Waste heat recovery components

A waste heat recovery and component technology, applied in heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve problems such as the reduction of waste heat recovery effect, and achieve the effect of improving efficiency, improving heat insulation effect, and being easy to pick and place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

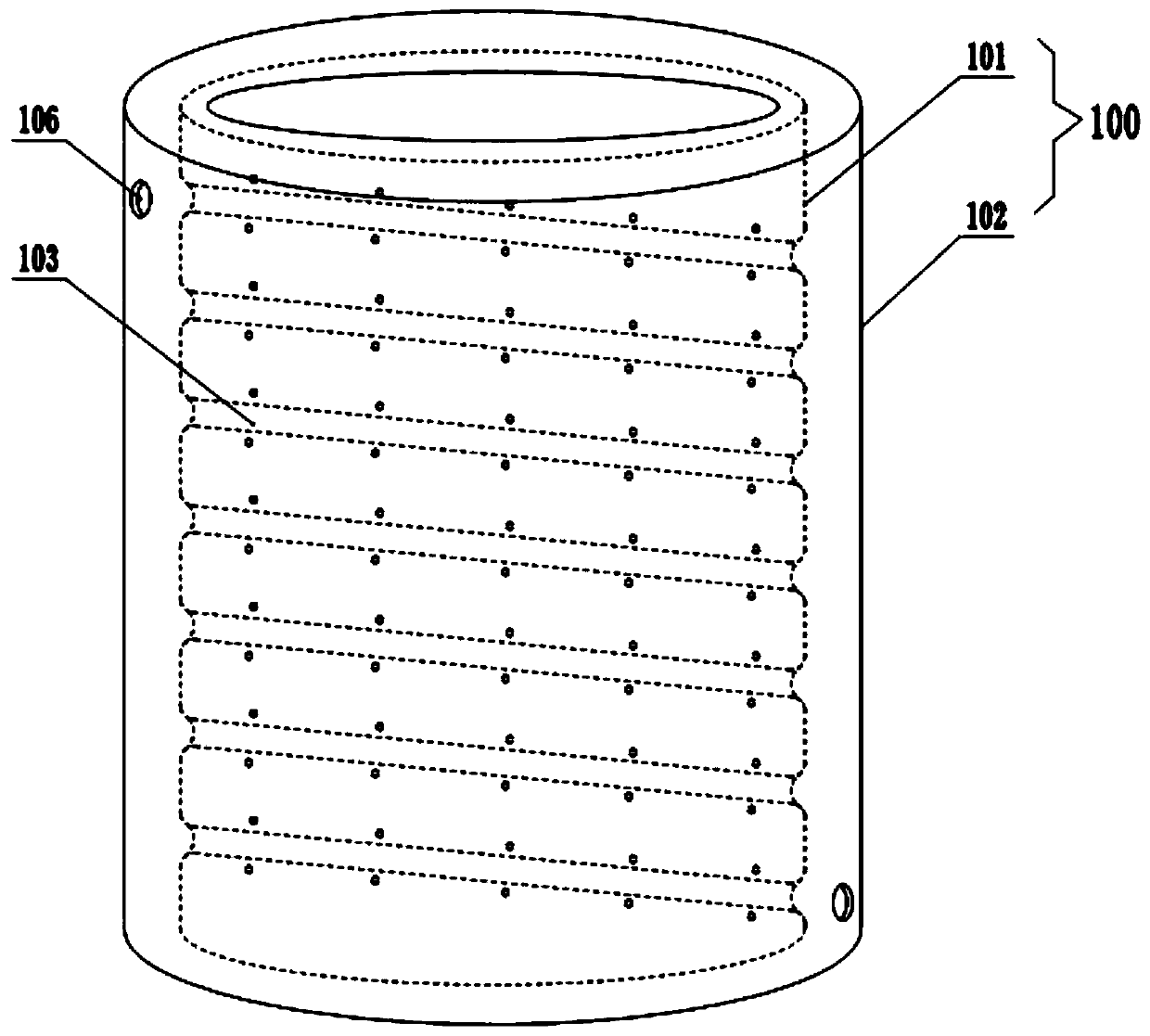

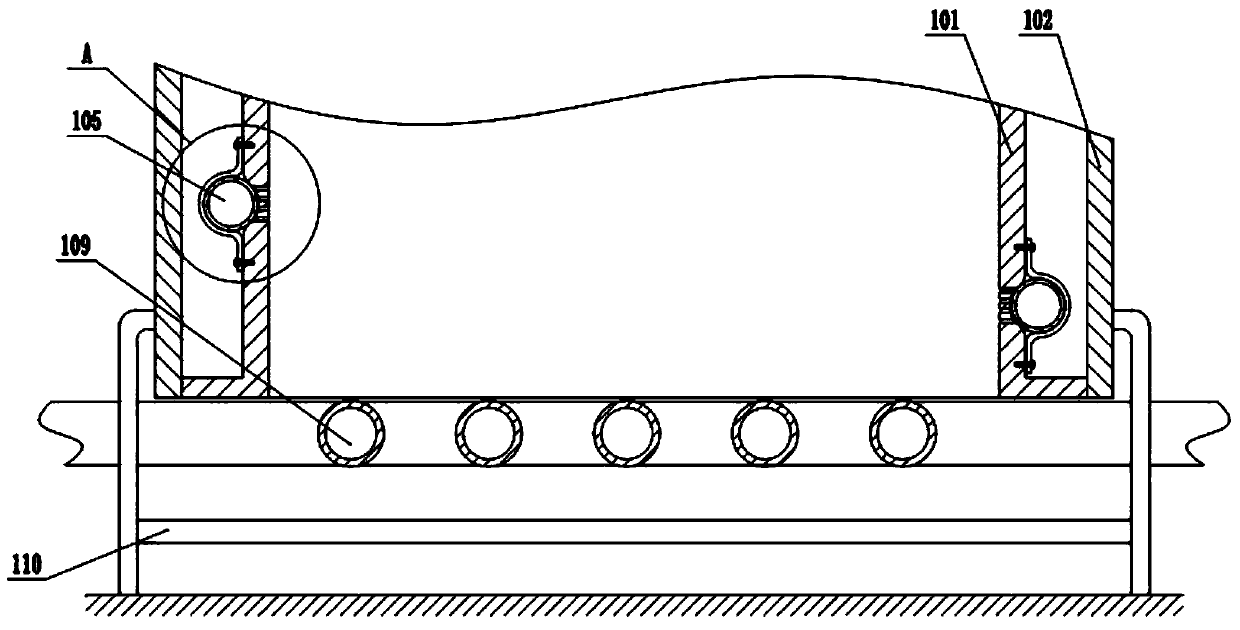

[0036] Embodiment 1 is basically as attached figure 1 and figure 2 shown:

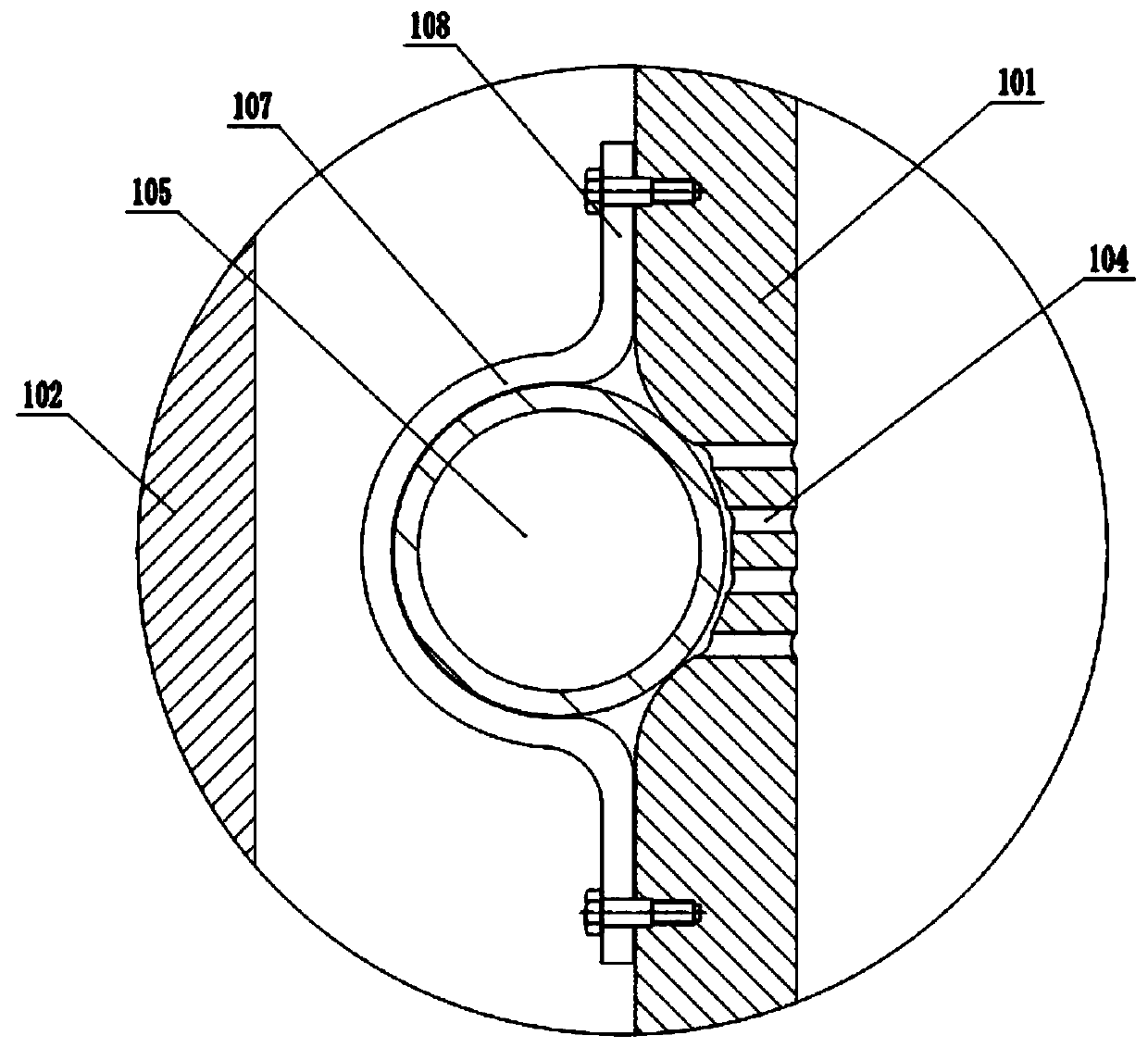

[0037] The waste heat recovery assembly includes a frame on which a vertically arranged heat-absorbing cylinder 100 is fixed. The heat-absorbing cylinder 100 is a sandwich structure, and specifically includes an inner cylinder 101 and an outer cylinder 102, and the inner cylinder 101 and the outer cylinder 102 are fixedly arranged , and a channel with closed upper and lower ends is formed between the inner and outer cylinders 102, a spiral groove 103 is opened on the outer wall of the inner cylinder 101, and the cross-section of the groove 103 is semicircular, such as image 3 , the inner wall of the inner cylinder 101 is provided with a plurality of heat dissipation holes 104 corresponding to the positions of the grooves 103 and communicated with each other, and the heat dissipation holes 104 are through holes, and the heat absorption pipes for the circulation of the heat exchange medium are clamped...

Embodiment 2

[0046] The difference between the second embodiment and the first embodiment is:

[0047] like Figure 5 As shown, a plurality of heat conducting units are evenly distributed along the protrusions 201 at the bottom of the top cover 200, and the heat conducting units are used to disperse the heat from the bottom of the top cover 200 to the heat absorption pipe 105, wherein the heat conducting units include the heat conducting plate 300 and the drive A drive mechanism for the heat-conducting plate 300 to swing back and forth around the horizontal axis. The heat-conducting plate 300 is located between the protrusion 201 and the inner cylinder 101 . In this embodiment, the drive mechanism includes a deceleration motor 301 and a guide rod 302 , and the deceleration motor 301 is fixed on the top cover 200 The top cover 200 is provided with a shaft hole for the output shaft of the reduction motor 301 to pass through, an incomplete gear 304 located under the top cover 200 is coaxially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com