Multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and power jointly producing system

A waste heat recovery and combined heat and power generation technology, which is applied in heat recovery systems, heating systems, hot water central heating systems, etc., can solve problems such as no application value, loss of application value, and reduced injection ratio, so as to achieve investment reduction, High operational reliability and improved heat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The exhaust steam waste heat recovery cogeneration system based on multi-effect cascade jet heat exchange proposed by the present invention is described in detail in conjunction with the drawings and examples as follows:

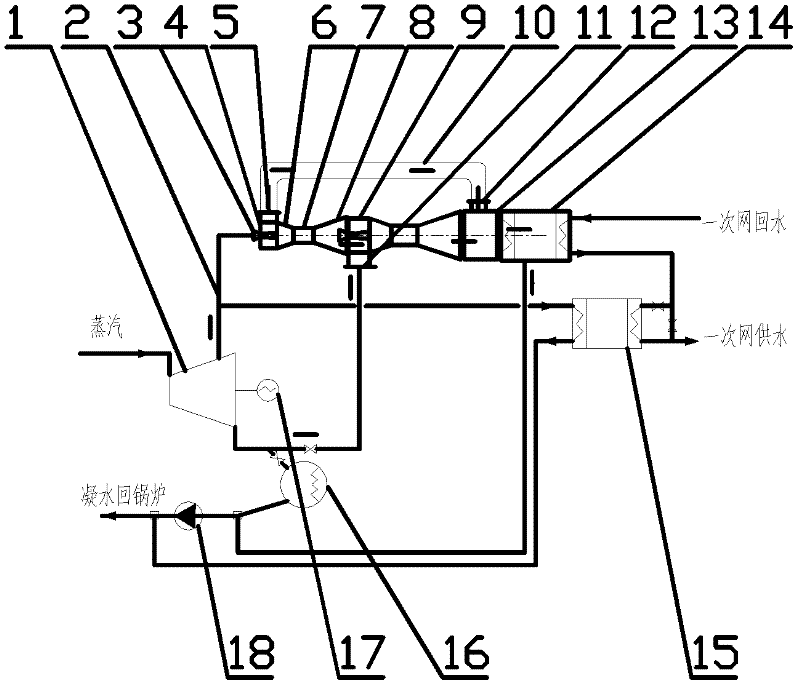

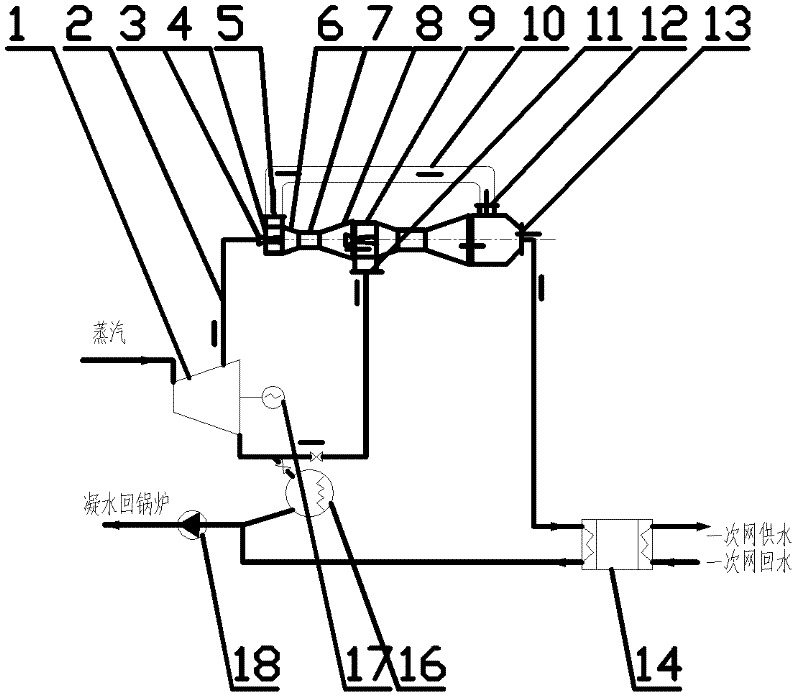

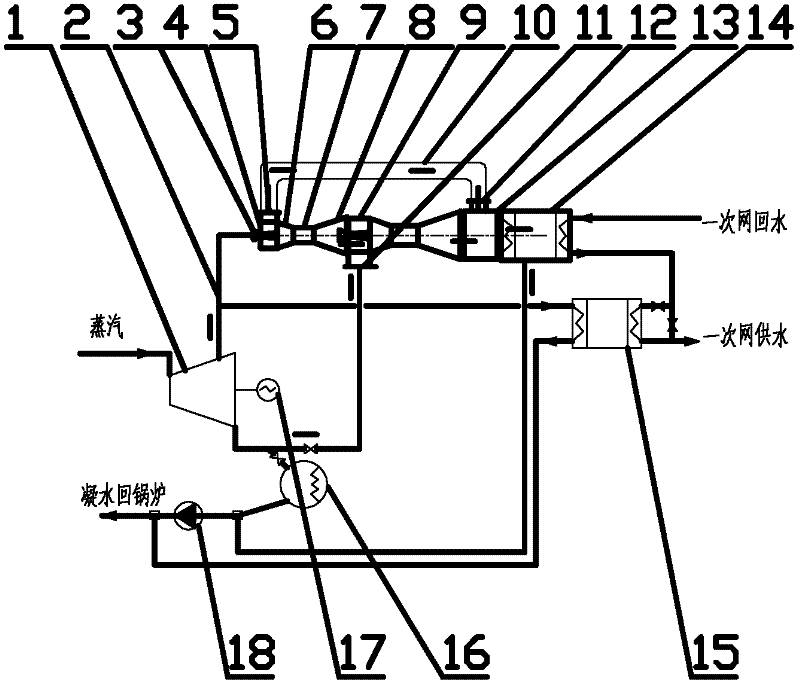

[0021] The structure of embodiment 1 of the waste steam waste heat recovery cogeneration system based on multi-effect cascade jet heat exchange of the present invention is as follows figure 1 as shown, figure 1 Among them, the integrated structure of low-pressure steam-water heater and jet heat pump is adopted, and the high-temperature heating network heater is connected in series. This embodiment includes: steam turbine 1, multi-effect cascade jet heat pump 4, final stage heater 15 of heating network, Heater 14, high-temperature heating network heater 15, condenser 16, generator 17, condensate pump 18; the multi-effect cascade jet heat pump 4 includes the first-stage injector 5, the last-stage injector connected in sequence as a whole Distributor 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com