Polysucrose fatty acid ester, preparation method thereof and application thereof to preparation of micro-scale lubricating oil

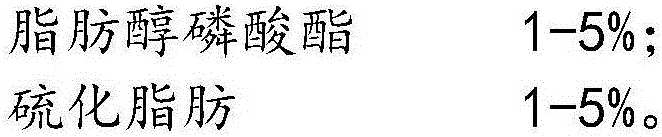

A technology of fatty acid ester and fatty alcohol phosphate ester, which is applied in the field of lubrication, can solve the problems of aggravating the environmental burden and non-degradable raw materials, and achieve the effects of remarkable environmental protection, good lubricity, and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 342.3g (1mol) of sucrose, 174.11g (1.5mol) of maleic acid, and 258.39g (1.5mol) of n-decanoic acid, add them to the reaction kettle respectively, stir and heat to 190°C, fully react for 12 hours, and drain the water under reduced pressure , which is a kind of polysucrose maleate n-decanoate.

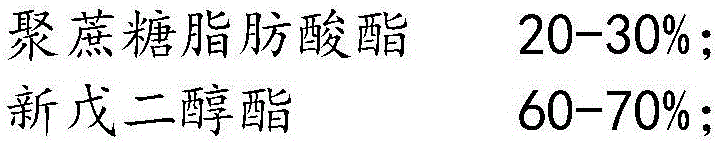

[0032] Weigh 300 g of polysucrose maleate n-caprate, 650 g of neopentyl glycol dicaprate, 30 g of trilauryl phosphate, and 20 g of vulcanized lard prepared above, and mix and stir at 40°C until it becomes transparent. A minimum quantity lubricant.

Embodiment 2

[0034] Take by weighing 342.3g (1mol) sucrose, 118.09g (1mol) succinic acid, 400.64g (2mol) lauric acid, 12g dilute sulfuric acid (10%) and add respectively in the reactor, stir and heat to 260 ℃, fully react for 6 hours, reduce Press out the water, which is a kind of polysucrose succinate laurate.

[0035] Weigh 200 g of polysucrose succinic laurate prepared above, 700 g of neopentyl glycol dilaurate, 40 g of trilauryl triphosphite, and 10 g of vulcanized rapeseed oil, and mix and stir at 60°C until it becomes transparent. A minimum quantity lubricant.

Embodiment 3

[0037] Weigh 342.3g (1mol) of sucrose, 175.37g (1.2mol) of adipic acid, and 256.42g (1mol) of palmitic acid and add them to the reaction kettle respectively, stir and heat to 240°C, fully react for 8 hours, and discharge the water under reduced pressure, that is It is a polysucrose adipate palmitate.

[0038] Weigh 250g of polysucrose adipate palmitate, 670g of neopentyl glycol dipalmitate, 50g of triisomeric tridecyl phosphate, and 30g of sulfurized soybean oil prepared above, mix and stir until transparent at a temperature of about 50°C It is a micro lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com