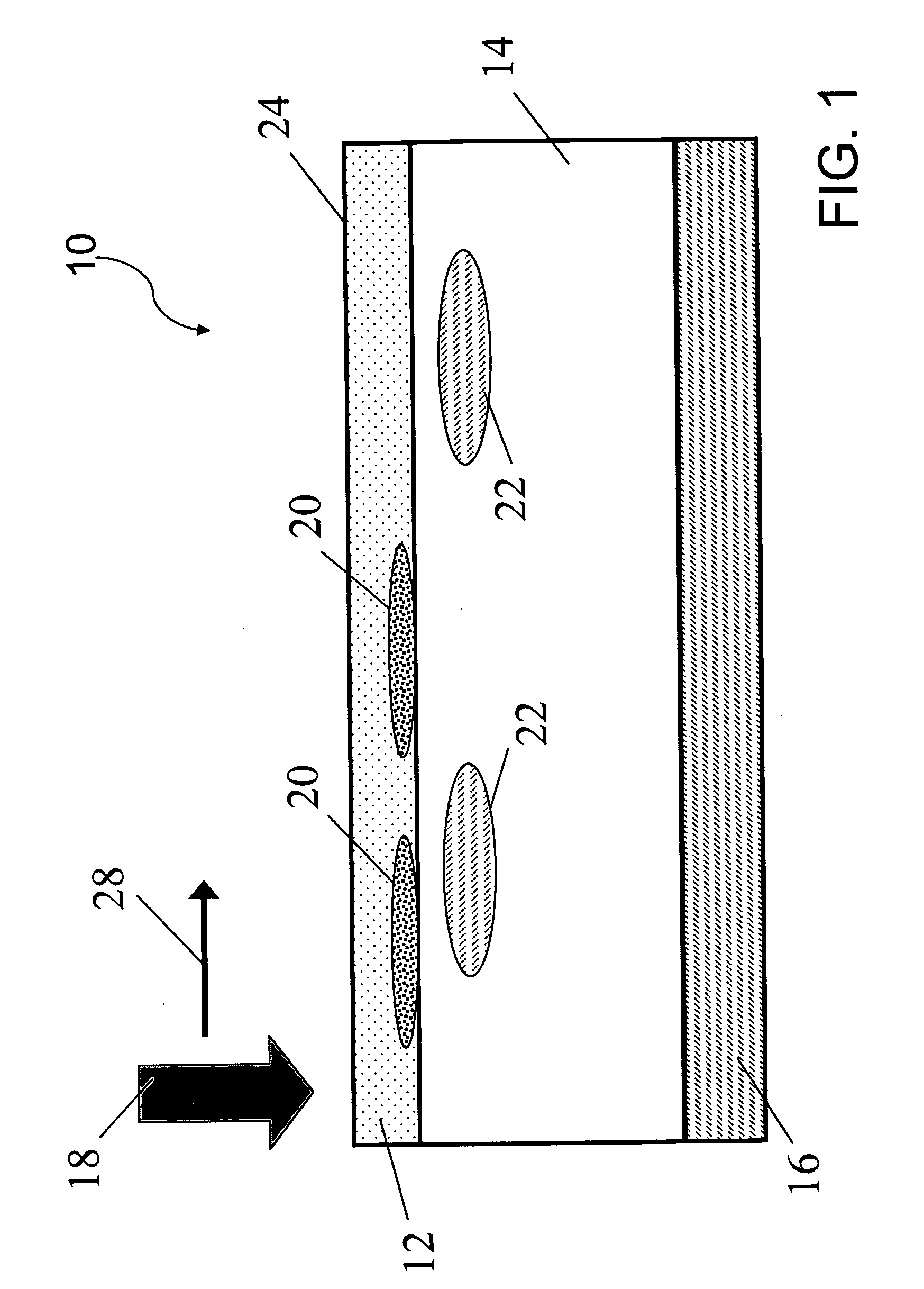

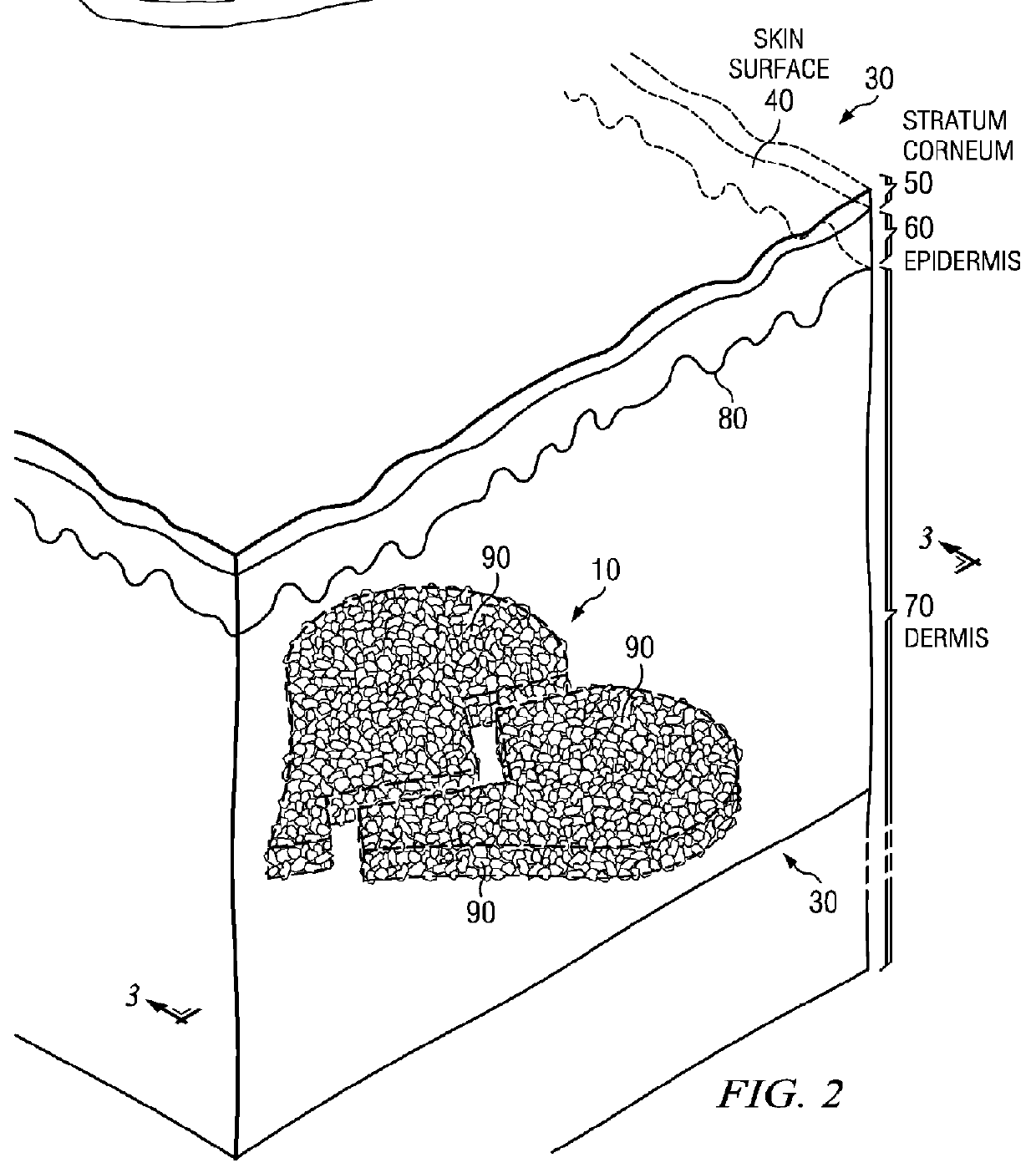

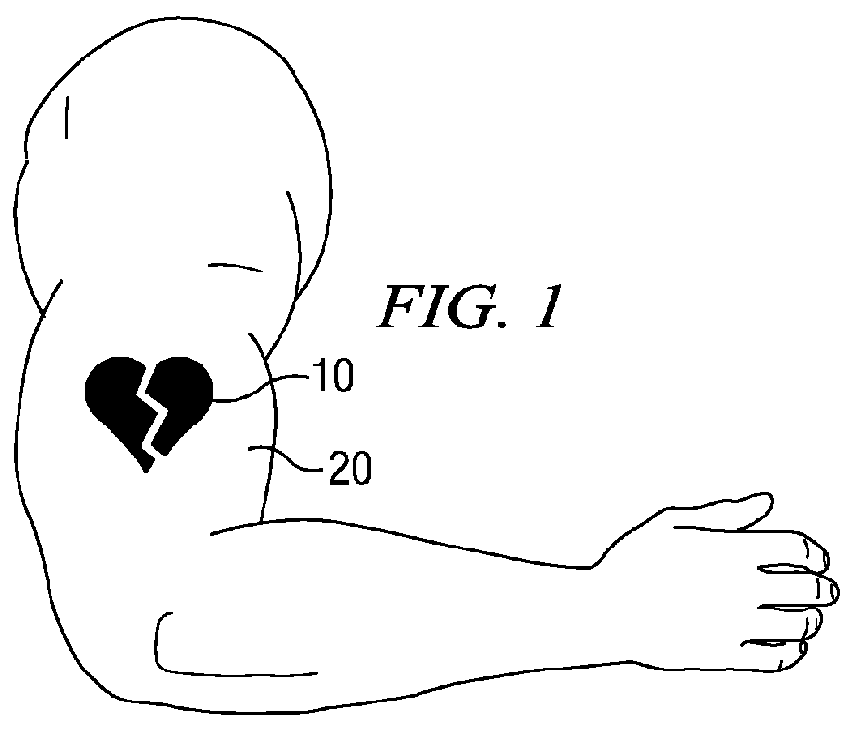

Tattoo removal system and method

ActiveUS8394359B1Short treatment timeCosmetic preparationsOrganic active ingredientsTattoo removalSkin treatments

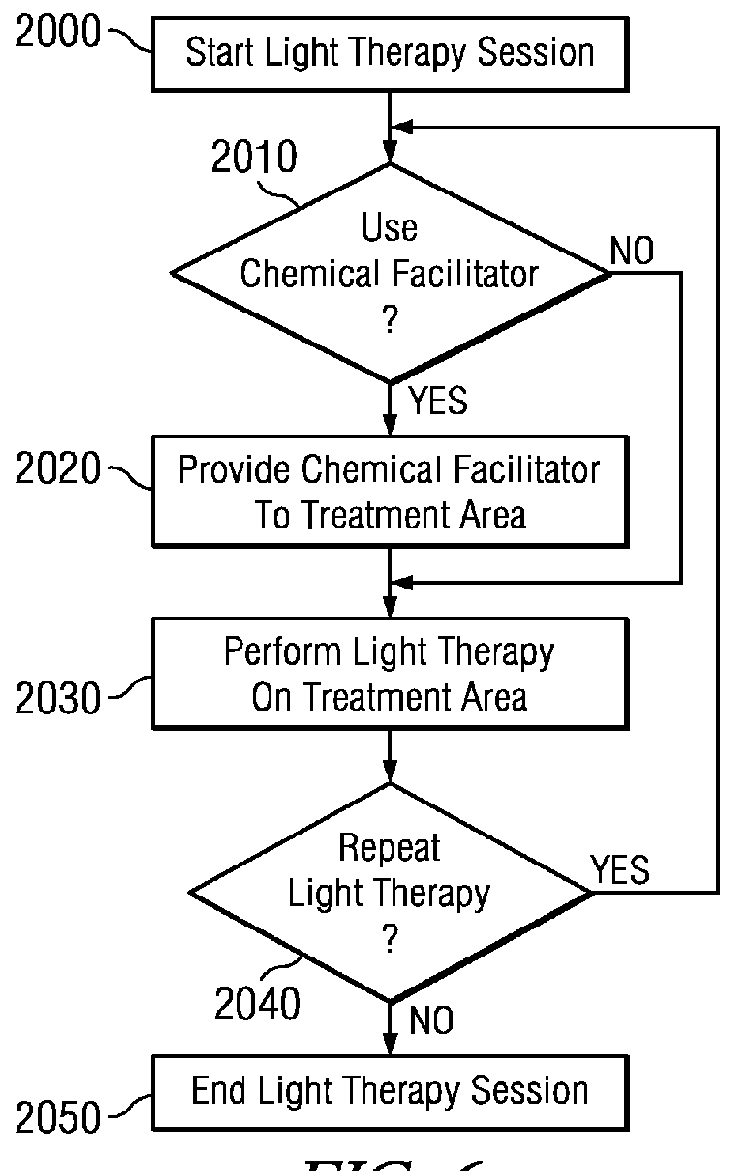

A treatment system and method includes use of a chemical facilitator to provide a result-effective event against one or more negative therapeutic effects related to exposing to a light output a skin portion including a condition treatable in whole or in part with light. In one exemplary embodiment for skin treatment including tattoo removal, perfluorodecalin is used to inhibit or resolve whitening, for example to speed a laser therapy session.

Owner:ON LIGHT SCI INC

Cryogenic fluid composition

InactiveUS20070114488A1Heat-exchange elementsMaintainance and safety accessoriesGas phaseHigh pressure

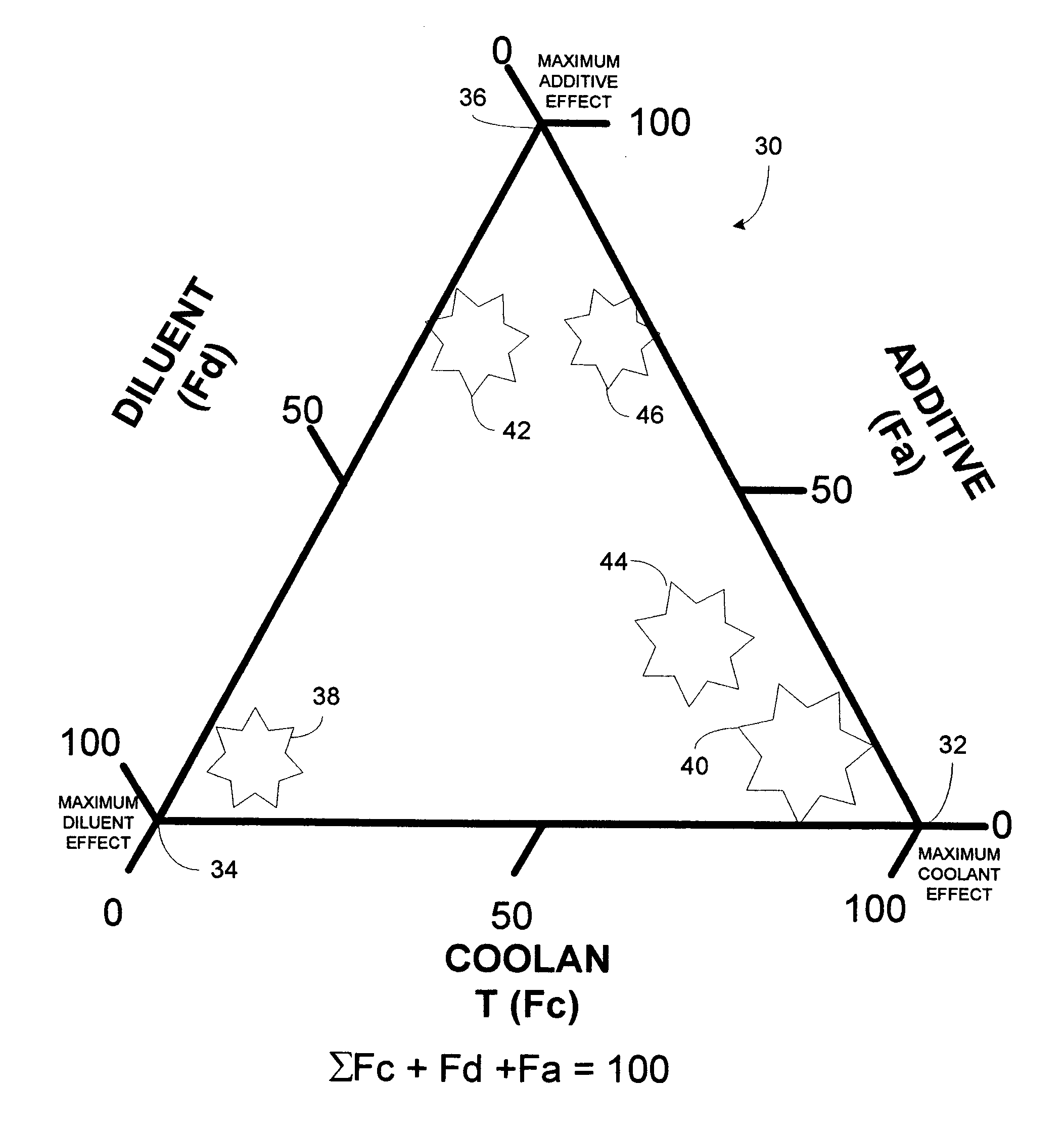

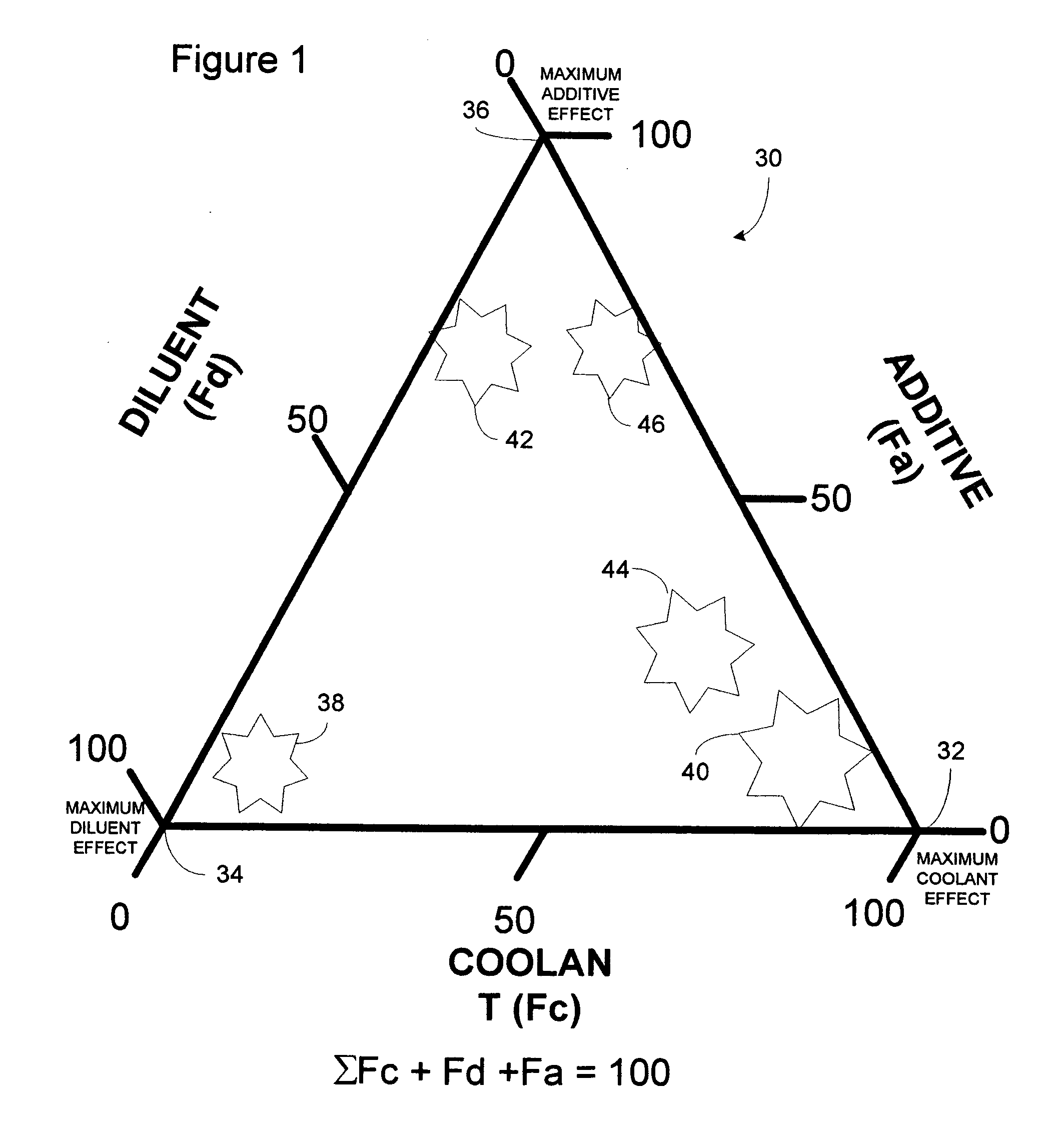

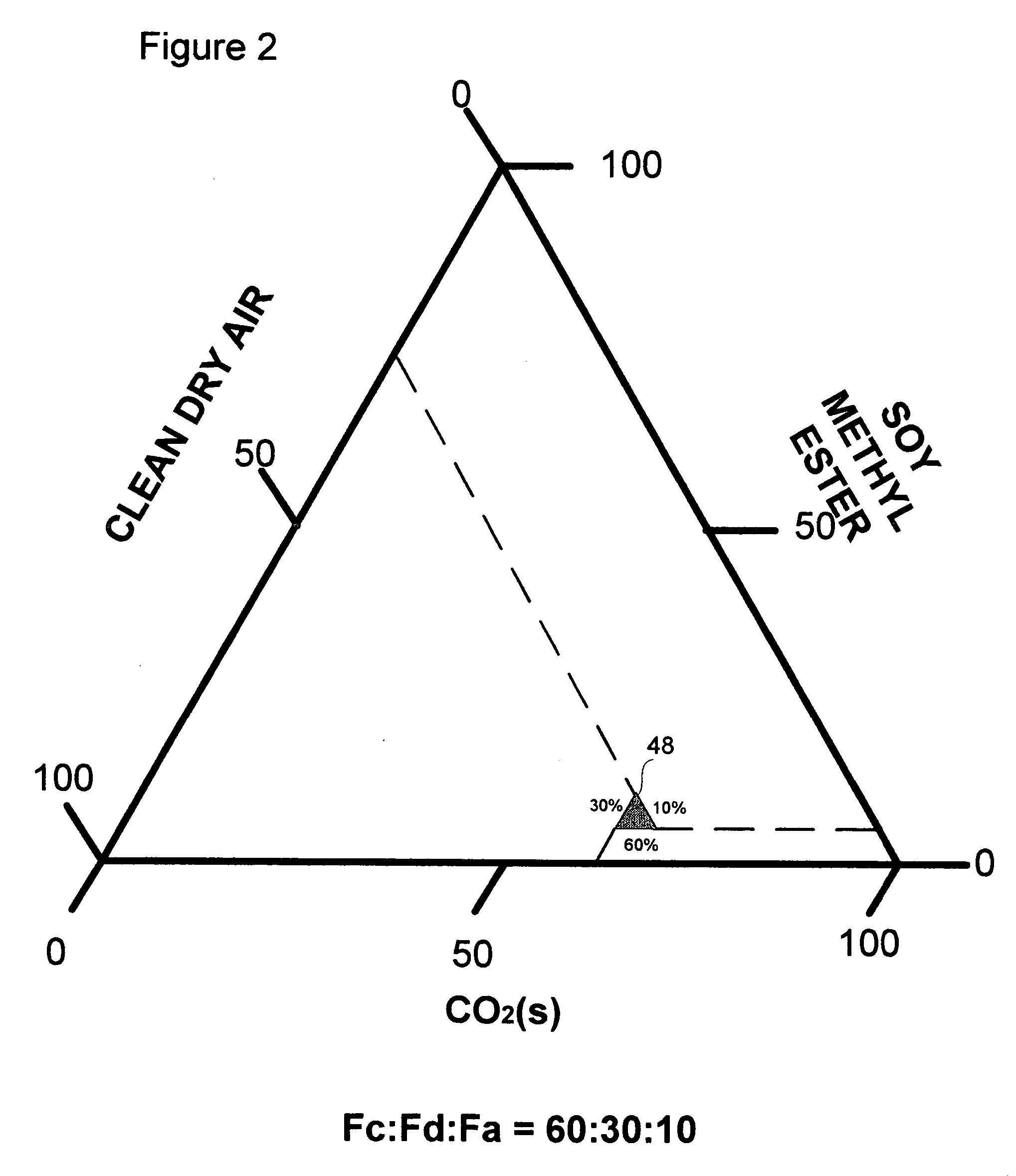

A cryogenic fluid composition, and method of forming same, having hyperbaric, lubricating and cooling properties includes selectivity combining a solid phase carbon dioxide, an inert diluent gas and additives in various proportions. The cryogenic machining fluid can be derived by combining a solid carbon dioxide coolant, which may contain or entrain one or more machining lubricant additives, and a diluent phase which is an inert and relatively non-condensing gas phase in various concentrations. The cryogenic fluid composition can be used in cleaning, machining or manufacturing processes to cool, lubricate or ablate a substrate. The cryogenic fluid composition can also be used in conjunction with laser treatment or machining processes without adversely affecting lasing qualities of the laser.

Owner:COOL CLEAN TECH

Method for promoting seed germination of cercidiphyllum japonicum and improving germination ratio of seeds

InactiveCN103430657AGood repeatabilityPracticalSeed and root treatmentHorticultureBiotechnologySeed dormancy

The invention discloses a method for promoting seed germination of a cercidiphyllum japonicum and improving the germination rate of seeds. The method is mainly achieved through steps of seed selecting, seed disinfecting, laser treatment, seed dormancy breaking treatment, seed germination, seedling transplant and the like. According to the invention, laser treatment, vitriolization, hormone treatment, fluctuating temperature stratification and temperature and illumination intensity control are comprehensively utilized, the seed germination of the cercidiphyllum japonicum can be prompted from all aspects such as the selection of culture medium, the germination ratio is high, a seeding root system of the seed of the cercidiphyllum japonicum is prosperous, the growth vigor is excellent, the speed is fast, and the survival rate is high.

Owner:SUZHOU RENCHENG BIO SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com