Trace lubricating oil and preparation method thereof

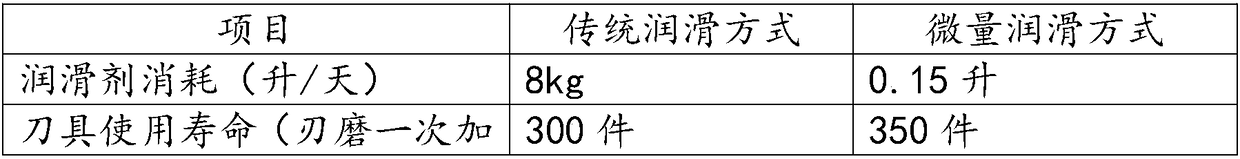

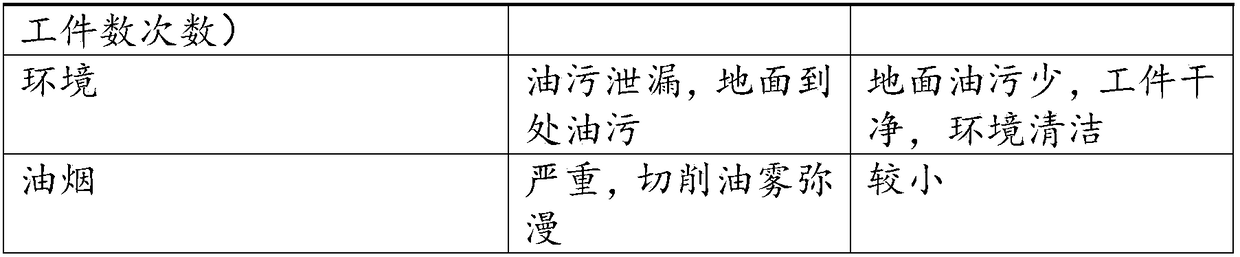

A lubricating oil and micro-quantity technology, which is applied in the field of lubrication, can solve the problems of non-degradable raw materials and aggravated environmental burdens, and achieve good rust resistance, good extreme pressure and anti-wear properties, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 1500g of castor oil and 100g of potassium tetraborate, put them into a stirrer, stir and react at a temperature of 100°C for 4 hours, and then the castor borate potassium salt can be used as a trace lubricating oil precursor.

[0033] Weigh 100 g of the above-mentioned trace lubricating oil precursor, 700 g of neopentyl glycol dioctyl ester, and 200 g of polyricinoleic acid ester, mix and stir at 50° C. until transparent, then a trace lubricating oil is obtained.

[0034] The preparation method of above-mentioned polyricinoleic acid ester, comprises the following steps:

[0035] Step 1: 1000g ricinoleic acid and catalyst (5g sodium perborate) are dropped into the polymerization kettle respectively;

[0036] Step 2: Filling with nitrogen to replace the air in the polymerization kettle;

[0037] Step 3: heat up to 200°C while stirring, and react for 4.5 hours;

[0038] Step 4: removing water under reduced pressure to obtain the product.

[0039] The trace lubrica...

Embodiment 2

[0044] Weigh 2000 g of castor oil and 100 g of potassium borate, put them into a stirrer and stir for 3 hours at a temperature of 110°C to react for 3 hours, which is castor borate potassium salt, which can be used as a trace lubricating oil precursor.

[0045] Weigh 50 g of the above-mentioned trace lubricating oil precursor, 850 g of dioctyl sebacate, and 100 g of polyricinoleic acid ester, mix and stir at 40°C until transparent, then a trace lubricating oil is obtained.

[0046] The preparation method of above-mentioned polyricinoleic acid ester, comprises the following steps:

[0047] Step 1: 1000g ricinoleic acid and catalyst (3g potassium perborate) are dropped into the polymerization kettle respectively;

[0048] Step 2: Filling with nitrogen to replace the air in the polymerization kettle;

[0049] Step 3: heat up to 220°C while stirring, and react for 4 hours;

[0050] Step 4: removing water under reduced pressure to obtain the product.

Embodiment 3

[0052] Weigh 1000g of castor oil and 100g of potassium metaborate, put them into a stirrer, stir and react at a temperature of 90°C for 4 hours, that is castor borate potassium salt, which can be used as a trace lubricating oil precursor.

[0053] Weigh 80 g of the above-mentioned trace lubricating oil precursor, 800 g of ethylene glycol dioleate, and 120 g of polyricinoleic acid ester, mix and stir at 60° C. until transparent, then a trace lubricating oil is obtained.

[0054] The preparation method of above-mentioned polyricinoleic acid ester, comprises the following steps:

[0055] Step 1: 1000g ricinoleic acid and catalyzer (15g cation exchange resin) are dropped into polymerization kettle respectively;

[0056] Step 2: Filling with nitrogen to replace the air in the polymerization kettle;

[0057] Step 3: heat up to 180°C while stirring, and react for 4 hours;

[0058] Step 4: remove water under reduced pressure, remove the cation exchange resin, and obtain the product....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com