Slag treatment device

A processing device and slag technology, which is applied in the direction of heating device, dry cargo processing, dry gas arrangement, etc., can solve problems such as easy to block leaks, safety accidents, and affect drying effect, so as to increase the residence time, slow down the moving speed, The effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

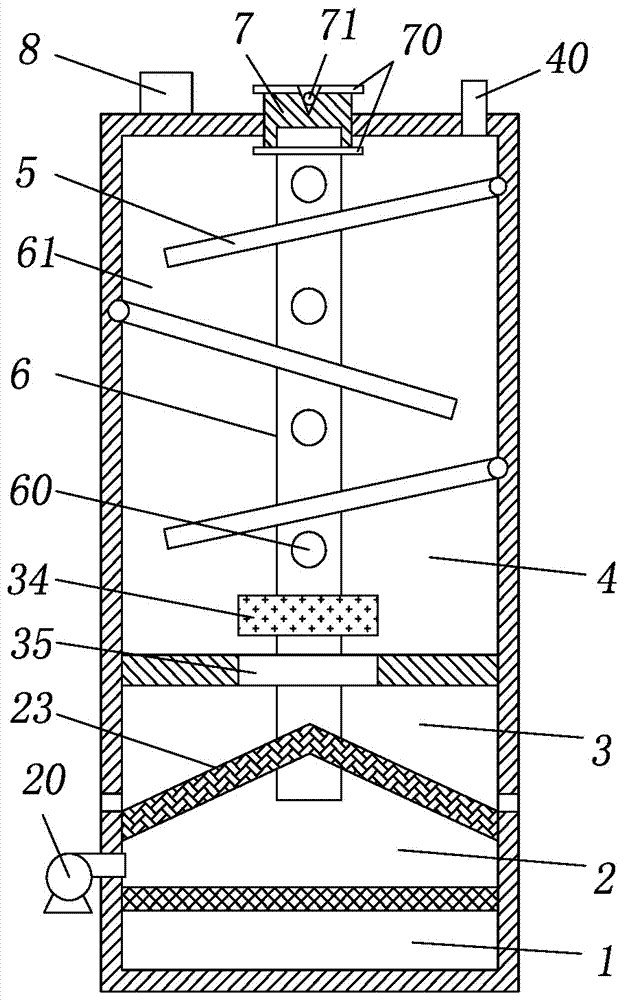

[0015] The reference signs in the drawings of the description include: combustion chamber 1, air flow chamber 2, blower 20, conical platform 23, discharge chamber 3, piston 34, through hole 35, material bin 4, feed port 40, slant plate 5 , connecting shaft 6, air outlet 60, leak 61, box body 7, limit block 70, pressure relief valve 71, vibrator 8.

[0016] The embodiment is basically as attached figure 1 As shown: the slag processing device, from bottom to top, includes a combustion chamber 1, an airflow chamber 2, a discharge chamber 3 and a material bin 4, wherein the combustion chamber 1 and the airflow chamber 2 form a combustion furnace; the airflow chamber 2 is connected with a blower 20, and The air is blown into the airflow chamber 2; the interface between the airflow chamber 2 and the discharge chamber 3 is a conical platform 23 with a high center and low surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com