Low-pressure coal saver for boiler

A low-pressure economizer and economizer tube technology, applied in indirect carbon dioxide emission reduction, combustion methods, lighting and heating equipment, etc., can solve the problem of increasing the heating surface of the high-pressure economizer, increasing the high-pressure Large air preheater and other problems, to avoid low temperature corrosion and ash blocking, high waste heat recovery effect, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The best embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

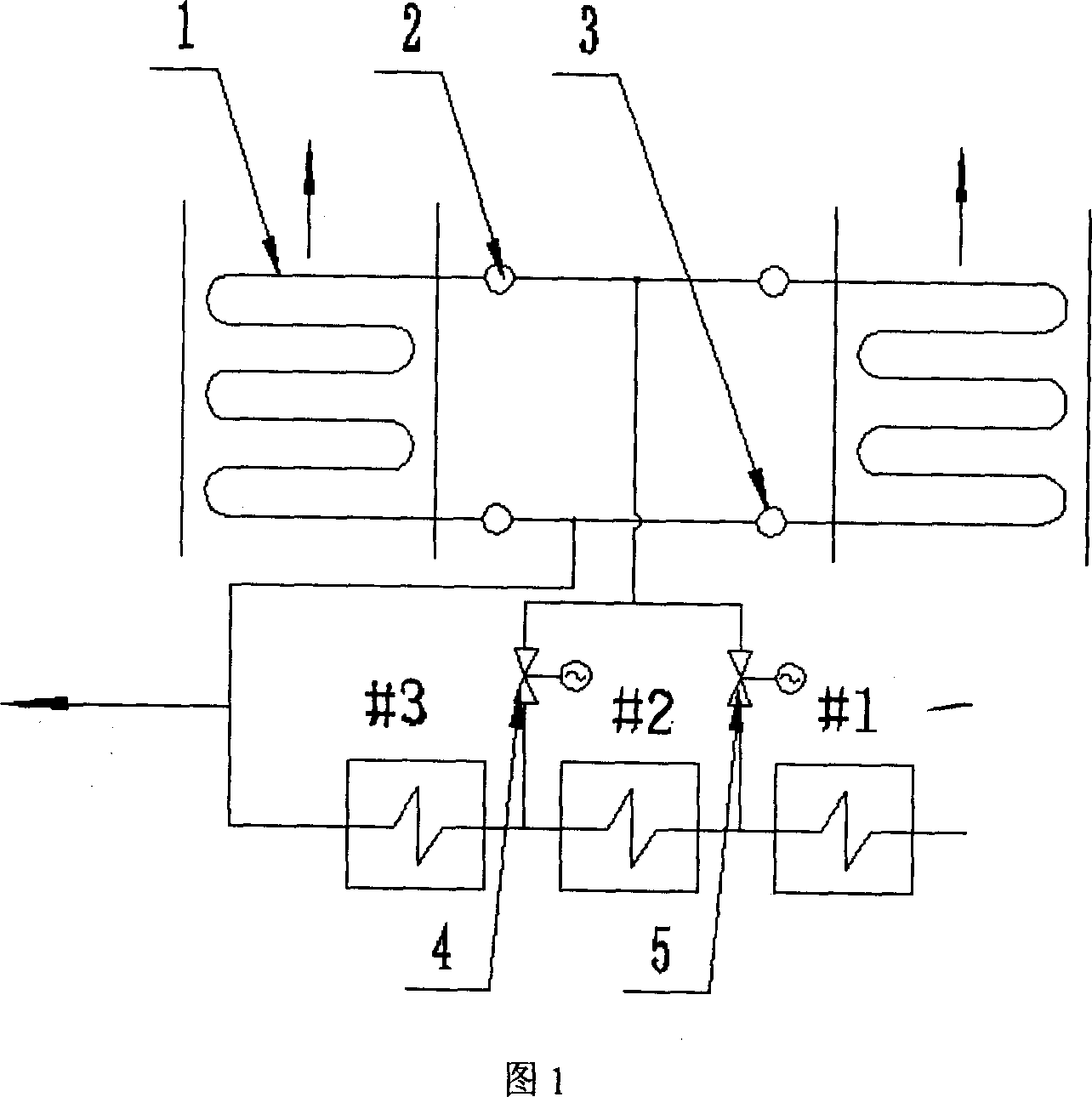

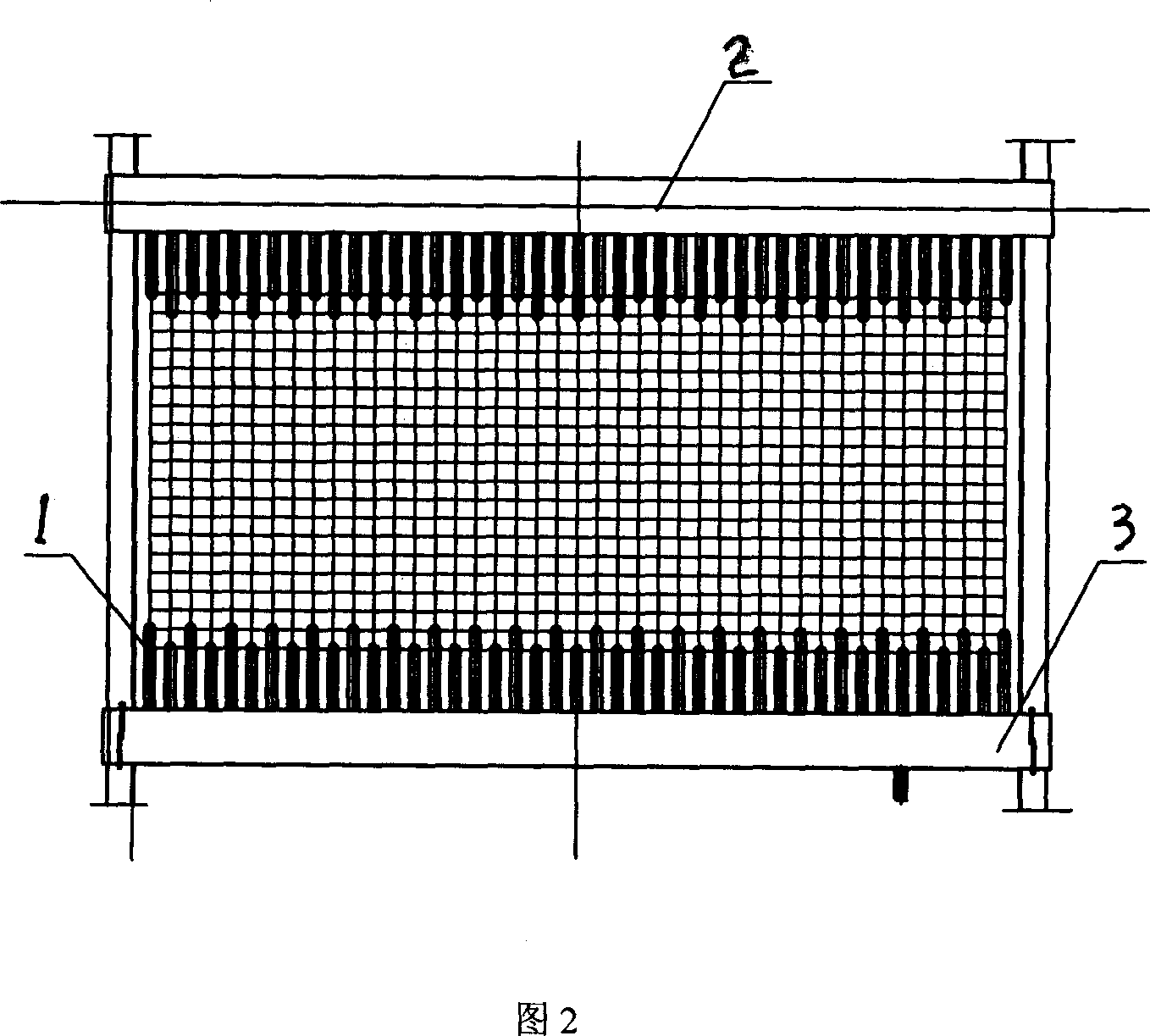

[0012] As shown in Figure 1 and Figure 2, the inlet header 2 is connected to the heater of the low-pressure recuperation system through pipelines, the outlet header 3 is connected to the deaerator through pipelines, and the low-pressure economizer is installed at the tail of the outlet of the boiler air preheater on the flue. The heat exchange tube bundles in the economizer tube panel are spiral finned tubes or longitudinally finned tubes. A high-temperature switching valve 4 and a low-temperature switching valve 5 are arranged in the pipeline connecting the inlet header 2 and the low-pressure heater. When the present invention works, the flue gas flowing out from the air preheater enters the outer space of the tube bundle 1 of the low-pressure economizer to flow, and releases heat so that the temperature of the flue gas is lowered. Condensed water is drawn fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com