A kind of spinning method of the high-viscosity polyester melt that reduces oligomer

A polyester melt and oligomer technology, used in textiles and papermaking, filament forming treatment, feeding solution to spinnerets, etc., can solve problems such as affecting the life of melt filters, reducing efficiency, and blocking filter holes. , to reduce the possibility of generation, reduce the melt flow rate, reduce the internal shear heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

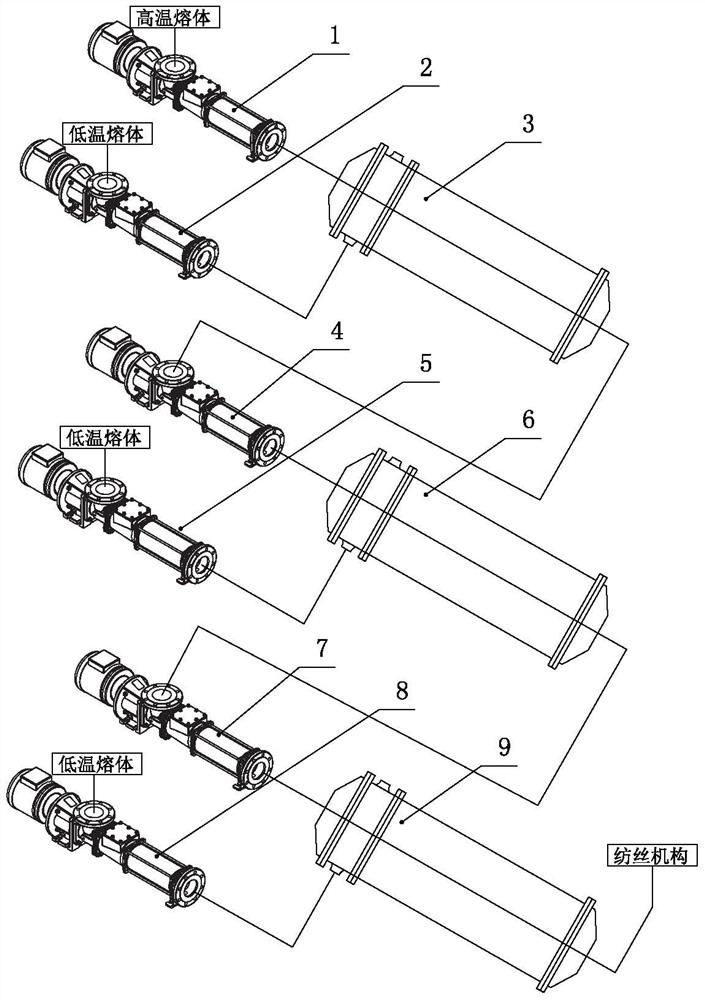

[0024] Such as figure 1 Shown, be a kind of spinning method that reduces the high viscosity polyester melt of oligomer, comprises the steps:

[0025] (1) The high-temperature melt after viscosity increase is transported to the spinning mechanism through the three-stage screw pump; the temperature of the high-temperature melt at the output end of the screw pump at each level is 285±5°C; the three-stage screw pumps are respectively the first-stage screw pump 1 , the second-stage screw pump 4 and the third-stage screw pump 7;

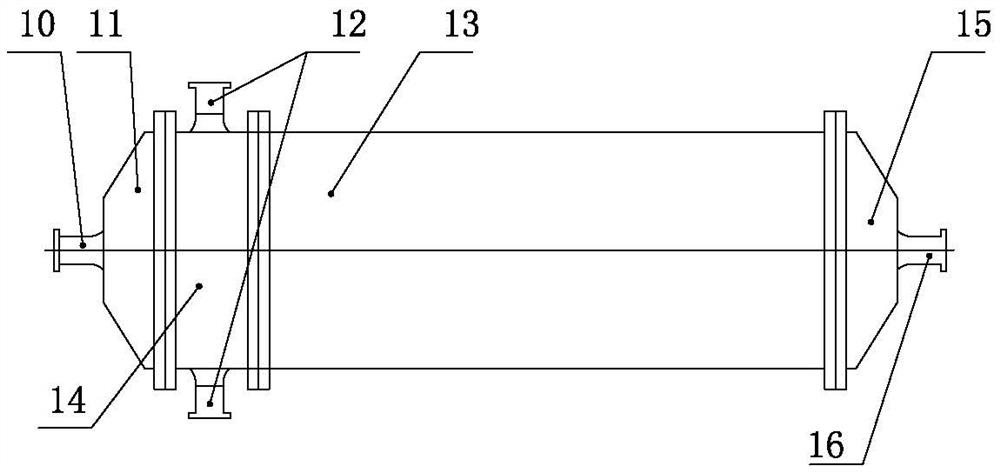

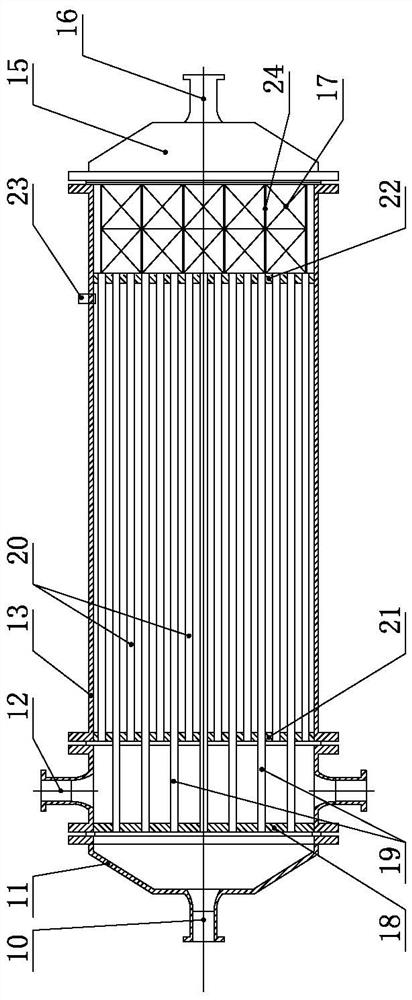

[0026] (2) Install a mixer after each stage of the multi-stage screw pump, specifically: the outlet of the first-stage screw pump 1 is connected to the high-temperature melt inlet 10 of the first-stage mixer 3, and the mixed output of the first-stage mixer 3 Port 16 is connected to the inlet of the second-stage screw pump 4, the outlet of the second-stage screw pump 4 is connected to the high-temperature melt inlet 10 of the second-stage mixer 6, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com