Odor removal device and method for plastic film processing

A plastic film and odor technology, applied in the field of plastic film processing, can solve the problems of poor purification effect, injury to workers, pollution of the environment, etc., and achieve the effect of slowing down the discharge rate, convenient disassembly and cleaning, and enhancing the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] According to an embodiment of the present invention,

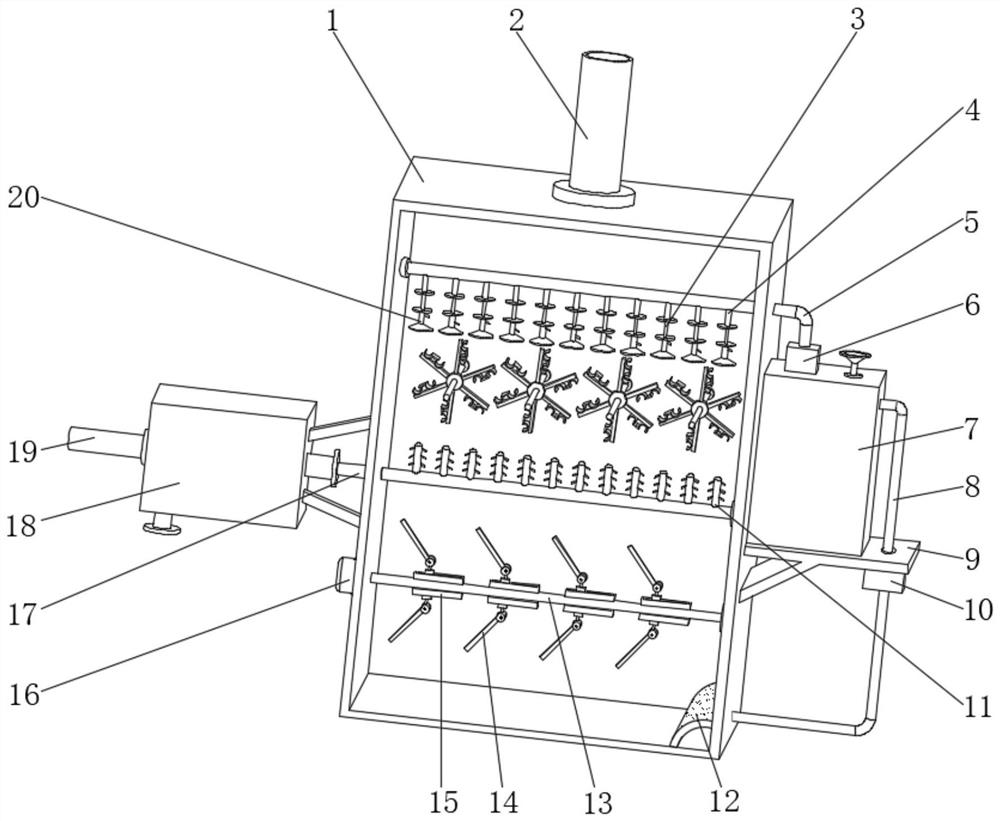

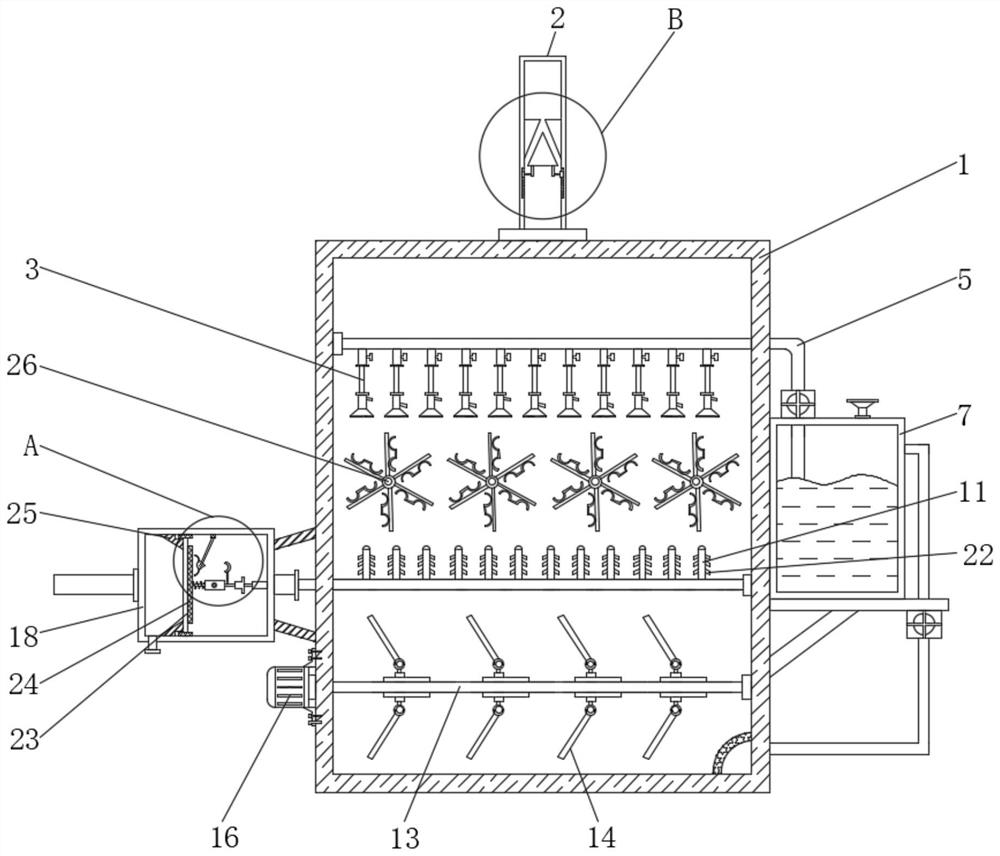

[0036] see figure 1 , a plastic film processing deodorization device, comprising a box body 1, one side of the outer wall of the box body 1 is fixedly connected with a mounting rod, and one end of the mounting rod is fixedly connected with a miscellaneous removal box 18, and the outer walls of both sides of the miscellaneous case 18 are An air intake pipe 19 is plugged in, and a purification assembly for filtering exhaust gas is provided inside the miscellaneous removal box 18, and a connecting pipe 17 is inserted into the inner wall of one end of the air inlet pipe 19, and one end of the connecting pipe 17 extends to the inside of the box body 1, and is connected to The top outer wall of the pipe 17 is plugged with equidistantly distributed exhaust pipes 11, the outer wall of one side of the box body 1 is fixedly connected with the support frame 9, and the top outer wall of the support frame 9 is fixedly connected ...

Embodiment 2

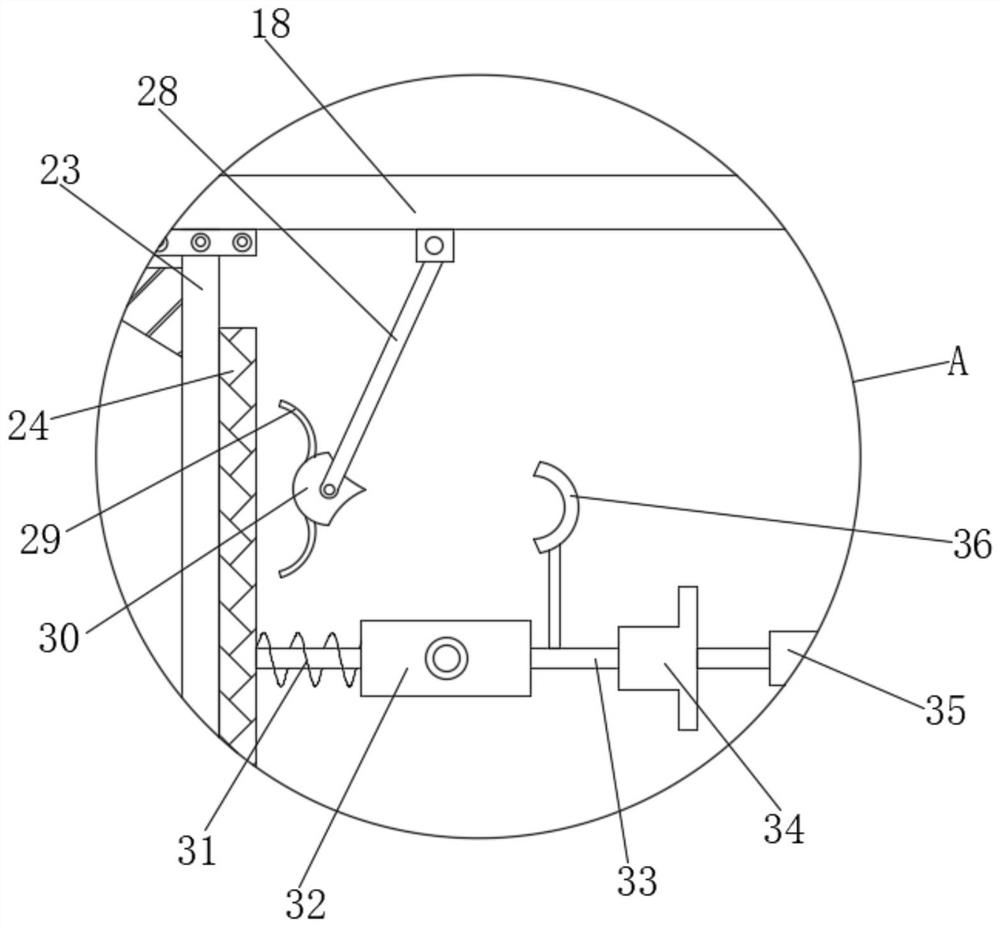

[0039] see Figure 1-3 , the purification assembly includes a second filter screen 23 fixedly connected to the inner wall on both sides of the trash removal box 18, and also includes a third filter screen 24 that is pressed against the outer wall on one side of the second filter screen 23, and the inner walls on both sides of the trash removal box 18 are An air guide plate 25 is fixedly connected, a pull rod 33 is fixedly connected to one side outer wall of the third filter screen 24, and a cylinder body 32 is fixedly connected to both inner walls of the miscellaneous removal box 18, and one end of the pull rod 33 is connected to Through the inside, the outer wall of one end of the pull rod 33 is sleeved with a first spring 31, and the inner wall of one side of the debris removal box 18 is fixedly connected with an electric push rod 35, and the outer wall of one end of the electric push rod 35 is fixedly connected with a card slot 34, and the pull rod One end of 33 and one sid...

Embodiment 3

[0041] see Figure 1-2 , the spray assembly includes a liquid outlet pipe 4 plugged on the outer wall of the bottom of the catheter tube 5, one end of the liquid outlet pipe 4 is plugged with a bellows 3, one end of the bellows 3 is plugged with a nozzle 20 on the outer wall, and one end of the liquid outlet pipe 4 The outer wall of the side is provided with a solenoid valve, and a shunt pipe is plugged into the outer wall of one side of the nozzle 20. During the process of spraying the treatment liquid through the nozzle 20, because there is a shunt pipe on the outer wall of the nozzle 20, part of the treatment liquid will pass through. The shunt pipe sprays out, and the treatment liquid sprayed out by the shunt pipe will be shot on the outer wall of one side of the other spray head 20, so the other spray head 20 can be shaken, thereby expanding the spraying area of the spray head 20 for the treatment liquid, so that the treatment The liquid is more fully in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com