Processing method for improving storage stability of highland barley

A technology of storage stability and processing method is applied in the processing field of improving the storage stability of highland barley, and can solve the problems of reducing the nutrition and commodity value of highland barley, prone to oxidative deterioration, and shortening the shelf life and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

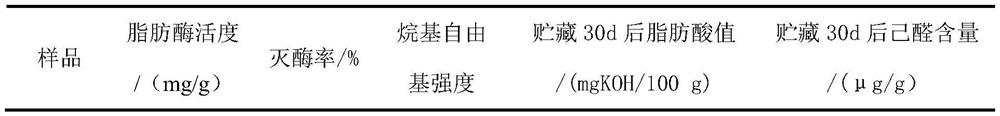

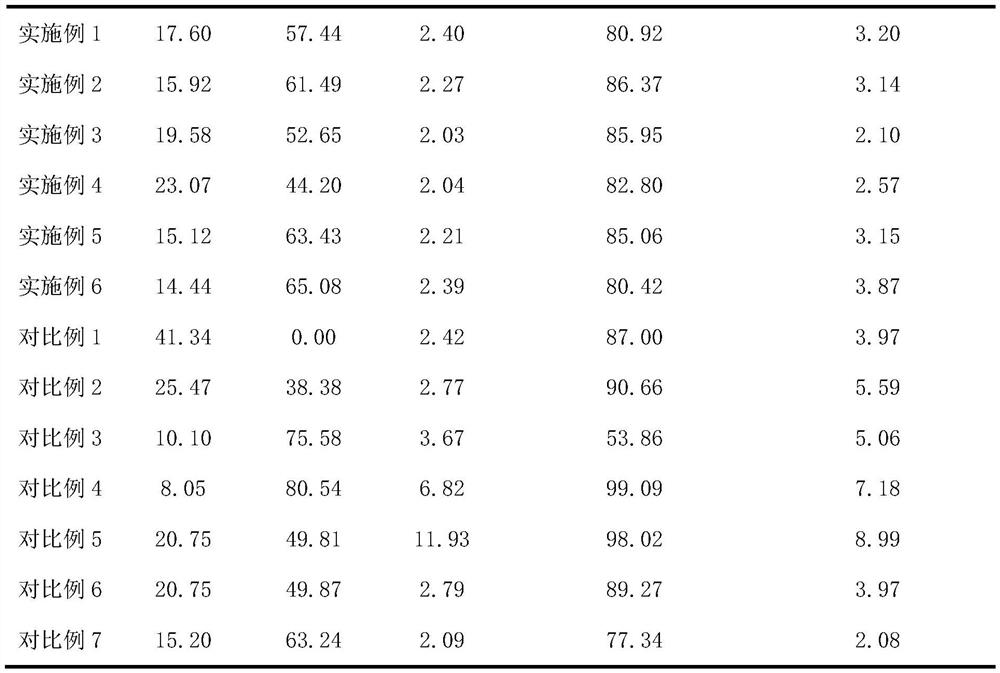

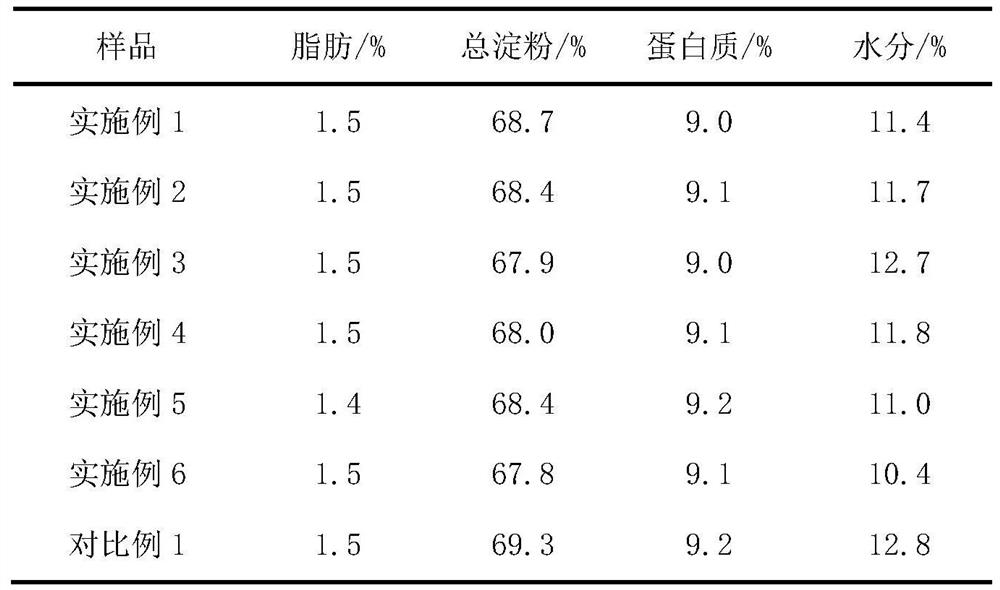

Examples

Embodiment 1

[0044] A processing method for improving storage stability of highland barley, comprising the steps of:

[0045] (1) water replenishment treatment: carry out water replenishment to 500g highland barley, control target water replenishment amount 1.5%, seal after fully mixing, place in room temperature and balance;

[0046] (2) Radio frequency treatment: place the highland barley treated with water in the container, spread it evenly, and the sample thickness is 4cm; place the aforementioned container containing highland barley in the center of the lower plate of the radio frequency chamber for radio frequency treatment; the target temperature of radio frequency is 105°C , the RF processing time is 14.5min, the distance between the plates is 120mm, the power is 1.43kW, and the resonance frequency is 27.12MHz;

[0047] (3) Cooling treatment: cool the highland barley after radio frequency treatment to room temperature and store it in a ziplock bag.

Embodiment 2

[0049] A processing method for improving storage stability of highland barley, comprising the steps of:

[0050] (1) water replenishment treatment: carry out water replenishment to 500g highland barley, control target water replenishment amount 3.5%, seal after fully mixing, place in room temperature and balance;

[0051] (2) Radio frequency treatment: place the highland barley treated with water in the container, spread it evenly, and the sample thickness is 4cm; place the aforementioned container containing highland barley in the center of the lower plate of the radio frequency chamber for radio frequency treatment; the target temperature of radio frequency is 105°C , the RF processing time is 14.2min, the distance between the plates is 120mm, the power is 1.43kW, and the resonance frequency is 27.12MHz;

[0052] (3) Cooling treatment: cool the highland barley after radio frequency treatment to room temperature and store it in a ziplock bag.

Embodiment 3

[0054] A processing method for improving storage stability of highland barley, comprising the steps of:

[0055] (1) water replenishment treatment: carry out water replenishment to 500g highland barley, control target water replenishment amount 5.5%, seal after fully mixing, place in room temperature and balance;

[0056] (2) Radio frequency treatment: place the highland barley treated with water in the container, spread it evenly, and the sample thickness is 4cm; place the aforementioned container containing highland barley in the center of the lower plate of the radio frequency chamber for radio frequency treatment; the target temperature of radio frequency is 105°C , the RF processing time is 14.0min, the distance between the plates is 120mm, the power is 1.43kW, and the resonance frequency is 27.12MHz;

[0057] (3) Cooling treatment: cool the highland barley after radio frequency treatment to room temperature and store it in a ziplock bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fatty acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com