Patents

Literature

53results about How to "Improve waste heat recovery effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

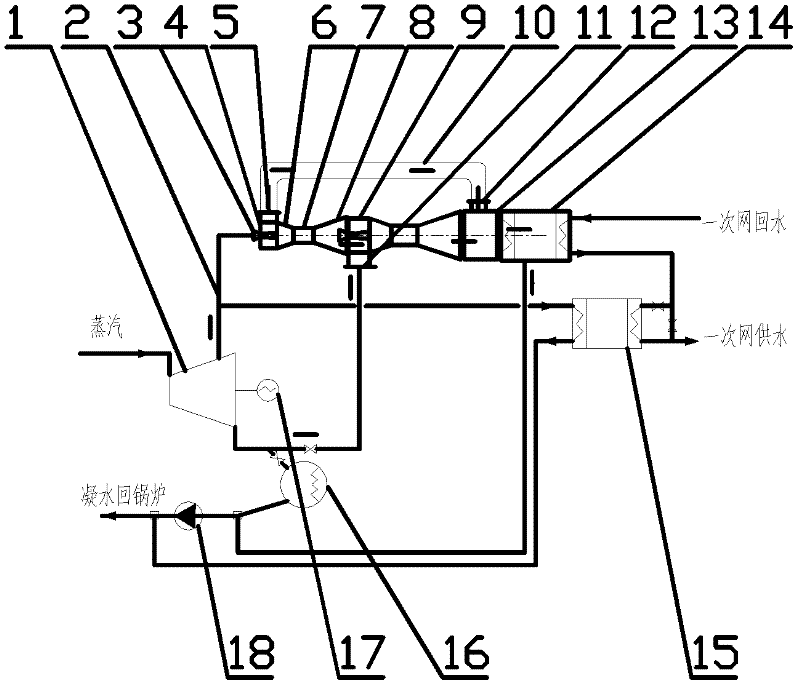

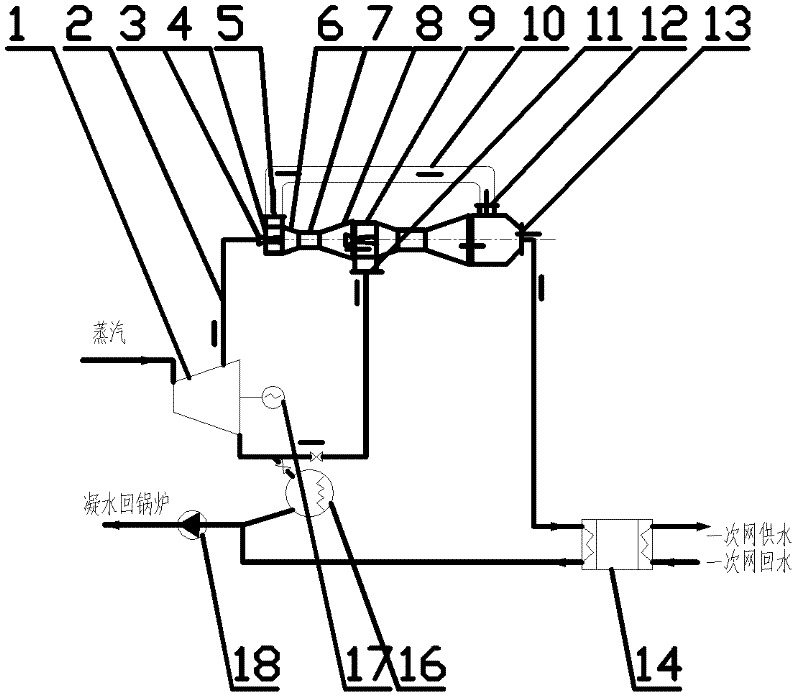

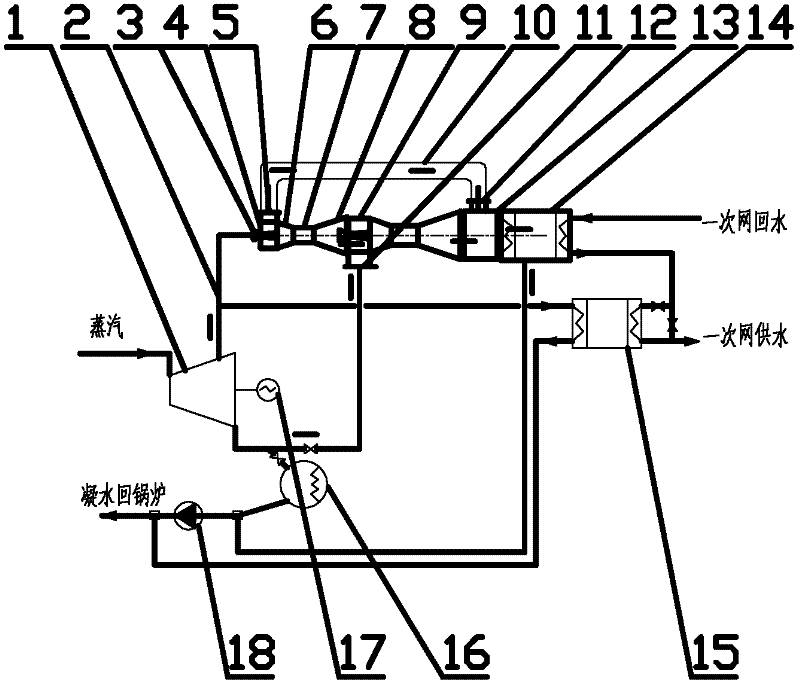

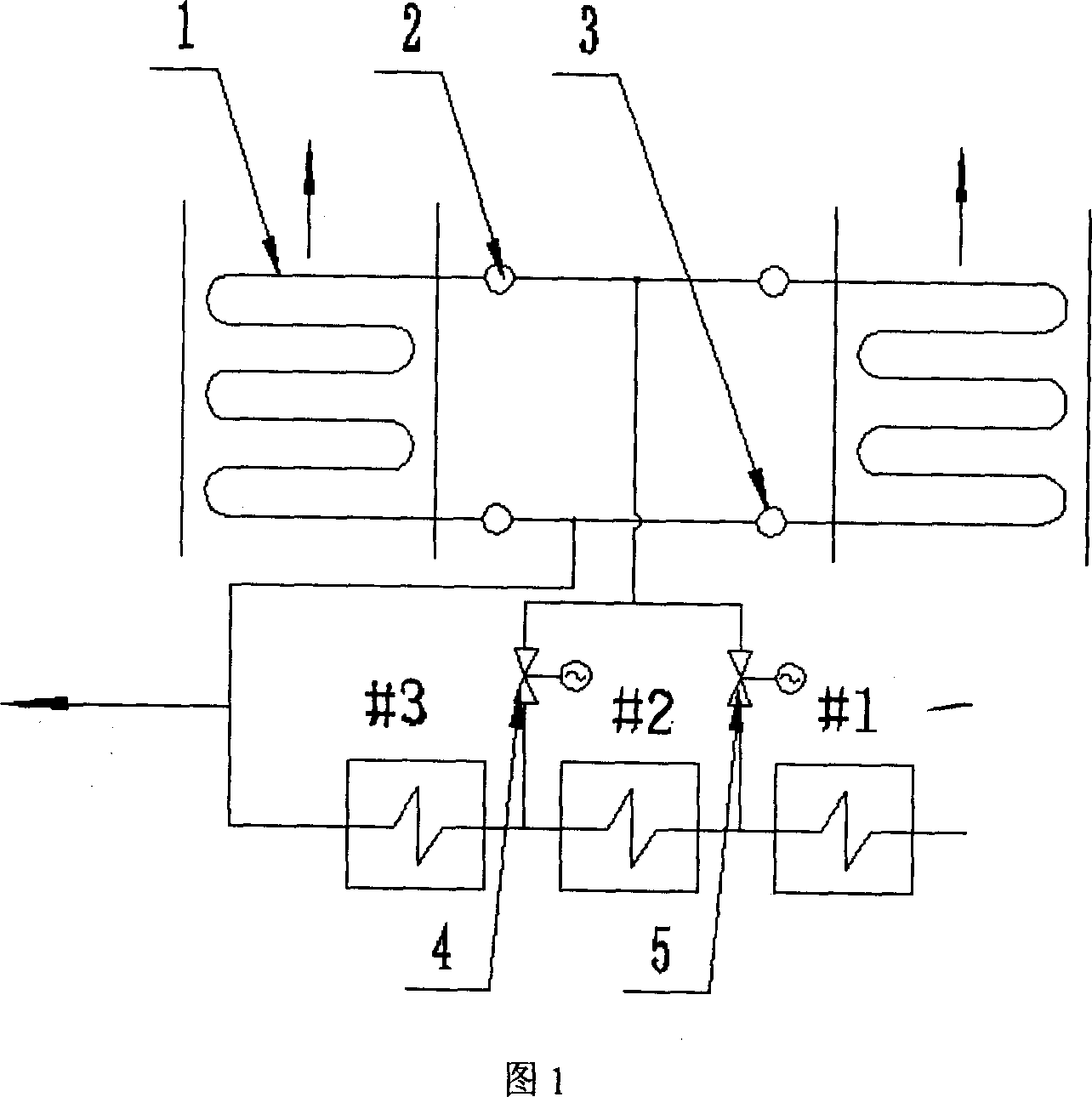

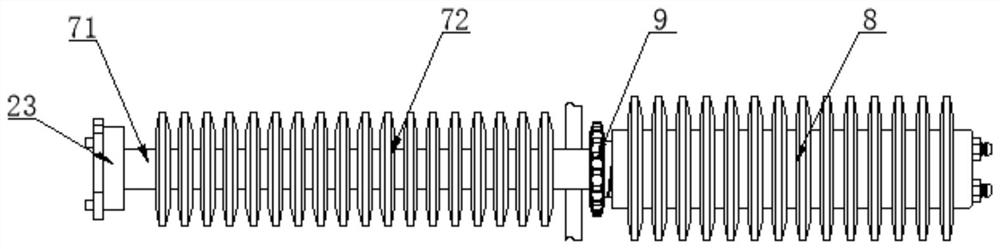

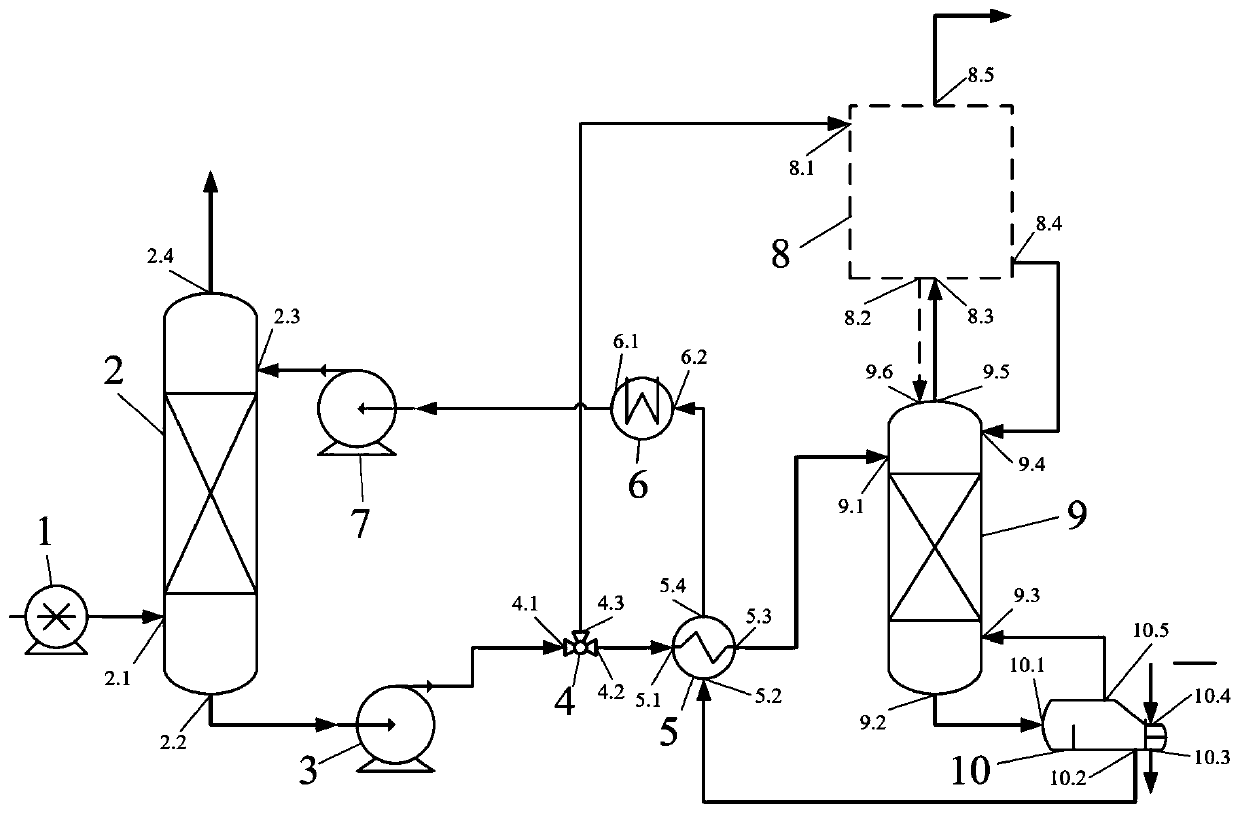

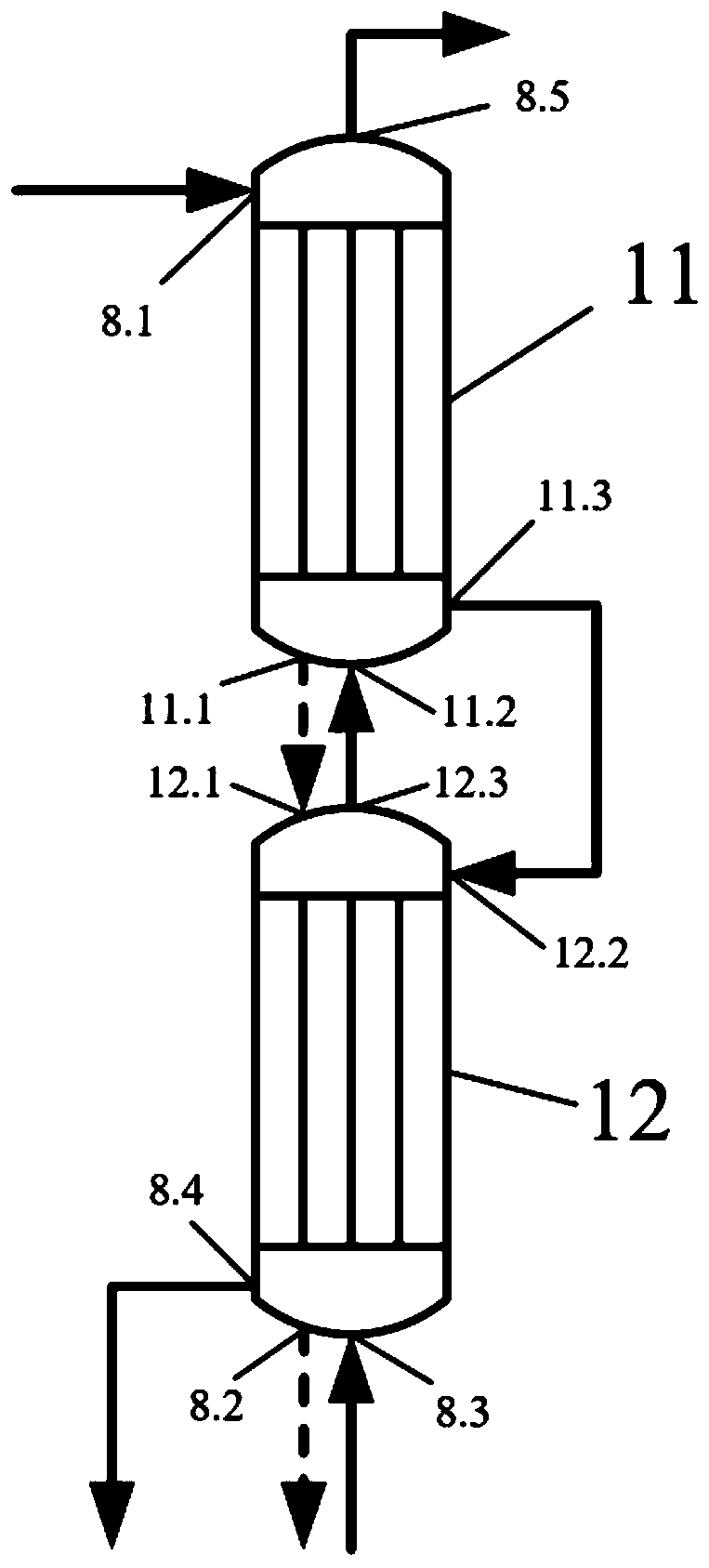

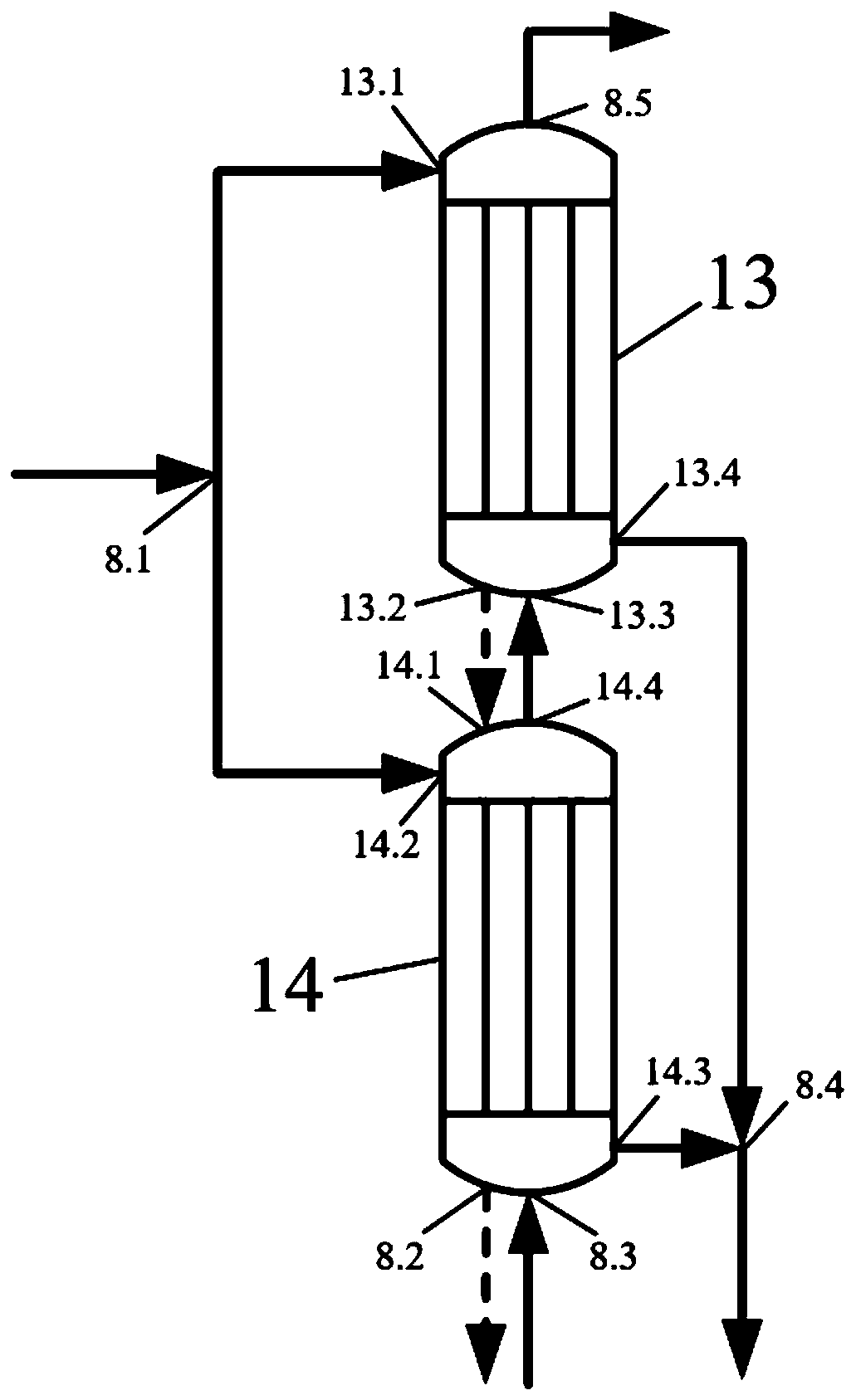

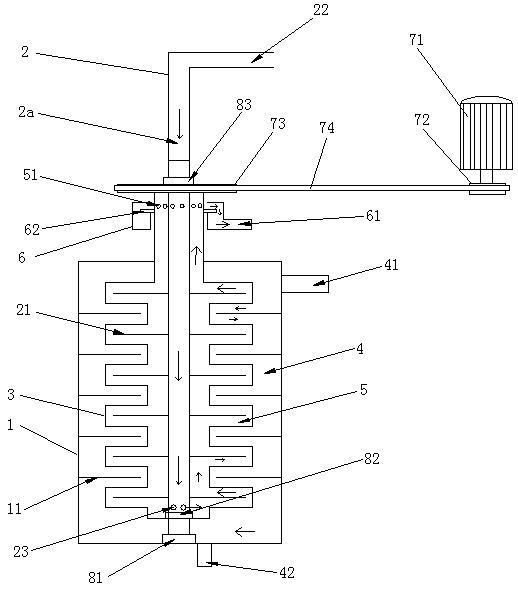

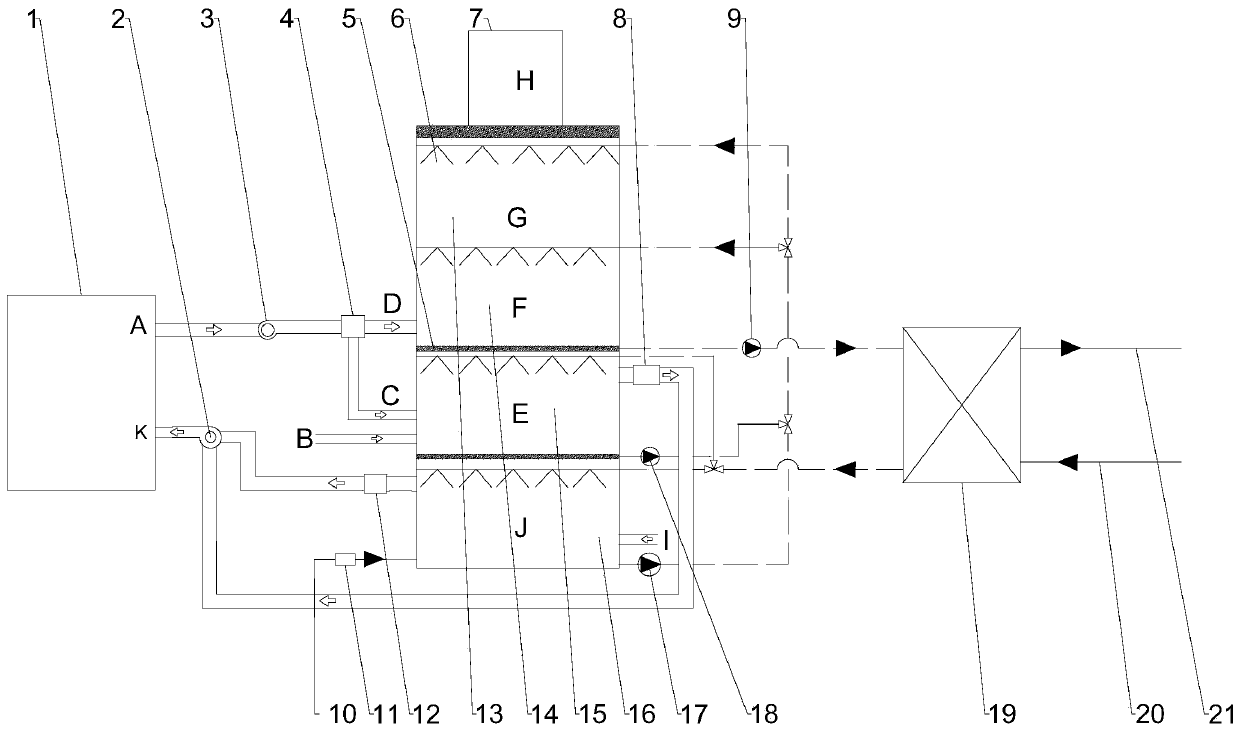

Multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and power jointly producing system

InactiveCN102519069AIncrease heating rateImprove energy efficiencyHeat recovery systemsLighting and heating apparatusWhole bodyCogeneration

The invention relates to a multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and electrical jointly producing system, belonging to the field of exhaust steam waste heat recovering and heat and power joint producing. The system comprises a steam turbine, a multi-effect cascade jet heat pump, a heating network last-stage heater, a low-pressure steam-water heater, a high-temperature heating network heater, a steam condenser, a power generator and a condensate pump. The multi-effect cascade jet heat pump comprises a cascade first-stage mixing section, a cascade first-stage throat part, a cascade first-stage diffusing section, a cascade last-stage diffusing section, and a cascade last-stage distributor which are connected into a whole body in sequence, wherein the cascade first-stage mixing section is provided with a cascade first-stage jet opening. The system adopts the multi-effect cascade workflow, thereby the irreversible loss of the jet heat pump is greatly reduced, a large proportion of the exhaust steam is mixed with the medium-pressure extraction steam used as the driving steam, and the pressure is increased greatly. The primary heating network returns water, the technical problems of recovering the exhaust steam waste heat efficiently by adopting the jet heat pump and supplying heat by using the recovered exhaust steam waste heat are solved, and the waste heat recovering capacity is improved by several times.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

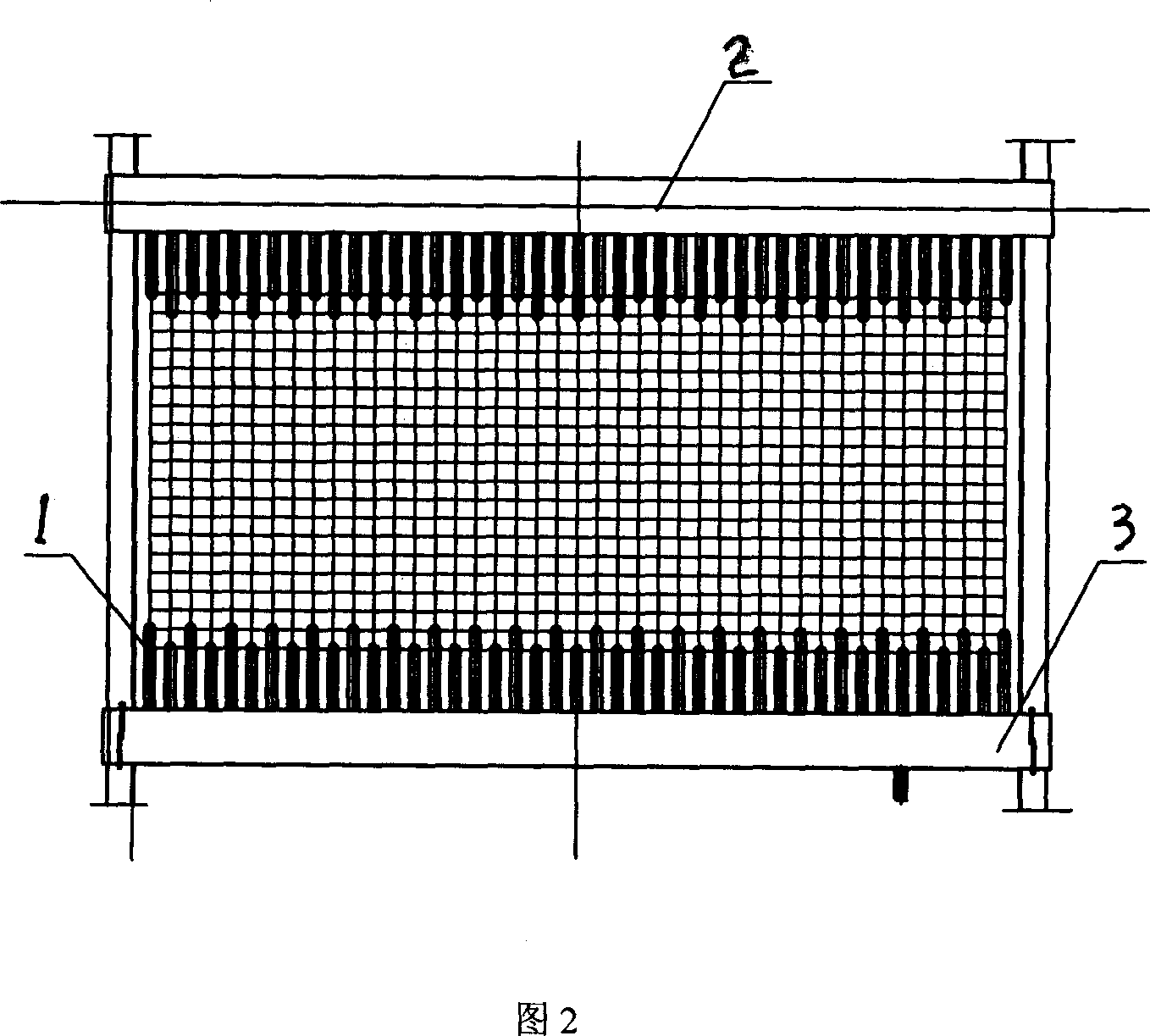

Low-pressure coal saver for boiler

InactiveCN1920387AMuch layoutEfficient recyclingCombustion processIndirect carbon-dioxide mitigationAir preheaterPower station

The invention relates to a left-heat recycle energy-saving device of boiler, wherein the low-pressure coal saver is mounted at the tail smoke channel at the outlet of air preheater, which is formed by tube beam, inlet couple bank, and outlet couple bank; the tube beam uses fin improved tube structure; the surfaces of base tube and fin are modified. The invention uses the condensed water inside the low-pressure recycle heating system to switch between high and low temperatures, while the outlet water is leaded into oxygen remover. The invention can reduce the smoke temperature and improve the cycle heat efficiency, with corrosion resistance.

Owner:SHANDONG UNIV

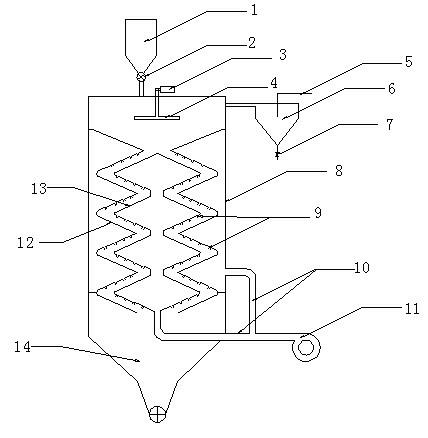

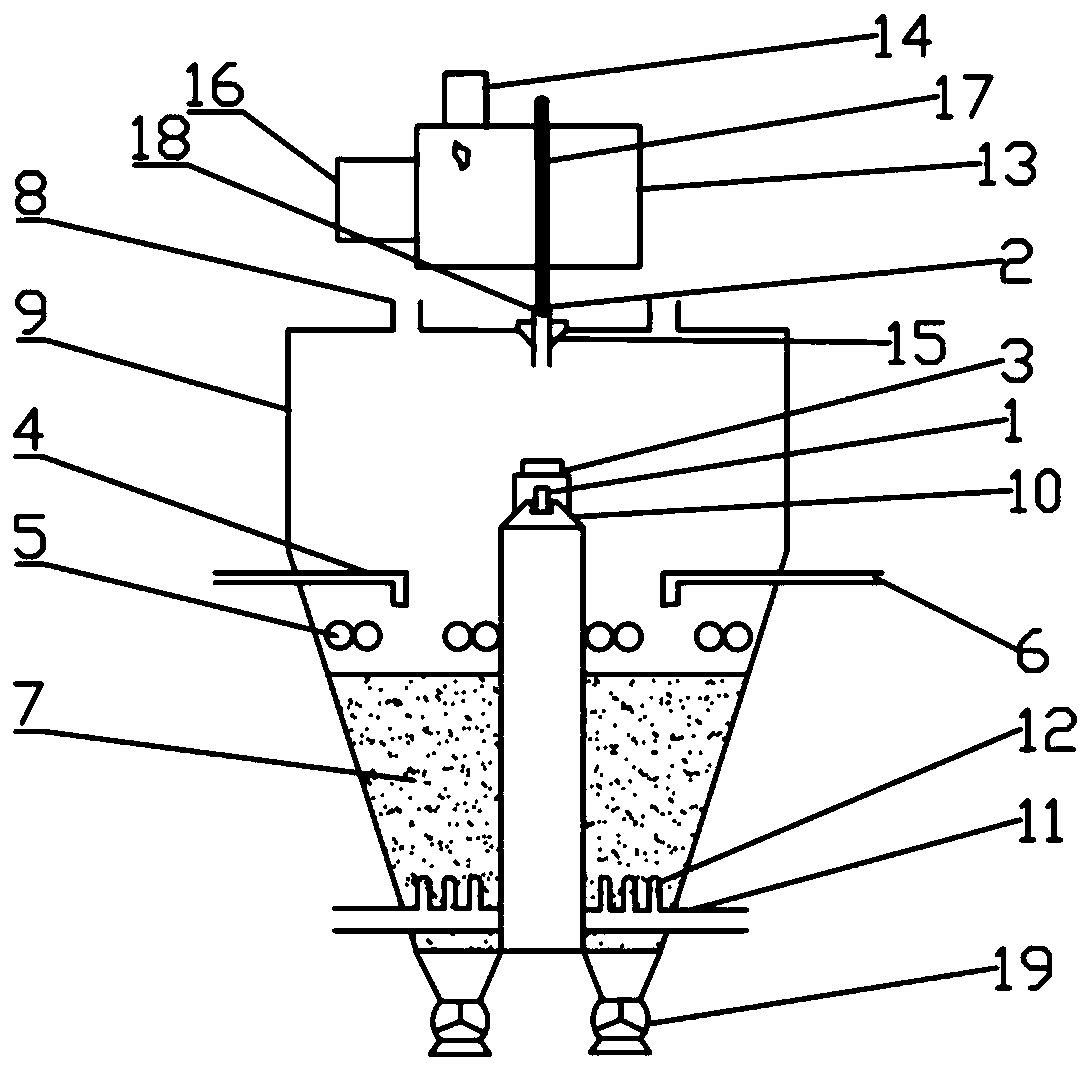

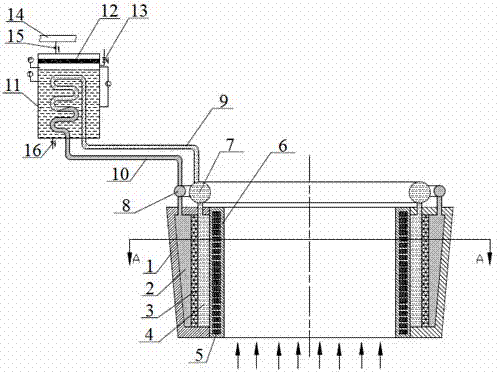

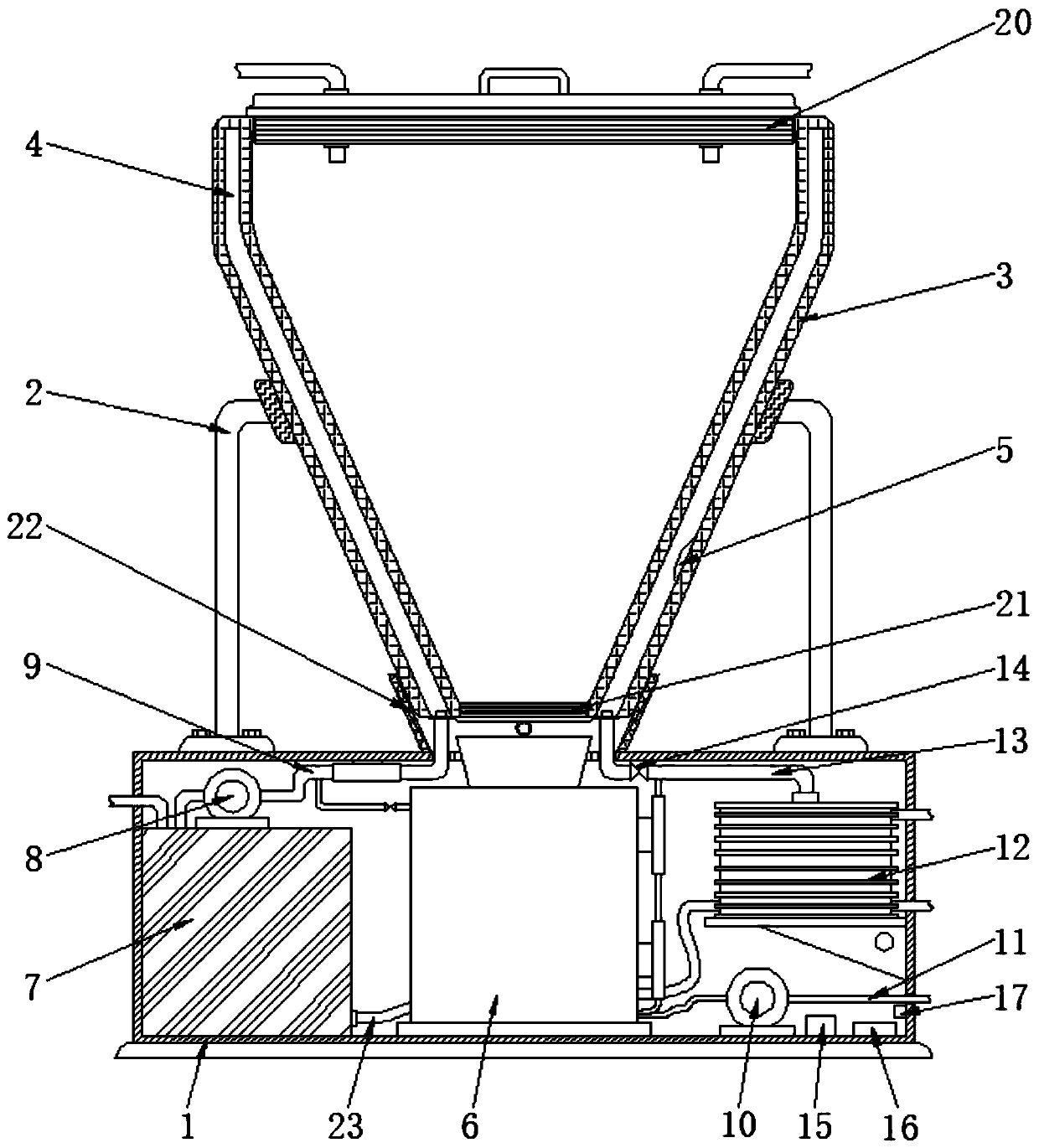

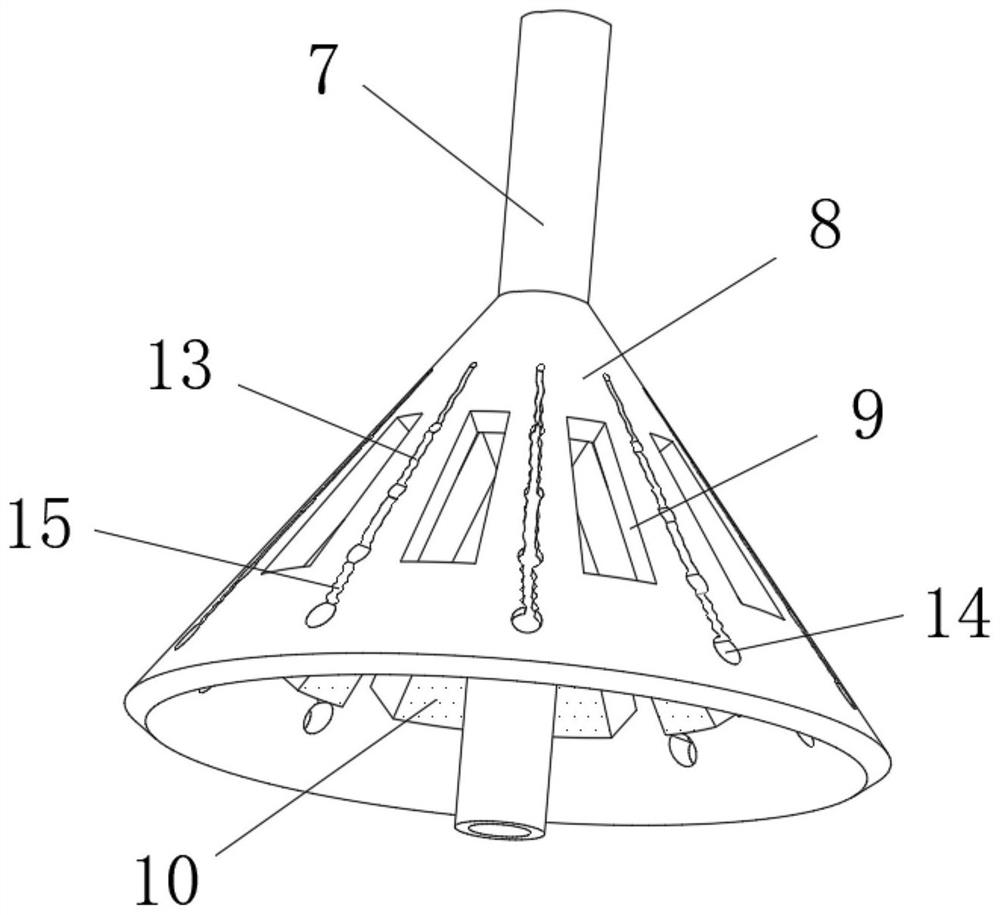

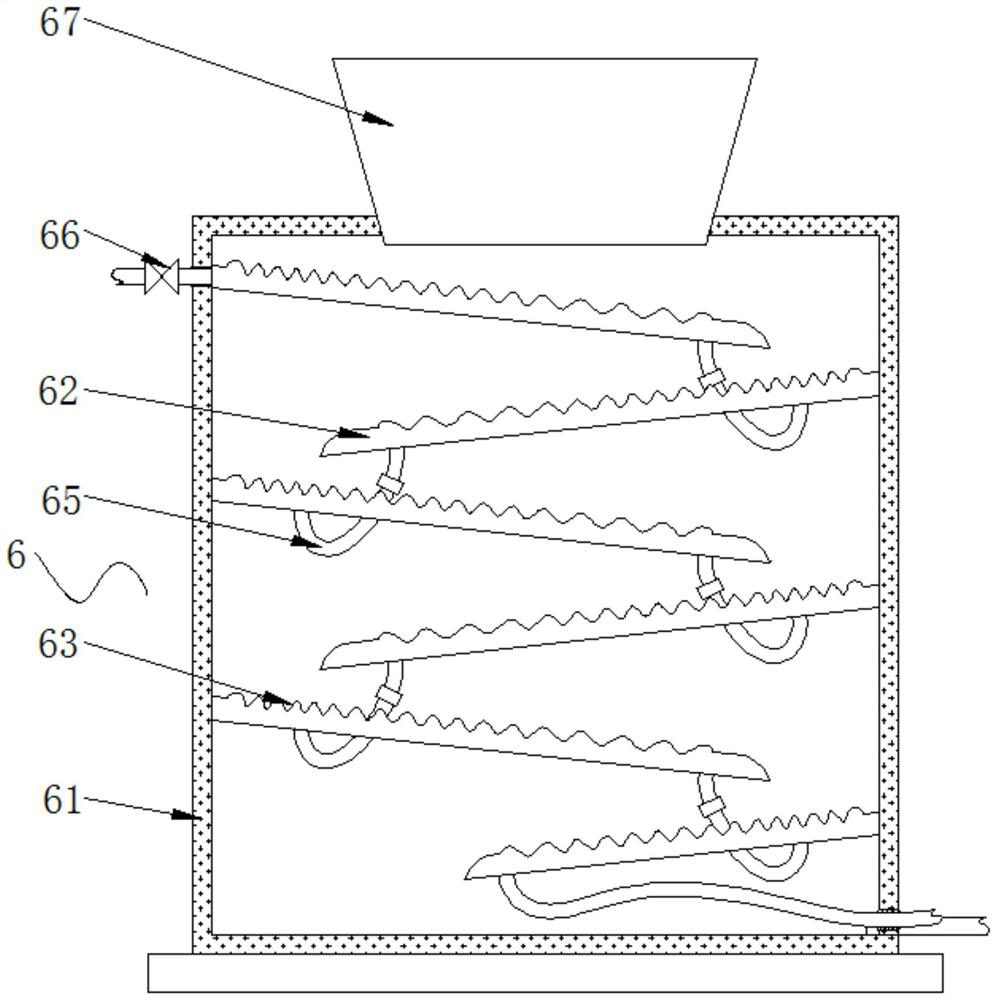

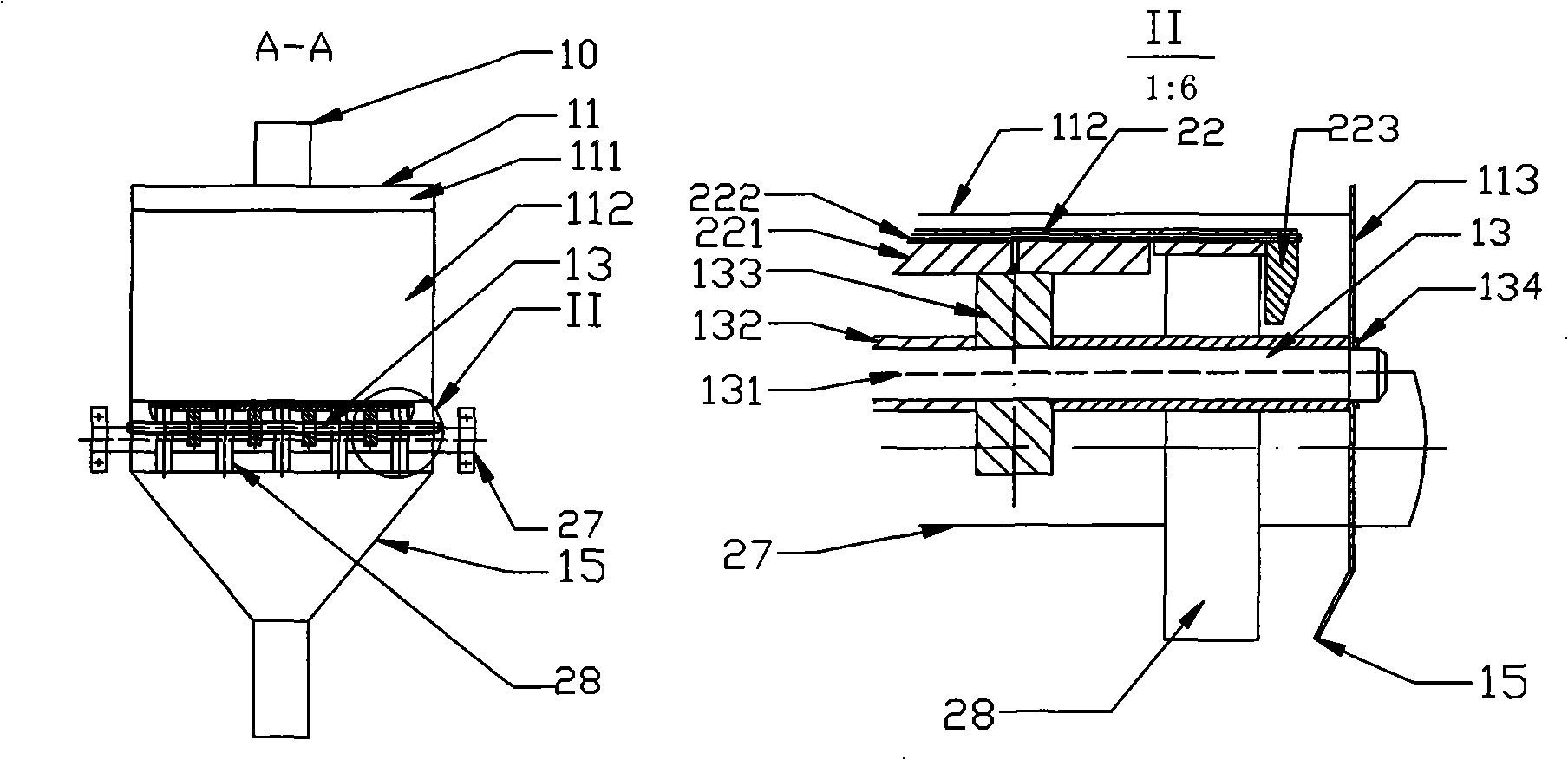

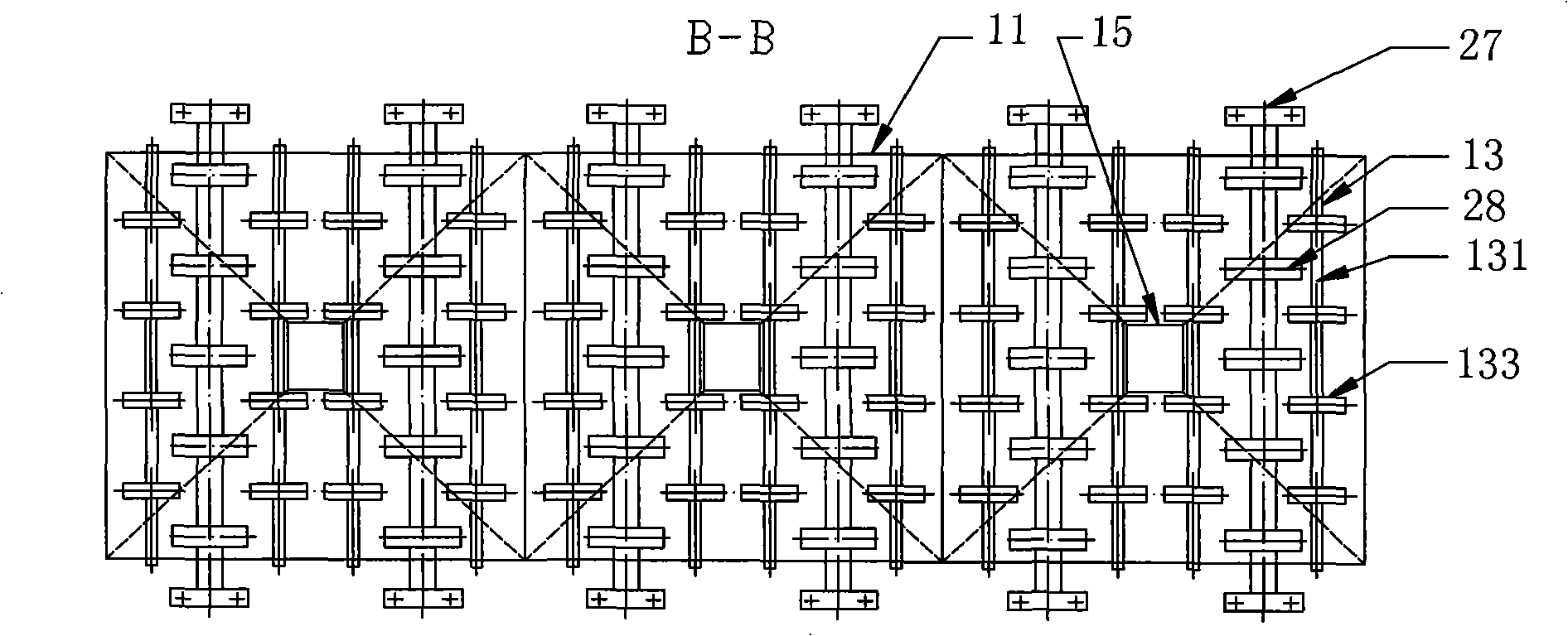

A tower structure high temperature material waste heat recovery device

InactiveCN102278894AIncrease capacityImprove cooling effectDirect contact heat exchangersEngineeringConical surface

The invention discloses a high-temperature material waste heat recovery device with a tower structure, which comprises a vertical cylinder body, a material storage bin, a dust removal device, a wind tower, a material retaining device, a material distribution device, and a hopper. The high-temperature material enters the inside of the vertical cylinder from the feed port, and flows through the gap between the wind tower and the material blocking device. The wind tower is a tower structure with cooling air in the middle, and ventilation holes are opened on the conical surface of the retaining device and the inverted conical surface of the wind tower. This structure can greatly increase the contact area between high-temperature materials and cooling air, and improve the cooling and waste heat recovery effect. After dust removal, the hot air can be transported to the place where it is needed for reuse, thereby realizing the cooling of hot materials and the recovery of waste heat. Reduced production costs.

Owner:SHENGHUO TECH HENAN +1

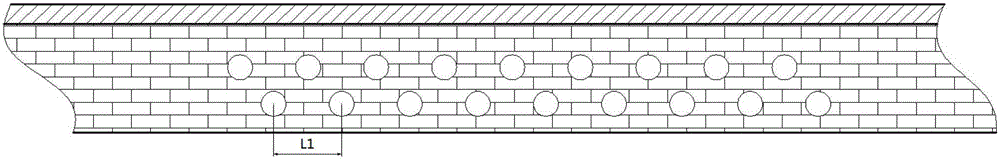

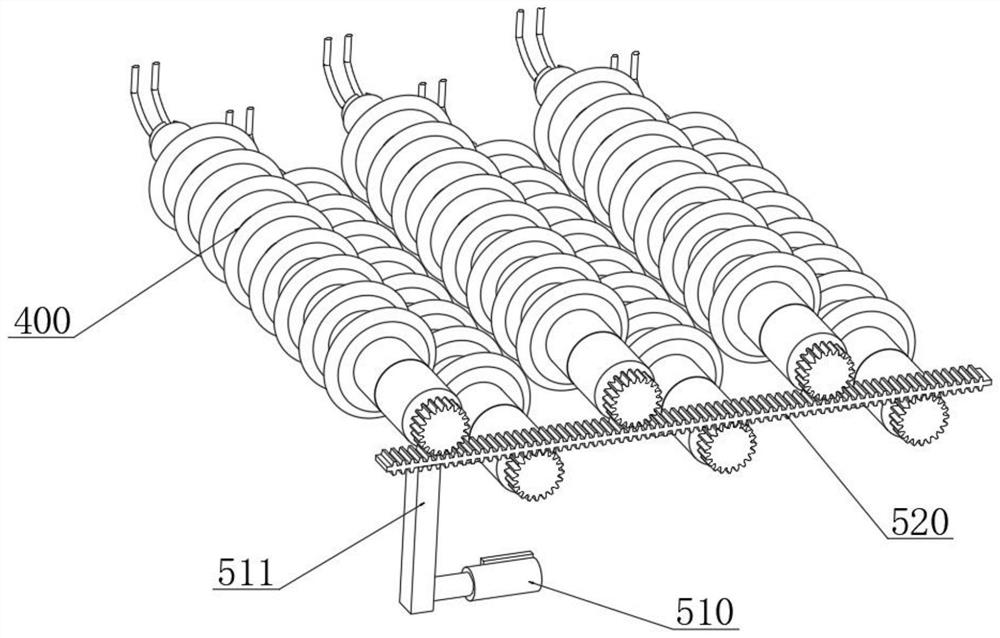

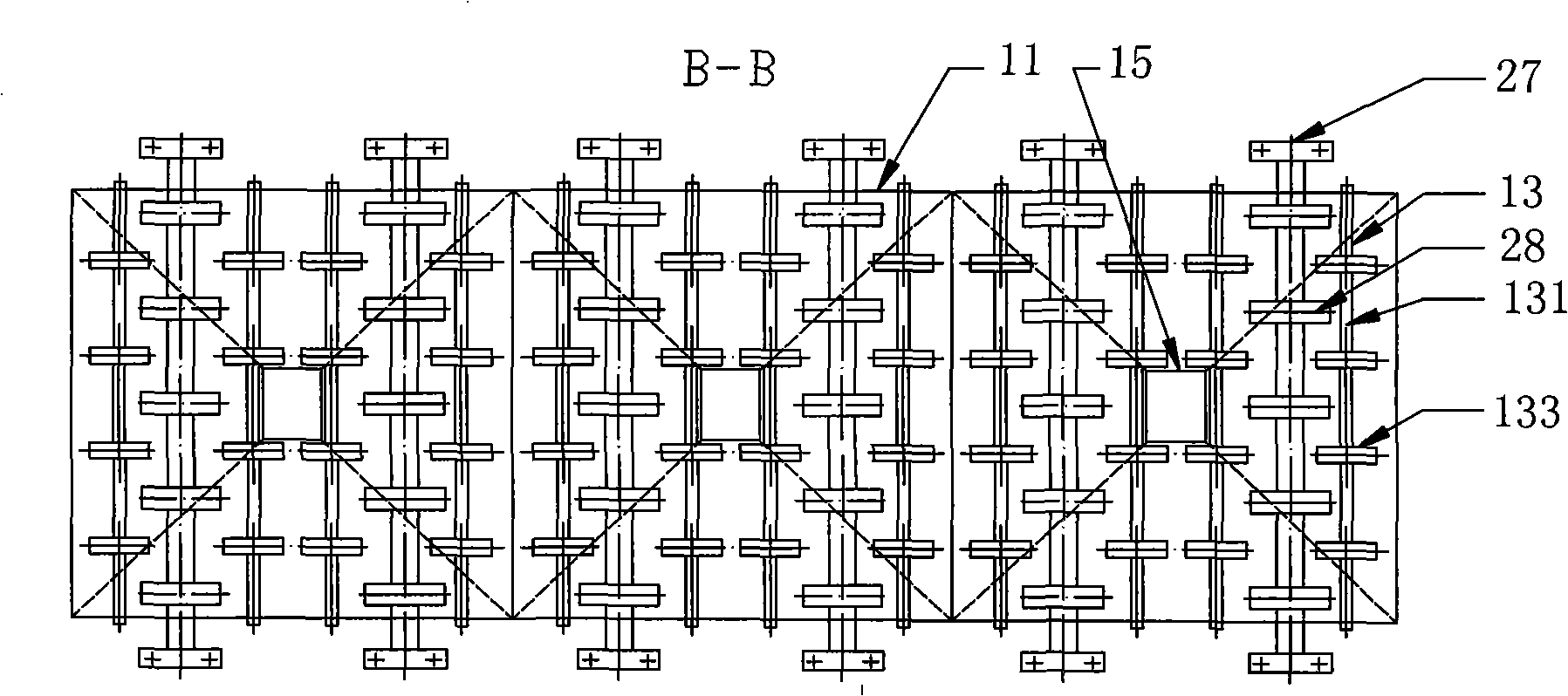

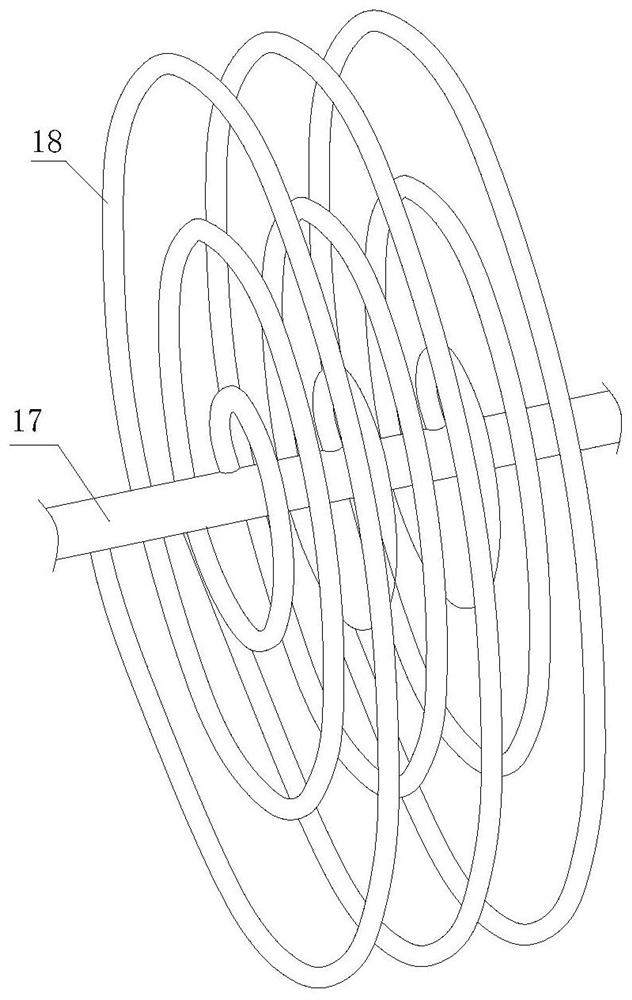

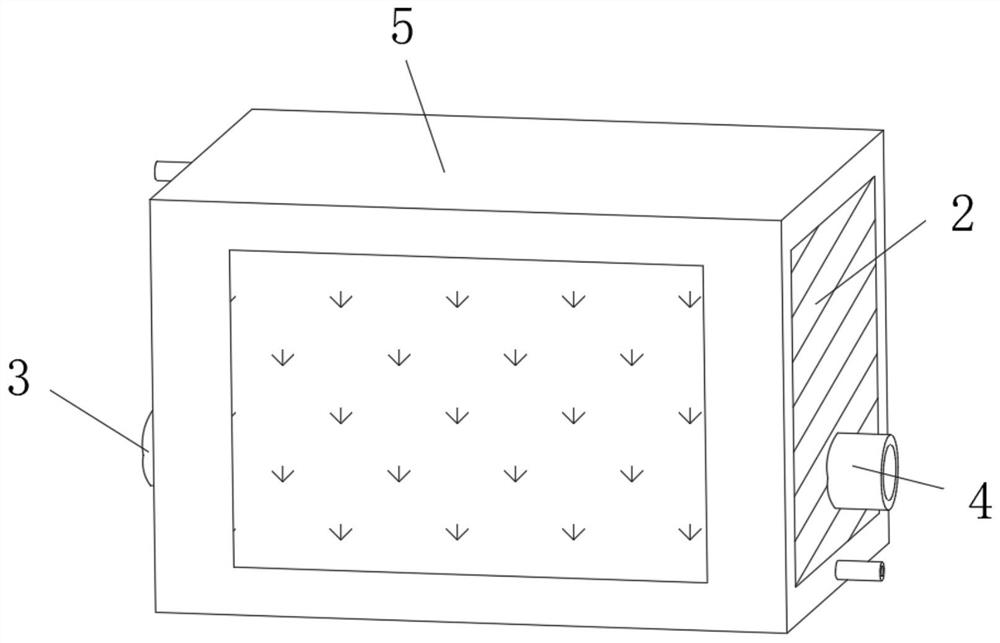

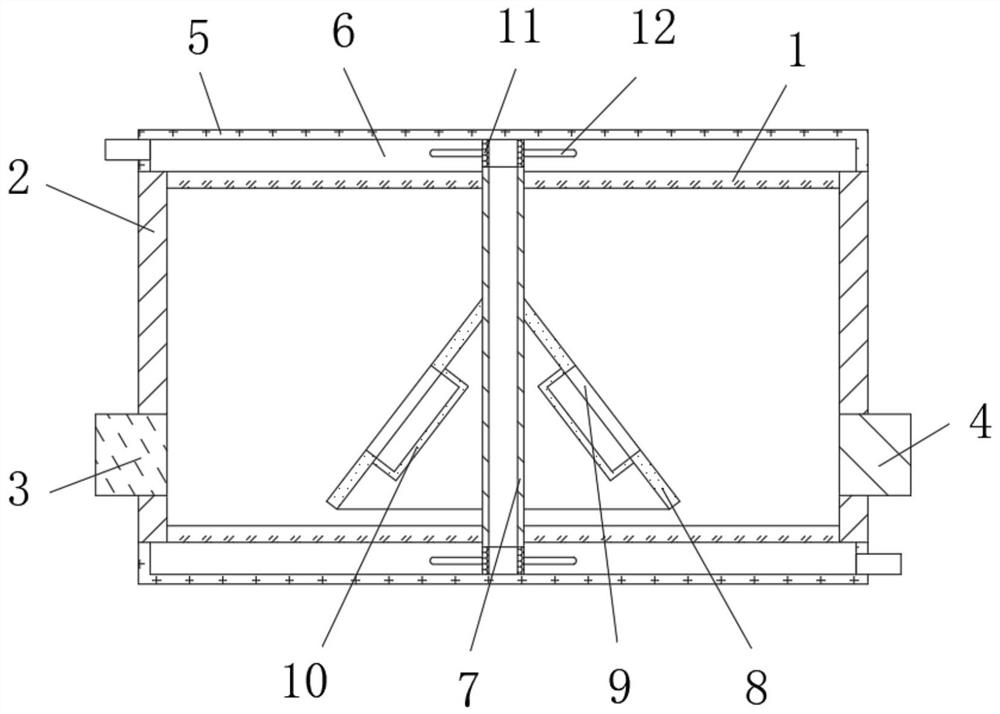

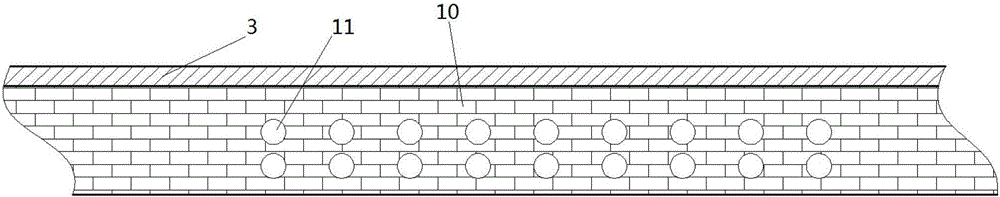

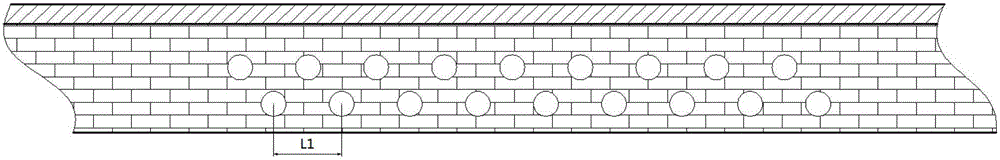

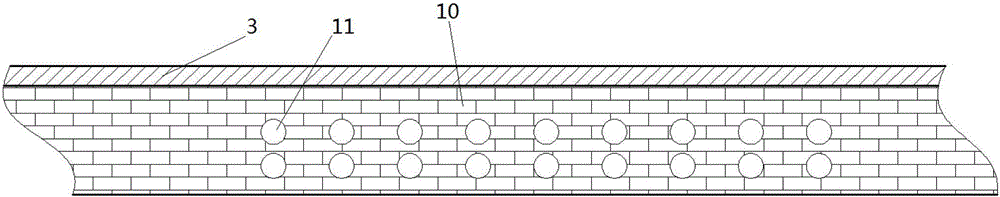

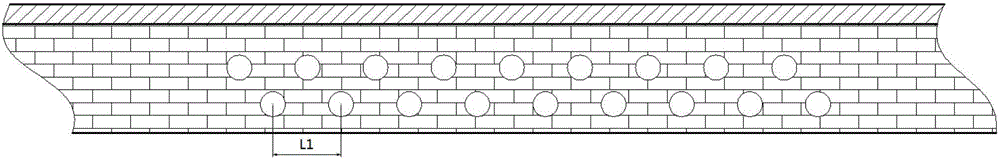

Waste heat recycling system with variable spacing between heat pipes

ActiveCN105758200AImprove waste heat utilization efficiencyReduce energy consumptionEnergy industryIncreasing energy efficiencyEngineeringHeat energy

The invention provides a heat pipe waste heat recycling system. The heat pipe waste heat recycling system comprises a heating device and heat pipes, wherein the heating device comprises a clinker passage, the heat pipes absorb heat energy in the clinker passage, and the spacing between every two adjacent heat pipes is gradually increased along the transportation direction of the clinker in the clinker passage. By utilizing the variable spacing between the heat pipes, the waste heat utilization efficiency can be greatly increased.

Owner:SHANDONG UNIV

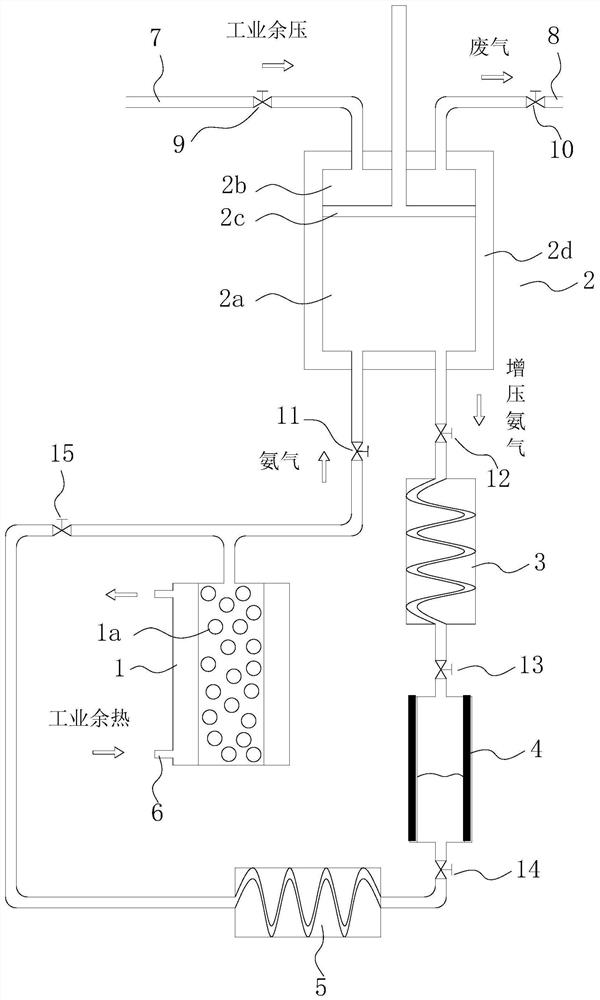

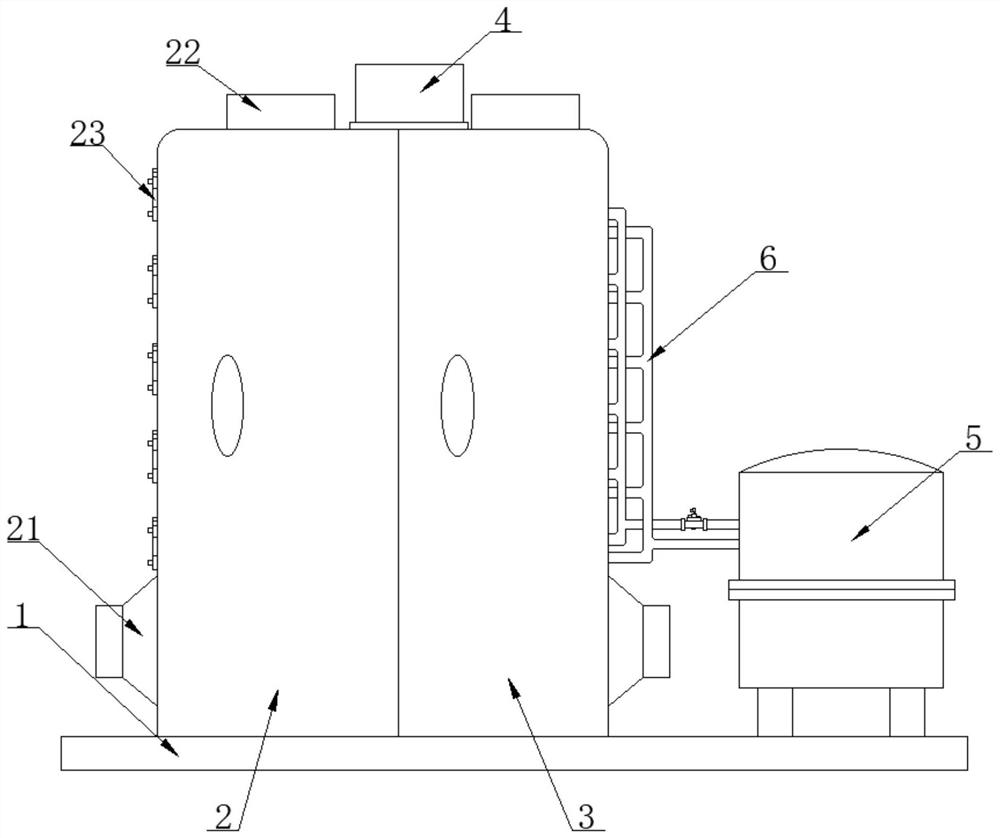

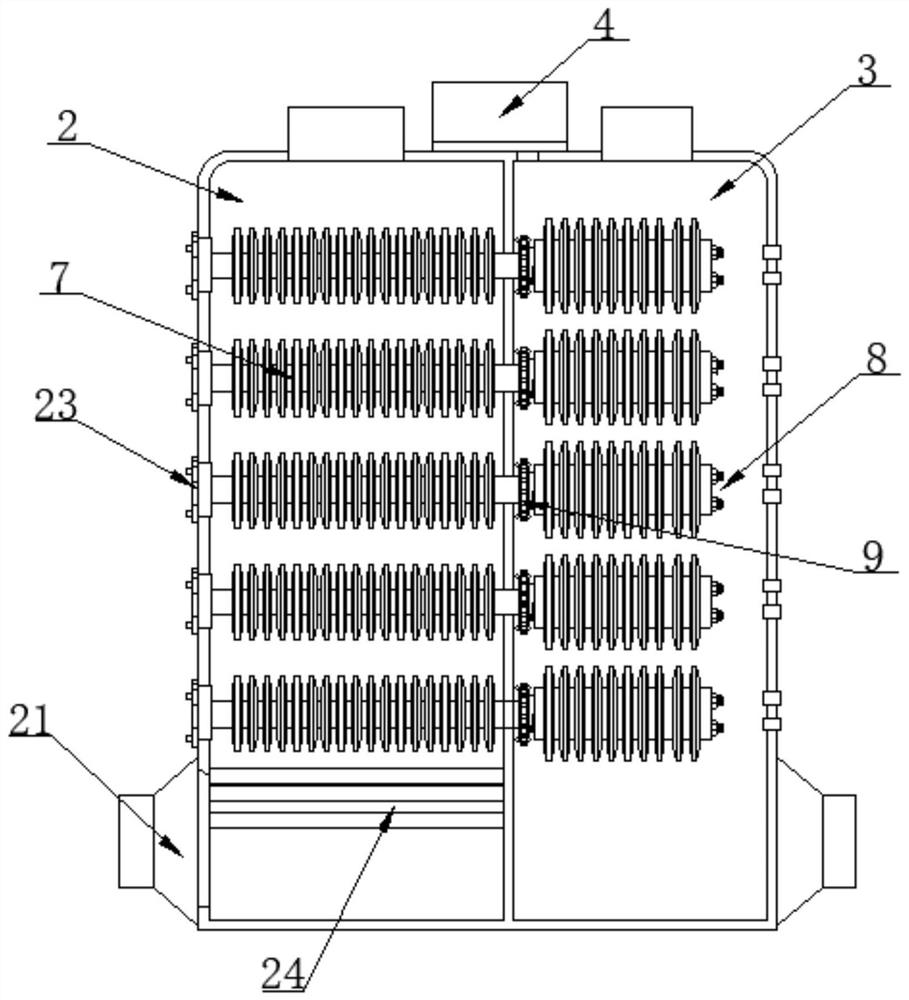

Industrial waste heat and residual pressure comprehensive recovery system

ActiveCN112833580AImproved heat and mass transfer propertiesImprove work efficiency and waste heat recovery efficiencyAbsorbers/adsorbersSustainable buildingsIndustrial wasteProcess engineering

The invention discloses an industrial waste heat and residual pressure comprehensive recovery system. The system comprises an adsorption type refrigeration assembly and an adsorbate supercharger which are connected through a pipeline to form an adsorbate circulation loop, the adsorption type refrigeration assembly is connected with a waste heat guide pipe, the waste heat guide pipe is used for desorbing a working medium pair of the adsorption type refrigeration assembly, the adsorbate enters the adsorbate supercharger, and the adsorbate supercharger is driven to work by the industrial residual pressure, so that the gaseous adsorbate in the adsorbate supercharger is compressed and then returns to the adsorption type refrigeration assembly. The system has the beneficial effects that (1), waste heat and residual pressure can be comprehensively recycled at the same time, (2), the restriction of adsorbate desorption capacity and rate of an adsorption bed in a traditional solid chemical adsorption type refrigeration / energy storage system by the ambient temperature of a condenser is relieved, the working efficiency and the waste heat recovery efficiency are improved, and (3), moreover, the system is simple in structure, low in investment cost, flexible in installation, easy in process transformation and convenient to operate.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

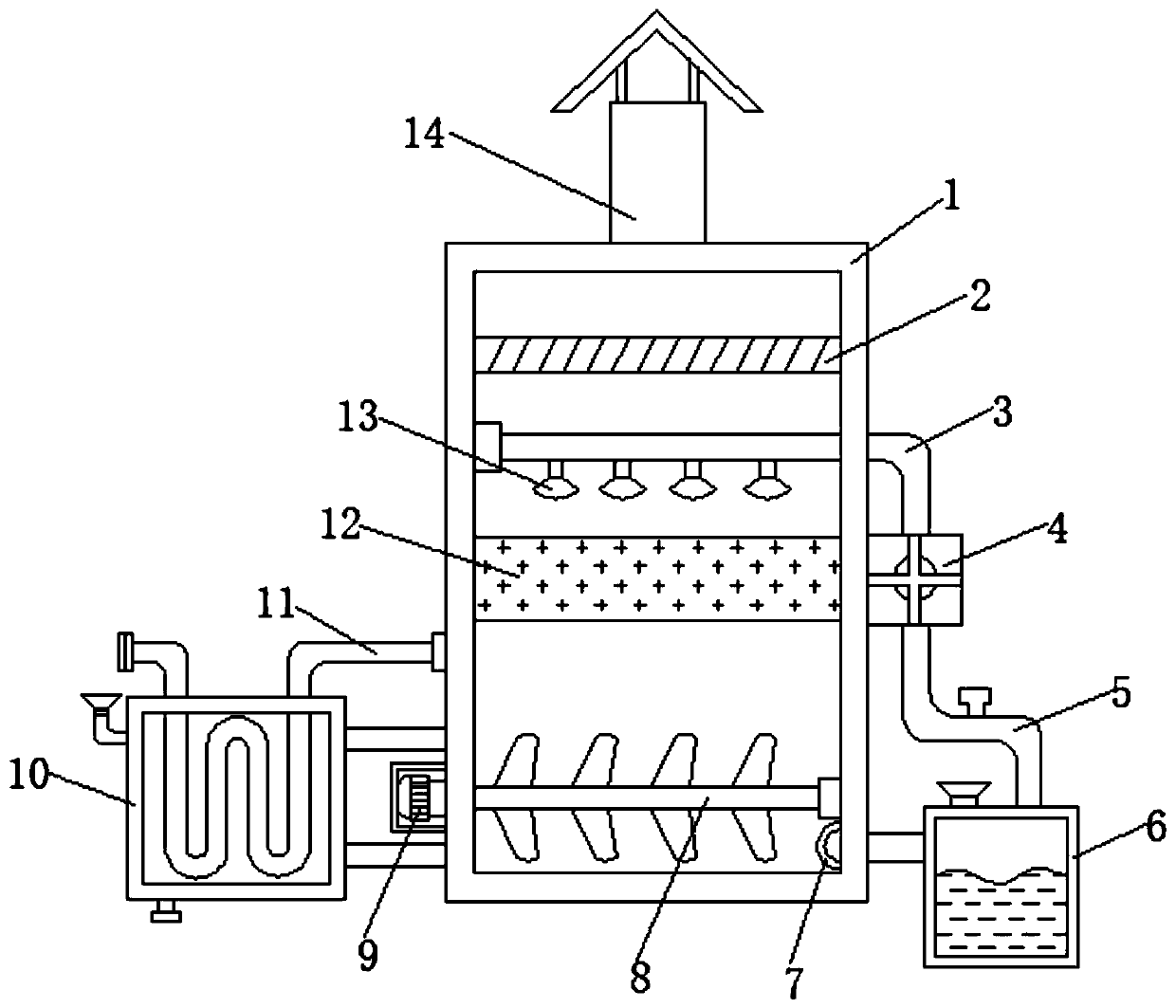

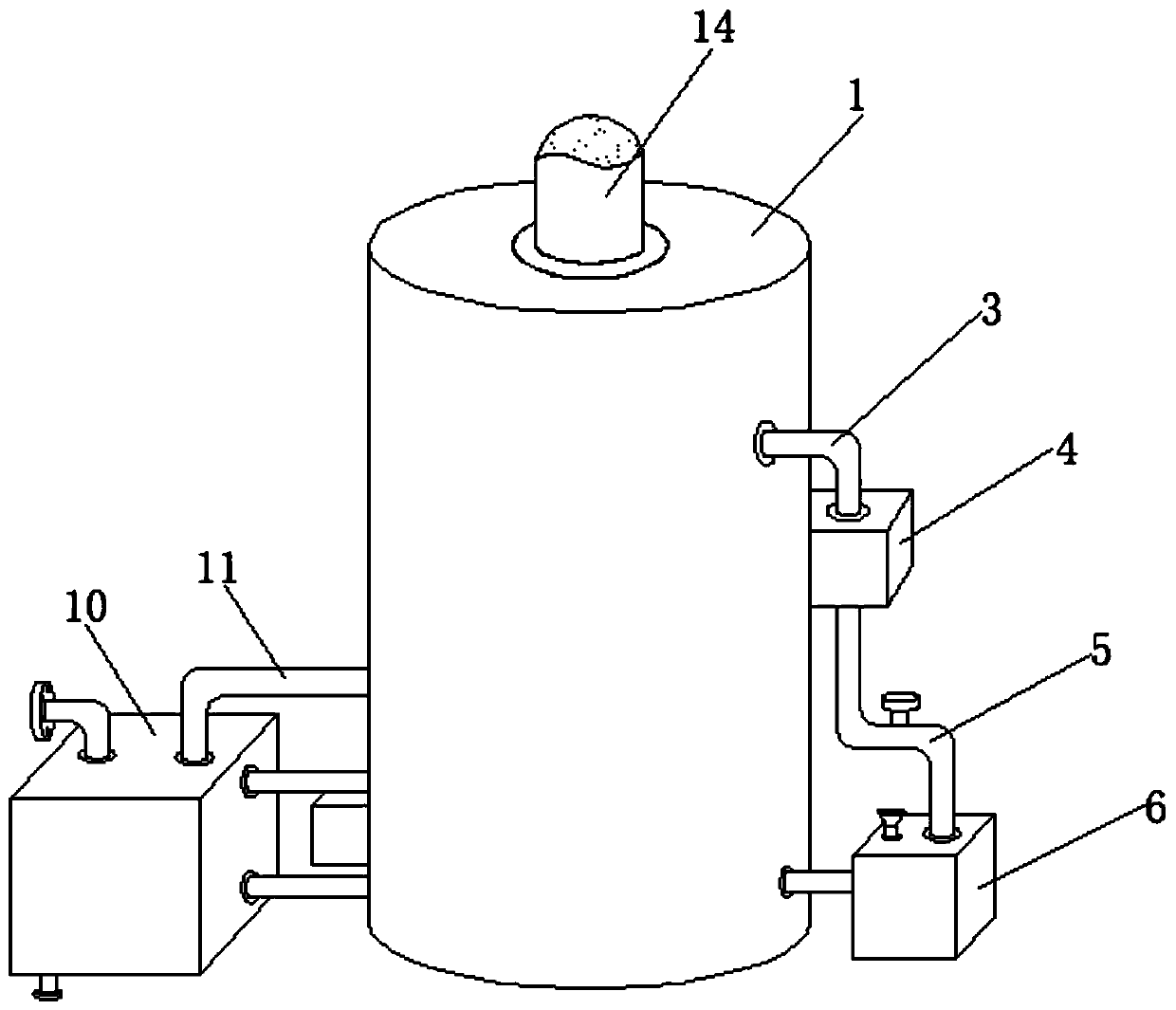

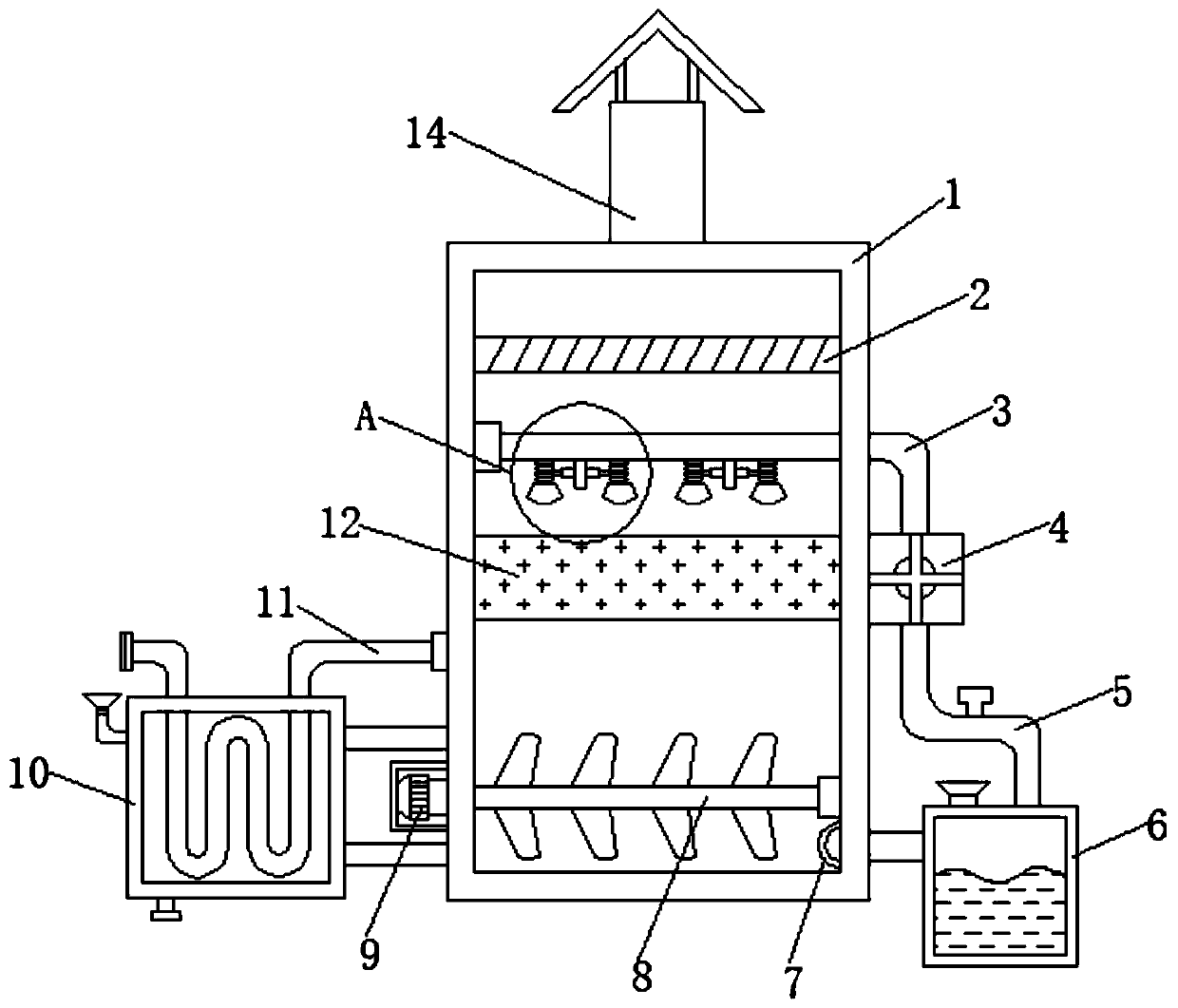

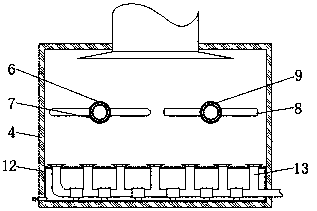

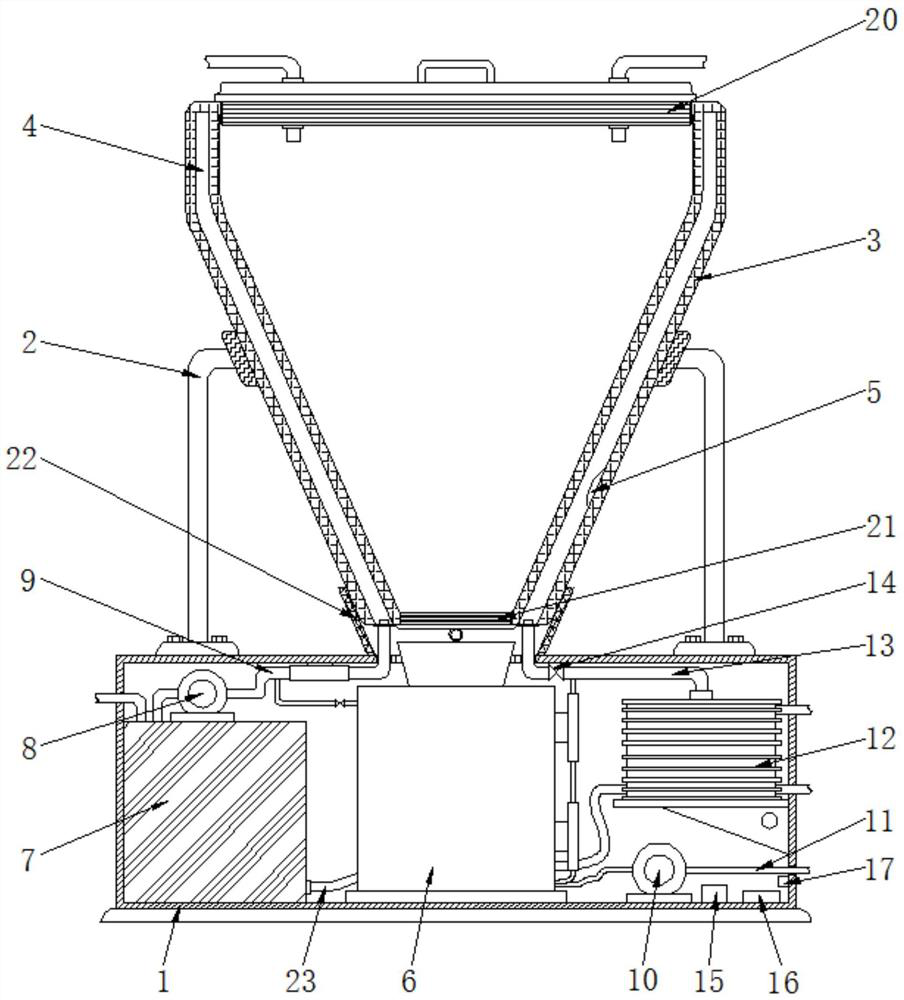

Thermal power plant combined type heat pipe smoke residual heat recycling device

ActiveCN111981880AAchieve temperature controlPrecise temperature controlCorrosion preventionIndirect heat exchangersProcess engineeringThermal recovery

The invention discloses a thermal power plant combined type heat pipe smoke residual heat recycling device and particularly relates to the field of residual heat recycling. The thermal power plant combined type heat pipe smoke residual heat recycling device comprises an installation seat, a smoke discharging bin and a residual heat recycling bin, wherein the top face of the installation seat is fixedly provided with a heat exchange water box, the smoke discharging bin and the residual heat recycling bin are fitted to each other on one side and are internally provided with combined type heat pipes in a running through manner, the surfaces of the combined type heat pipes are rotatably connected with screw thread driving sleeves located inside the smoke discharging bin in a sleeved manner, and the surfaces of the screw thread driving sleeves are movably connected with heat exchange pipe sleeve components in a sleeved manner. The thermal power plant combined type heat pipe smoke residual heat recycling device is provided with novel combined type heat pipe structures, the heat conduction fluid flow volume inside the heat exchange pipe sleeve components is actively changed by utilizing amechanical control component, and the bare lengths of the heat pipe ends inside the residual heat recycling bin are changed, heat exchange efficiency control is realized, the heat recycling airflow temperature is changed, precise temperature control is realized, use of recycled heat energy is facilitated, and the practicability of the residual heat recycling device is improved.

Owner:HUAINAN TIANJIAAN POWER GENERATION PLANT ANHUI ELECTRIC POWER CO LTD

CO2 chemical absorption system and method for reinforcing waste heat recovery of hydrophilic and hydrophobic double-membrane heat exchangers

PendingCN110170235AEnhanced total water mass transferImprove waste heat recovery efficiencyDispersed particle separationWaste heat recovery unitCo2 absorption

The invention discloses a CO2 chemical absorption system and method for reinforcing waste heat recovery of hydrophilic and hydrophobic double-membrane heat exchangers. The CO2 chemical absorption system for reinforcing waste heat recovery of the hydrophilic and hydrophobic double-membrane heat exchangers comprises CO2 absorption equipment, CO2 recovery equipment, a rich solution pump, a lean solution pump, a lean solution cooler, a diverging three way valve, a rich and lean solution heat exchanger, a booster fan and a regenerated gas waste heat recovery unit. The CO2 chemical absorption systemfor reinforcing waste heat recovery of the hydrophilic and hydrophobic double-membrane heat exchangers, disclosed by the invention, has the advantages that water vapor and liquid water can be correspondingly and effectively recovered for different working conditions by combining the hydrophilic-membrane heat exchanger and the hydrophobic-membrane heat exchanger as a heat exchanging medium betweenthe regenerated gas and a cold rich solution; convective heat exchange reinforcing from the regenerated gas to the cold rich solution is realized from two aspects of sufficiently utilizing water vapor latent heat and promoting water vapor / liquid water transfer enhancement convective heat exchange. Therefore, the waste heat recovery efficiency of the regenerated gas is greatly enhanced; moreover,multiple combination modes are also suitable for waste heat recovery demands in large-scale industrial application.

Owner:HUAZHONG AGRI UNIV

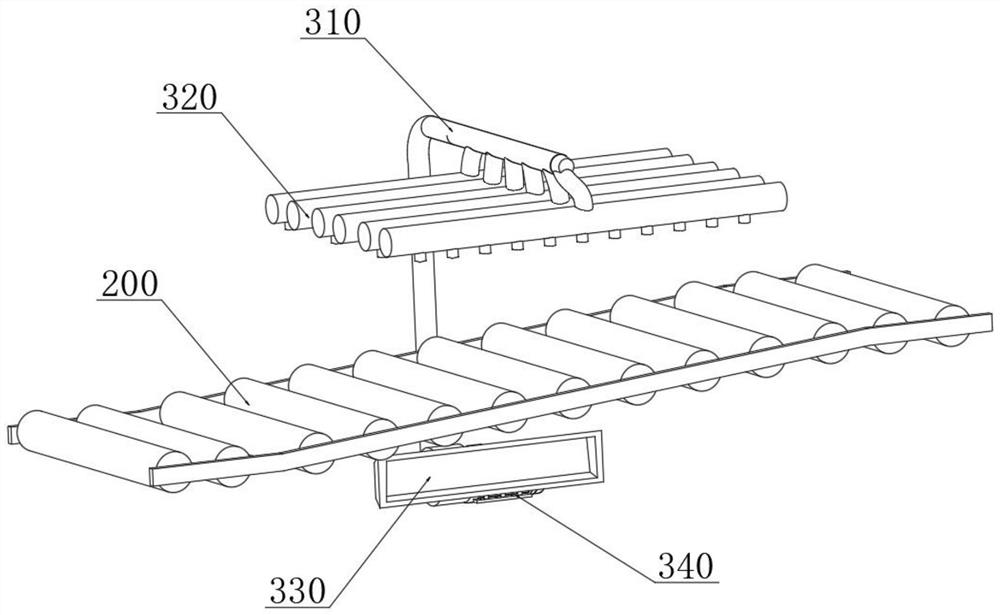

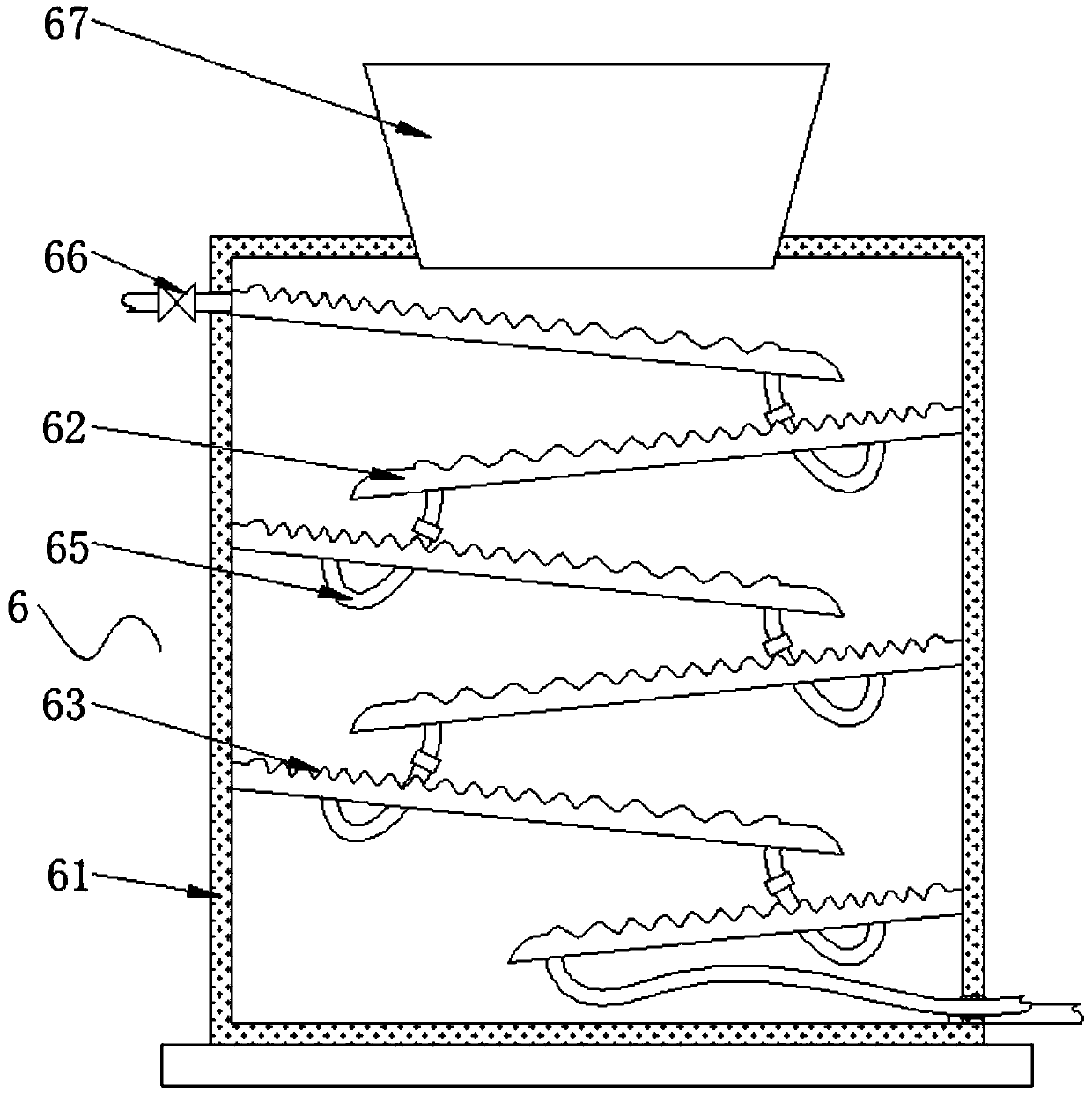

Liquid slag dry granulating and waste heat recovery device with slag wool crushing function and operation method of device

ActiveCN111020073AAvoid reunionAvoid cloggingRecycling and recovery technologiesLiquid slagReciprocating motion

The invention discloses a liquid slag dry granulating and waste heat recovery device with a slag wool crushing function and an operation method of the device. The device comprises a granulating bin, agranulating system, a slag wool crushing device and a moving bed. A temperature measuring device and a slag falling pipe are arranged on the top wall of the granulating bin. The granulating system isarranged in the granulating bin and comprises a rotating cup, the rotating cup is located under the slag falling pipe, and a partition wall is arranged on the lower portion of the rotating cup. A shear crusher doing reciprocating motion is arranged on the partition wall. The position of the moving bed is lower than the position of the shear crusher. The moving bed comprises a rake and a crusher.The rake and the crusher are arranged in the granulating bin, the rake can do reciprocating motion, and the position of the crusher is lower than the position of the rake. A bulk material accumulationportion is arranged at the bottom of the granulating bin. A cooling air pipeline is arranged at the bottom of the granulating bin. According to the liquid slag dry granulating and waste heat recoverydevice, slag wool generated in the granulating process can be crushed efficiently, accidents can be reduced, and the waste heat recovery rate can be improved.

Owner:XI AN JIAOTONG UNIV

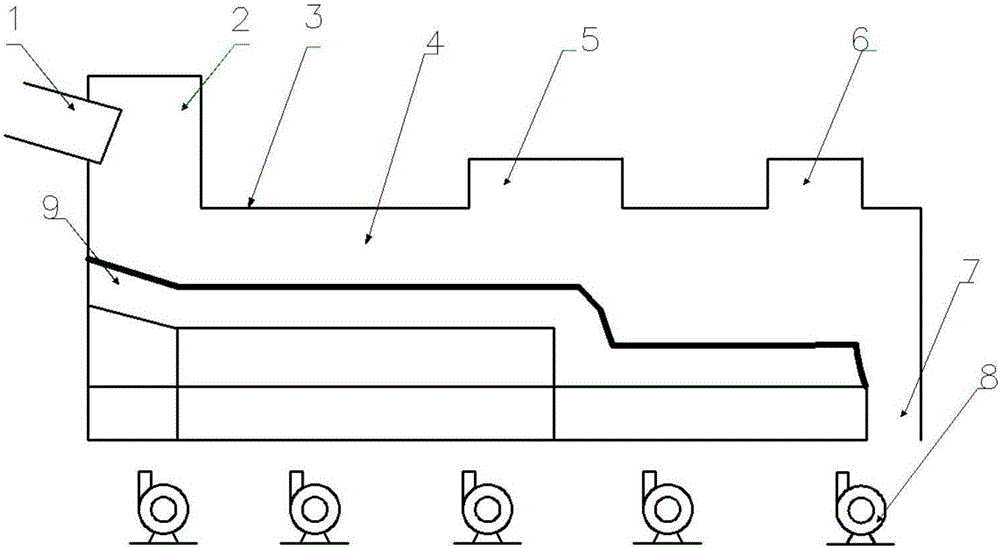

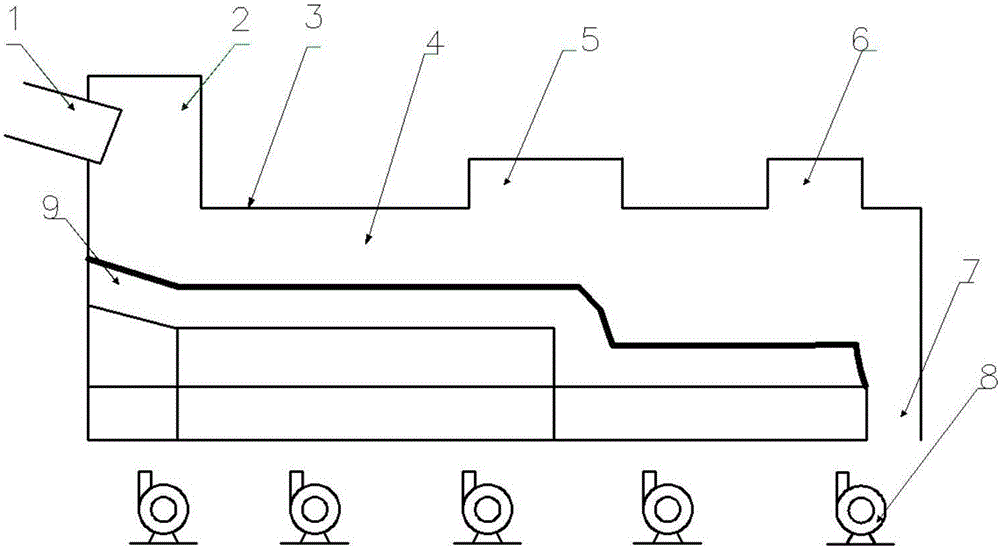

Energy-saving method for boiler waste heat recovery

ActiveCN106765259AImprove waste heat recovery effectEasy to useLighting and heating apparatusCombustion technology mitigationWaste heat recovery unitEconomic benefits

The invention discloses an energy-saving method for boiler waste heat recovery. The method mainly comprises the steps that flues are separated; waste heat recovery devices are arranged, communication among the waste heat recovery devices is controlled; waste heat is utilized; and standby flues are distributed. Flow dividing is conducted on a boiler flue, the boiler flue is divided into a plurality of common-used main flues and the multiple standby flues for standby application, so that the smoke and heat discharged from the boiler are divided into the multiple common-used main flues. The multiple graded waste heat recovery devices are arranged in the main flues and the standby flues to recover the heat and sequentially transfer the heat energy to grade higher waste heat recovery devices through a water medium, and the standby flues can participate in the work of waste heat recovery under the condition that the main flues cannot fully allocate the waste heat. Usage is more convenient, the applicability is stronger, the effect of waste heat recovery is better, and the economic benefit is significantly improved.

Owner:广东东热新能源技术有限公司

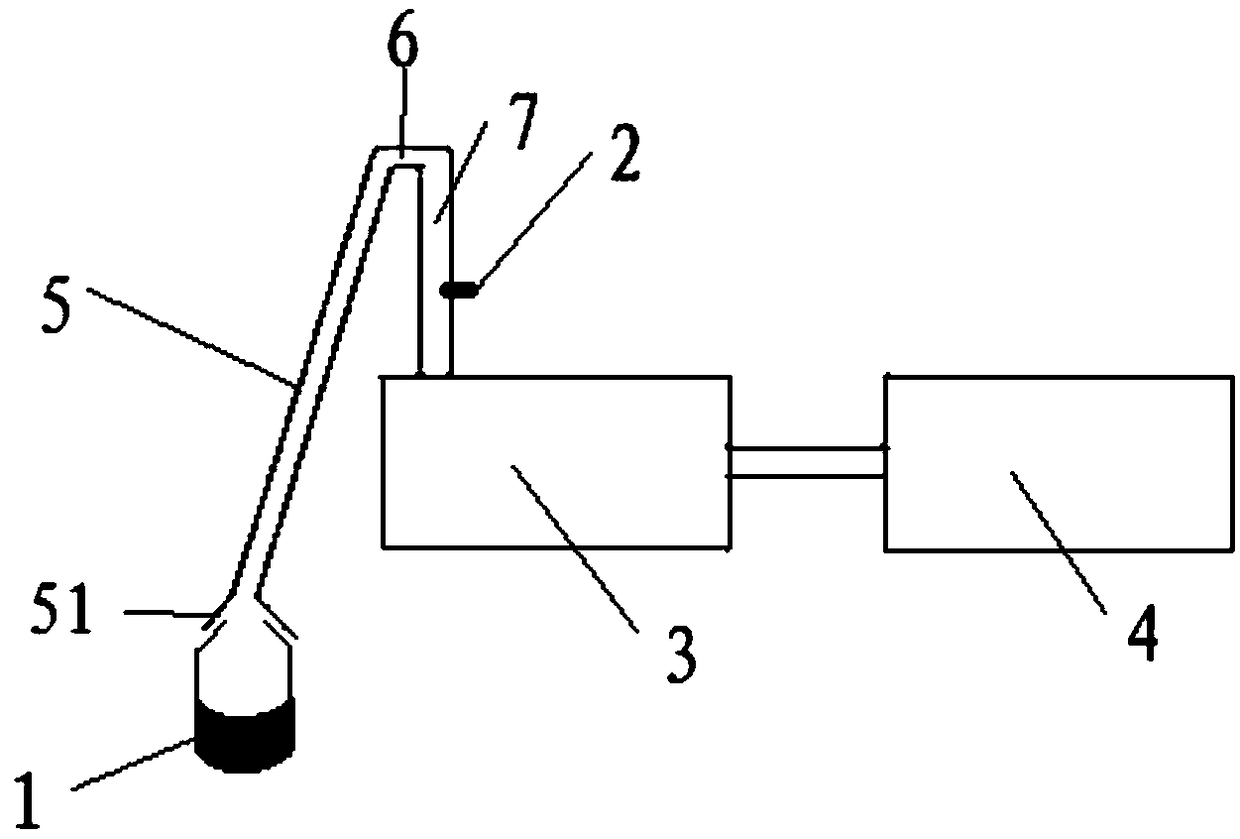

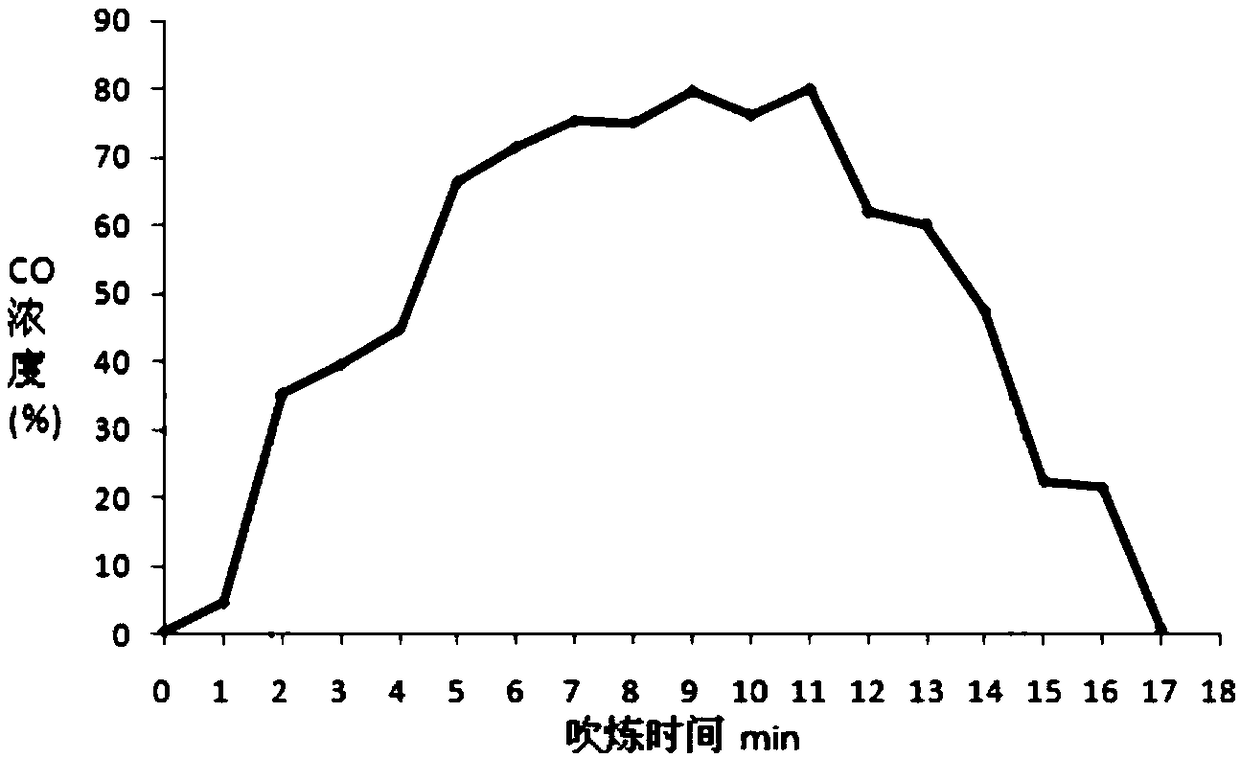

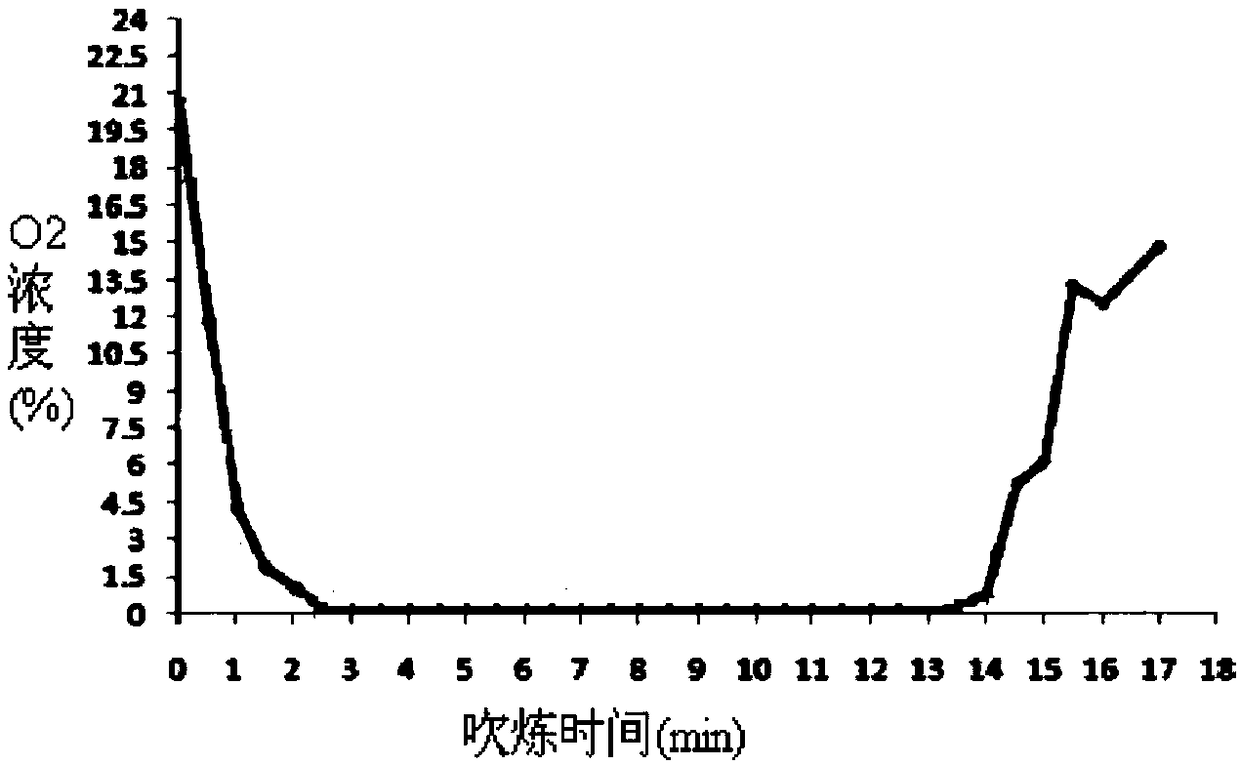

Steelmaking converter flue gas treatment device and method

InactiveCN109280735AReduce contentAvoid explosionIncreasing energy efficiencyExhaust gas handlingSteelmakingFlue gas

The invention discloses a steelmaking converter flue gas treatment device and method. The steelmaking converter flue gas treatment device comprises a converter, a flue, an ignition device, a dust removing device and a recycling device; the top of the converter is provided with a converter port; the flue is used for vaporizing and cooling flue gas generated by the converter; the ignition device isarranged on the flue wall of the flue and used for igniting the flue gas in the flue; the dust removing device is connected with an outlet of the flue and used for conducting dust removing treatment on the flue gas ignited by the ignition device; and the recycling device is used for recycling the flue gas obtained after dust removing. According to the steelmaking converter flue gas treatment device and method, the technical problem that low-temperature-section waste heat recycling of the converter flue gas is not facilitated due to the fact that CO and O2 mixed gas with a certain concentrationexists in the converter flue gas, explosion is prone to occurring, and potential safety hazards exist is solved; and the technical effects that the concentration of CO and O2 in the CO and O2 mixed gas is decreased through an ignition reaction before the CO and O2 mixed gas in the flue gas reaches an explosion temperature point, the condition that the flue gas explores in the low-temperature section is avoided, and effective recycling of the low-temperature-section waste heat of the flue gas is achieved are achieved.

Owner:SHOUGANG CORPORATION

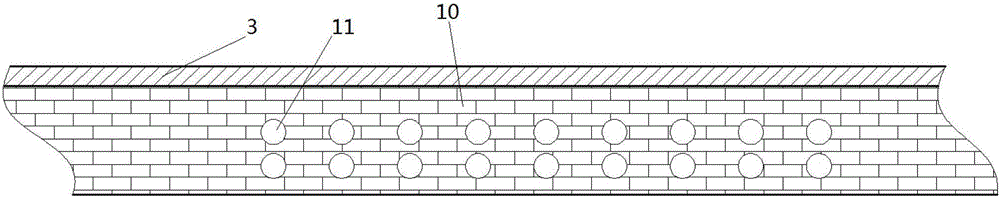

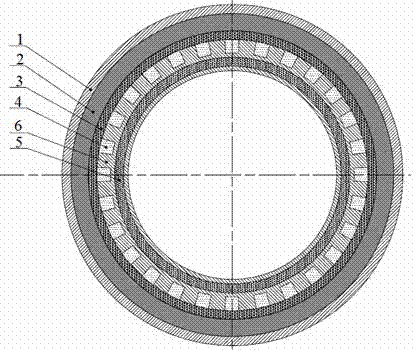

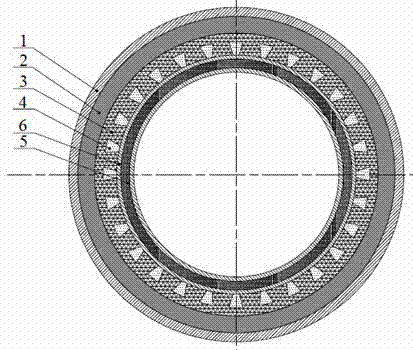

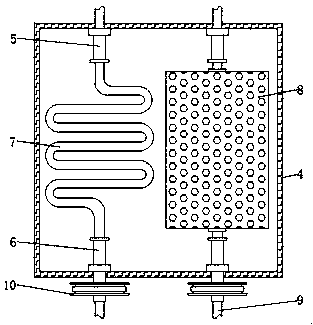

Coke oven gas waste heat recovery system

ActiveCN104845645AAvoid damageImprove waste heat recovery effectEnergy inputDistillation gas withdrawalWaste heat recovery unitProduct gas

The invention relates to a coke oven gas waste heat recovery system. The coke oven gas waste heat recovery system comprises a split-type heat pipe, the split-type heat pipe comprises an evaporator device and a condenser, the evaporator device comprises a heat absorbing surface region formed by a coke oven gas guiding pipeline, the condenser comprises a steam pocket and a condenser pipeline arranged in the steam pocket, the inlet end of the condenser pipeline is communicated with a working medium outlet of the evaporator device via a gas working medium pipeline, the outlet end of the condenser pipeline is communicated with a working medium inlet of the evaporator device via a liquid working medium pipeline, a fill cavity is arranged in the heat absorbing region, and a phase-change material layer is arranged in the heat absorbing region. The coke oven gas waste heat recovery system has the advantages that by means of reconstructing the coke oven gas guiding pipeline (an ascension pipe and a bridge pipe) into the evaporator with the split-type heat pipe, coke oven gas waste heat can be recovered by the split type heat pipe; by means of arranging the phase-change material layer in the heat absorbing region, generation of periodic heat shock to a waste heat recovery device can be avoided, and waste heat recovery and production stability are improved effectively.

Owner:WISDRI ENG & RES INC LTD

Low-temperature waste heat recycling device

InactiveCN108507395AAvoid cloggingIncrease the heat exchange areaRecuperative heat exchangersHeat recovery systemsWarm waterEngineering

The invention discloses a low-temperature waste heat recycling device. A cold water pipe is vertically arranged in an outer barrel, a rotary barrel is arranged between the outer barrel and the cold water pipe, the rotary barrel is connected with a rotary driving mechanism, the section of the side wall of the rotary barrel is of a square toothed structure, an outer partition plate is arranged on the inner wall of the outer barrel inwards in the radial direction, an inner partition plate is arranged on the outer wall of the cold water pipe outwards in the radial direction, a cold water channel is formed in the cold water pipe, the upper end of the cold water pipe is provided with a cold water inlet, the lower portion of the cold water pipe is provided with a cold water outlet hole, a waste heat water channel is formed between the outer barrel and the rotary barrel, the upper portion of the outer barrel is provided with a waste heat water inlet, the lower portion of the outer barrel is provided with a waste heat water outlet, a warm water channel is formed between the rotary barrel and the cold water pipe, the warm water channel communicates with the cold water channel through the cold water outlet hole, the upper portion of the rotary barrel is provided with a warm water outlet hole, a warm water collector is arranged outside the warm water outlet hole, and the warm water collector is provided with a warm water outlet. The low-temperature waste heat recycling device has the advantages of being simple in structure, low in manufacturing cost and high in heat exchange efficiency.

Owner:宁波金名片能源科技有限公司

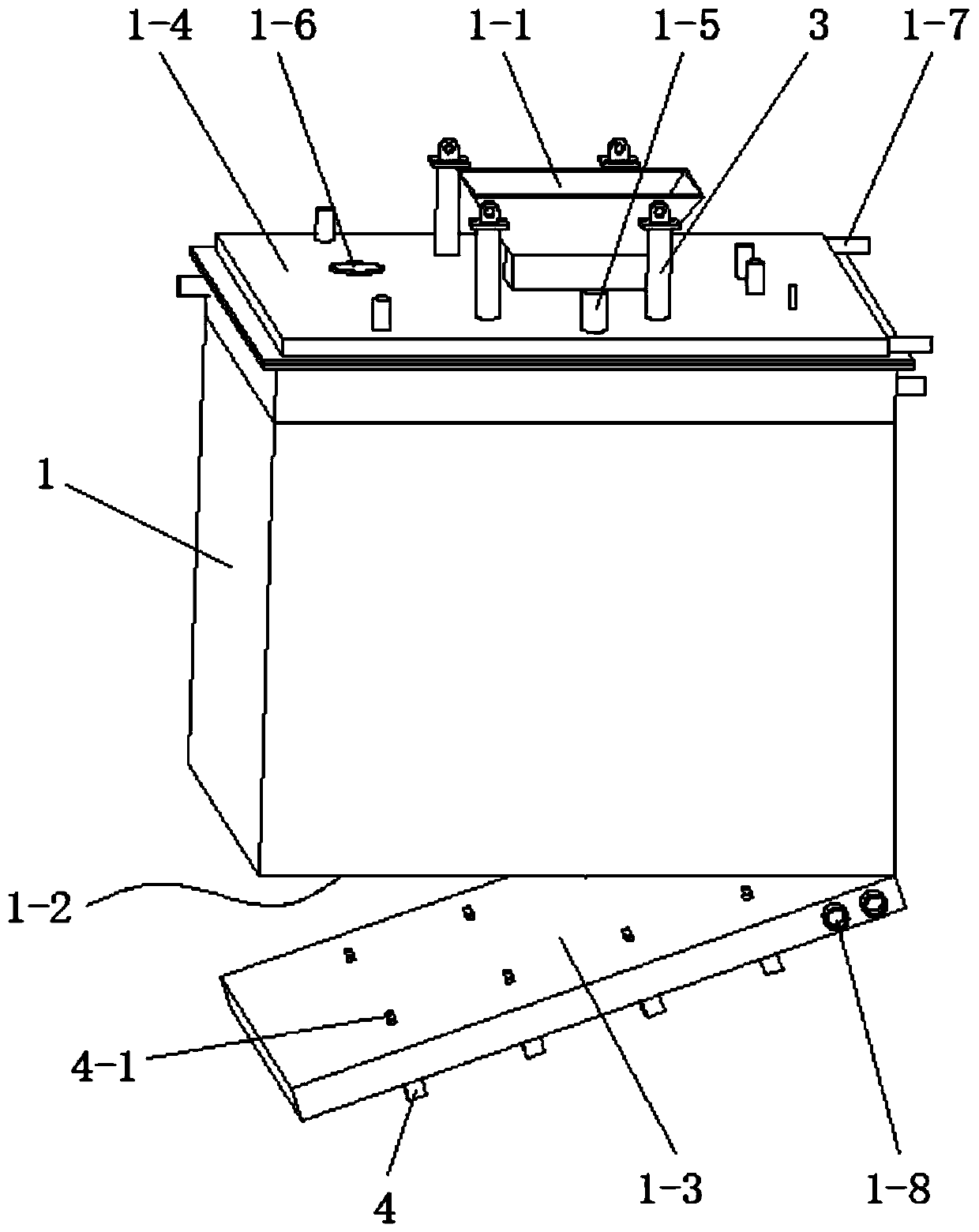

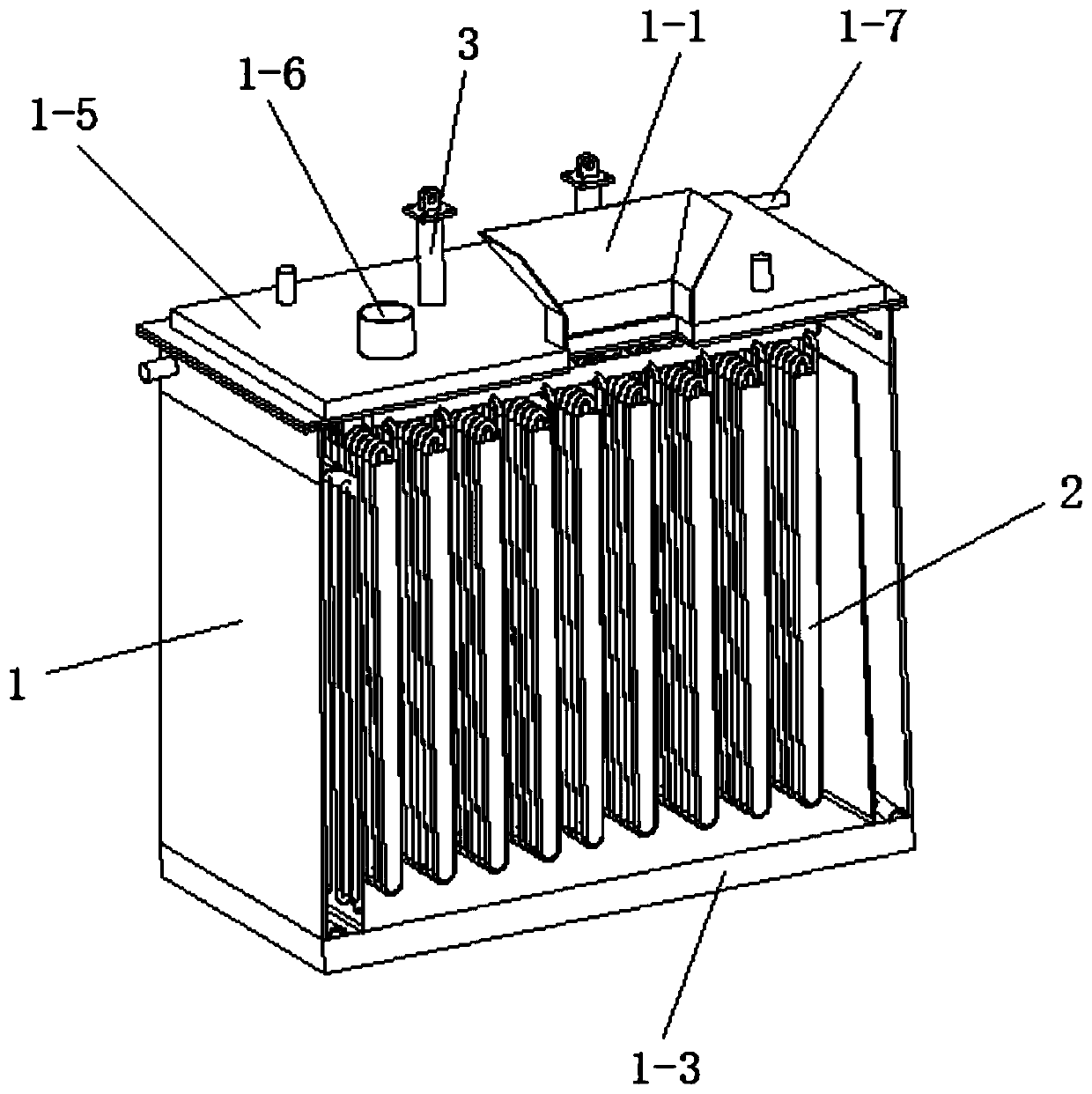

Extra-high temperature liquid metallurgical slag waste heat recovery device and waste heat recovery system

PendingCN110186019AImprove securityLower temperature spanLiquid degasificationBoiler cleaning apparatusMetallurgical slagSemi solid

The invention relates to an extra-high temperature liquid metallurgical slag waste heat recovery device which comprises a heat exchange box body. The heat exchange box body is provided with an inlet allowing extra-hot high-temperature liquid metallurgical slag to flow into the heat exchange box body; a first heat exchange tube group used for absorbing the heat of the extra-hot high-temperature liquid metallurgical slag is arranged in the heat exchange box body; a discharge opening is formed in the bottom surface of the heat exchange box body, and a quick opening door capable of controlling thedischarge opening to be opened or closed is formed in the discharge opening; the heat exchange box body is also provided with a jacking assembly used for decomposing and pushing semi-solid metallurgical slag formed after heat exchange of the extra-high temperature liquid metallurgical slag; and the jacking assembly comprises a plurality of power ejection rods and a first driving device for driving the power ejection rods to move towards the discharge opening. Meanwhile, the invention also relates to a waste heat recovery system comprising the extra-high temperature liquid metallurgical slag waste heat recovery device. Through multi-stage comprehensive utilization of the extra-high temperature liquid metallurgical slag, the full utilization of waste heat of the extra-high temperature liquid metallurgical slag is realized, the heat energy utilization efficiency is greatly improved, and the maximum energy conservation and emission reduction are realized.

Owner:江苏联储能源科技有限公司

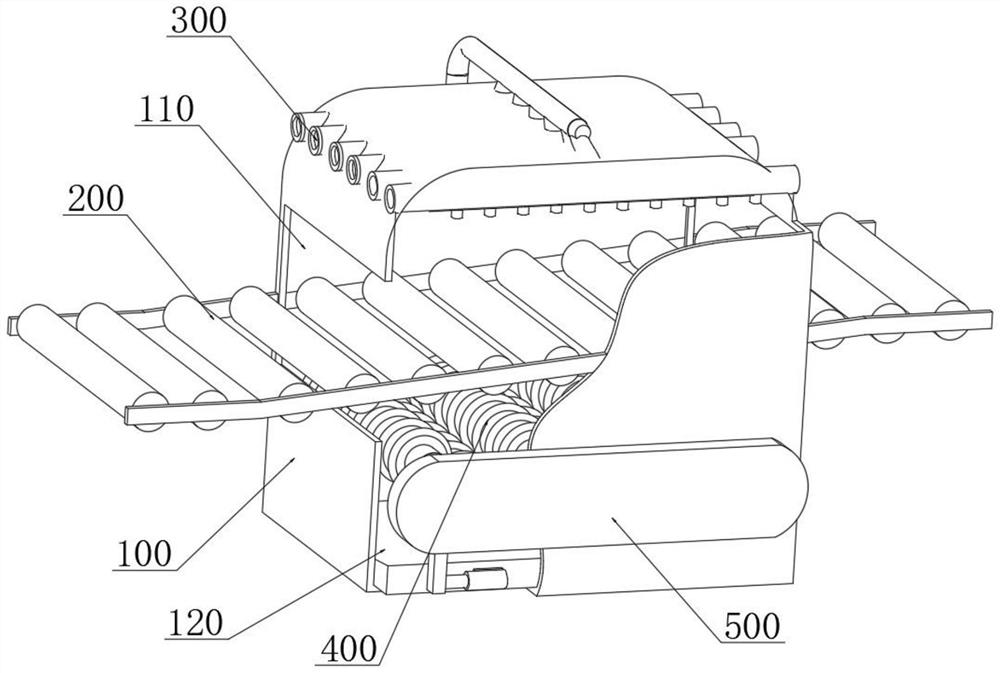

High-temperature forging and pressing waste heat recovery mechanism for press forging piece

ActiveCN113465433AGuaranteed utilizationIncrease profitIndirect heat exchangersHeating/cooling devicesThermodynamicsProcess engineering

The invention discloses a high-temperature forging and pressing waste heat recovery mechanism for a press forging piece. The mechanism comprises a heat preservation circulation box, a circulation conveying mechanism, a circulating spraying mechanism, a heat exchange component and a liquid exchange driving mechanism, wherein forge piece circulation windows are formed in the two sides of the heat preservation circulation box, the two ends of the circulation conveying mechanism penetrate through the heat preservation circulation box through the forge piece circulation windows, a transmission box fixedly installed at one side of the heat preservation circulation box is arranged at the outer side of the liquid exchange driving mechanism, and the liquid exchange driving mechanism is in transmission connection with the end of the heat exchange component; and the heat exchange component comprises a static pressure tube and a moving sleeve, and the moving sleeve is movably connected to the outer side of the static pressure tube in a sleeving mode. According to the mechanism, the liquid flow heat exchange component is arranged, the waste heat of the high-temperature forge piece is fully exchanged and absorbed through the heat exchange component, the waste heat of the forge piece acts on water liquid or other liquid for heating, the waste heat of the high-temperature forge piece is fully utilized and absorbed, and the heat utilization rate in the forge piece production process is guaranteed, so that the environment-friendly purposes of waste heat recovery and energy utilization rate improvement are achieved.

Owner:XINGHUA SANCHENG PRECISION FORGING

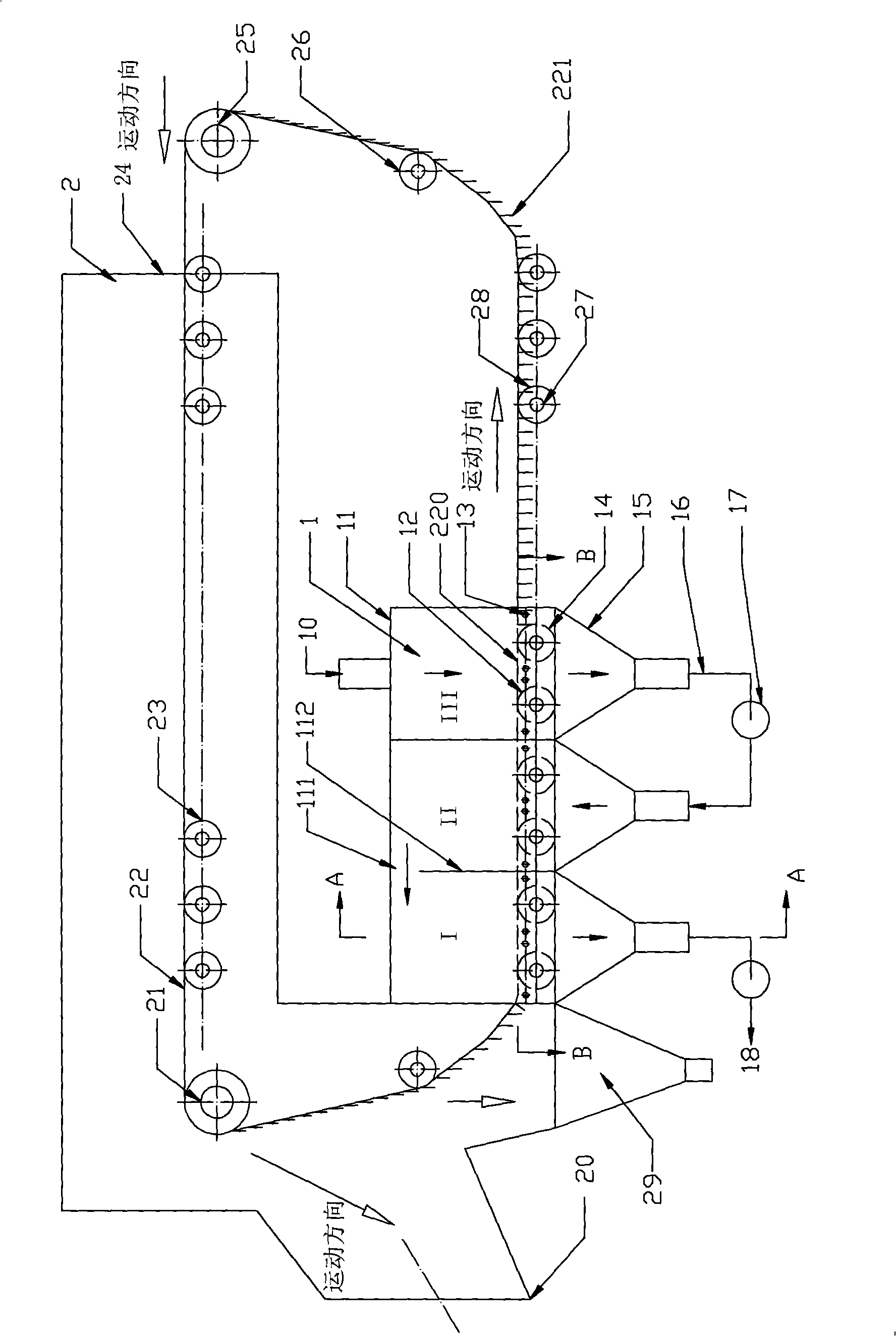

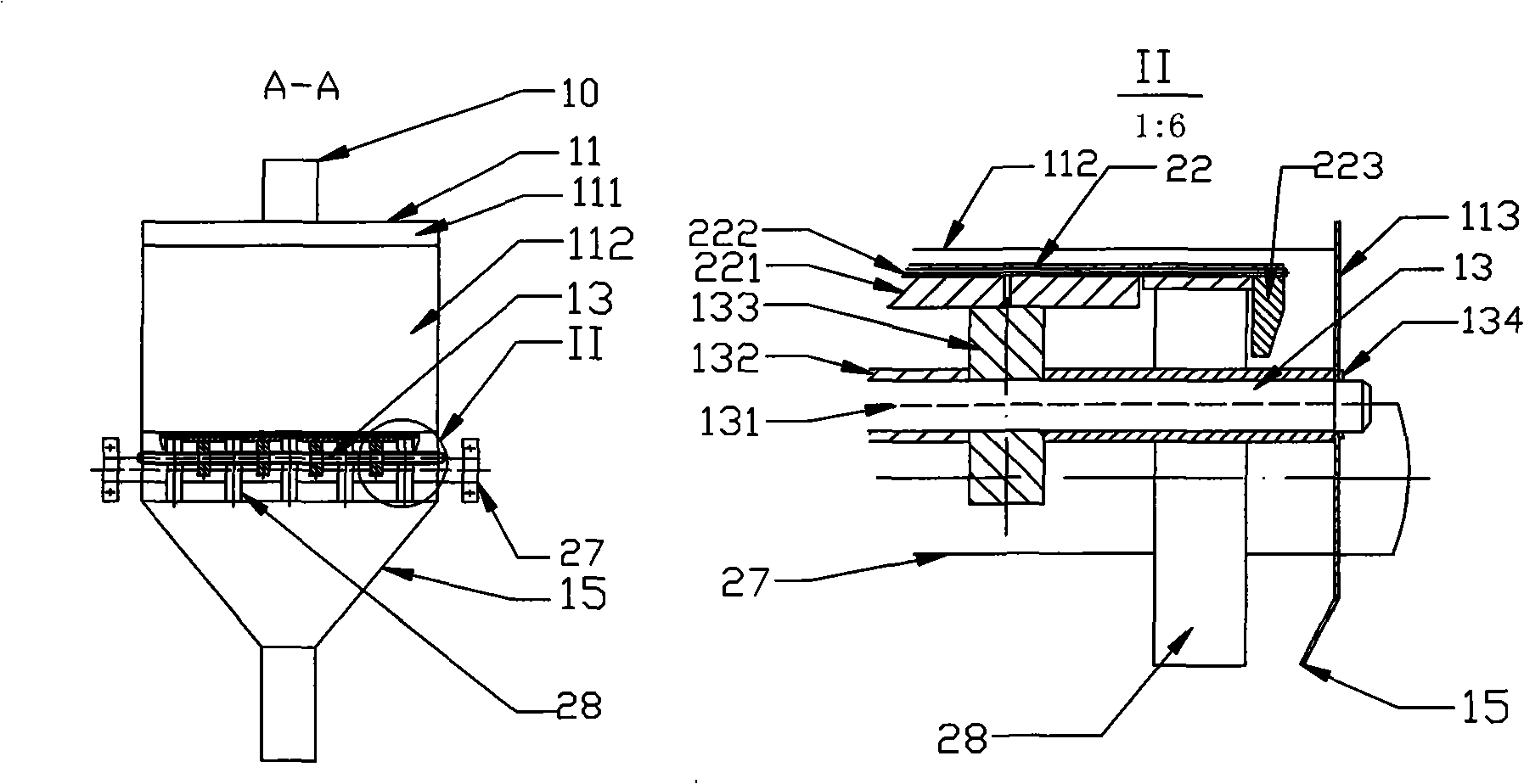

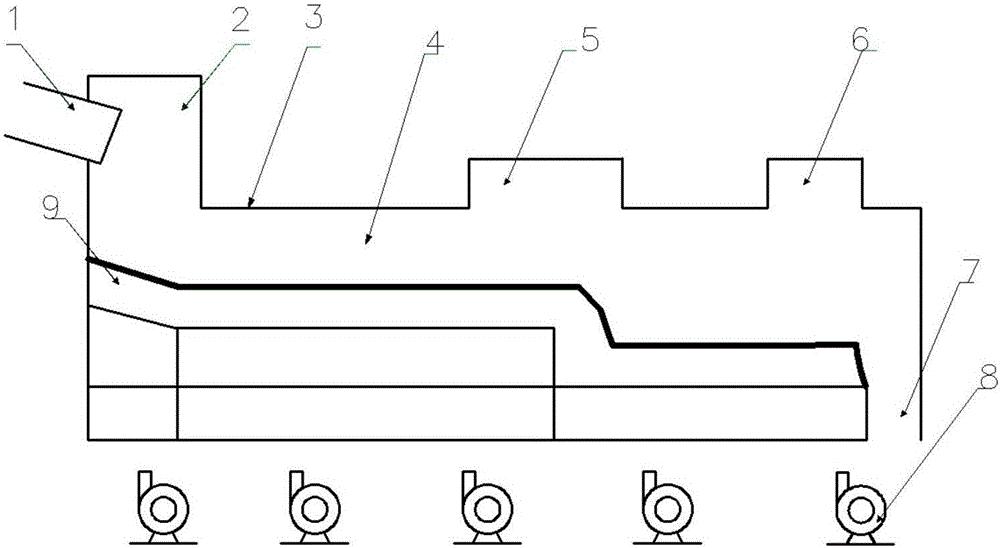

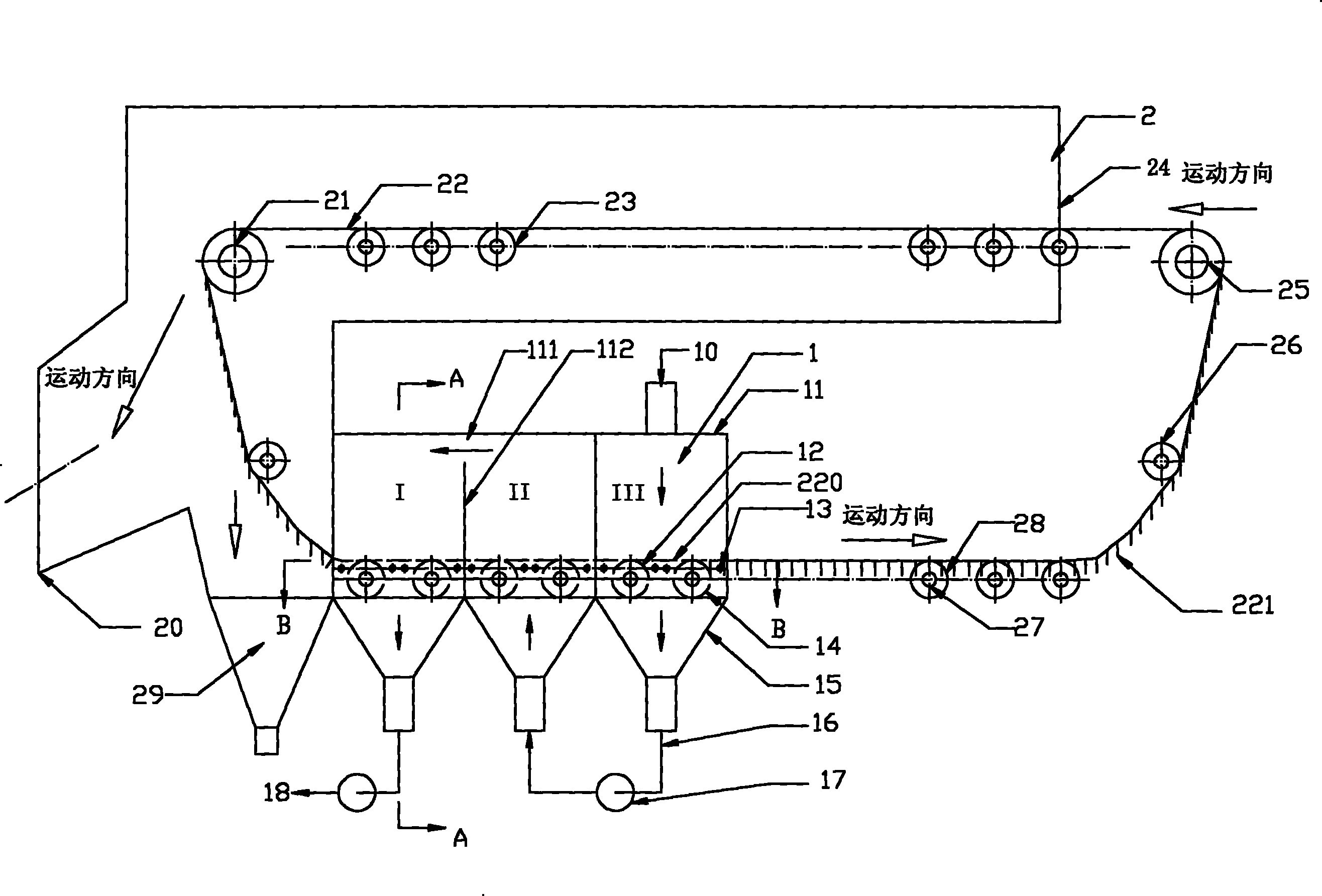

Method and device for recovering after heat of grates of drying grate

InactiveCN101526310AReduce invalid releaseIncrease profitIncreasing energy efficiencyWaste heat treatmentThermal energyEngineering

The invention discloses a method and a device for recovering the after heat of grates of a drying grate and relates to the equipment manufacturing of metallurgical industry. The method and the device are mainly used for a drying grate-rotary kiln-circle-cooling machine process to produce spheric agglomeration. The method adopts the technical scheme that a grate back stroke section on the lower part of the drying grate is additionally provided with at least three grate after heat recovering sections sequentially comprising an after heat recovering section I, an after heat recovering section II, an after heat recovering section III and the like which correspond to the moving direction of the grates, wherein each after heat recovering section is provided with a wind cover above the grate to be cooled and a wind box below the grate so as to ensure that low-temperature hot wind sequentially passes through the wind box and the wind cover from the higher after heat covering section to the lower after heat covering section until reaching the after heat recovering section I, namely, the low-temperature hot wind is subjected to at least three times of heat exchange with the grates; the grates are cooled sequentially; the temperature of the hot wind is raised gradually; and finally the high-temperature hot wind is discharged so as to achieve the high-efficiency recovery of the after heat of the grates, reduce ineffective release of heat during the cooling of the grates, improve the heat energy utilization rate and save the energy resource.

Owner:JIANGSU UNIV

Spraying device for environment-friendly waste treatment

PendingCN110841459AAvoid wasting resourcesIncrease contact timeCombination devicesElectric machineryWaste treatment

The invention discloses a spraying device for environment-friendly waste treatment. The spraying device comprises a box body, a fixing column is arranged on the outer wall of one side of the box body,a water storage tank is arranged on the outer wall of one end of the fixing column, a gas inlet pipe is inserted into the inner wall of the top of the water storage tank, one end of the gas inlet pipe extends into the box body, and a liquid return pipe is inserted into one end of the box body; a liquid storage tank is inserted into one end of the liquid return pipe, a connecting pipe is insertedinto the outer wall of the top of the liquid storage tank, a water pump is inserted into one end of the connecting pipe, a spray pipe is inserted into the outer wall of the top of the water pump, spray heads distributed at equal intervals are inserted into the outer wall of the bottom of the spray pipe, and a motor is arranged on the outer wall of one side of the box body. A large amount of heat carried in waste gas in the gas inlet pipe can be absorbed through the water storage tank, resource waste caused by direct heat emission is avoided, meanwhile, the cross section of the gas inlet pipe is S-shaped, the contact time of the waste gas and water can be prolonged, and the waste heat recovery effect is improved.

Owner:天门市怡田饮品科技有限公司

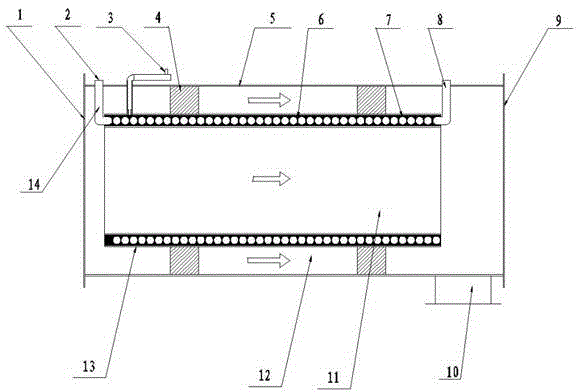

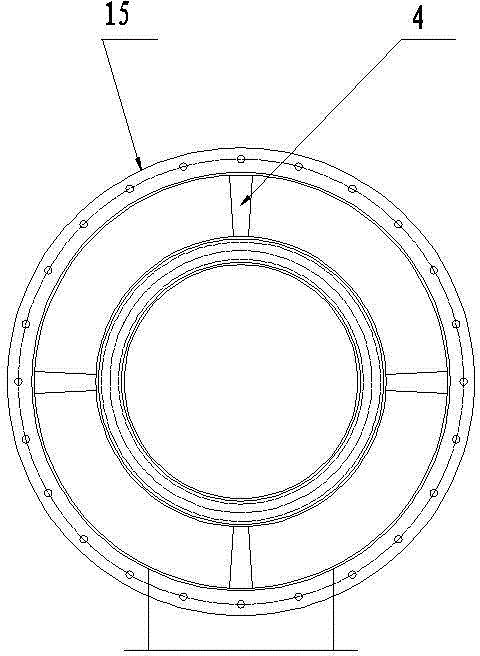

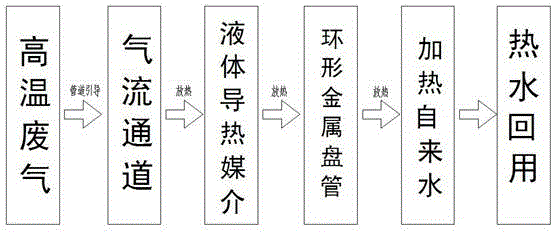

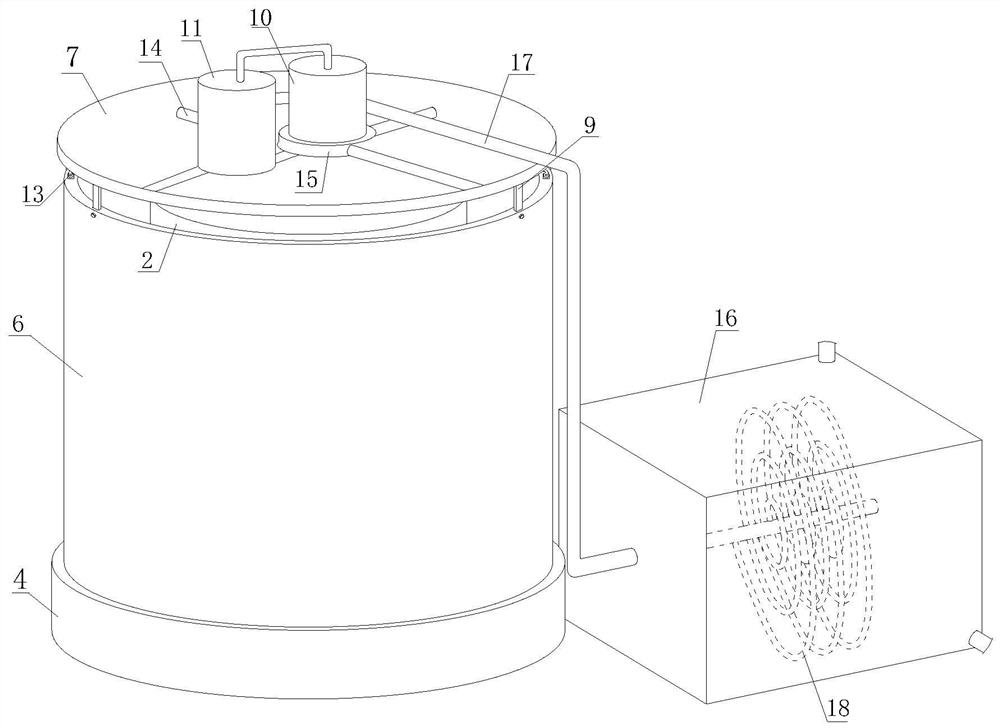

Method and device for cooling high-temperature waste gas and recovering waste heat

ActiveCN102818389BReasonable structurePracticalIndirect heat exchangersHeat exchange apparatusThermal energyExhaust fumes

The invention provides a method and a device for cooling high-temperature waste gas and recovering waste heat. The method includes that the high-temperature waste gas is in contact with the outer wall of a heat exchange unit barrel via gas flow channels, and heat of the high-temperature waste heat is dissipated, so that the high-temperature gas is cooled; and the heat transmitted via the outer wall of the heat exchange unit barrel is absorbed by heat-conduction media and is transmitted to a metal pipe arranged among the heat-conduction media, water in the metal pipe is heated, and hot water is recycled. By the method, the temperature of exhausted high-temperature industrial waste gas can be effectively and quickly reduced, large quantities of hot water which is a byproduct and is produced after conversion of heat energy can be provided, and effects of energy conservation and emission reduction are realized for enterprises. The device comprises a shell and the heat exchange unit barrel, is simple in structure, good in cooling effect and high in heat recovery efficiency. Daily maintenance for the device is as simple as cleaning for a common ventilating pipeline.

Owner:科创扬州环境工程科技股份有限公司

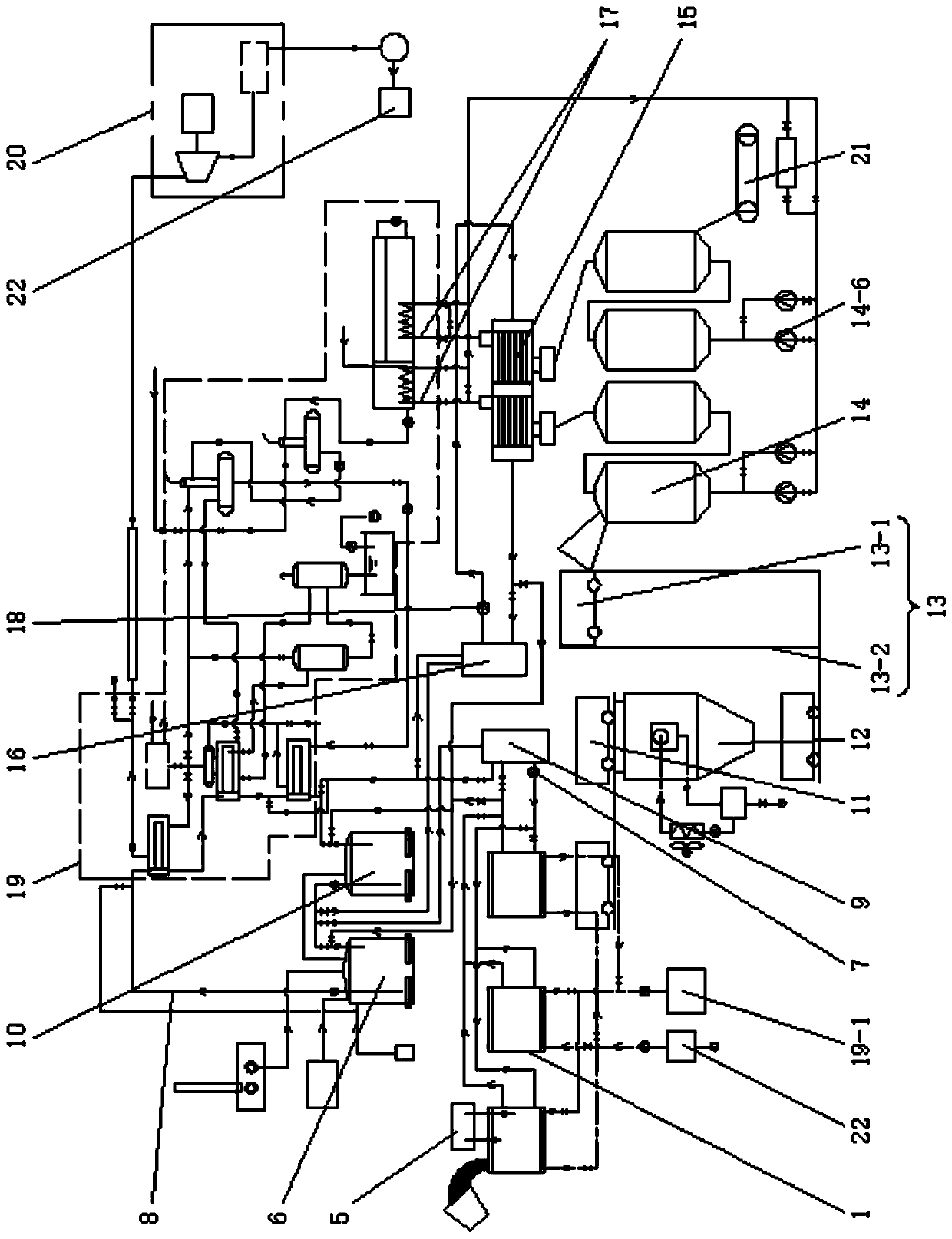

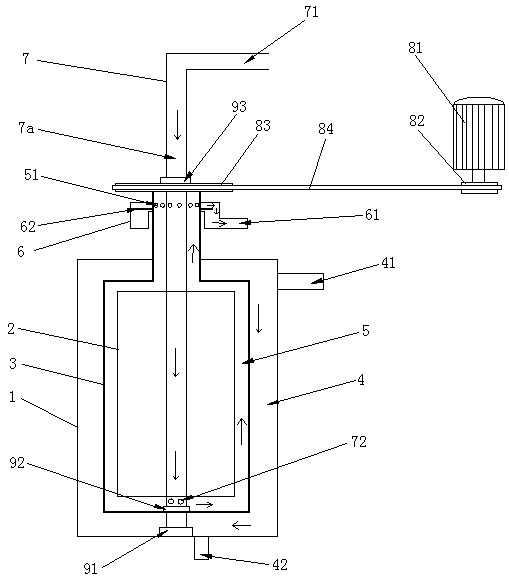

Molten iron tank waste heat utilization system

PendingCN112050666AReduce lossHave the effect of reusingCorrosion preventionStationary tubular conduit assembliesAir pumpProcess engineering

The invention discloses a molten iron tank waste heat utilization system. The molten iron tank waste heat utilization system comprises a supporting base, a groove for fixedly installing a molten irontank is formed in the upper surface of the supporting base, a heat preservation plate surrounding the periphery of the molten iron tank is arranged on the periphery of the molten iron tank, a spiral heat exchange pipe is wound on the outer surface of the molten iron tank, the bottom periphery of the heat preservation plate is inserted into a positioning cylinder, a metal ring is arranged over theheat preservation plate, a coaxial circular plate is arranged in the metal ring, the metal ring and the circular plate are fixed through a plurality of fixing pipes arranged at equal intervals, and anintermittent air pump is fixedly installed on the upper surface of the circular plate. According to the invention, a moving module is matched with the intermittent air pump, hot air floating on the surface of the molten iron tank can be pumped away and then utilized, meanwhile, the contact area between the spiral heat exchange pipe and the molten iron tank can be increased, the heat exchange efficiency is improved, and the waste heat utilization efficiency of the molten iron tank is improved.

Owner:胡志鹏

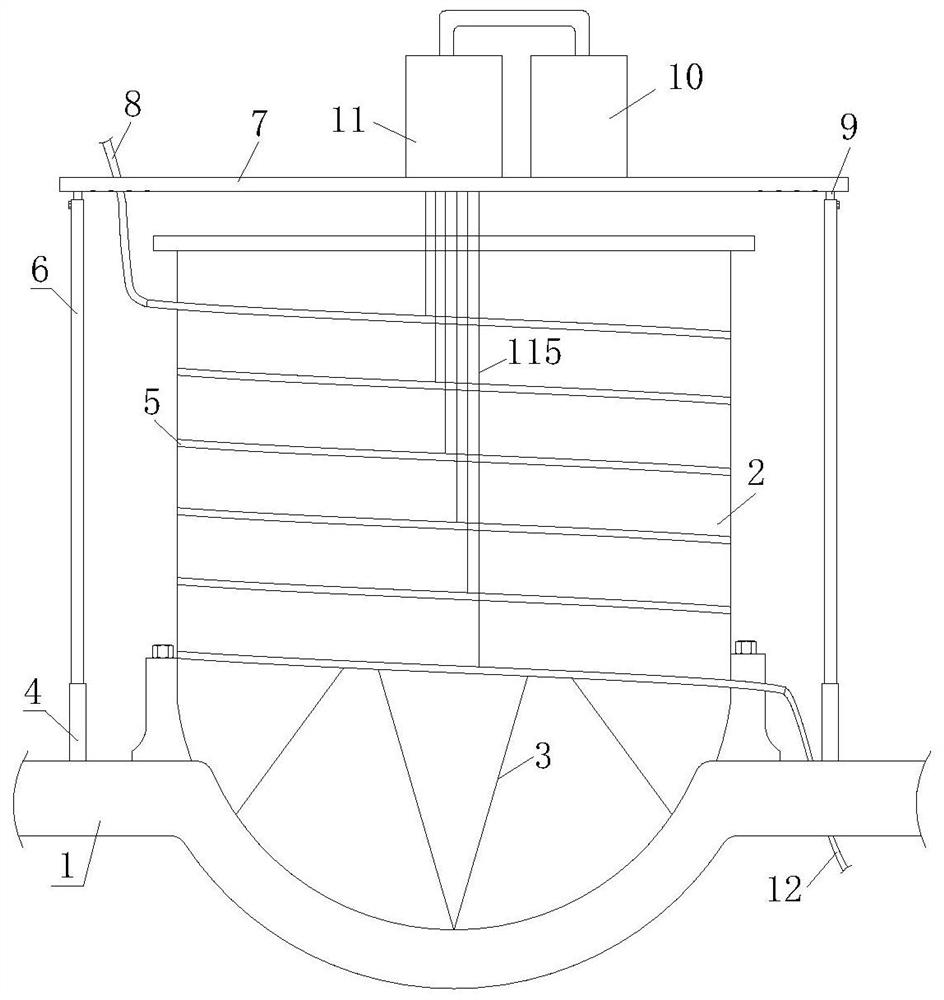

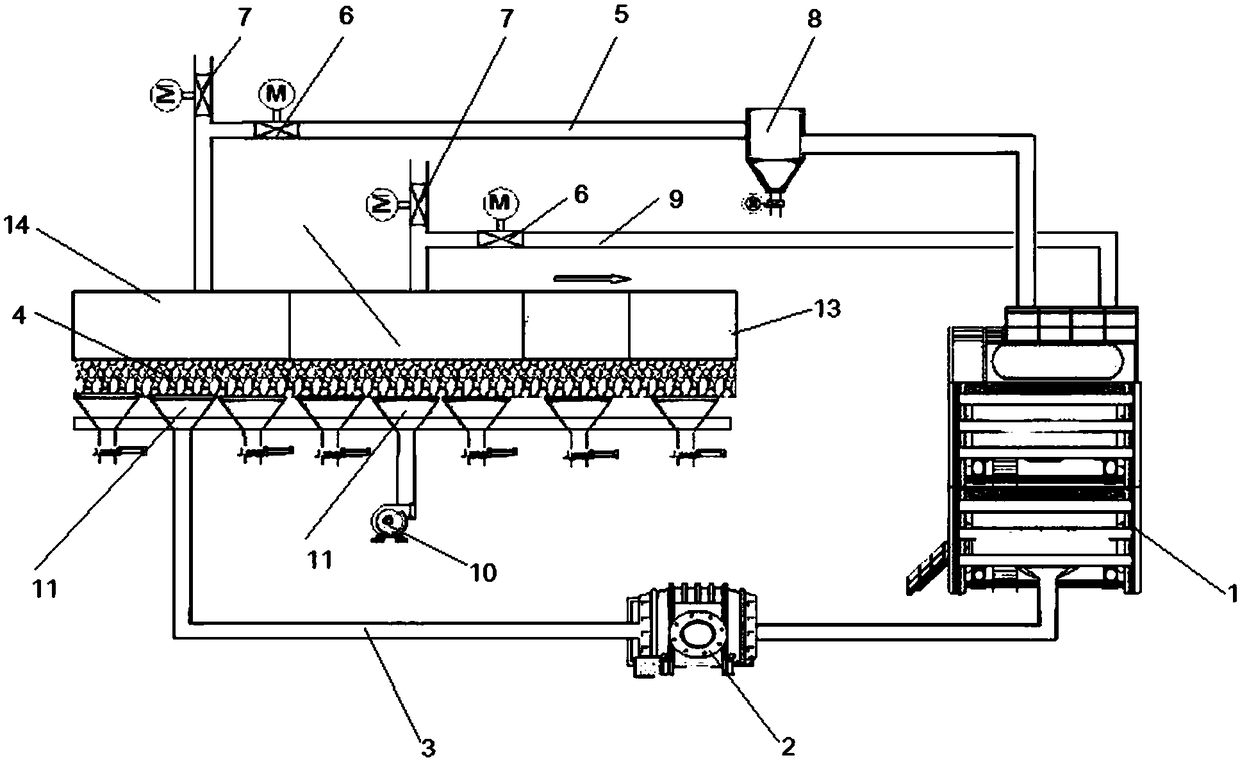

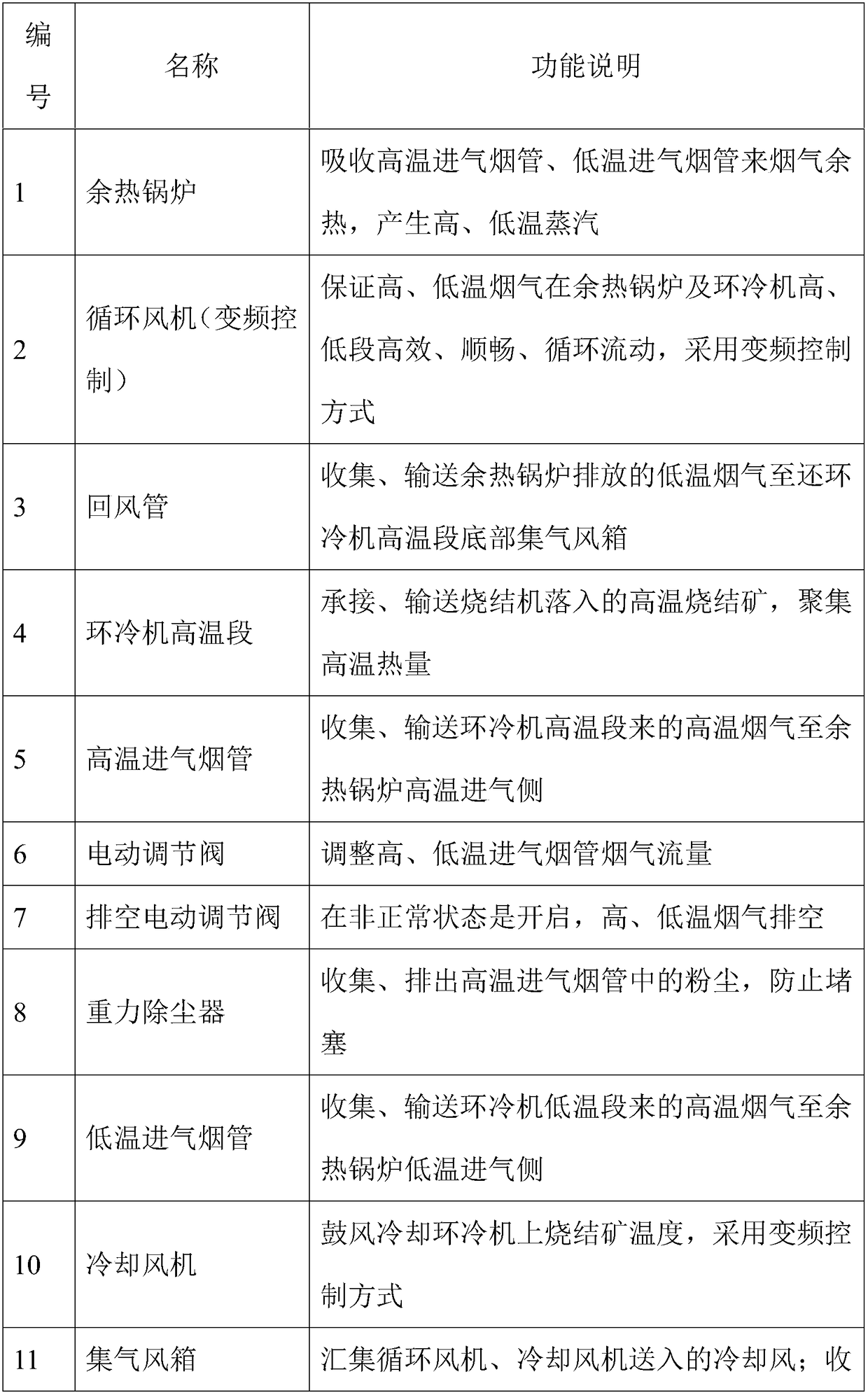

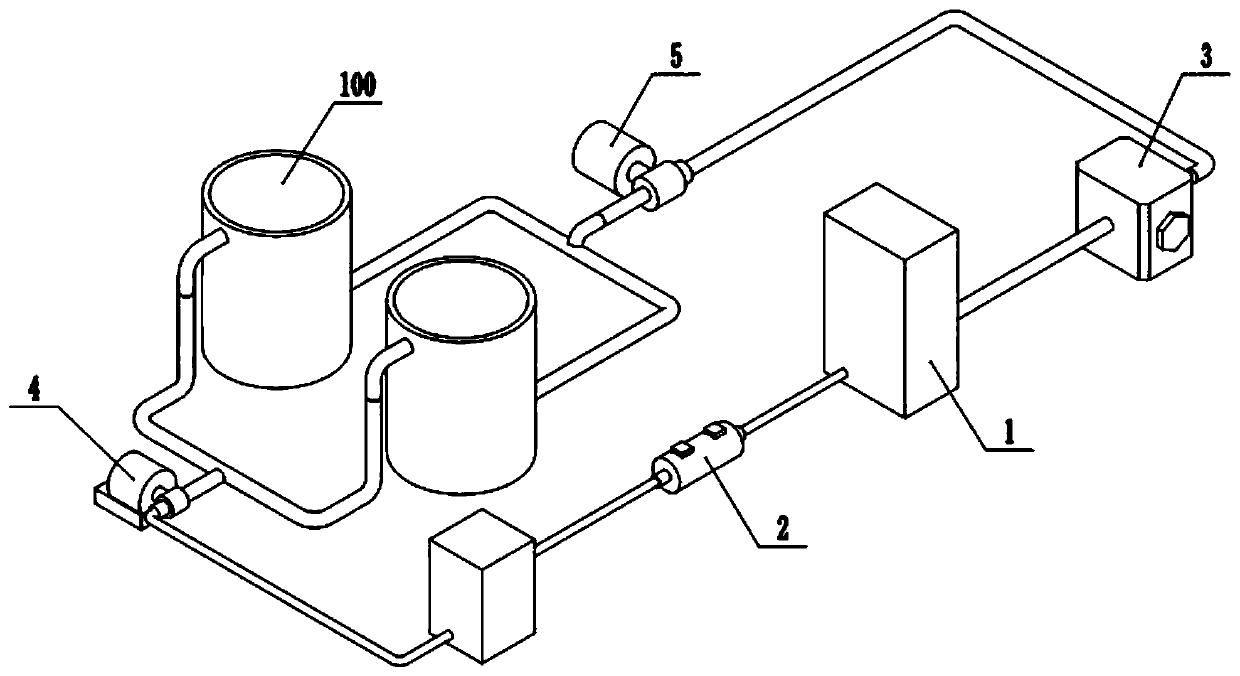

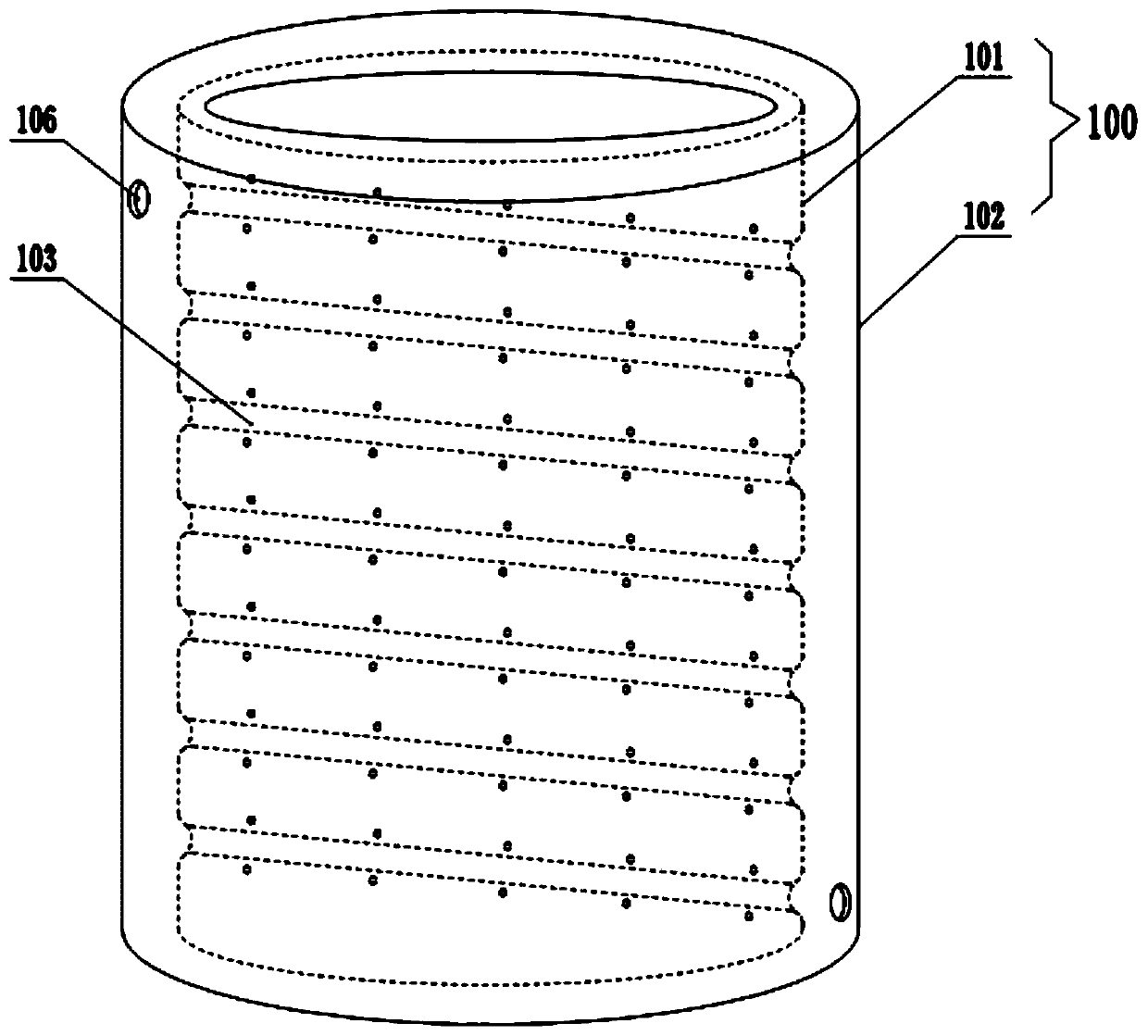

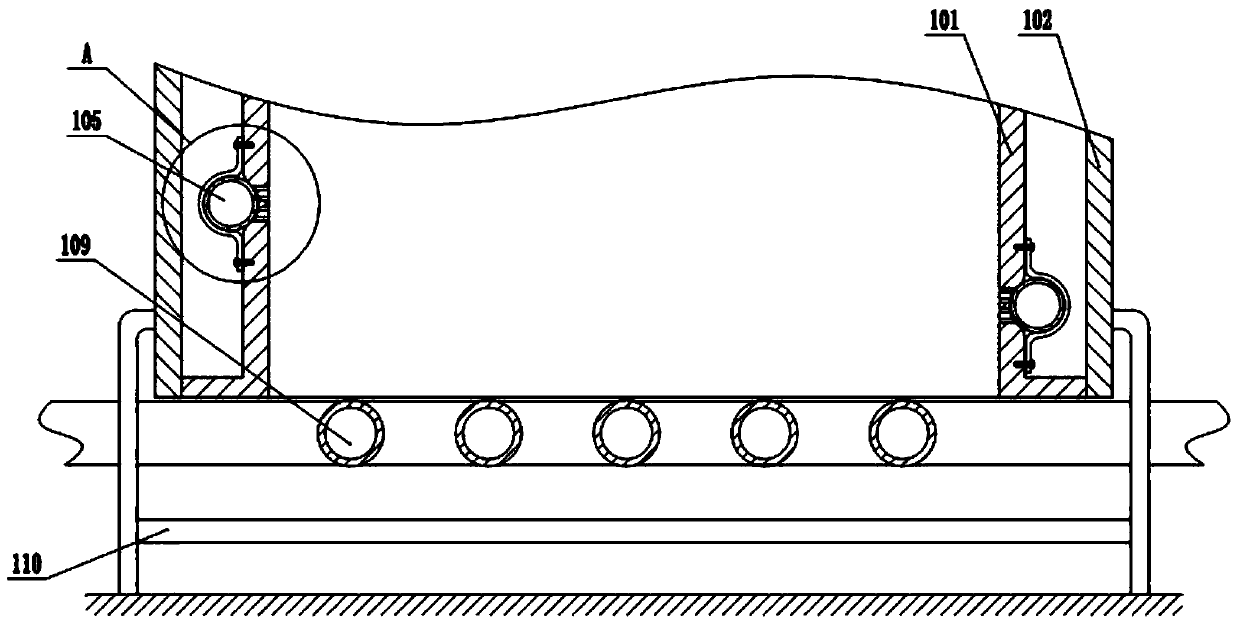

Sintering waste heat power generation system waste heat recovery device and application method thereof

PendingCN108592646AImprove waste heat recovery effectIncrease power generationIncreasing energy efficiencyControl devices for furnacesWaste heat recovery unitFlue gas

The invention discloses a sintering waste heat power generation system waste heat recovery device and an application method thereof. The sintering waste heat power generation system waste heat recovery device comprises a waste heat boiler, a circular cooling machine, a gas collection cover, a high-temperature gas inlet smoke pipe, a low-temperature gas inlet smoke pipe, a return air pipe, a circulating fan and a cooling fan, wherein the waste heat boiler is provided with a high-temperature flue gas inlet, a low-temperature flue gas inlet and a flue gas outlet; the circular cooling machine comprises a circular cooling machine high-temperature section and a circular cooling machine low-temperature section; the gas collection cover is arranged on the circular cooling machine; the first end ofthe high-temperature gas inlet smoke pipe is connected to the portion, at the circular cooling machine high-temperature section, of the gas collection cover, and the second end of the high-temperature gas inlet smoke pipe is connected with the high-temperature flue gas inlet; the first end of the low-temperature gas inlet smoke pipe is connected to the portion, at the circular cooling machine low-temperature section, of the gas collection cover, and the second end of the low-temperature gas inlet smoke pipe is connected with the low-temperature flue gas inlet; the first end of the return airpipe is connected with the circular cooling machine high-temperature section, and the second end of the return air pipe is connected with the flue gas outlet of the waste heat boiler; the circulatingfan is arranged on the return air pipe; the cooling fan is arranged on the circular cooling machine low-temperature section. Through the sintering waste heat power generation system waste heat recovery device, the waste heat recovery effect is improved, the power generating capacity is increased, the auxiliary power supply rate of a system is increased, and economic returns are increased.

Owner:MAANSHAN IRON & STEEL CO LTD

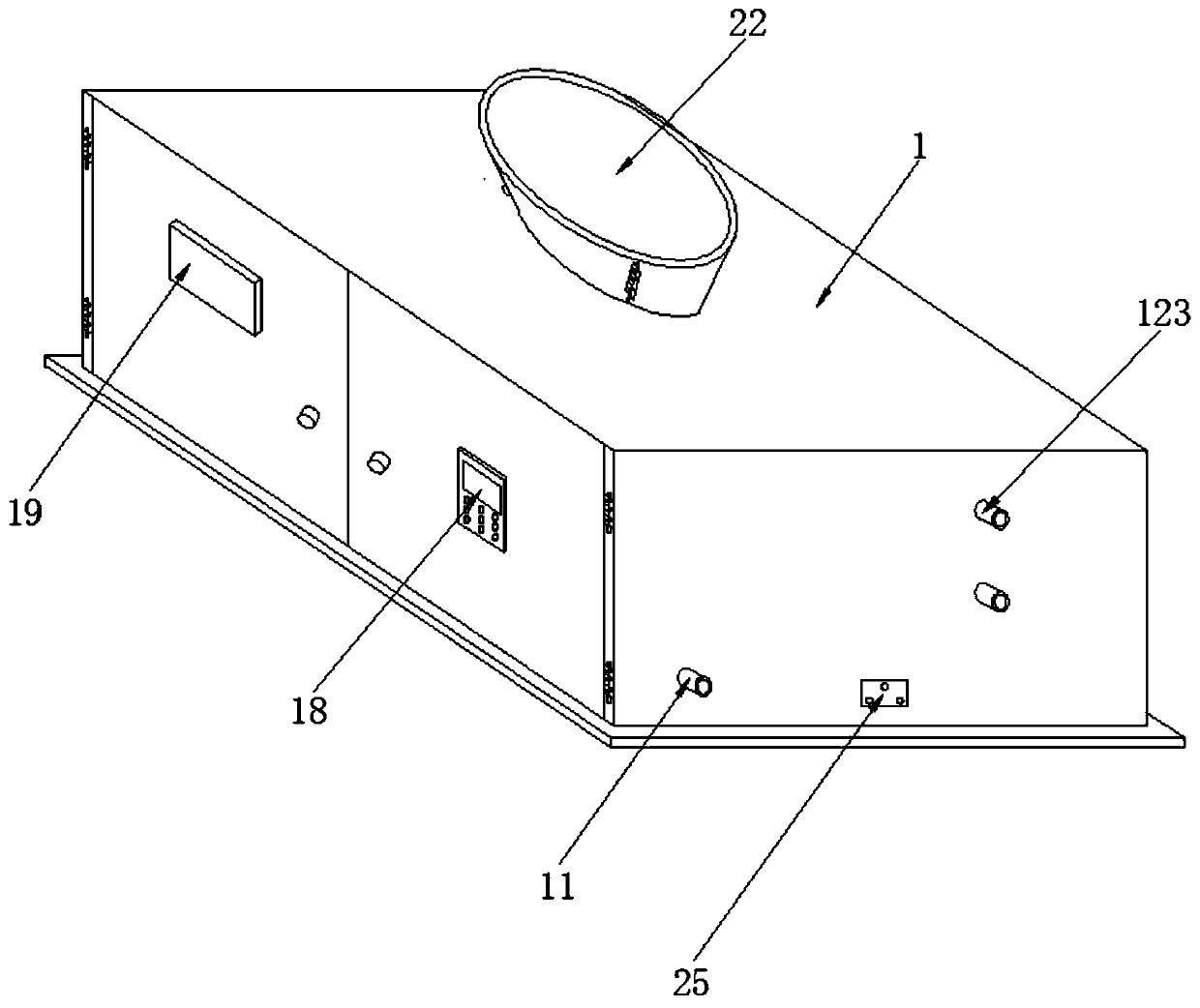

Waste heat recovery system

ActiveCN110081757BReduce CooldownSolve wasteRecuperative heat exchangersHeat exchanger casingsLiquid storage tankIndustrial equipment

Owner:重庆岩昱节能科技有限公司

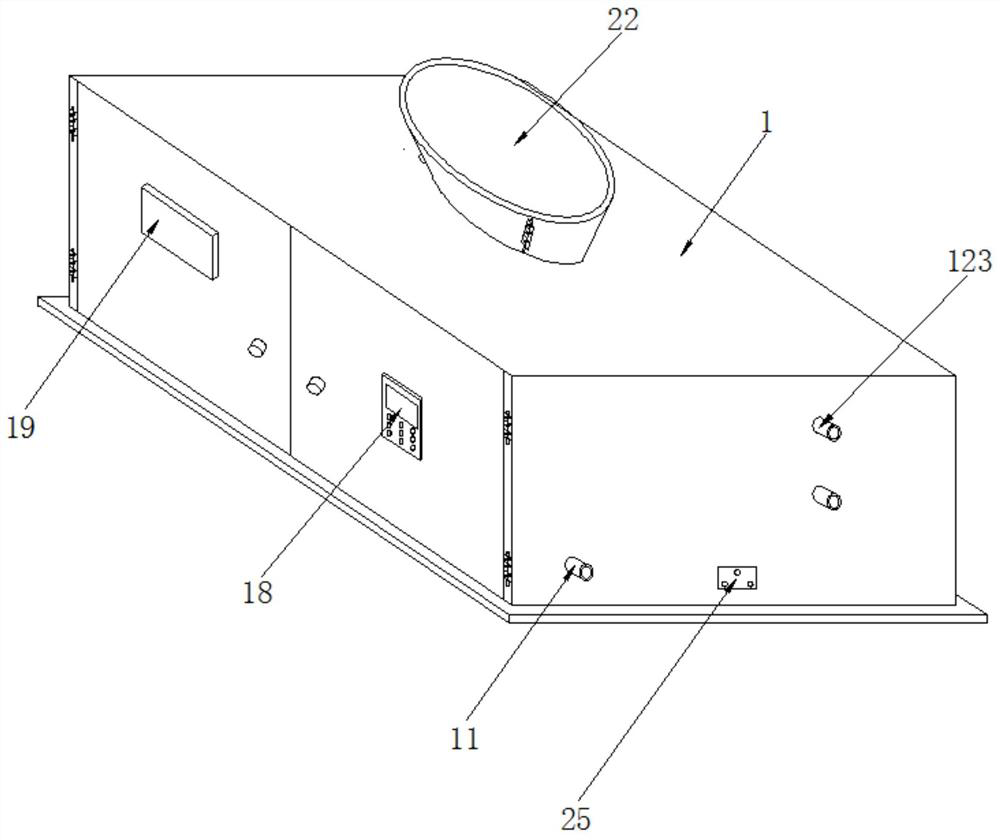

Environment-friendly waste heat recovery device of boiler pressure vessel and working method of environment-friendly waste heat recovery device

ActiveCN110763064AImprove recycling effectRealize real-time detectionHeat storage plantsHeat exchange apparatusLiquid wasteProcess engineering

The invention discloses an environment-friendly waste heat recovery device of a boiler pressure vessel and a working method of the environment-friendly waste heat recovery device. The environment-friendly waste heat recovery device comprises a machine box. A supporting frame is fixedly connected to the two sides of the top of the machine body through bolts, and a pressure vessel body is placed ina conic sleeve ring of the supporting frame. Empty grooves are formed in the pressure vessel body, and a temperature sensor is fixedly mounted on the inner wall of one empty groove. The number of outlets of the empty grooves is two. The invention relates to the technical field of boiler waste heat recovery equipment. According to the environment-friendly waste heat recovery device of the boiler pressure vessel and the working method of the environment-friendly waste heat recovery device, omni-directional waste heat recovery on the boiler pressure vessel can be achieved, the problems that wasteheat recovery is only carried out on boiler waste slag, and waste heat resources on the inner wall of the boiler pressure vessel are still wasted are solved well, the waste heat recovery effect is greatly enhanced, meanwhile, waste heat recovery is carried out on liquid waste, gas waste and solid waste, and the aim of carrying out comprehensive waste heat recovery on the boiler pressure vessel isachieved well.

Owner:合肥化机装备制造有限公司

Low-temperature waste heat recovering device

InactiveCN108519013AAvoid cloggingImprove heat exchange efficiencyRecuperative heat exchangersHeat transfer modificationWater channelWarm water

The invention discloses a low-temperature waste heat recovering device. The low-temperature waste heat recovering device comprises an outer barrel; an inner barrel is arranged in the outer barrel; a rotating barrel is arranged between the inner barrel and the outer barrel and is connected with a rotating driving mechanism; a waste hot water channel is formed between the outer barrel and the rotating barrel; a waste hot water inlet is formed in the upper part of the outer barrel; a waste hot water outlet is formed in the lower part of the outer barrel; a warm water channel is formed between therotating barrel and the inner barrel; warm water discharge holes are formed in the upper part of the rotating barrel; a warm water collector is arranged outside the warm water discharge holes; a warmwater outlet is formed in the warm water collector; a cold water pipe is vertically arranged on the inner barrel; the upper part of the cold water pipe penetrates out of the rotating barrel; a cold water channel is formed in the cold water pipe; a cold water inlet is formed in the upper end of the cold water pipe; and cold water discharge holes are formed in the lower part of the cold water pipeand communicate with the warm water channel. The low-temperature waste heat recovering device has the advantages of simple structure, convenience in fabrication, and high heat exchange efficiency.

Owner:宁波金名片能源科技有限公司

Energy-saving and environment-friendly waste heat recycling device

InactiveCN112050678AExtended stayImprove heat exchange capacityRecuperative heat exchangersHeat transfer modificationProcess engineeringMechanical engineering

The invention belongs to the technical field of environment-friendly machinery, and particularly relates to an energy-saving and environment-friendly waste heat recycling device. The energy-saving andenvironment-friendly waste heat recycling device aims to solve the problem that the waste heat recycling effect of high-temperature gas is poor in the prior art. According to the scheme, the energy-saving and environment-friendly waste heat recycling device comprises a treatment box, wherein the two sides of the treatment box are open; cover plates are fixed on the two sides of the treatment box;a gas inlet pipe and a gas outlet pipe are fixed on the two sides of the treatment box respectively; a wrapping box is fixed on the outer wall of a treatment cylinder; a circulation cavity of a concentric-square-shaped structure is formed between the inner wall of the wrapping box and the outer wall of the treatment box; and a communicating pipe which is arranged in a penetrating mode is rotationally connected between the top and the bottom of the treatment box. According to the energy-saving and environment-friendly waste heat recycling device, an umbrella-shaped flow guide piece is used forcarrying out collision buffering on the entering gas, and a connecting net cylinder is driven to rotate, so that the power of the gas is used for improving the recycling effect of energy through therotational friction between the connecting net cylinder and water and the rotational friction between a collision piece and the water, and the actual waste heat recycling effect of the device on the waste gas is improved through the operation effect of mutual cooperation.

Owner:苏州浔宇新材料科技有限公司

Energy-saving environment-friendly lime kiln furnace capable of recycling flue gas waste heat

InactiveCN108383401ATo achieve the purpose of energy saving and environmental protectionImprove thermal conductivityFlue gasLime kiln

The invention discloses an energy-saving environment-friendly lime kiln furnace capable of recycling flue gas waste heat, which includes a base plate. One side of the top of the base plate is fixedlyconnected with a purifying box. The top of the purifying box is fixedly connected with a transmission box. The top of the transmission box is fixedly connected with a waste heat recovery box. Both sides of the back surface of the inner wall of the waste heat recovery box are rotatably connected with a first hollow rotating shaft through a bearing. Both sides of the front surface of the inner wallof the waste heat recovery box are rotatably connected with a second hollow rotating shaft through a bearing. The lime kiln furnace relates to the technical field of the lime kiln furnaces. The energy-saving environment-friendly lime kiln furnace capable of recycling flue gas waste heat greatly enhances the waste heat recovery effect, perfectly enlarges the application range of waste heat of recovery, realizes two methods of waste heat recovery, gas-liquid heat conduction and gas-gas heat conduction, for flue gas produced by lime kiln furnaces, accomplishes the purpose of thoroughly recyclingthe waste heat produced by flue gas and enhancing the utilization range of the waste heat , so that the purpose of energy conservation and environmental protection for the use of the lime kiln furnaceis well achieved.

Owner:芮少春

A Waste Heat Recovery System with Varying Heat Pipe Spacing

ActiveCN105758200BImprove waste heat utilization efficiencyReduce energy consumptionEnergy industryIncreasing energy efficiencyThermal energyWaste heat recovery unit

Owner:SHANDONG UNIV

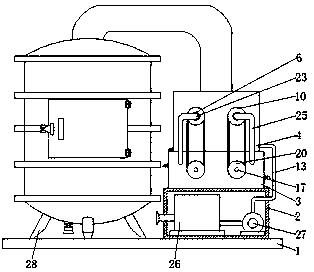

Gas Boiler Flue Gas Waste Heat Recovery and Purification System for Combustion Air and Gas Humidification

ActiveCN109268820BRaise the dew pointIncrease temperature differenceIndirect carbon-dioxide mitigationCombustion apparatusThermodynamicsFlue gas

The invention provides a gas-fired boiler flue gas waste heat recovery and purification system with a function of humidifying combustion air and gas. The system comprises a spray type heat exchange tower, an intermediate circulating water system, a flue gas circulation device and a gas mixing device, wherein the combustion air, the gas and boiler flue gas are subjected to water-heat exchange withthe intermediate circulating water system in the spray heat exchange tower and are humidified; the humidified gas returns to a boiler through the gas mixing device to continue burning. The invention uses the intermediate circulating water as a medium to realize the humidification and recirculation of the flue gas as well as recovery of the latent heat of the flue gas under the high intermediate circulating water temperature condition; furthermore, the latent heat of the high temperature flue gas and sensible heat are utilized to heat the humidified gas and combustion air; after being subjectedto recirculation, the humidified flue gas, combustion air and gas are mixed and introduced into the gas boiler, so that NOx emission can be reduced, and the dew point of the flue gas is increased; therefore, the purposes of reducing pollutant emission from the gas boiler and improving the heating effect of the boiler are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

A heat pipe waste heat recovery system

ActiveCN105737622BReduce energy consumptionImprove waste heat recovery effectEnergy industryIndirect heat exchangersEvaporationEngineering

The invention provides a heat pipe waste heat recycling system which comprises heating equipment and heat pipes. The heating equipment comprises a shell and a clinker channel. A heat preservation material is arranged between the shell and the clinker channel. Each heat pipe comprises an evaporation end and a condensation end. The evaporation ends of the heat pipes are arranged in the heat preservation material. According to the heat pipe waste heat recycling system, the waste heat utilization efficiency can be greatly increased through the heat pipes.

Owner:SHANDONG UNIV

An environment-friendly boiler pressure vessel waste heat recovery device and its working method

ActiveCN110763064BRealize waste heat recoverySolve wasteHeat storage plantsHeat exchange apparatusLiquid wasteProcess engineering

The invention discloses an environment-friendly waste heat recovery device of a boiler pressure vessel and a working method of the environment-friendly waste heat recovery device. The environment-friendly waste heat recovery device comprises a machine box. A supporting frame is fixedly connected to the two sides of the top of the machine body through bolts, and a pressure vessel body is placed ina conic sleeve ring of the supporting frame. Empty grooves are formed in the pressure vessel body, and a temperature sensor is fixedly mounted on the inner wall of one empty groove. The number of outlets of the empty grooves is two. The invention relates to the technical field of boiler waste heat recovery equipment. According to the environment-friendly waste heat recovery device of the boiler pressure vessel and the working method of the environment-friendly waste heat recovery device, omni-directional waste heat recovery on the boiler pressure vessel can be achieved, the problems that wasteheat recovery is only carried out on boiler waste slag, and waste heat resources on the inner wall of the boiler pressure vessel are still wasted are solved well, the waste heat recovery effect is greatly enhanced, meanwhile, waste heat recovery is carried out on liquid waste, gas waste and solid waste, and the aim of carrying out comprehensive waste heat recovery on the boiler pressure vessel isachieved well.

Owner:合肥化机装备制造有限公司

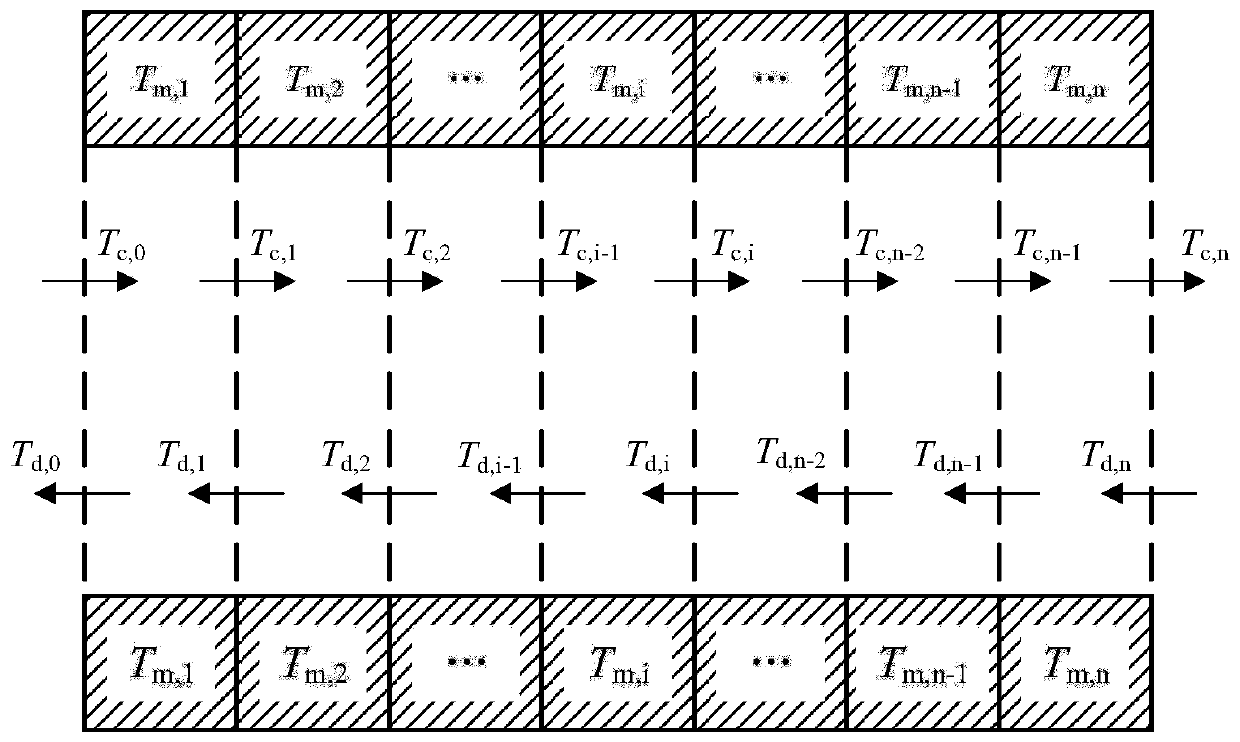

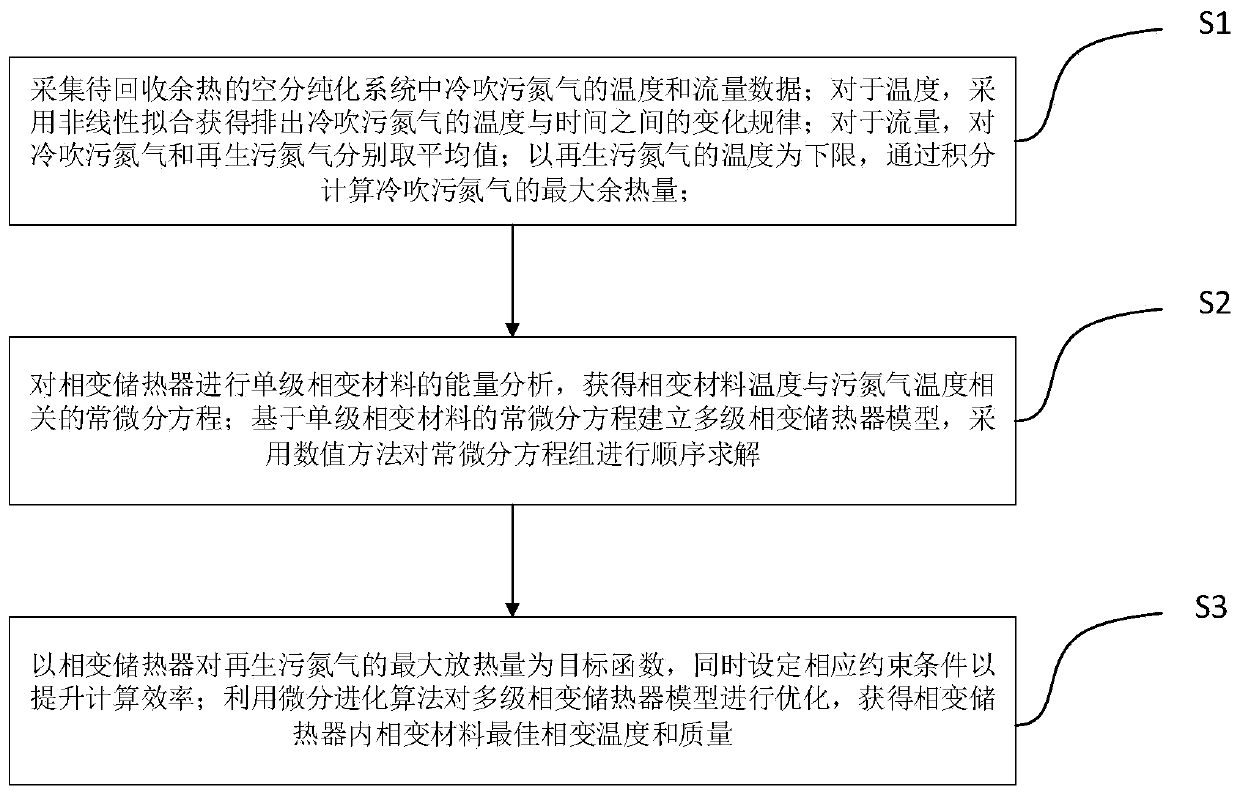

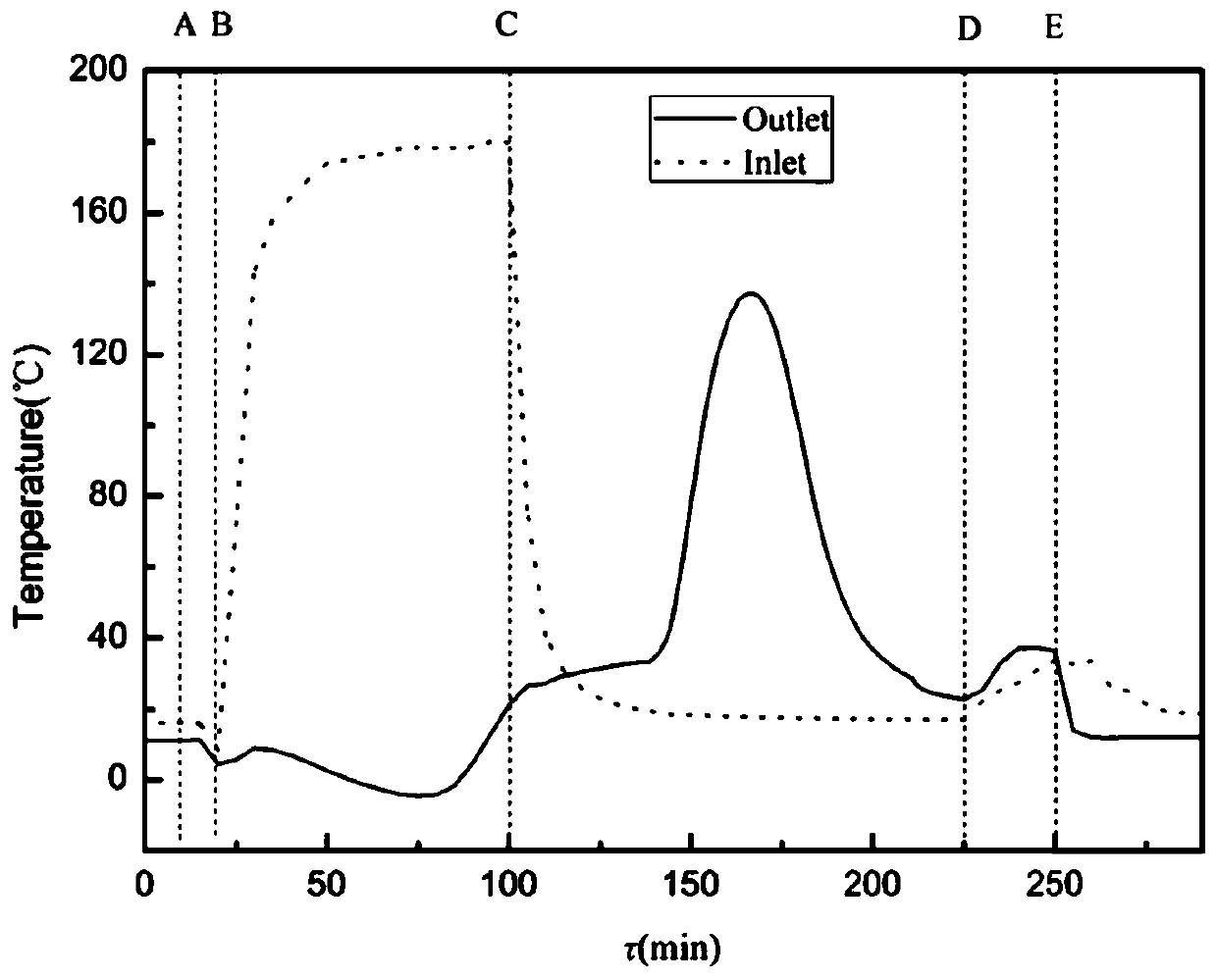

Waste heat recovery device applied to air separation purification system and key parameter determination method thereof

ActiveCN111048157ARealize energy saving and consumption reductionImprove waste heat recovery effectComputational theoretical chemistryInstrumentsMathematical modelEngineering

The invention discloses a waste heat recovery device applied to an air separation purification system and a key parameter determination method of the waste heat recovery device. The key parameter determination method comprises the steps that actual temperature and flow data of cold blowing polluted nitrogen of an air separation purification device are collected; for the temperature, nonlinear fitting is adopted to obtain the temperature and flow change rule of the discharged cold blowing polluted nitrogen; in order to improve the waste heat recovery capacity, a phase change heat accumulator adopts a multi-stage form, a multi-stage phase change heat accumulator mathematical model is established based on a system of ordinary differential equations, and a numerical method is adopted to sequentially solve the corresponding system of ordinary differential equations; the maximum heat release of the phase change heat accumulator to the recycled polluted nitrogen is taken as an objective function, and meanwhile, corresponding constraint conditions are set, so that the calculation efficiency is improved; and the multi-stage phase change heat accumulator model is optimized by using a differential evolution algorithm to obtain key parameters such as optimal phase change temperature and quality of a phase change material in the phase change heat accumulator. The waste heat recovery effectof the cold blowing polluted nitrogen is improved to the greatest extent, the power of an electric heater is reduced, and energy conservation and consumption reduction of the air separation purification system are realized.

Owner:ZHEJIANG UNIV

Method and device for recovering after heat of grates of drying grate

InactiveCN101526310BReduce invalid releaseIncrease profitIncreasing energy efficiencyWaste heat treatmentThermal energyEngineering

The invention discloses a method and a device for recovering the after heat of grates of a drying grate and relates to the equipment manufacturing of metallurgical industry. The method and the device are mainly used for a drying grate-rotary kiln-circle-cooling machine process to produce spheric agglomeration. The method adopts the technical scheme that a grate back stroke section on the lower part of the drying grate is additionally provided with at least three grate after heat recovering sections sequentially comprising an after heat recovering section I, an after heat recovering section II, an after heat recovering section III and the like which correspond to the moving direction of the grates, wherein each after heat recovering section is provided with a wind cover above the grate to be cooled and a wind box below the grate so as to ensure that low-temperature hot wind sequentially passes through the wind box and the wind cover from the higher after heat covering section to the lower after heat covering section until reaching the after heat recovering section I, namely, the low-temperature hot wind is subjected to at least three times of heat exchange with the grates; the grates are cooled sequentially; the temperature of the hot wind is raised gradually; and finally the high-temperature hot wind is discharged so as to achieve the high-efficiency recovery of the after heatof the grates, reduce ineffective release of heat during the cooling of the grates, improve the heat energy utilization rate and save the energy resource.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com