High-stability waterborne epoxy resin modified emulsified asphalt and preparation method thereof

A technology of water-based epoxy resin and emulsified asphalt, which can be applied to cohesive pavement paved on site, building components, building insulation materials, etc. It can solve the problems of unfavorable rapid opening of traffic, unsmooth spraying construction, and slow strength formation speed. Achieve extended working time, reduce the risk of thickening or segregation, and low kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

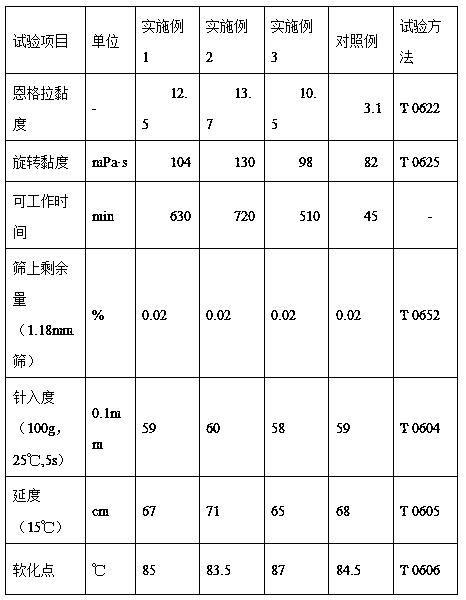

Examples

Embodiment 1

[0028] According to the mass fraction, 4 parts of organic bentonite and 0.02 parts of hydroxyethyl cellulose were added to 30.88 parts of water, and stirred at a high speed for 120 minutes with a high-speed disperser at a speed of 1500 r / min to obtain a thickened slurry JY1; Hexaalkyltrimethylammonium chloride, 1.8 parts of cetyl alcohol polyoxyethylene ether and 10 parts of ARADUR® 250 polyamide curing agent (supplied by Huntsman Company of the United States, active hydrogen equivalent of 425-455g / eq) were added to the slurry JY1 , and heated to 50°C, stirred at a high speed for 30 minutes, and the rotation speed was 1000r / min, then adjusted the pH value of the system to 2.0 with industrial hydrochloric acid with a concentration of 33%, and obtained mixed soap liquid ZY1, which was set aside; heated 40 parts of 70# base asphalt to 140-150°C, then add 0.1 part of tall oil fatty acid into the base asphalt while stirring, and after stirring and dispersing evenly, carry out high-s...

Embodiment 2

[0030] According to the mass fraction, 5 parts of lithium-based bentonite and 0.2 parts of polyvinyl alcohol (grade 17-99) were added to 37.5 parts of water, and stirred at a high speed for 60 minutes with a high-speed disperser at a speed of 2000 r / min to obtain a thickened slurry JY2; 0.6 parts of dodecyl dimethyl benzyl ammonium chloride, 0.3 parts of nonylphenol polyoxyethylene ether-10 and 6 parts of ARADUR® 22 modified fatty amine curing agent (supplied by Huntsman Company of the United States, the active hydrogen equivalent is 810-830g / eq) into the slurry JY2, heated to 60°C, stirred at a high speed for 60 minutes, and the rotation speed was 500r / min, then adjusted the pH value of the system to 3.0 with industrial phosphoric acid with a concentration of 85%, and obtained the mixed soap liquid ZY2. Standby; heat 45 parts of 70# base asphalt to 135-145°C, then add 0.5 parts of rosin acid to the base asphalt while stirring, and after stirring and dispersing evenly, pass the...

Embodiment 3

[0032] According to the mass fraction, 3 parts of sodium bentonite and 0.03 parts of hydroxymethyl cellulose were added to 28.27 parts of water, and stirred at a high speed for 120 minutes with a high-speed disperser at a speed of 2000 r / min to obtain a thickened slurry JY3; Octadecyltrimethylammonium bromide, 2.5 parts of octylphenol polyoxyethylene ether-10 and 3 parts of 1,3-cyclohexanedimethylamine (supplied by Sinopharm Chemical Reagent Beijing Co., Ltd., purity 99.0%) were added to In the slurry JY3, heated to 40°C, stirred at a high speed for 60 minutes, and the rotation speed was 1000r / min, and then adjusted the pH value of the system to 4.0 with industrial hydrochloric acid with a concentration of 33%, to obtain a mixed soap liquid ZY3, and set aside; 35 parts of 90# base Heat the asphalt to 130-140°C, then add 0.2 parts of stearic acid to the base asphalt while stirring, and after stirring and dispersing evenly, carry out high-speed shear emulsification through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com