A clean production method for synthesizing methyl chloride

A technology of clean production and methyl chloride, applied in chemical instruments and methods, organic chemistry, disproportionation separation/purification of halogenated hydrocarbons, etc., to achieve the effect of wide pressure adaptation range and reduced unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

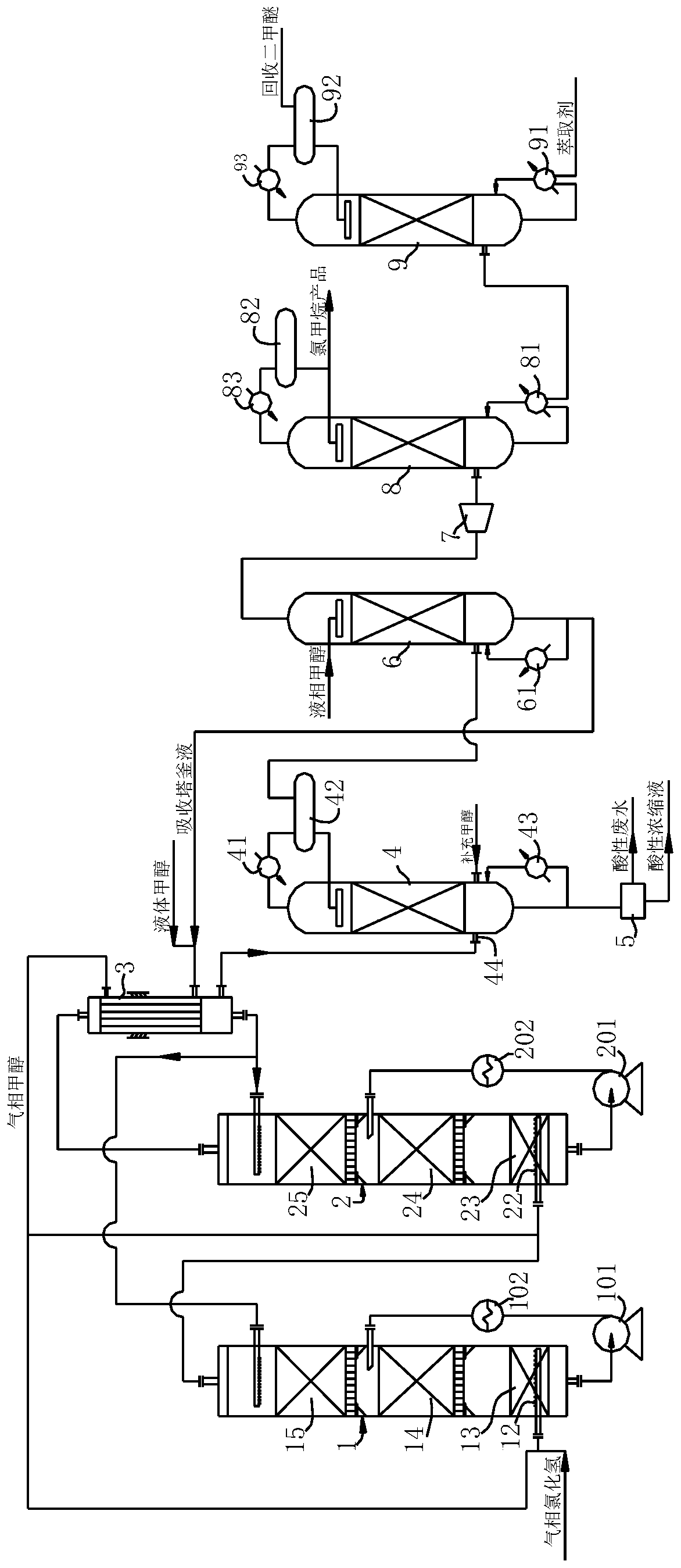

Image

Examples

Embodiment 1

[0075] A clean production method for synthesizing methyl chloride. In this embodiment, both the primary reactor and the secondary reactor are tower reactors, and the shells of both are made of graphite composite carbon fiber material. According to different needs, in other embodiments, the shells of both the primary reactor and the secondary reactor can also be made of steel-lined enamel or steel-composite special engineering plastics.

[0076] The primary reactor and the secondary reactor are equipped with a reaction zone and a washing zone from bottom to top, wherein the reaction zone is divided into a bubbling reaction zone and a gas phase reaction zone, and the gas phase reaction zone is above the bubbling reaction zone , A gas distributor is installed in the bubbling reaction zone, and a washing liquid distributor is installed above the washing zone. In this embodiment, the gas distributor is made of graphite material, and an atomizing nozzle is installed on the gas distr...

Embodiment 2

[0099] This embodiment is basically the same as the embodiment, the difference is that

[0100] 1) Methyl chloride synthesis steps:

[0101] 1.1 Gas-phase hydrogen chloride with a pressure of 0.5MPa and gas-phase methanol with a pressure of 0.5MPa enter the bubbling reaction zone of the primary reactor through the gas distributor of the primary reactor at a molar ratio of 1.2:1, and then pass through the primary reactor The gas phase reaction zone continues to react, the outlet gas velocity of the gas distributor of the primary reactor is 5-10m / s, the catalyst aqueous solution in the primary reactor is zinc chloride aqueous solution, and the reaction of the raw material mixed gas in the primary reactor The reaction time of the zone is kept at 40-45s.

[0102] The reaction temperature in the reaction zone of the primary reactor is 155°C, the reaction pressure is 0.4MPa, and the primary crude CH at the outlet of the primary reactor 3 The volume content of HCl in the Cl mixed g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com