Method and device for recovering after heat of grates of drying grate

A waste heat recovery device and technology for waste heat recovery, which are applied in the field of waste heat recovery of grate beds of chain grate machines, can solve the problems of low efficiency of waste heat utilization methods, reduce ineffective release of cooling heat of grate beds, etc., so as to achieve efficient recovery and utilization and improve waste heat recovery. effect, the effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] According to the structure and size of the B2.8×36m grate machine running chain, the specific implementation instructions will be carried out.

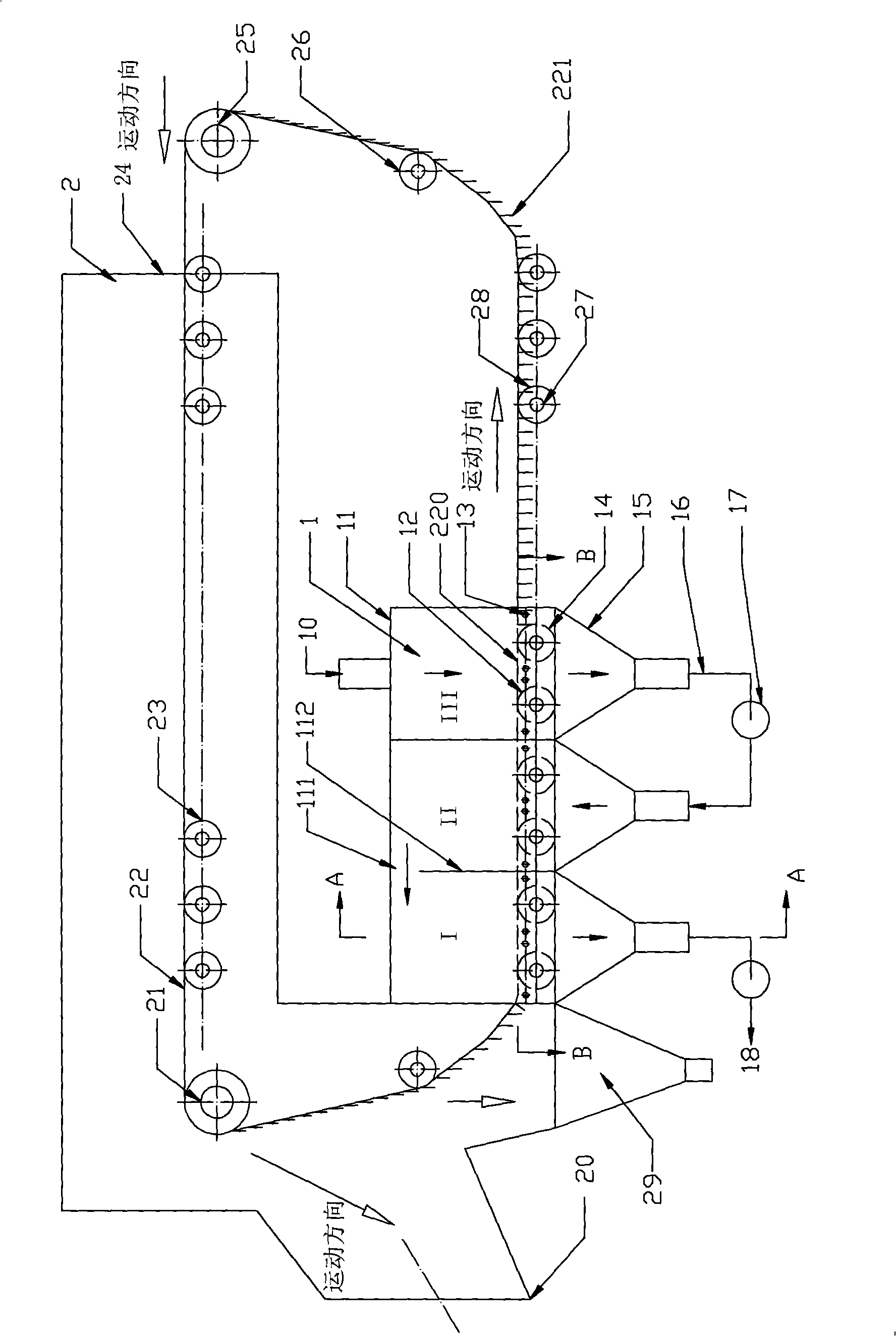

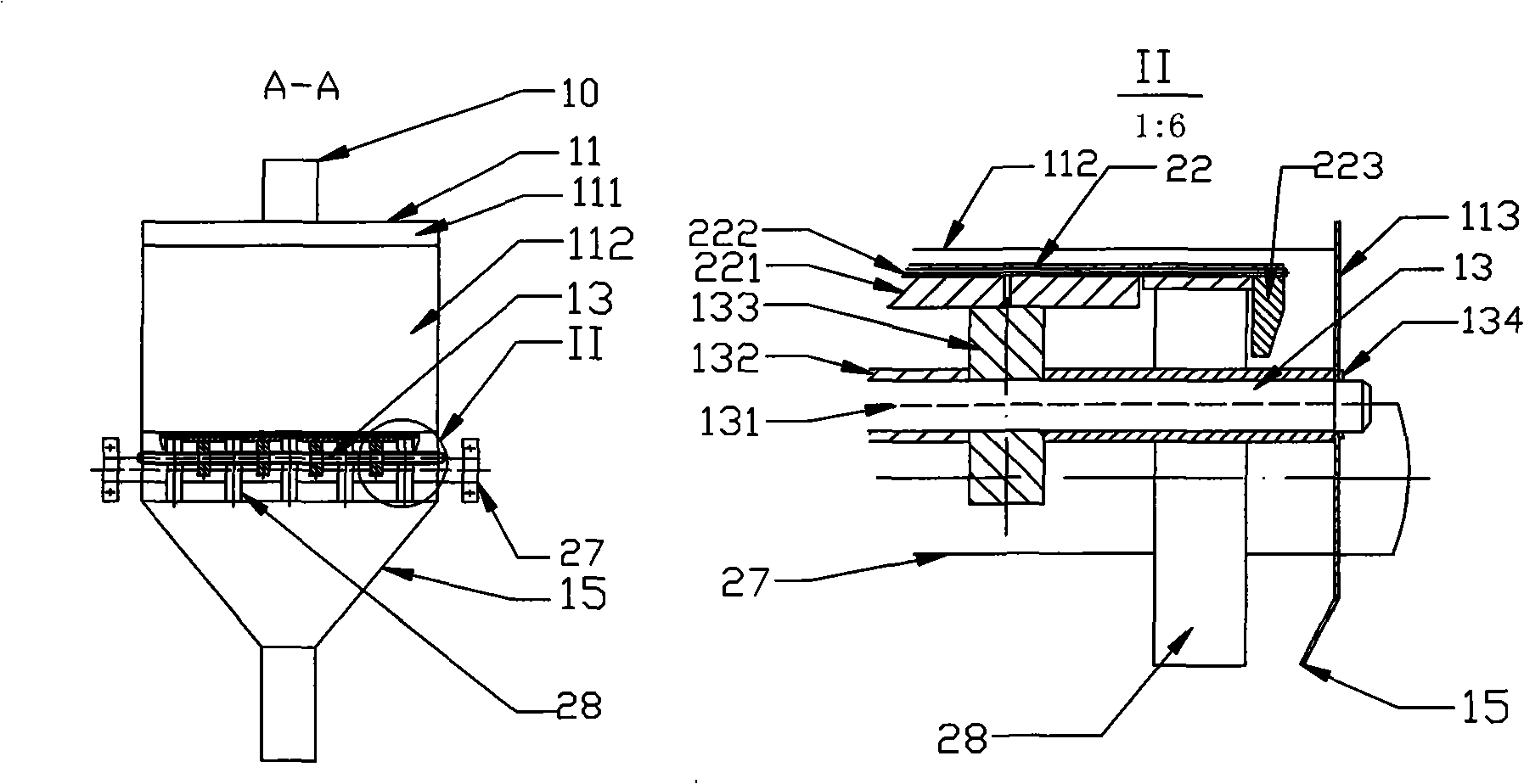

[0021] Such as figure 1 As shown, the grate machine 2 includes: a grate bed 22 for conveying pellets and a grate bed 220 for a return section, a driving sprocket (head sprocket) 21 and a driven sprocket (tail sprocket) 25 for driving the grate bed, and a support grate The upper support roller 23 and the lower support roller 28 of the bed, the grate bed tensioner 26, the support roller shaft 27, the grate machine cover 24, the ash box 29 for collecting dust and the interface part 20 connected with the rotary kiln etc. are composed.

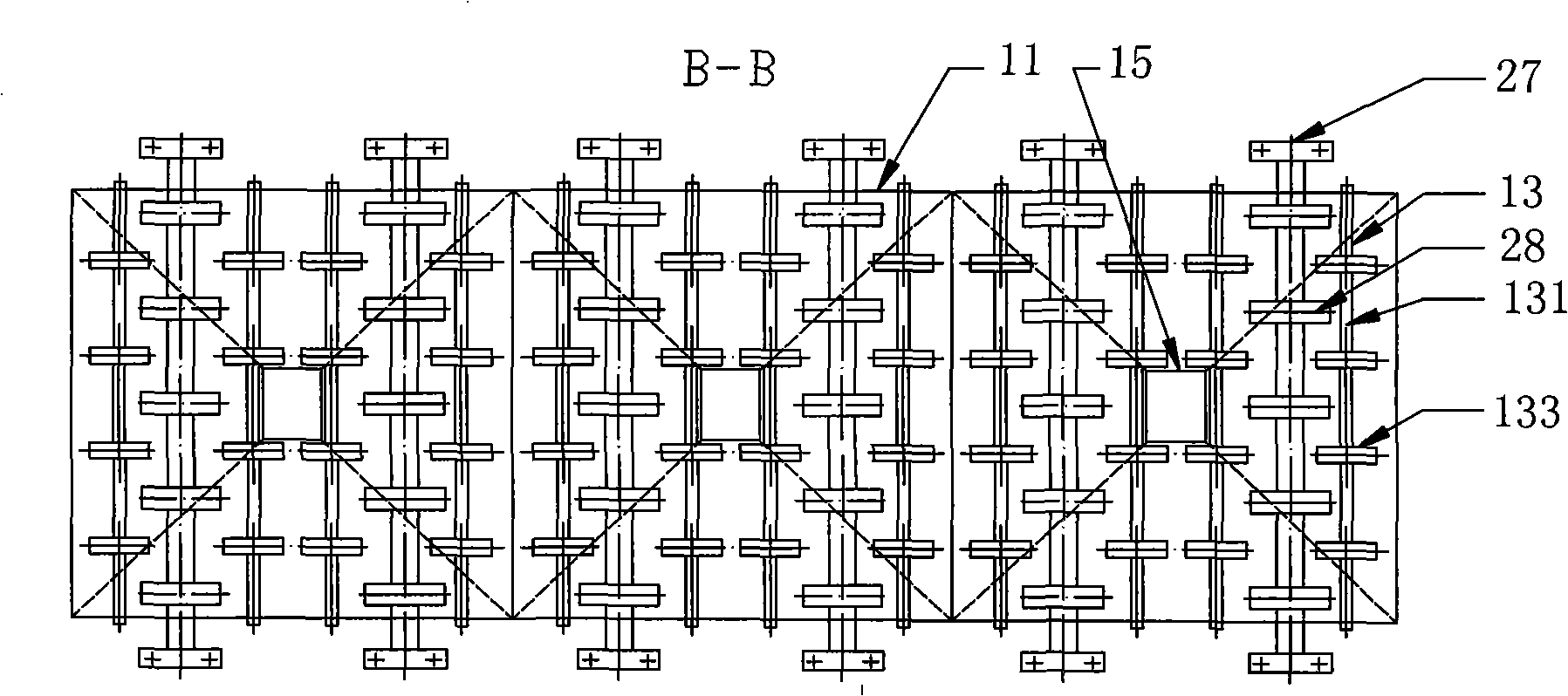

[0022] Such as figure 1 , 2 Shown in and 3, the installation position relationship of the grate bed waste heat recovery device 1 of the present invention is: the return section grate bed 220 installed on the lower part of the grate machine is docked with the ash box 29 and installed in parallel; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com