Catalyst distillation component and catalyst distillation method used said component

A technology of catalytic distillation and components, which is applied in chemical instruments and methods, fractionation, chemical/physical processes, etc., can solve the problems of high catalyst strength requirements, affecting mass transfer and reaction effects, and high production technology requirements, so as to overcome mass transfer The effect of falling effect, good liquid redistribution ability, and high catalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

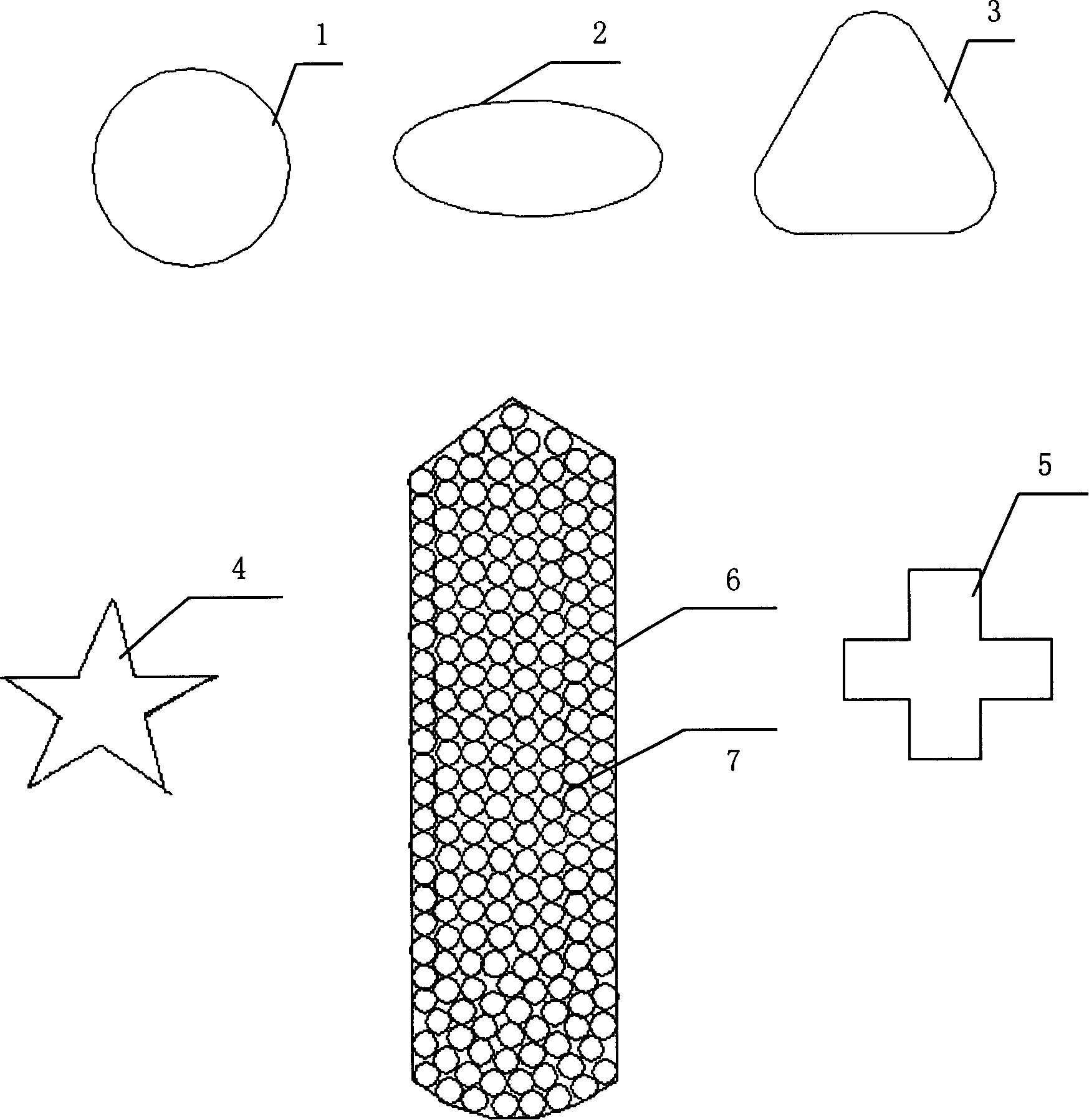

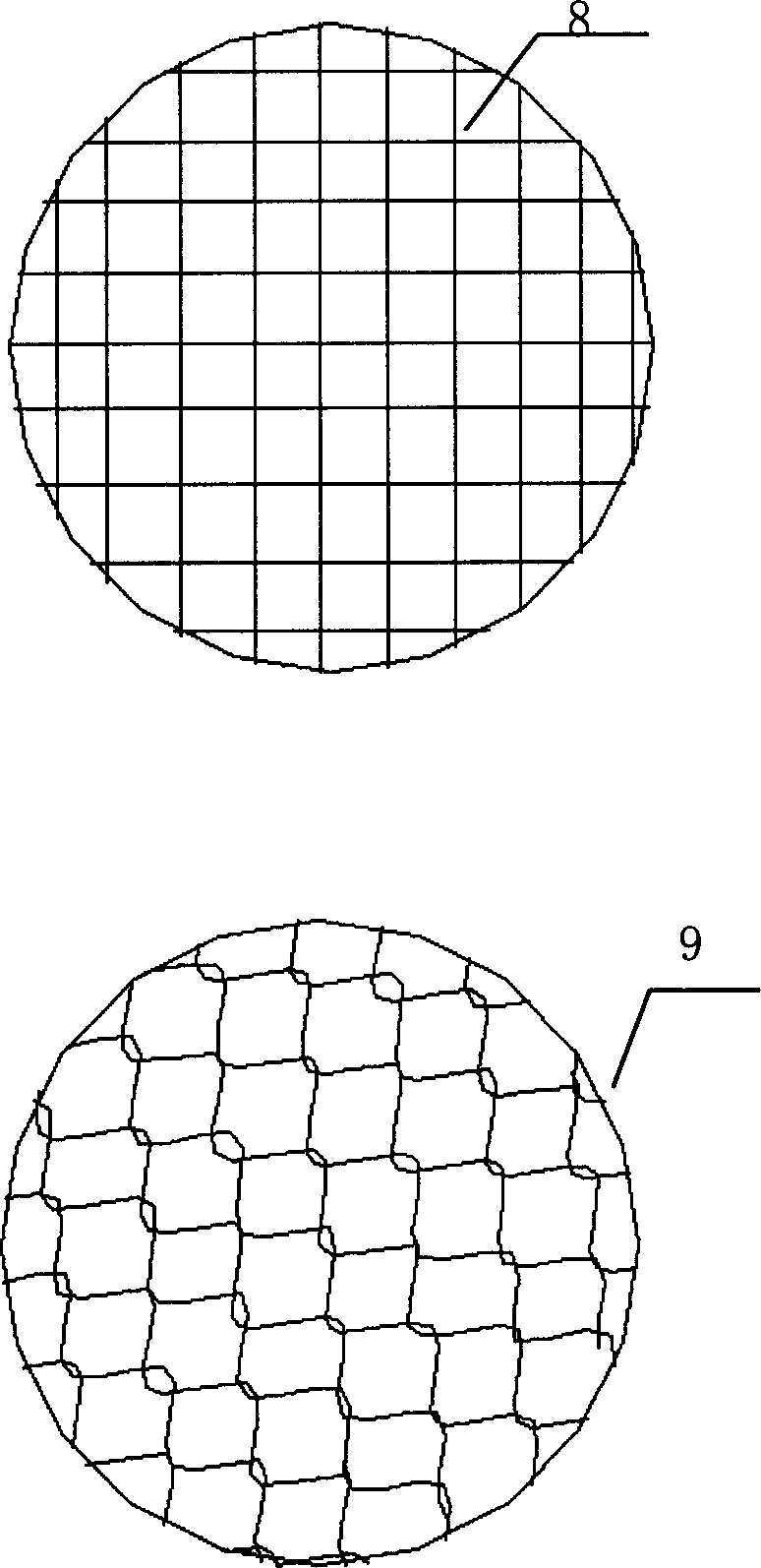

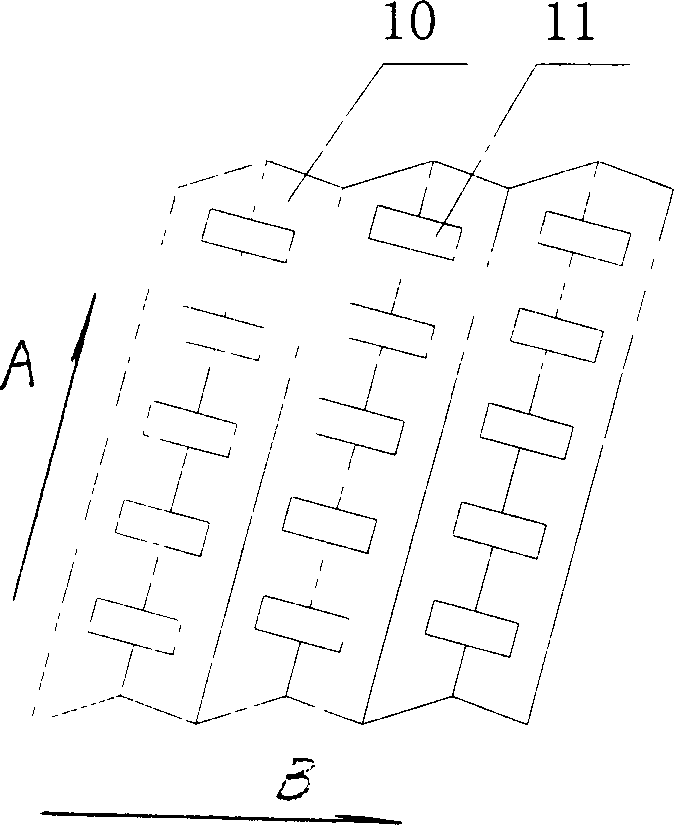

Method used

Image

Examples

Embodiment

[0051] The catalytic distillation assembly of the present invention is used for C 3 The industrial side line experimental device for MPEA removal by catalytic distillation, the material composition is shown in Table 1, the temperature: 105-40°C, the pressure 1.9Mpa, the diameter of the industrial side line device is 300mm, and the height is 23000mm. The catalytic distillation assembly of the present invention is made into an integral assembly with a diameter of 300mm and a height of 220mm. The catalyst used in the catalytic distillation assembly adopts the solid ball BC series hydrogenation catalyst with a diameter of φ3mm produced by the Beijing Research Institute of Chemical Industry. The wire mesh container of the catalyst is 13mm in diameter plane wire mesh cylinder, the length is the same as the length of the free channel of the filler of the present invention, the filler plate is made of stainless steel corrugated plate with a pattern pressed on the surface, the wave dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com