Waste heat recovery device applied to air separation purification system and key parameter determination method thereof

A technology of waste heat recovery device and key parameters, which is applied in the field of waste heat recovery device of air separation purification system, can solve the problems of energy waste, difficult utilization of heat of cold blowing nitrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

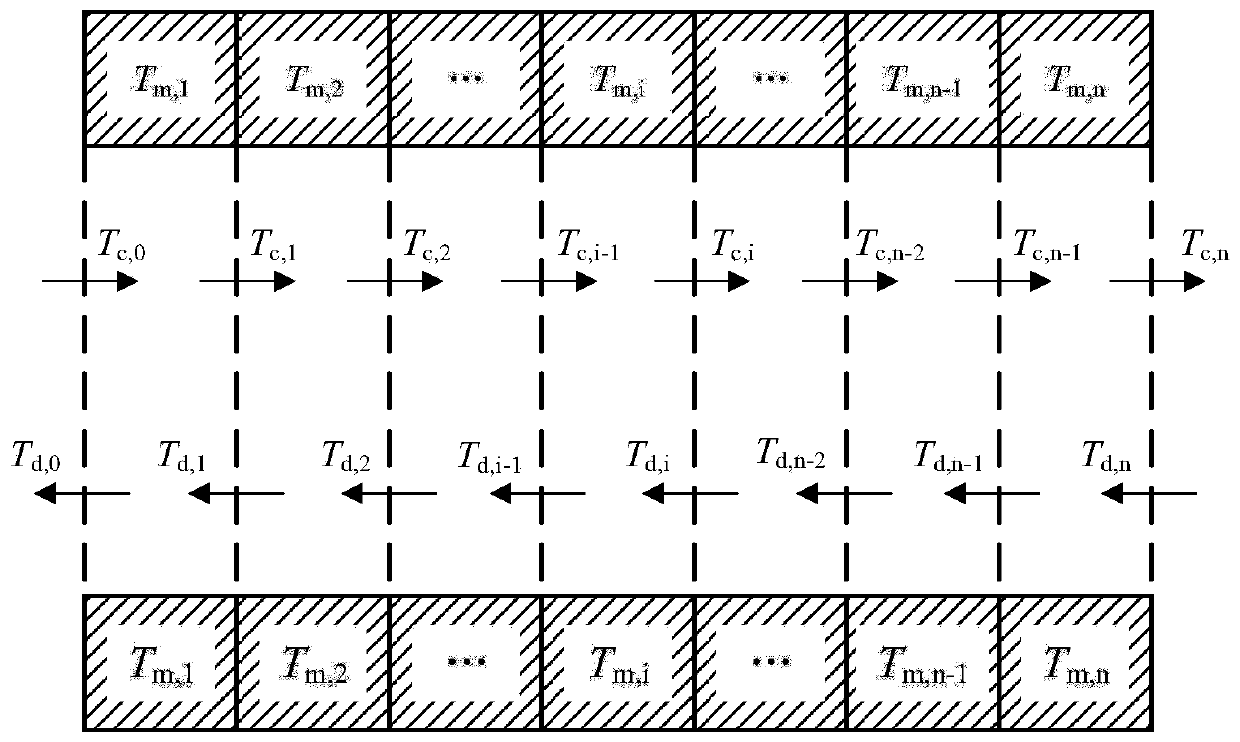

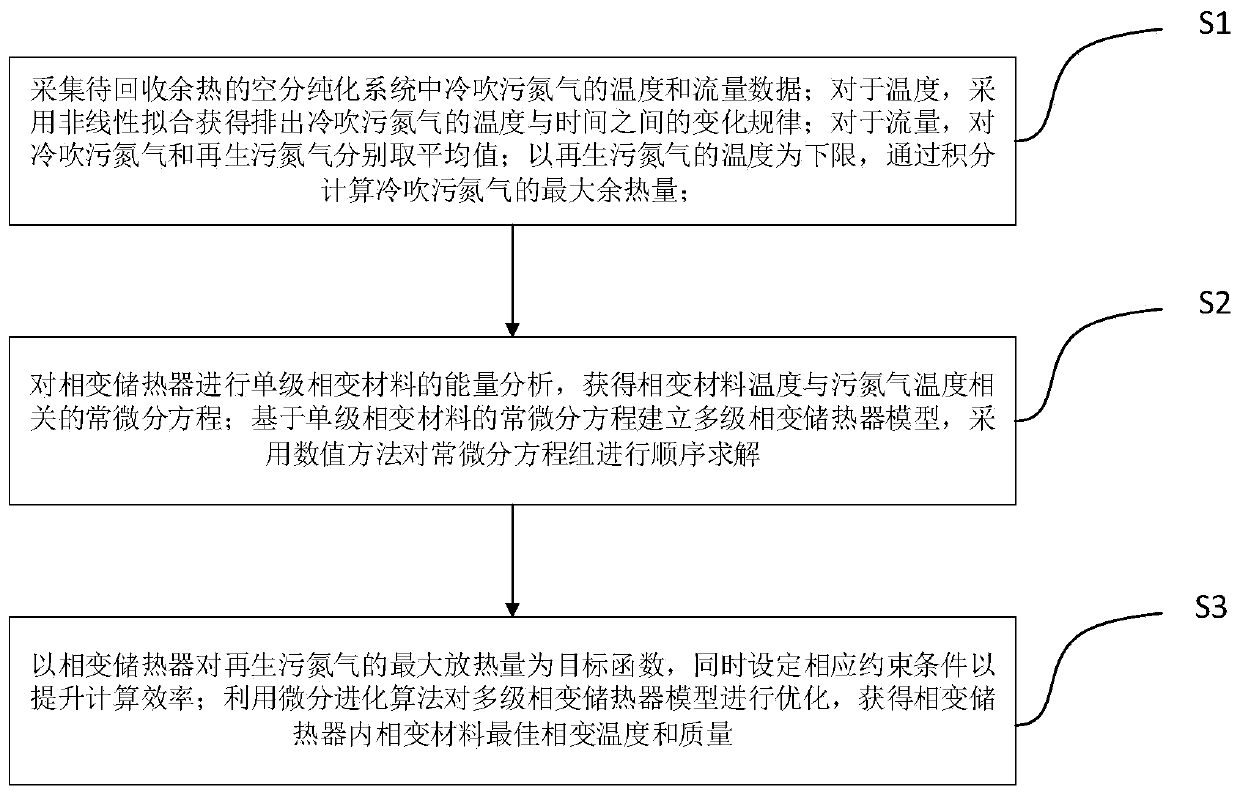

Method used

Image

Examples

Embodiment

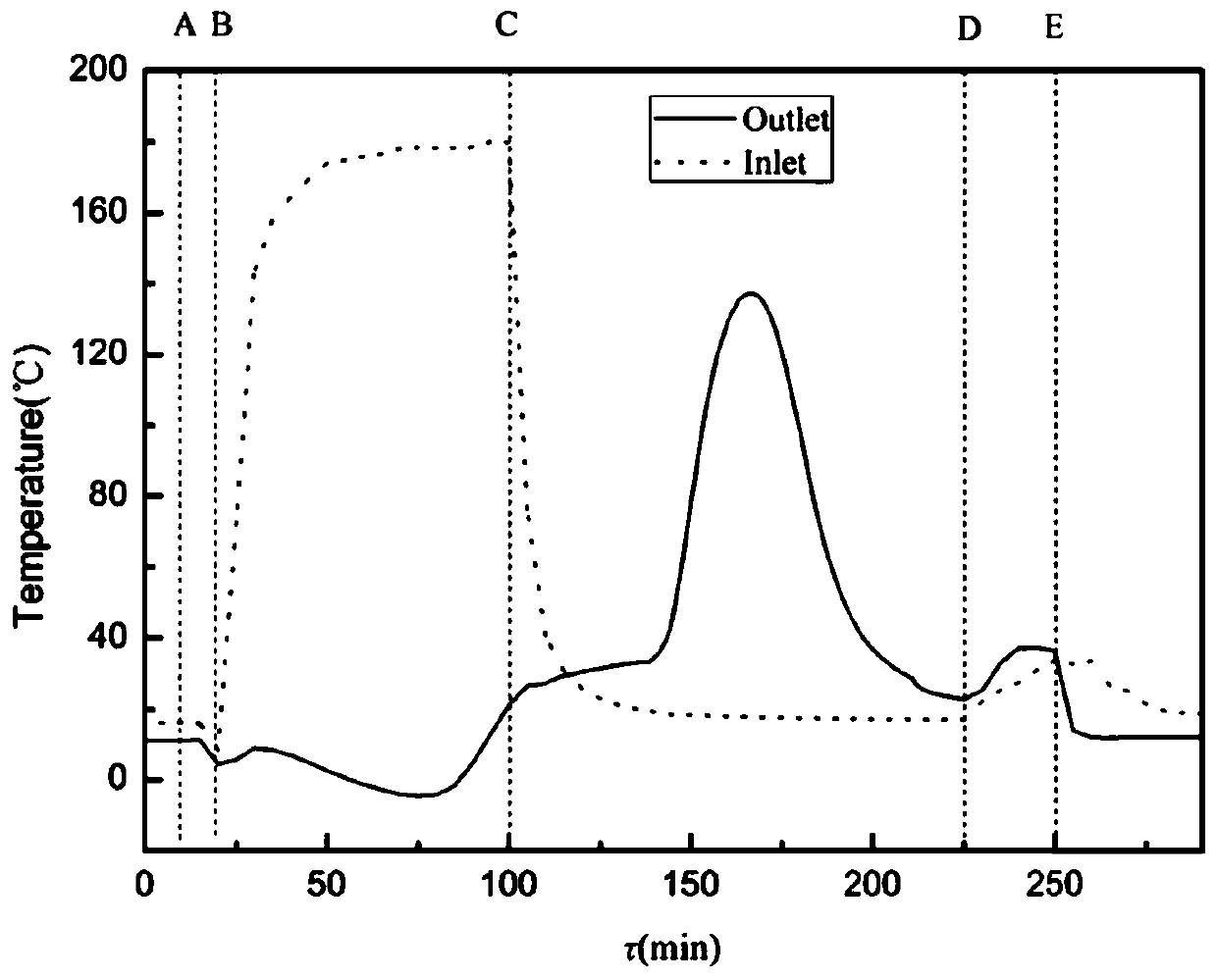

[0145] Data analysis: Select an 80,000 air separation and purification system for data collection, and the temperature and flow rate changes of the sewage nitrogen at the inlet and outlet are as follows: image 3 and Figure 4 shown. Depend on image 3 It can be seen that the regeneration process of the air separation and purification system is divided into four stages, among which, AB is the depressurization stage, BC is the heating stage, CD is the cold blowing stage, and DE is the boosting stage. The actual running time of each stage is 10, 80, 125 and 25 minutes. Depend on Figure 4 It can be seen that the flow rate of contaminated nitrogen in the above four stages is significantly different, and the flow rate of contaminated nitrogen gas in cold blowing is significantly higher than that in other stages. For the convenience of calculation, the average value of the dirty nitrogen flow in the heating and cold blowing process is: 48420.53m 3 / h and 60711 m 3 / h. Waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com