High-overload transformer oil and preparation process thereof

A technology of transformer oil and preparation process, which is applied in the petroleum industry, base material, lubricating composition, etc., can solve the problems of restricting the popularization and application of high-overload distribution transformers, and cannot meet the requirements of higher grades, and achieve good promotion and application value , solve the burden of returning home and improve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

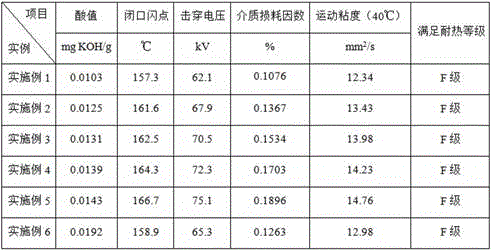

[0029] A high-overload transformer oil, the high-overload transformer oil is formulated from natural ester insulating oil and mineral insulating oil at a volume percentage of 40%:60%, and its performance parameters are shown in Table 1.

[0030] The preparation method of the natural ester insulating oil comprises the following steps:

[0031] (1) Heat the soybean oil and stir it at a speed of 60r / min. When the oil temperature reaches 68°C, add NaOH solution with a concentration of 7°Bé at the same temperature as the oil (the dosage is 10% of the oil weight), NaOH After the addition of the solution, continue to stir for 10 minutes, reduce the rotation speed to 30r / min, continue to stir for 30 minutes, and after standing for 12 hours, drain the saponins at the bottom;

[0032] (2) Heat the soybean oil to 83°C, add distilled water at 91°C at a stirring speed of 80r / min for washing, the amount of distilled water is 15% of the oil weight, keep stirring for 10min, then let stand for...

Embodiment 2

[0043] A high-overload transformer oil, the high-overload transformer oil is formulated from natural ester insulating oil and mineral insulating oil at a volume percentage of 47%:53%, and its performance parameters are shown in Table 1.

[0044] The natural ester insulating oil and mineral insulating oil are the same as in Example 1.

[0045] The preparation process of the above-mentioned high overload transformer oil comprises the following steps:

[0046] (1) Heat the natural ester insulating oil to 85°C under the condition of 30Pa vacuum mechanical stirring, and the stirring speed is 95 r / min;

[0047] (2) Keep the temperature of natural ester insulating oil at 85°C, add mineral insulating oil under 30Pa vacuum condition, first mechanically stir for 25 minutes, then ultrasonically oscillate for 7min, the mechanical stirring speed is 95 r / min, and the ultrasonic oscillation frequency is 25KHz;

[0048] (3) Raise the new transformer oil after vacuum mixing to 105°C, and cont...

Embodiment 3

[0050] A high-overload transformer oil, the high-overload transformer oil is formulated from natural ester insulating oil and mineral insulating oil at a volume percentage of 50%:50%, and its performance parameters are shown in Table 1.

[0051] The natural ester insulating oil and mineral insulating oil are the same as in Example 1.

[0052] The preparation process of the above-mentioned high overload transformer oil comprises the following steps:

[0053] (1) Heat the natural ester insulating oil to 90°C under the condition of 40Pa vacuum mechanical stirring, and the stirring speed is 92 r / min;

[0054] (2) Keep the temperature of the natural ester insulating oil at 90°C, add it to the mineral insulating oil under the vacuum condition of 40Pa, first mechanically stir for 23 minutes, then ultrasonically oscillate for 7min, the mechanical stirring speed is 92 r / min, and the ultrasonic oscillation frequency is 28KHz;

[0055] (3) Raise the new transformer oil after vacuum mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com