Rapid pressure reduction test device and method for large-size aircraft assembly

A test device and aircraft technology, applied in the testing of machine/structural components, pump devices, measuring devices, etc., can solve problems such as unavailability of large-sized aircraft components, rapid decompression tests, etc., to improve rapid descent and speed up flow speed , Good universality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

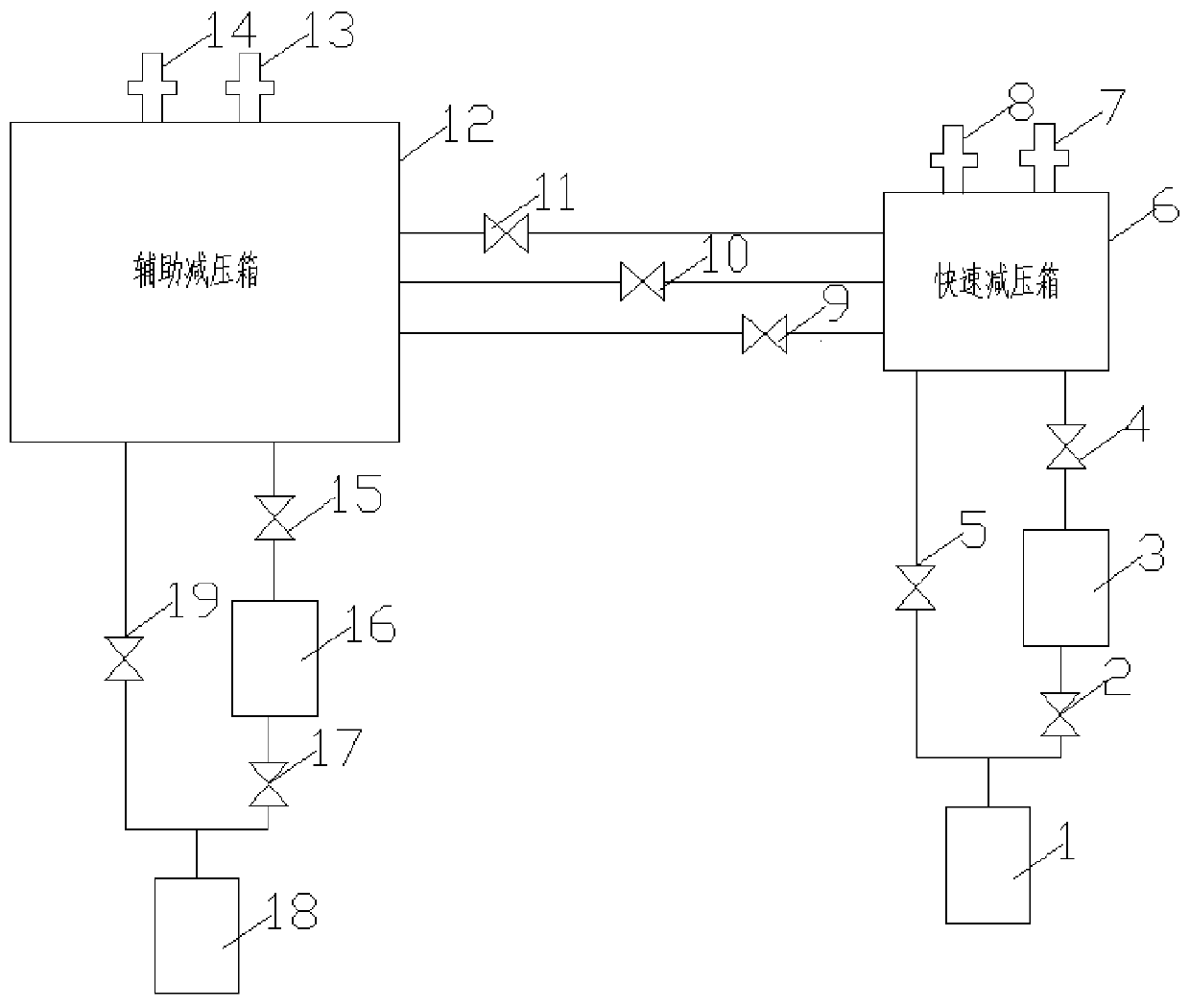

[0041] Such as figure 1As shown, the large-scale aircraft component rapid decompression test device provided by the embodiment of the present invention includes a rapid decompression tank system and an auxiliary decompression tank system.

[0042] The rapid decompression box system includes a rapid decompression box 6, a first vacuum absolute pressure transmitter 7 and a first full-scale vacuum gauge 8 arranged on the fast decompression box 6, and connected in turn to the rapid decompression box 6. The second vacuum valve 4 of an output end, the first molecular pump 3, the first vacuum valve 2 and the first mechanical vacuum pump 1; connected to the other output.

[0043] The auxiliary decompression box system includes an auxiliary decompression box 12, a second vacuum absolute pressure transmitter 13 and a second full-scale vacuum gauge 14 arranged on the auxiliary decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com