Water washing device

A washing device and pool technology, which is applied in the direction of water treatment and refining, can solve the problems of complex and large equipment, non-continuous production, time-consuming efficiency, etc., and achieve the effect of increasing the washing area, speeding up the washing rate, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

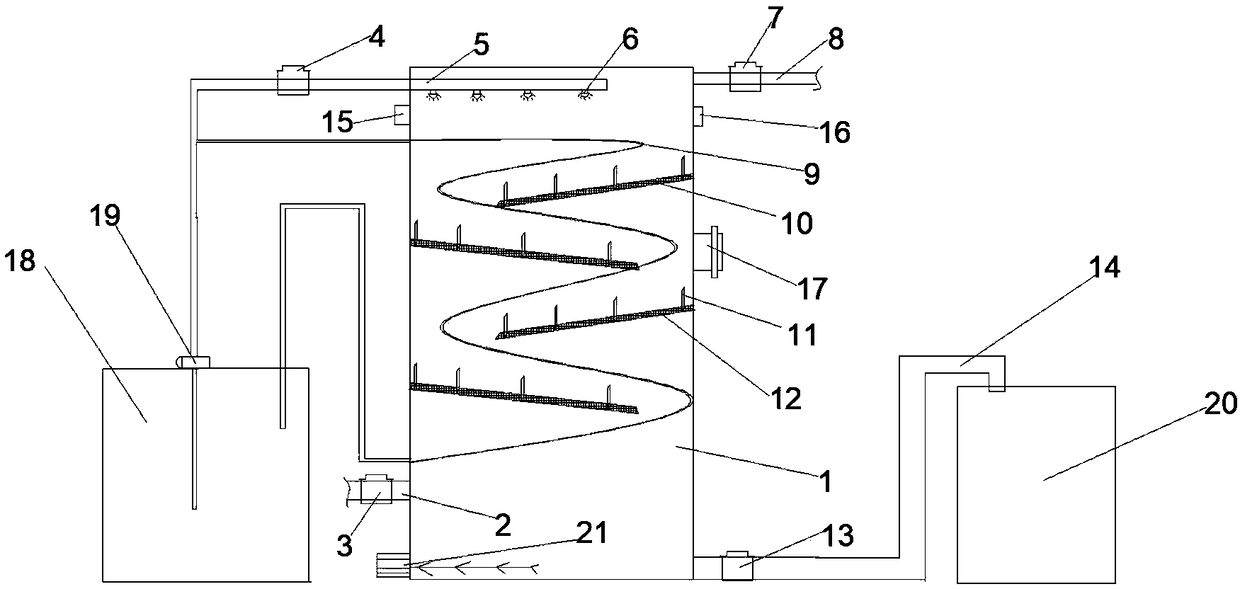

[0024] Such as figure 1 As shown, a water washing device includes a washing machine body 1, a feed pipe 2 is connected to the lower part of the outer surface of the water washing machine body 1 by bolts, a first valve 3 is connected to the bolts on the feed pipe 2, and an inlet valve 3 is connected to the upper outer wall of the water washing machine body 1 by bolts. The water pipe 5 is connected with the water inlet pipe 5 by bolts on the water inlet pipe 5, and the water inlet pipe 5 is provided with a nozzle 6 running through the body, and there are 4 nozzles 6. The material pipe 8 is bolt-connected with a third valve 7; the inside of the washing machine body 1 is provided with a deflector 10 obliquely, and the deflector 10 is provided with a baffle 11. The plate 11 is located on the upper part of the deflector 10, and the baffle 11 is arranged in a vertical direction. The deflector 10 is inclined downward, and the angle between it and the horizontal plane is preferably 30°...

Embodiment 2

[0026] Such as figure 1 As shown, this embodiment is a further optimization made on the basis of Embodiment 1. Specifically, a movable stirring motor 21 is provided at the inner lower end of the washing body 1 near the bottom, and the movable stirring motor 21 includes a stirring blade, a rotating shaft And the motor, the rotating shaft is arranged perpendicular to the side wall of the washing machine body 1, and runs through the wall of the washing machine body 1 to be connected with the motor.

[0027] In this embodiment, the water washing rate can be accelerated by setting the movable stirring motor 21 .

Embodiment 3

[0029] Such as figure 1 As shown, this embodiment is a further optimization made on the basis of Embodiment 1 and Embodiment 2. Specifically, a flange cover 17 is provided on the outside of the washing body 1, and a handle is provided on the flange cover 17; The upper end of the flange cover 17 is provided with a sampling port 16 near the discharge pipe 8 .

[0030] In this embodiment, by setting the flange cover 17, the filter screen 12 can be taken out and cleaned through the flange cover 17 when the filter screen 12 is blocked, which is convenient for maintenance of the body; by setting the sampling port 16, the washing process can be monitored in real time, so that the operator cannot judge the solution in time. Whether the solution meets the water washing standard, and the operator's misjudgment leads to incomplete washing of the solution.

[0031] working principle

[0032] Open the first valve 3 and the movable stirring motor 21 switch and close the water inlet pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com