Side joint pillar type electric melting pipe fitting

An electrofusion pipe fitting and column type technology, which is applied in the direction of pipes/pipe joints/pipes, pipe connection layout, mechanical equipment, etc., can solve the problems of large overall positioning outer diameter and terminal occupation, etc. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

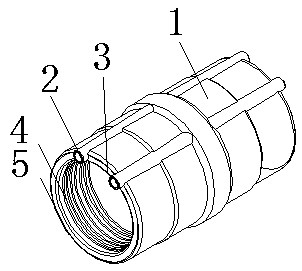

[0061] Such as figure 1 As shown, the present invention discloses a side post-type electrofusion pipe fitting, which includes a pipe body 1 and two terminals 2 arranged on the end wall of the end, and the pipe body includes two ends 3 and a first Heating wire 4; the first hot-melt material layer 5 is fixed on the inner wall surface of the pipe body; and the first heating wire is fixed in the first hot-melt material layer; both ends of the first heating wire are electrically connected respectively terminal. The terminal is arranged on the outer wall of the pipe body. The terminal is partially buried in the pipe body, and its top is exposed outside the pipe body. The terminal centerline is perpendicular to the end wall of the terminal.

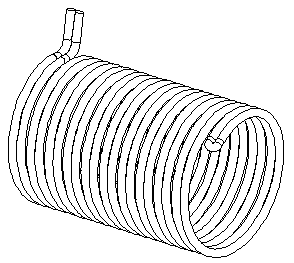

[0062] Its heating wire is as figure 2 As shown, the first heating wire includes two parallel cylindrical spiral heating wires that spiral in the same direction, and the two cylindrical spiral heating wires are connected at the same side of...

Embodiment 2

[0066] Such as Figure 4 As shown, the present invention discloses a side-connected post-type electrofusion pipe fitting, which includes a pipe body and two lugs arranged on the end wall of the end head on the pipe body, and the pipe body includes two end ends and the first heating wire; the first hot-melt material layer is fixed on the inner side of the pipe body; and the first heating wire is fixed in the first hot-melt material layer; the two ends of the first heating wire are respectively electrically connected terminal. The terminal is arranged on the outer wall of the pipe body. The terminals are all installed at the end away from the nozzle. The terminals are all embedded in the pipe body, and the tops thereof are exposed outside the pipe body.

Embodiment 3

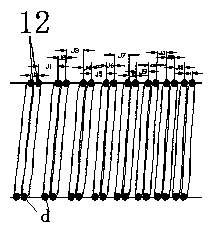

[0068] Such as Figure 5 As shown, the present invention discloses a side-connected post-type electrofusion pipe fitting, which includes a pipe body and four lugs respectively arranged on the end walls of the ends on both sides of the pipe body. The pipe body includes two A terminal and the first heating wire; the first hot-melt material layer is fixed on the inner side of the pipe body; and the first heating wire is fixed in the first hot-melt material layer; the two ends of the first heating wire are respectively Electrically connect the lugs. The terminal is arranged on the outer wall of the pipe body. The terminals are all installed at the end away from the nozzle. The terminal is partially buried in the pipe body, and its top is exposed outside the pipe body. An installation groove 6 is provided on the outer edge of the end wall of the terminal head, and the terminal head is installed in the installation groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com