Integrated heater of core-making fluid

A heater, integrated technology, used in manufacturing tools, metal processing equipment, parts of molding machines, etc., can solve the problems of leakage, inability to achieve high heat exchange efficiency, bulky and other problems, and achieve easy installation, miniaturization, and heat exchange. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

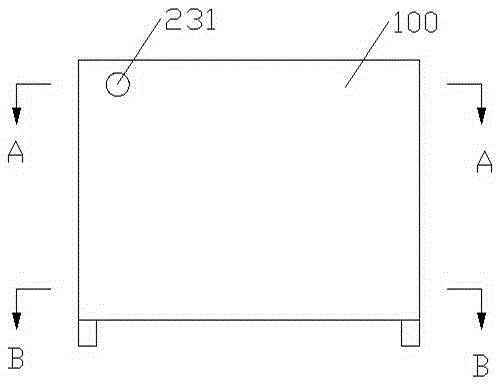

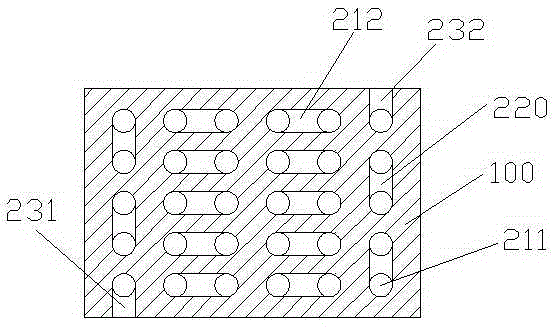

[0025] Embodiment one: see Figure 1 to Figure 5 , as shown in the legend therein, an integral heater for core-making fluid, used for heating air, includes an integrally cast heating body 100, the heating body 100 is provided with a flow channel structure, the flow channel structure includes along X Five flow channel units arranged in sequence along the axis direction and four transition flow channels 220 extending along the X-axis direction, each flow channel unit includes six main body flow channels 211 arranged in sequence along the Y-axis direction and extending along the Z-axis direction, and four transition flow channels 220 extending along the Y-axis direction. Five detour channels 212 extending in the axial direction, the detour channels 212 communicate with the ports of two adjacent body channels 211 , and the transition channels 220 communicate with the body channels 211 of adjacent channel units.

[0026] The two free ports of the body flow channel of the above-ment...

Embodiment 2

[0033] The rest is the same as the first embodiment, except that the integral heater is heated by gas, the heating body is reserved with a gas heating cavity, and the flow channel structure is arranged around the gas heating cavity.

Embodiment 3

[0035] The rest is the same as in Embodiment 1, except that the five flow channel units are arranged in sequence along the first setting direction, the above-mentioned transition flow channels extend along the first setting direction, and the above-mentioned six body flow channels are sequentially arranged along the second setting direction Arranged, the above-mentioned body flow channel extends along the third setting direction, the above-mentioned roundabout flow channel is arranged in sequence along the second setting direction, the above-mentioned first setting direction, the above-mentioned second setting direction and the above-mentioned third setting direction are not on the same plane Inside, the first set direction and the second set direction form an angle A, the first set direction and the third set direction form an angle B, the second set direction and the third set direction The set direction forms an included angle C, the angle range of the above-mentioned angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com