A tower structure high temperature material waste heat recovery device

A tower structure, high-temperature material technology, applied in direct contact heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems that cannot meet the layout requirements, high-temperature material waste heat recovery device occupies a large area, etc. , to achieve significant energy saving effects, enhanced cooling and waste heat recovery effects, and improved cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

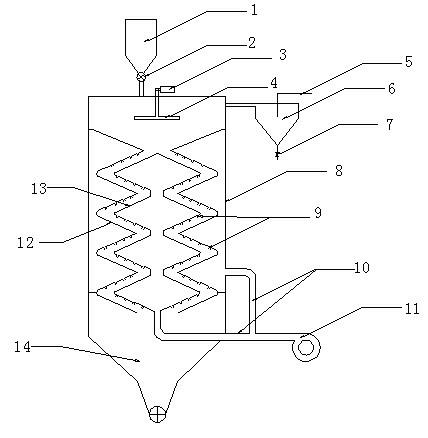

[0014] as attached figure 1 The present invention shown comprises a vertical cylinder 8, a storage bin 1, a dust removal device 6, a wind tower 13, a material blocking device 12, and a hopper 14. The tower structure is composed of a plurality of wind towers 13, and the number of wind towers 13 is 4 One, the upper and lower surfaces of the blocking device 12 are conical surfaces. The conical surface of the wind tower 13 is used for feeding materials, and the inverted conical surface is provided with ventilation holes 9, and the inverted conical surface of the blocking device 12 is used for feeding materials, and the conical surface is provided with ventilation holes 9, and the middle and lower parts of the wind tower 13 are connected to There is a ventilation duct 10, and the cooling wind blown in by the blower enters the wind tower 13 from the ventilation duct 10, and the angle between the wind tower 13 and the material blocking device 12 is enough to allow the material to flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com