Patents

Literature

76results about How to "Guarantee the quality of spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

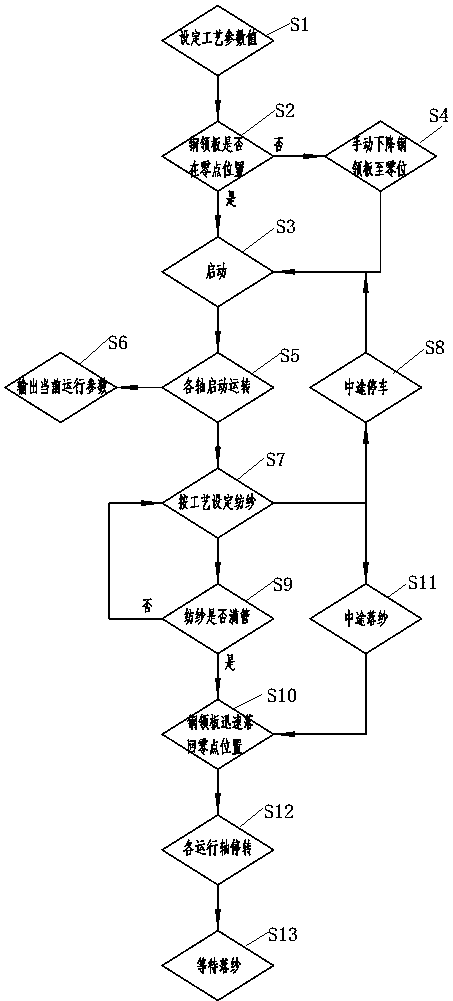

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

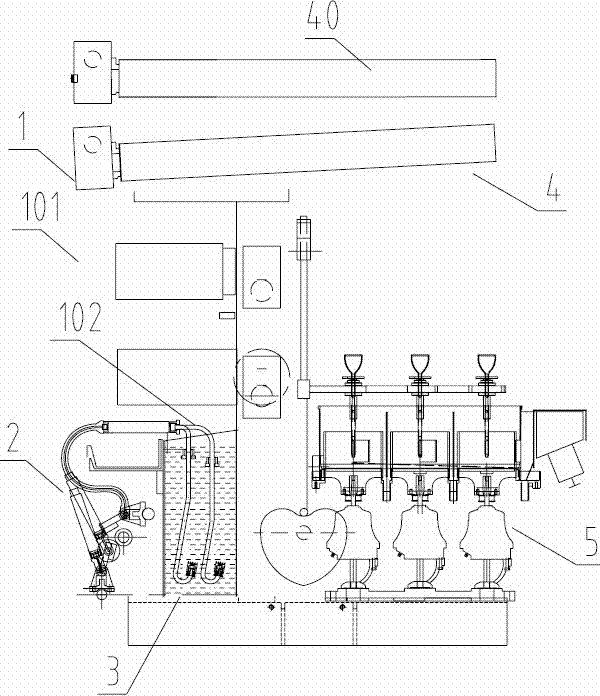

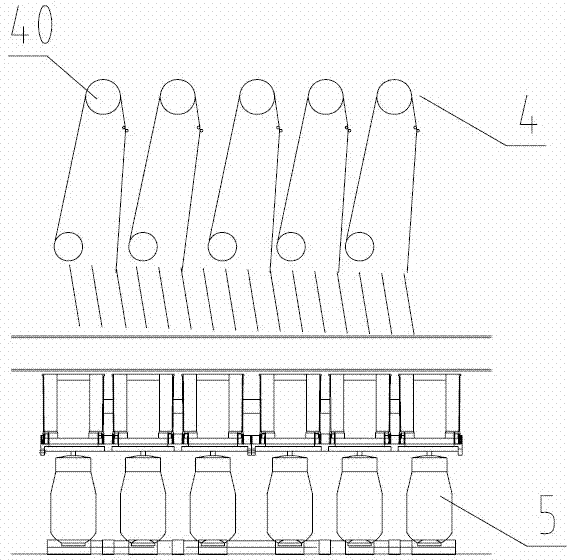

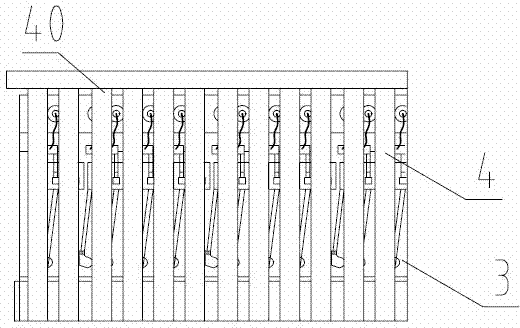

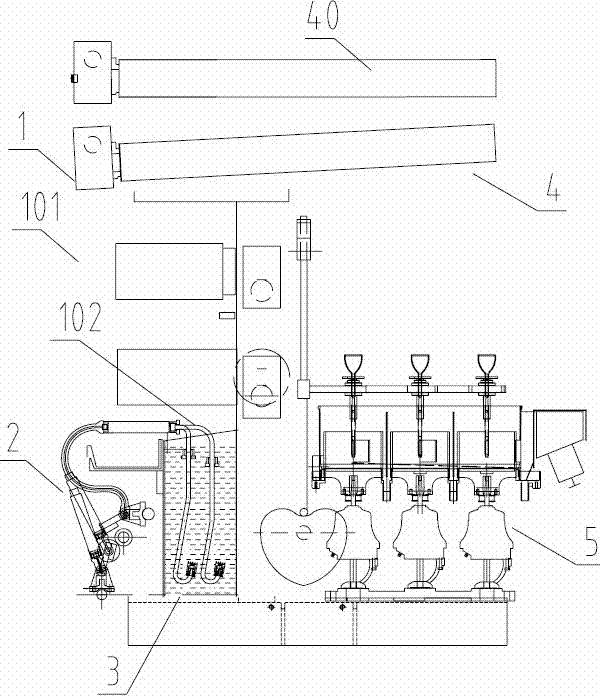

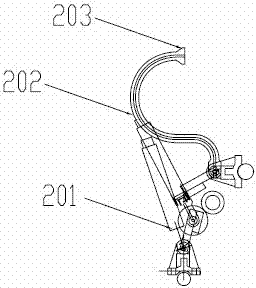

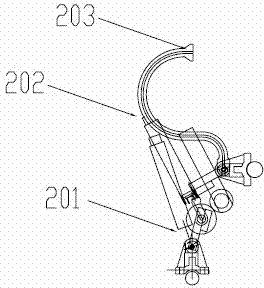

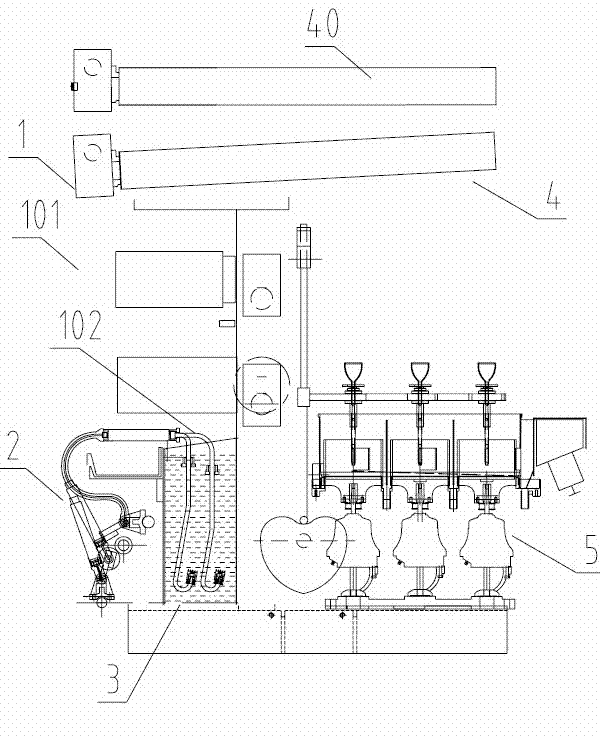

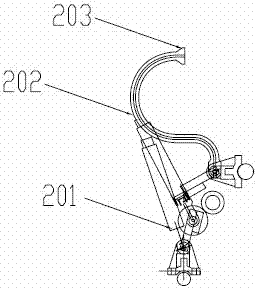

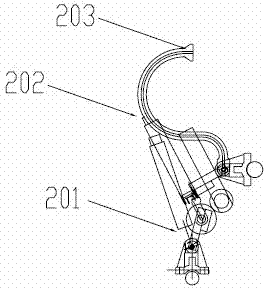

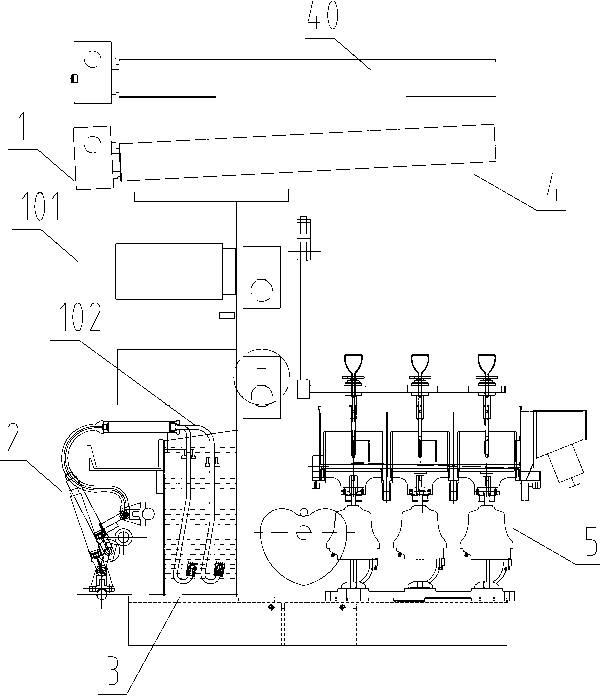

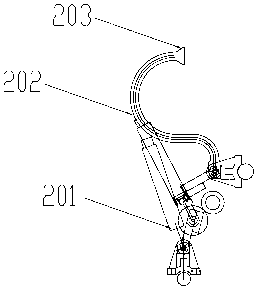

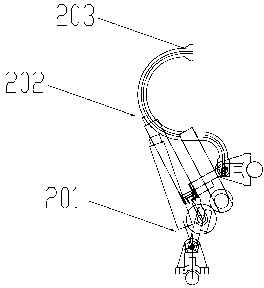

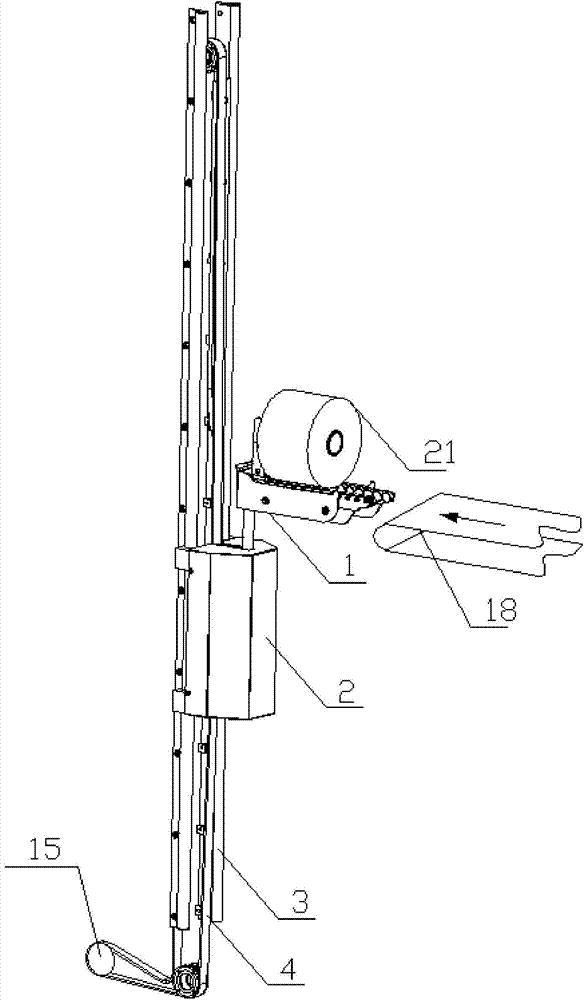

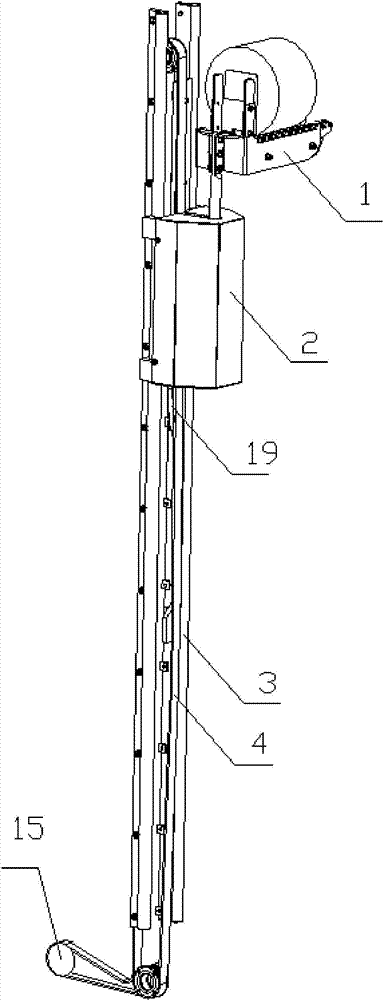

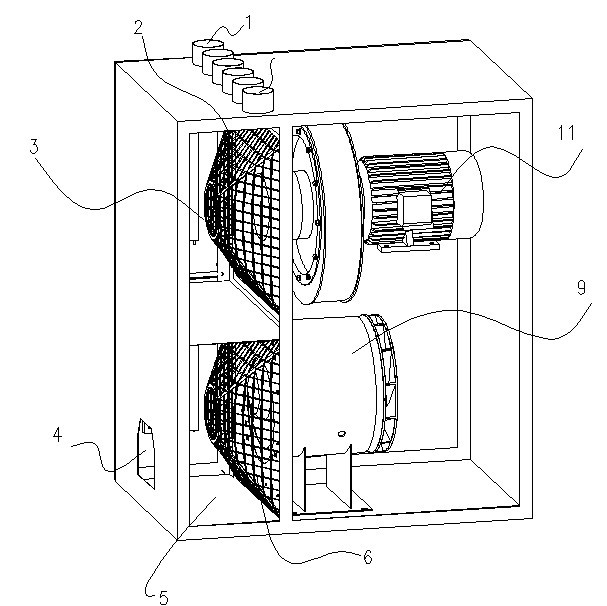

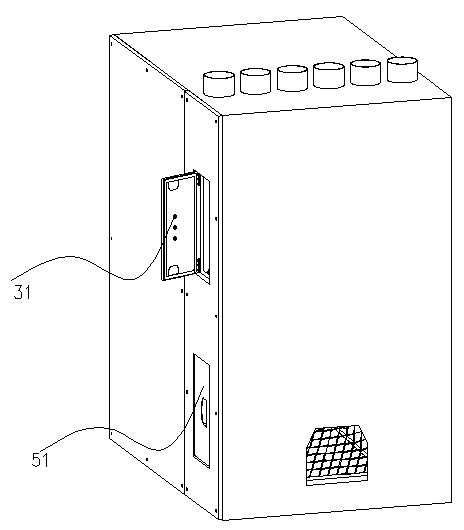

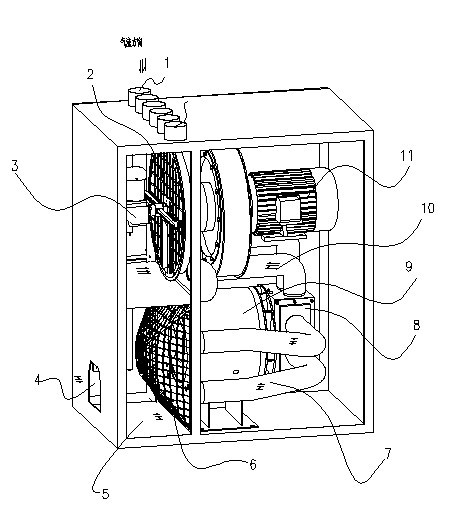

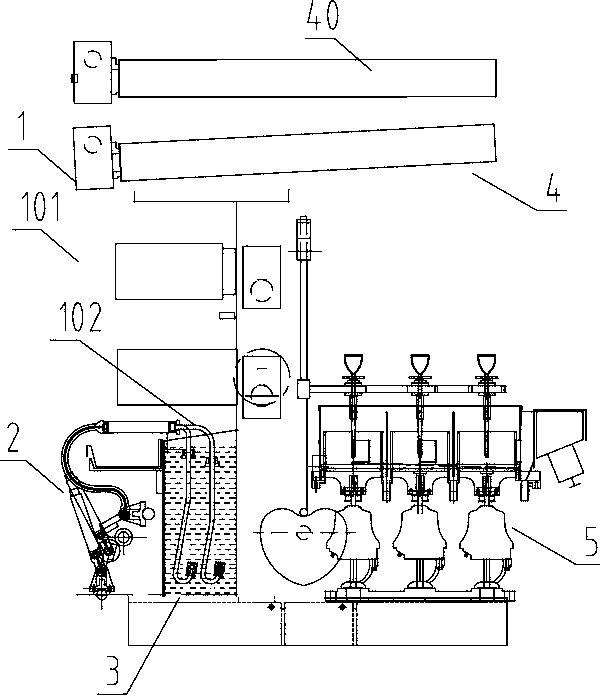

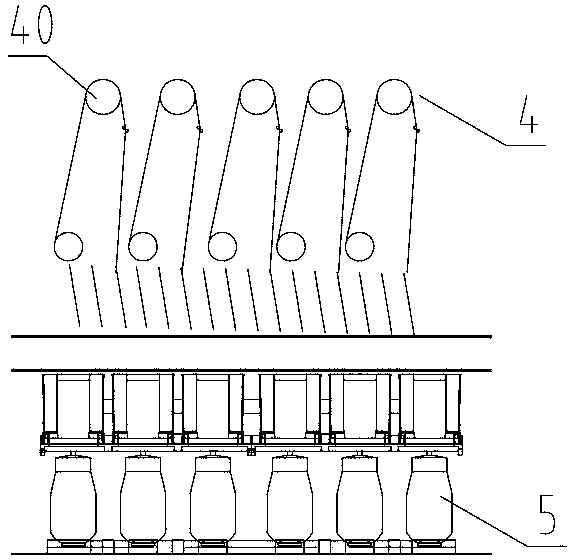

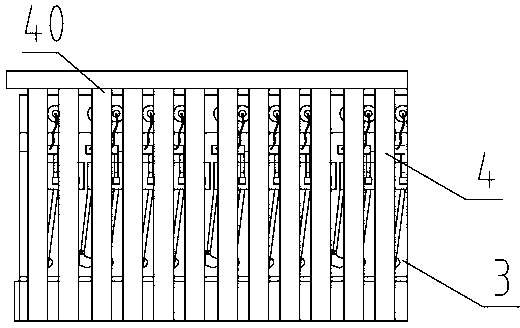

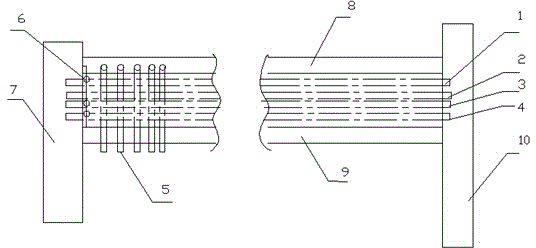

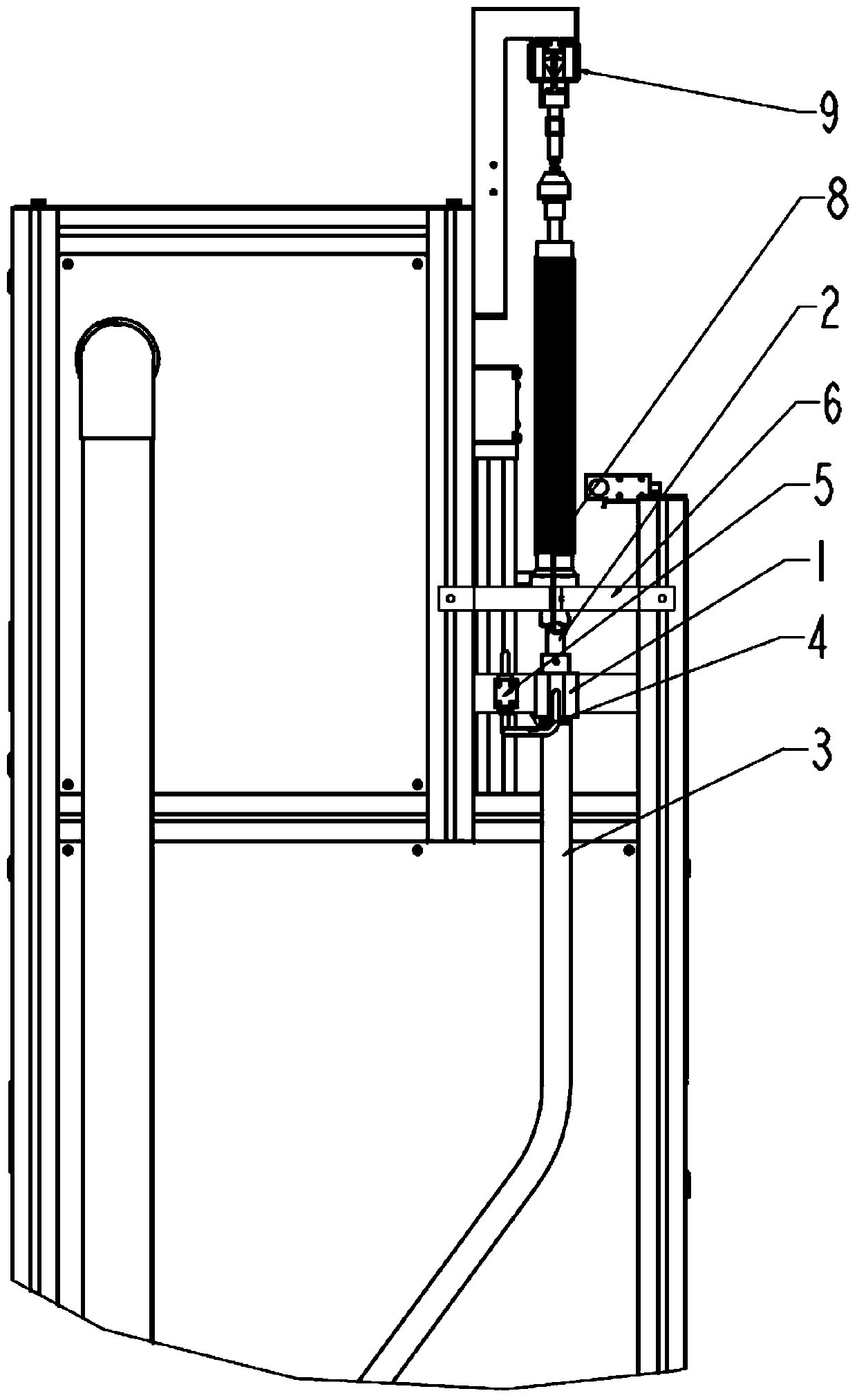

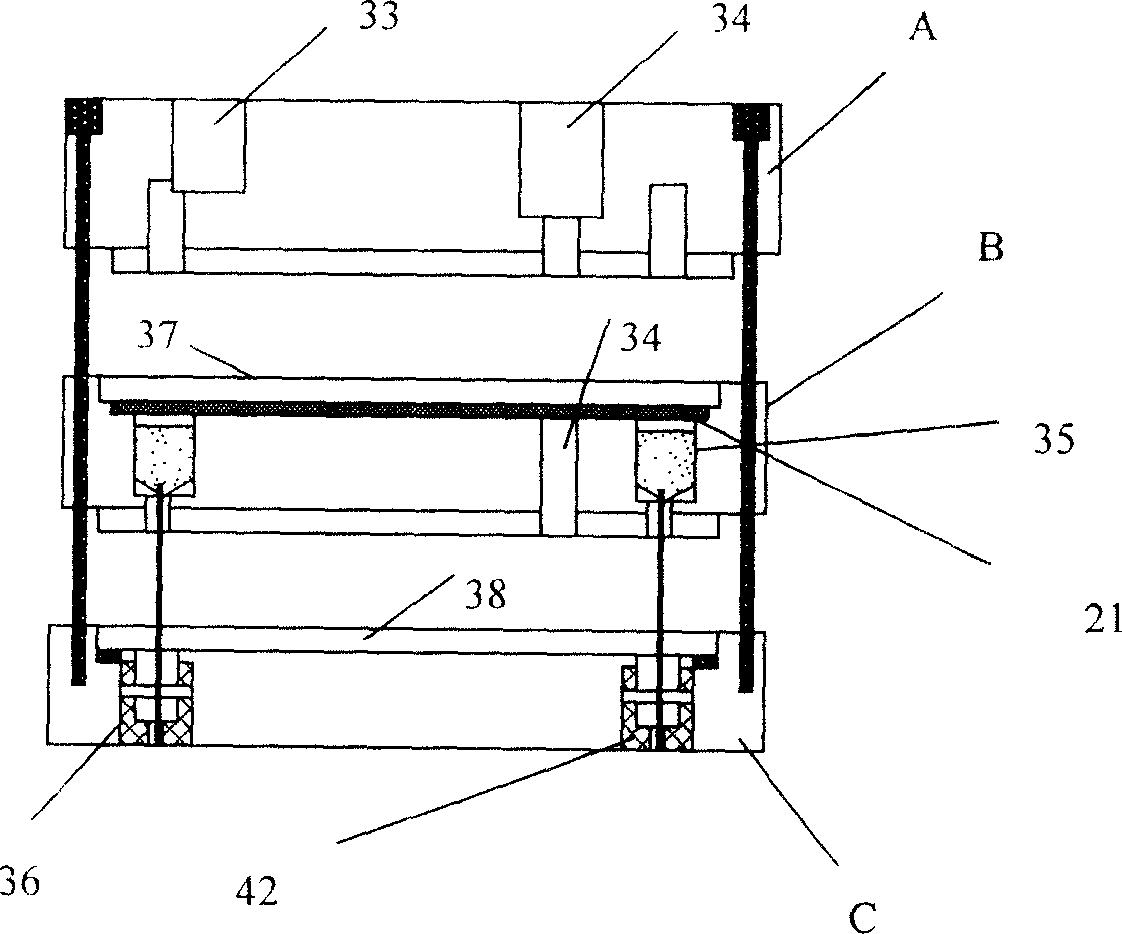

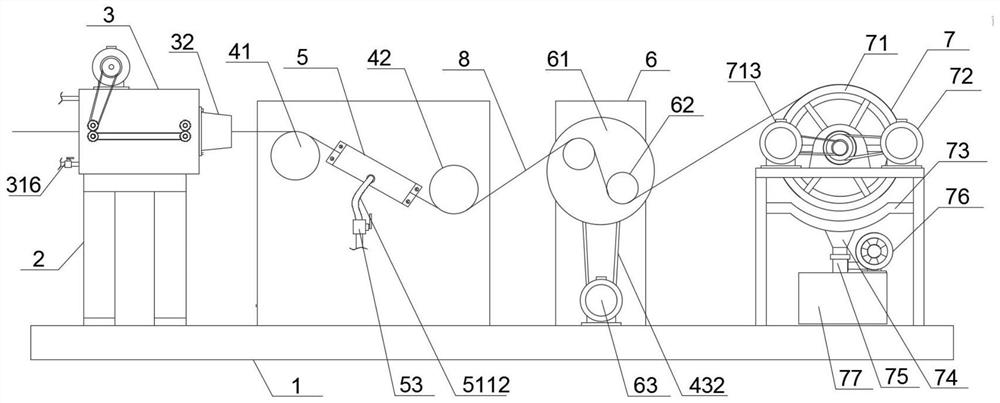

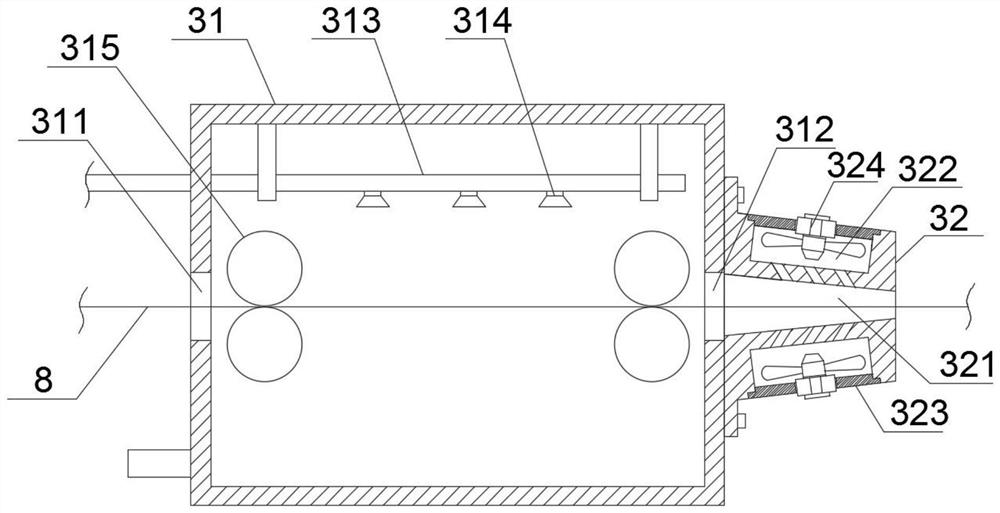

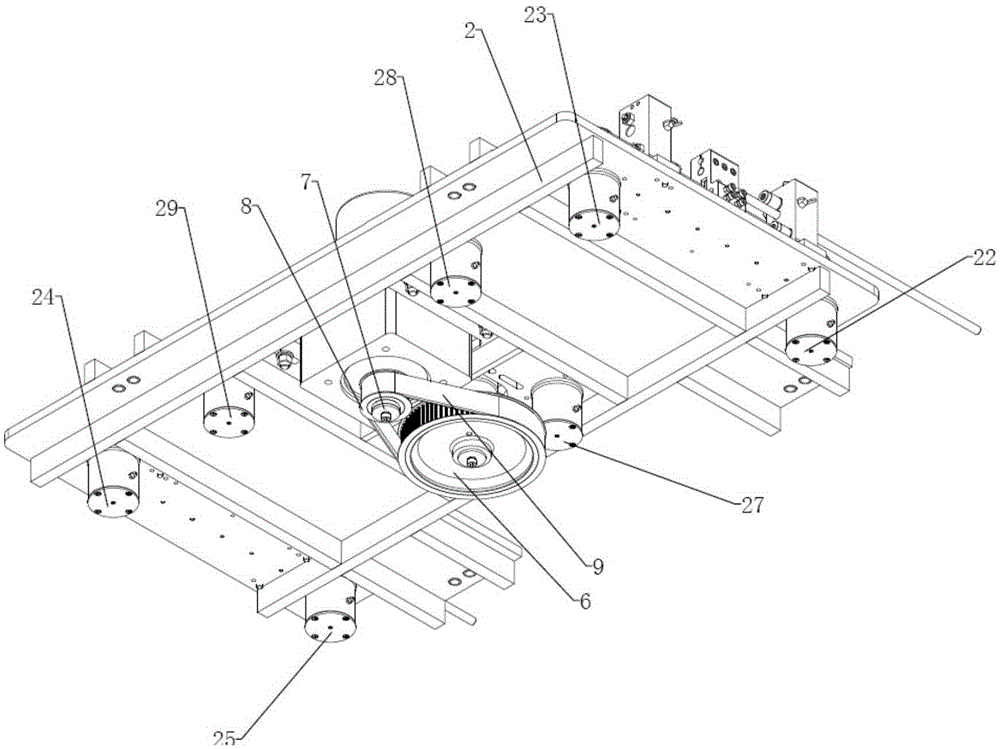

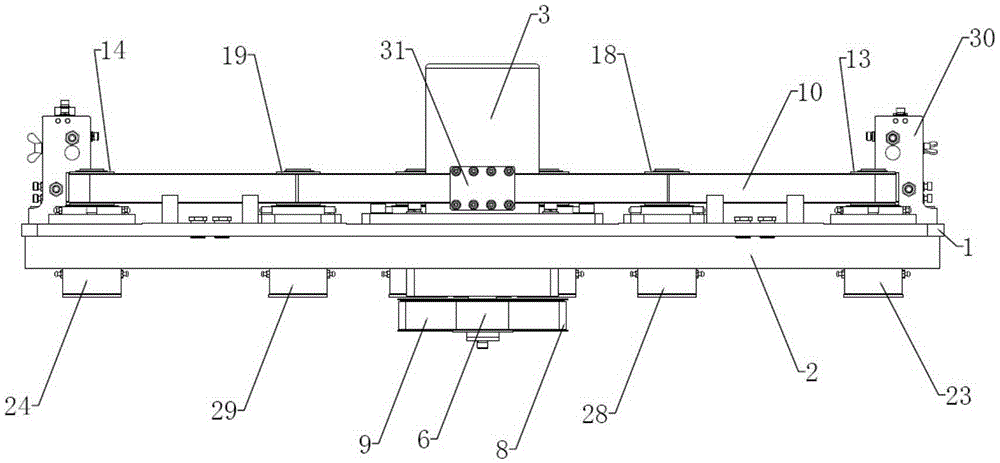

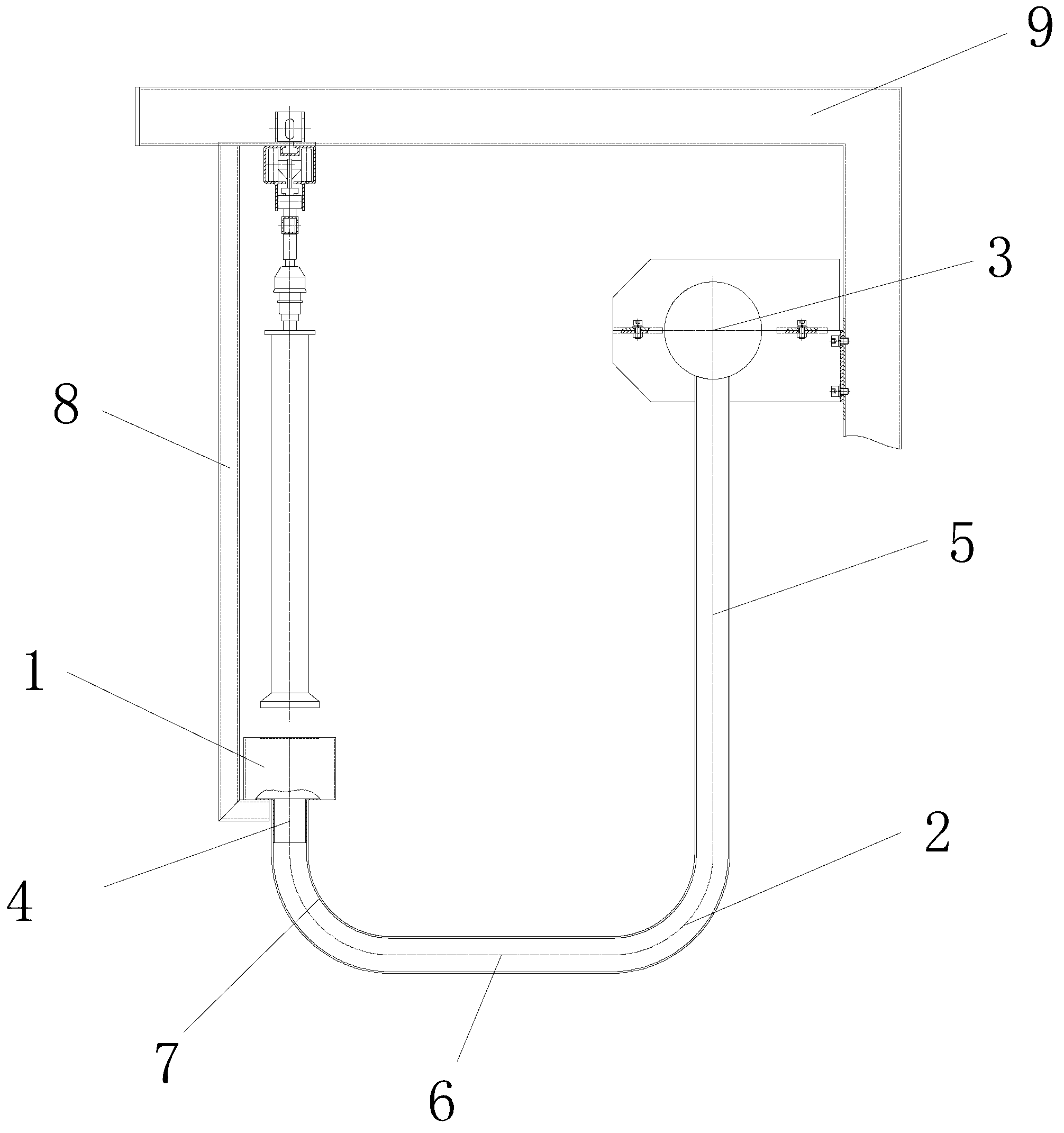

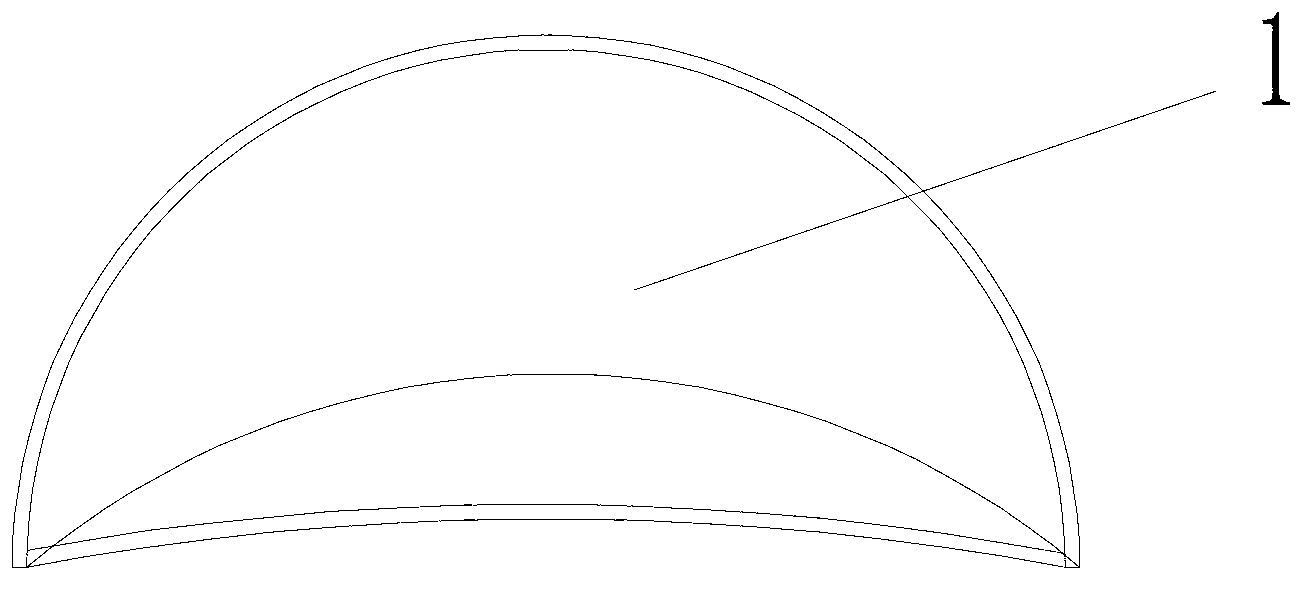

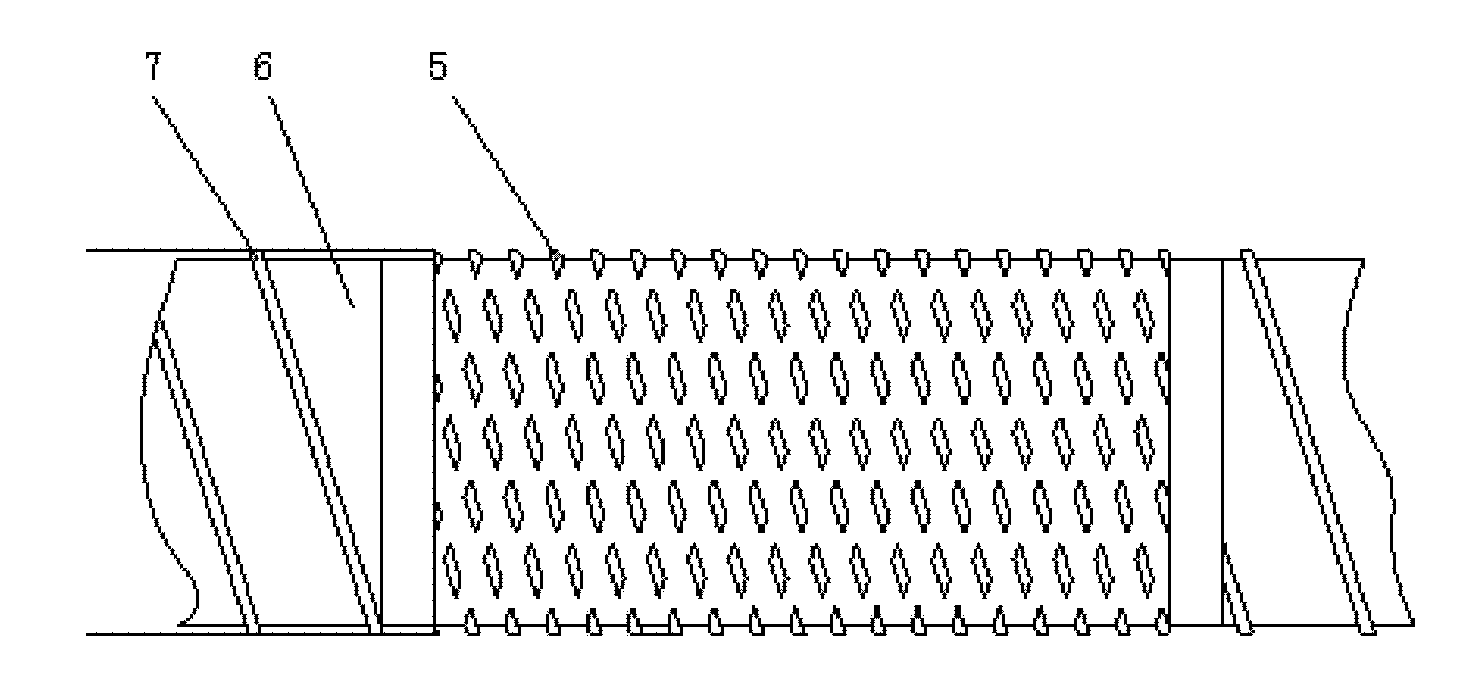

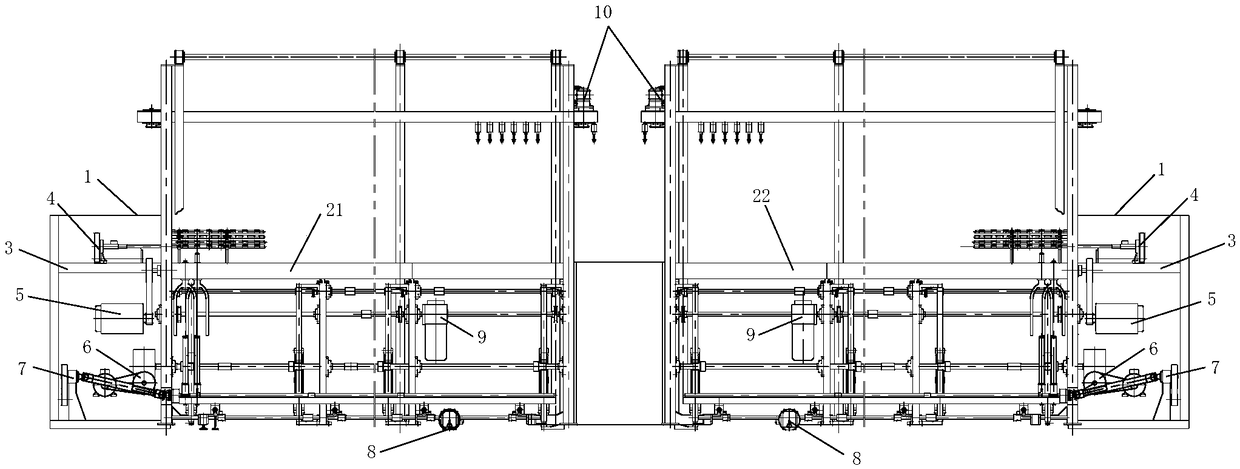

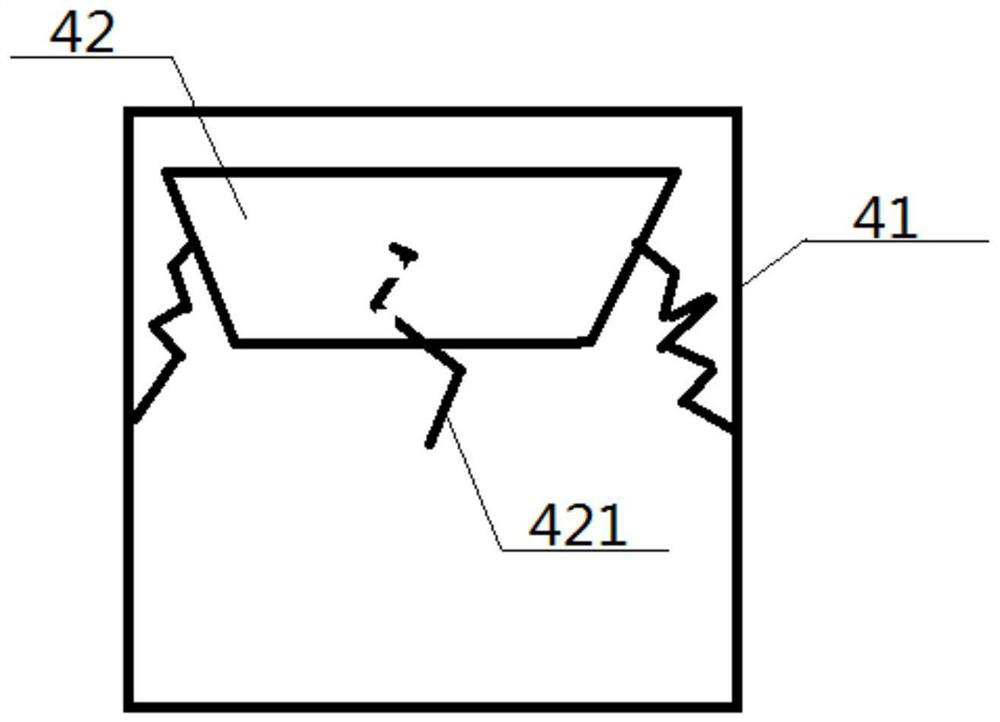

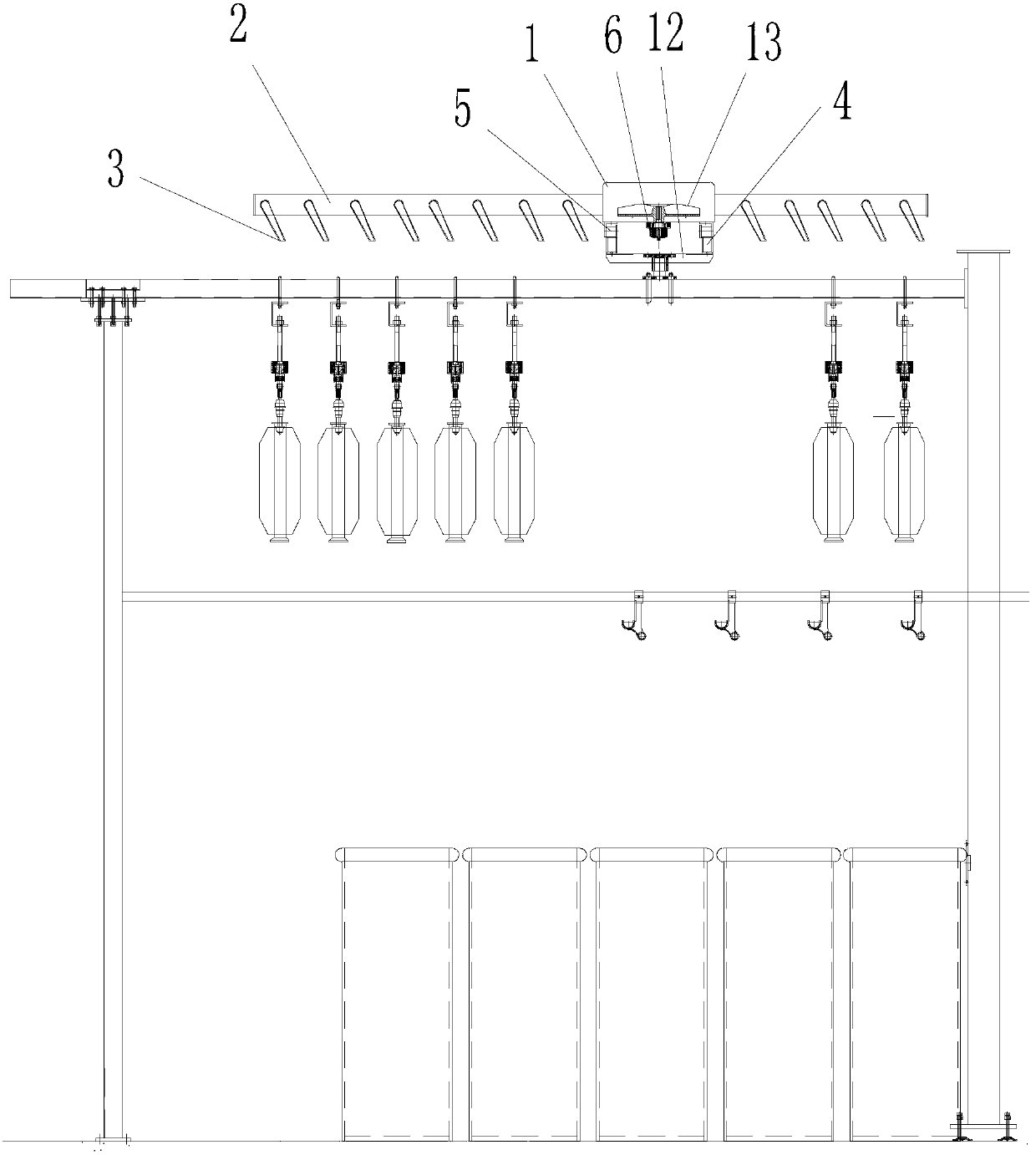

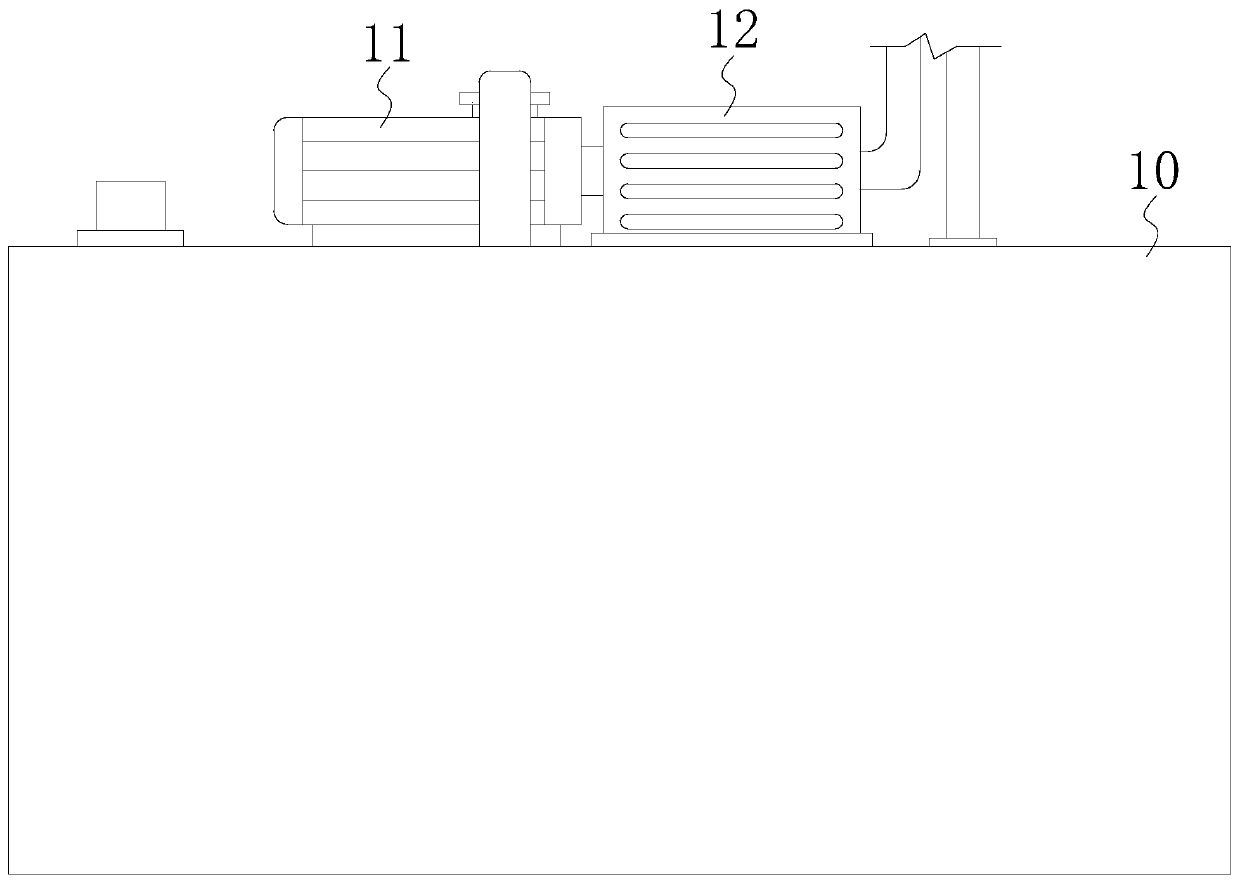

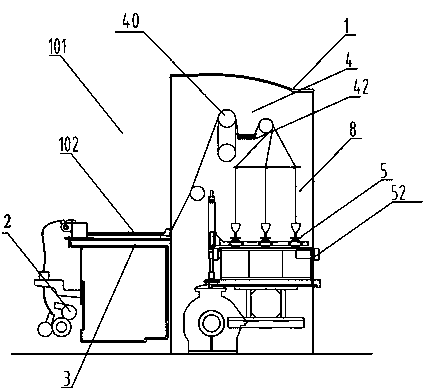

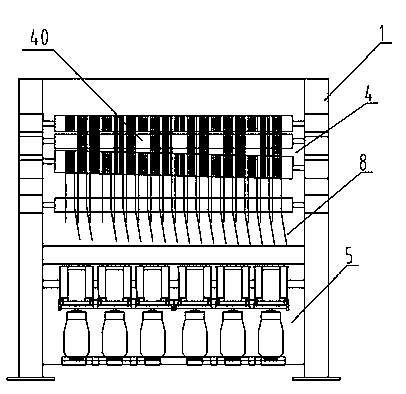

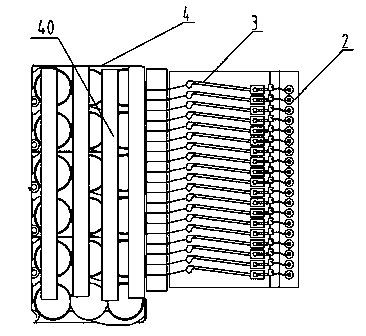

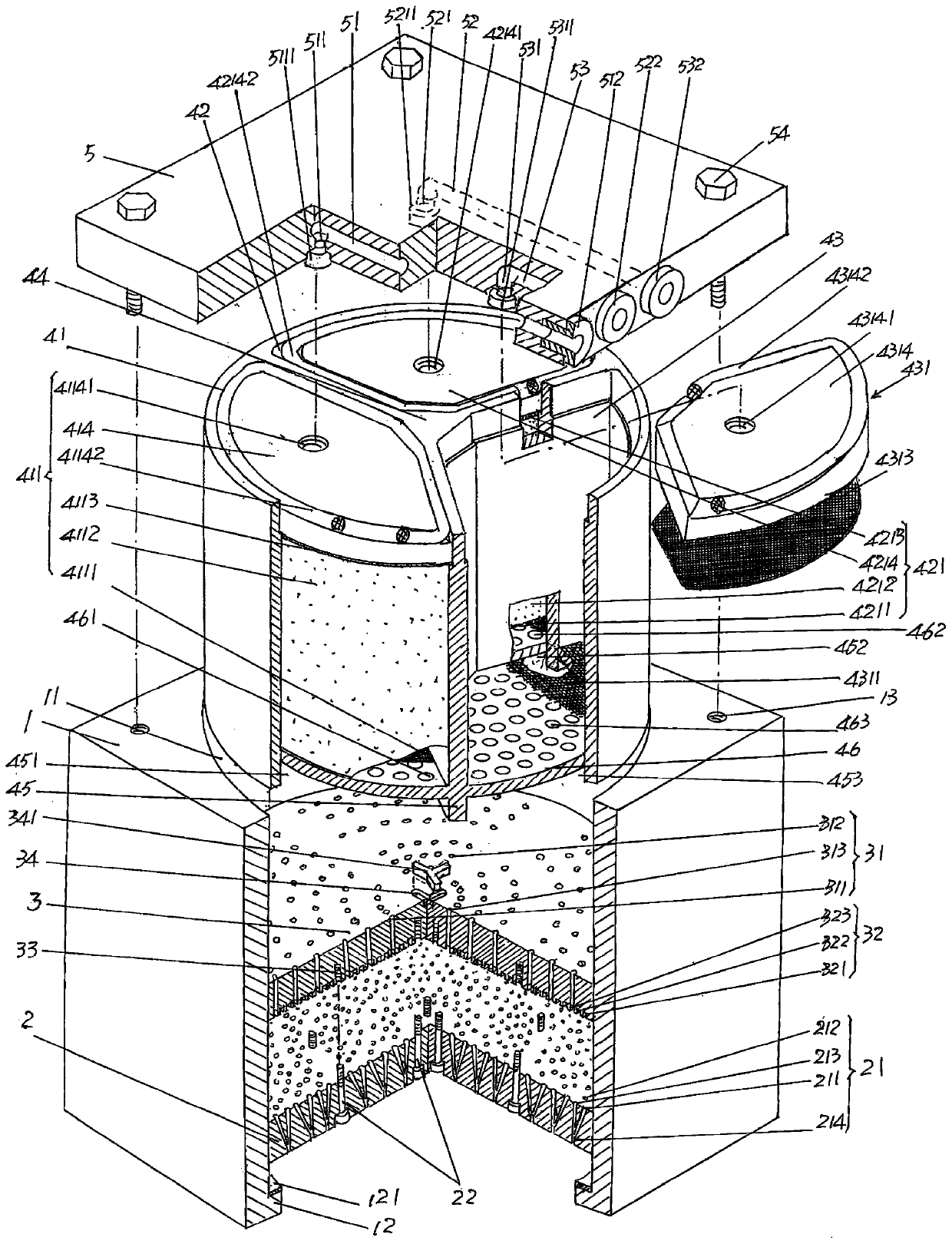

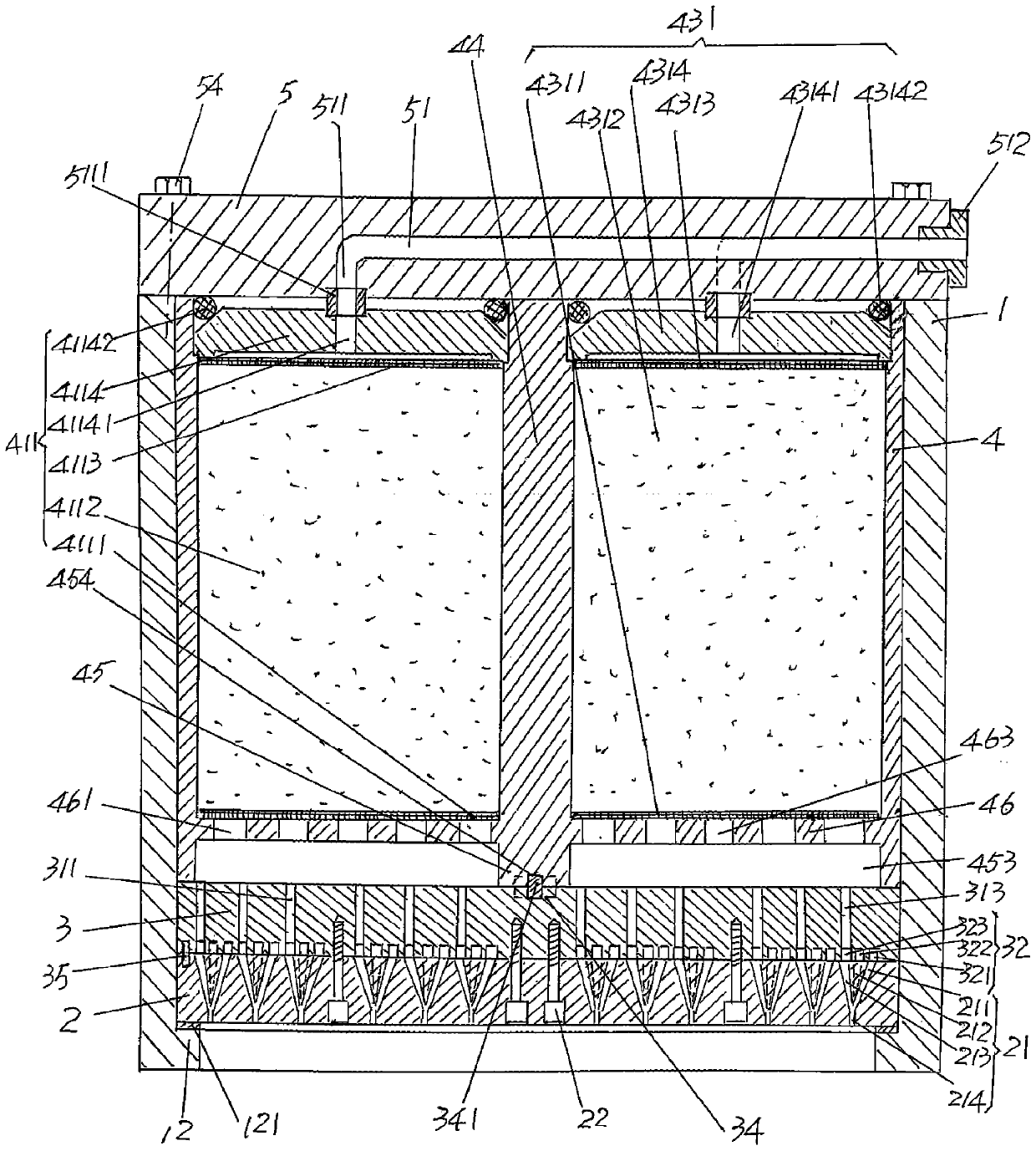

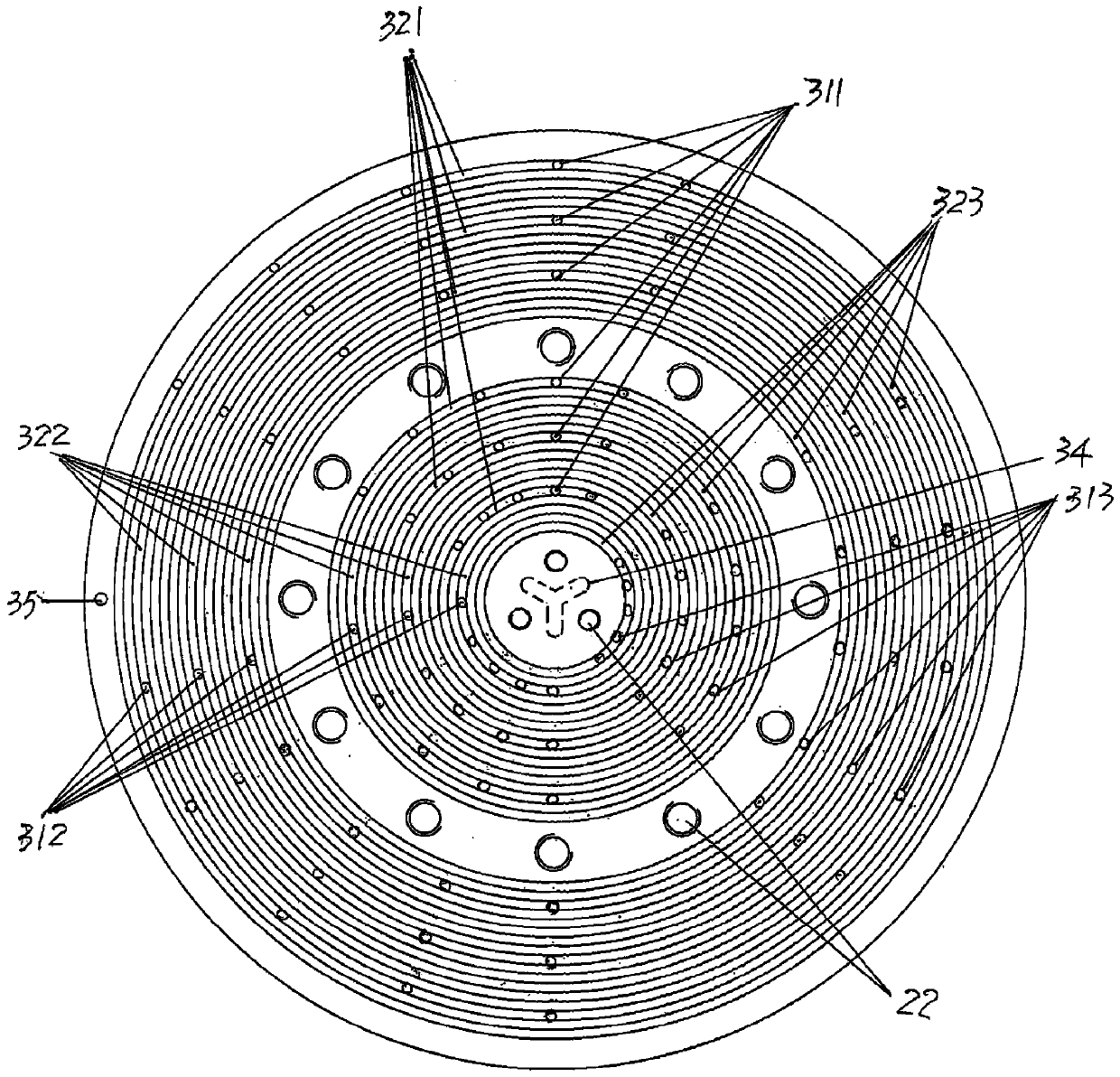

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

Spinning technology of semi continuous high speed spinning machine

InactiveCN103305935AThe transmission mechanism is simpleEasy to maintainArtificial thread manufacturing machinesWet spinning methodsPhysicsSpinning

The invention relates to a spinning technology of a semi continuous high speed spinning machine, belongs to the technical field of semi continuous spinning machine spinning, and comprises the steps of glue supplying, filament forming, spinning and winding, wherein the spinning is accomplished by a spinning device which comprises one or more spinning rollers arranged on an operating surface corresponding to the spinning surface, the filament winds around the spinning roller, the drafting, solidification and deacidification of the spinning step are accomplished under the rotation of the spinning roller. According to the spinning technology provided by the invention, the problems that the spinning speed can not be accelerated and dual attention to the working efficiency and the product quality cannot be given, caused by the insufficiency reaction of the semi continuous high speed spinning machine filament, are solved, the changing of the spinning roller distribution direction enables the spinning machine to accelerate spinning speed and reserve the structure of other parts of the conventional device, the filament to walk farther, and the reaction of the filament and the acid bath to be more efficient, both the working efficiency and the product quality are considered.

Owner:YIBIN HIEST FIBER +2

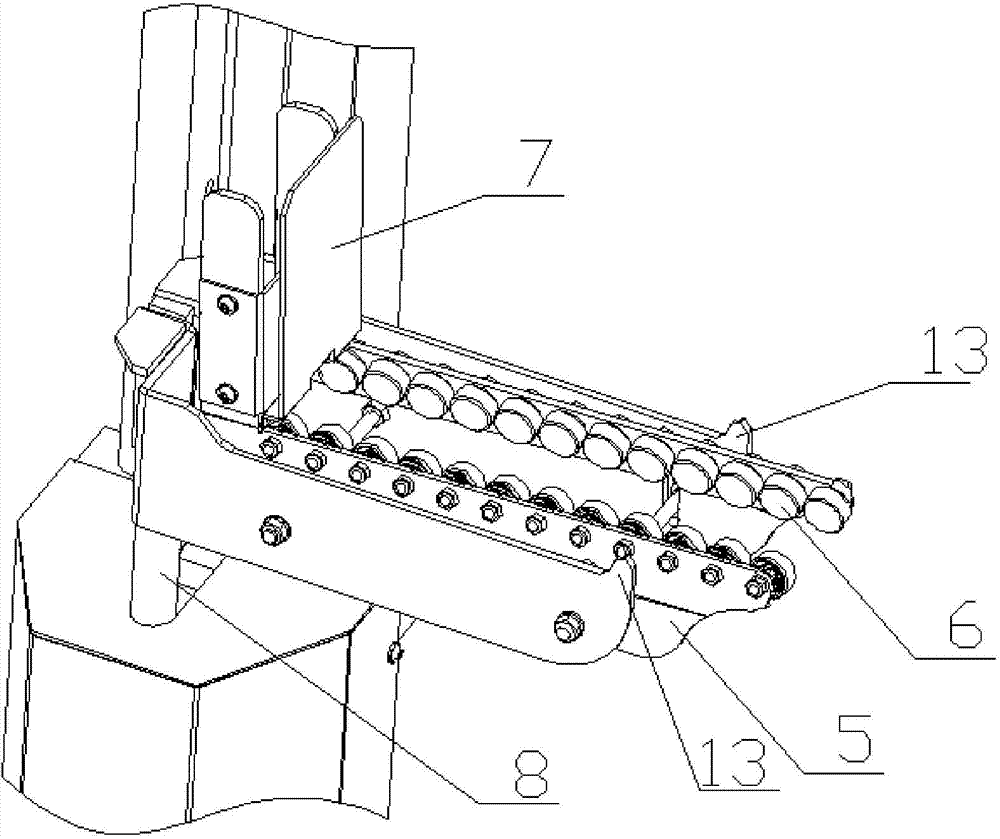

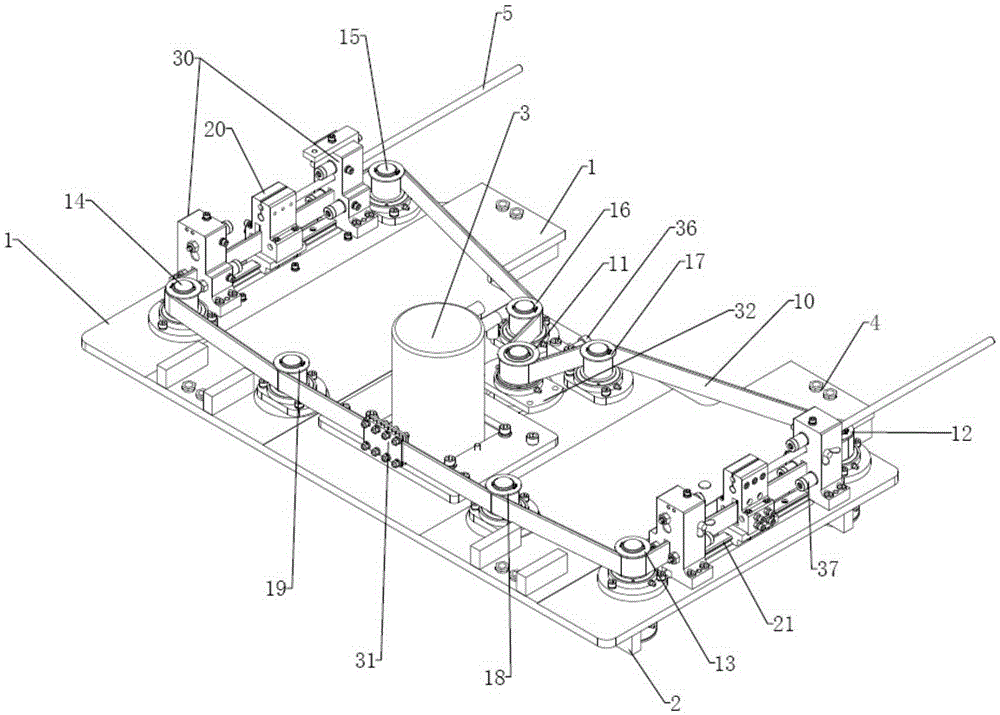

Cone yarn carrying steering mechanism

ActiveCN104762706AAvoid damageIncrease productivityTextile disintegration and recoveryTextiles and paperYarnConveyor belt

The invention discloses a cone yarn carrying steering mechanism which comprises a frame, a cone yarn supporting mechanism, a steering transmission mechanism and a driving mechanism. A supporting portion which can just contain cone yarn is formed on the cone yarn supporting mechanism and can be just in corresponding linkage with the tail end of a conveyor belt of cone yarn outputting equipment. A steering shaft is fixedly connected to the lower end of the cone yarn supporting mechanism and can rotate around a vertical shaft to be inserted into the steering transmission mechanism. The steering transmission mechanism can be installed on the frame in a lifting mode in the longitudinal direction. The driving mechanism drives the steering transmission mechanism to ascend or descend. The steering transmission mechanism ascends and descends to drive the steering shaft to rotate forwards or reversely by 90 degrees in a reciprocating mode. The cone yarn carrying steering mechanism is simple in structure and ingenious and does not occupy large space, ascending, steering and conveying of the cone yarn to the next working procedure can be automatically achieved at the same time, the production efficiency of the spinning technology is effectively improved, manual operation is avoided, damage to the cone yarn is avoided, and the spinning quality is ensured.

Owner:苏州智尊智能科技有限公司

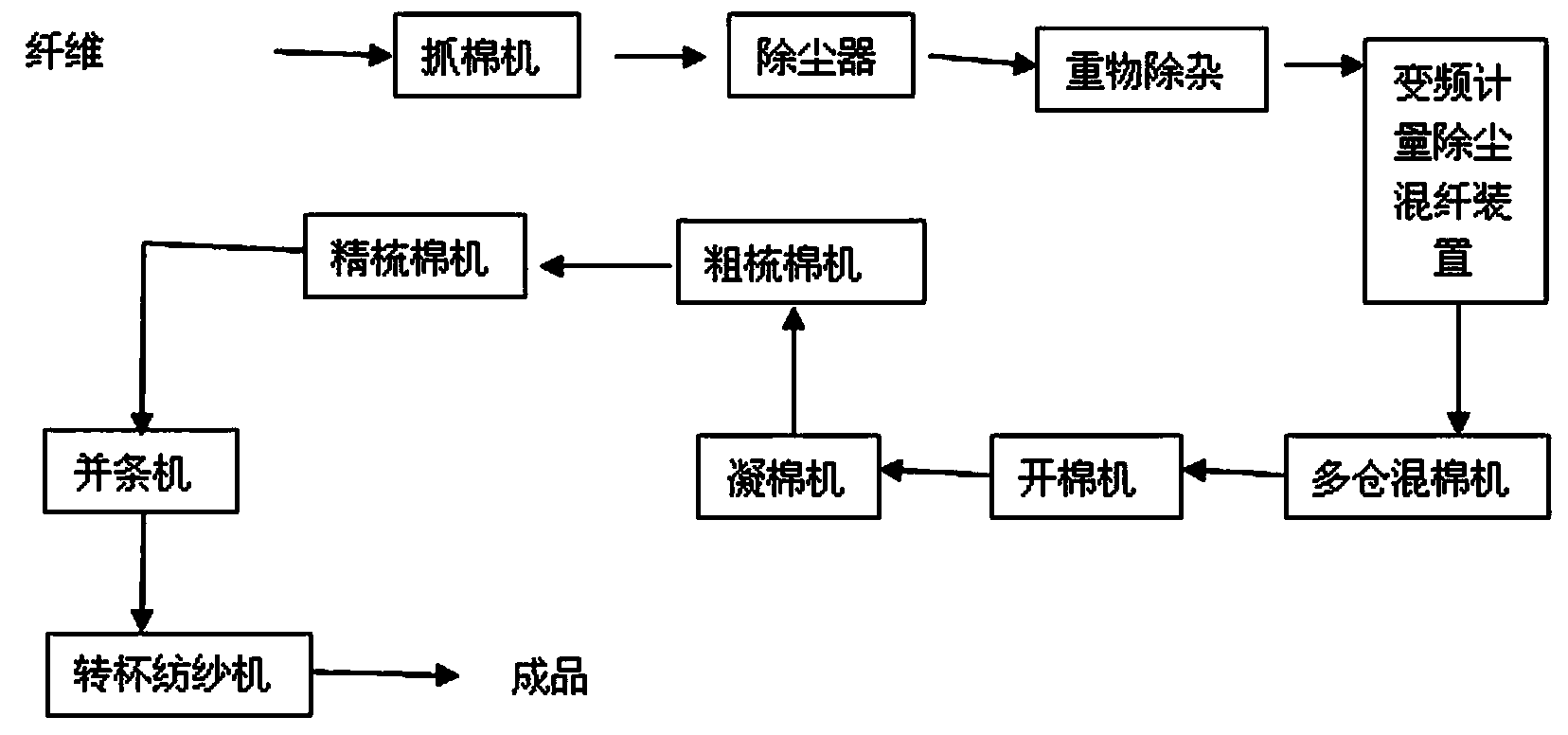

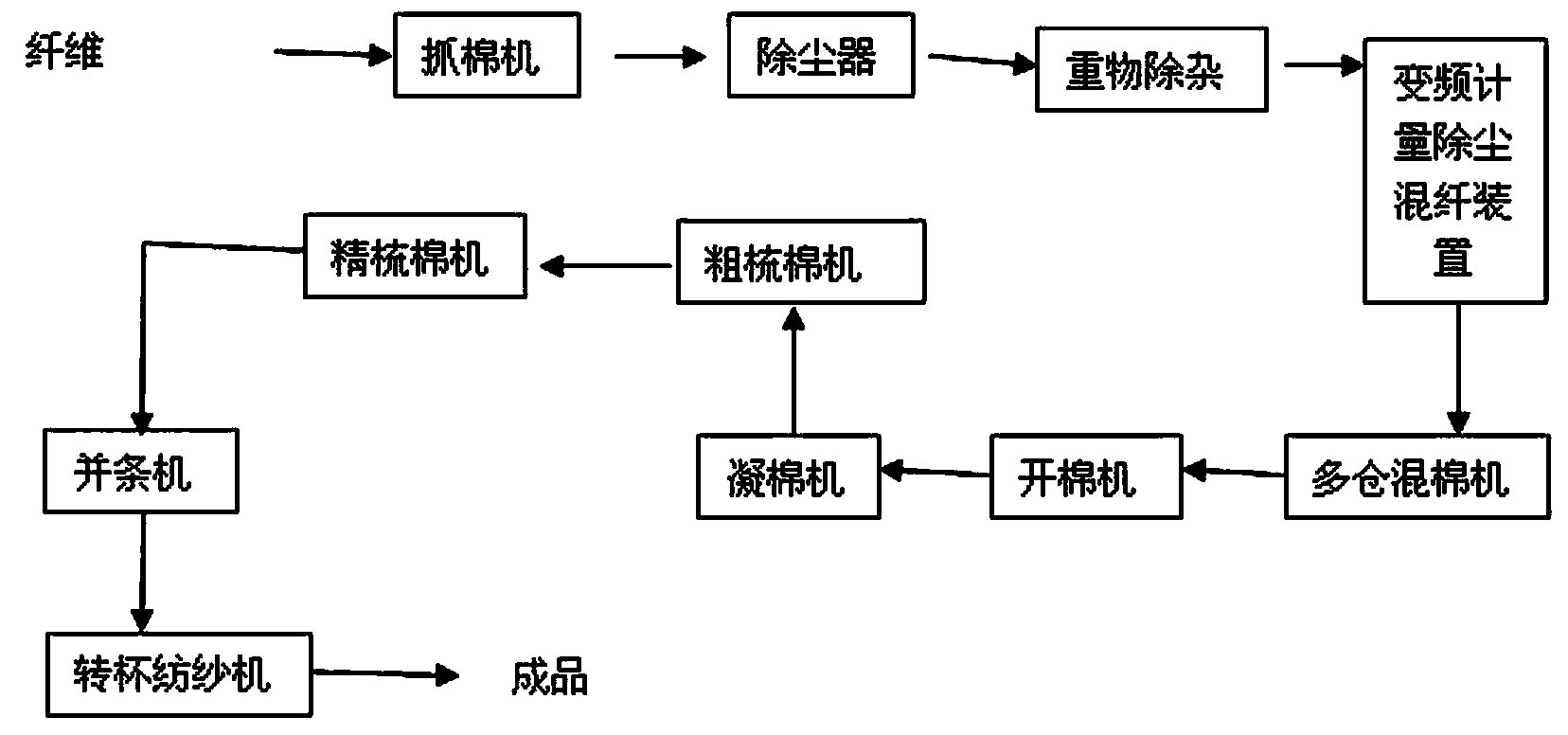

Production method of superfine high count yarn

ActiveCN103526350AImprove spinning efficiencyIncrease speedContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a production method of superfine high count yarn. According to the technology, fiber sequentially goes the procedure of cotton grabbing, dedusting, heavy article impurity removing, cotton opening, cotton condensing, cotton combing, strip combining and rotor spinning yarn. The quality of superfine high count yarn reaches the quality of ring spinning. The production method of superfine high count yarn has the characteristics of high speed, high yield, large coiling block, short technology of rotary spinning, ensures spinning quality and improves the spinning speed at the same time.

Owner:YIBIN WEILUO TEXTILE

Automatic cotton cleaning device for spinning machine suction box

The invention discloses an automatic cotton cleaning device for a spinning machine suction box, which mainly comprises a cotton sucking flute pipe, a flute pipe air collecting pipe, a flute pipe air collecting pipe inlet, a broken-end strand suction box, a broken-end strand filter net, a centrifugal fan and fiber aggregation negative pressure pipe, a negative pressure air collecting pipe, a negative pressure air collecting pipe inlet, a negative pressure suction box, a hair filter net, a negative pressure centrifugal fan, an automatic cotton cleaning delivery pipe, a negative pressure valve, an automatic cotton cleaning air sucking pipe, a storage tank and a filter net, wherein one end of the automatic cotton cleaning delivery pipe is connected with the hair filter net, while the other end is connected with the storage tank through the negative pressure valve; and one end of the automatic cotton cleaning air sucking pipe is communicated with the broken-end strand filter net, while the other end is communicated with the storage tank and is provided with a filter net. During doff stop, the cotton is not needed to be specially cleaned manually, and the whole device is simple in structure, and is time-saving and labor-saving for cleaning the cotton.

Owner:YUNSHENG HLDG GRP

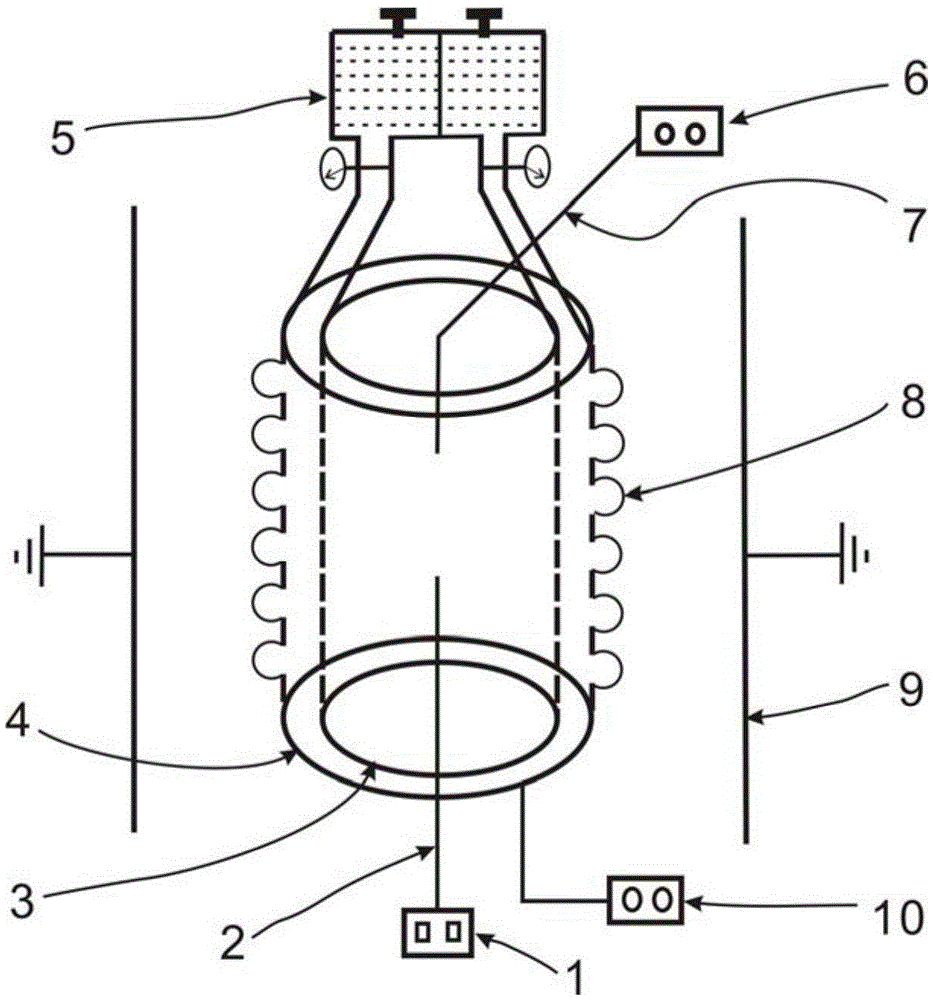

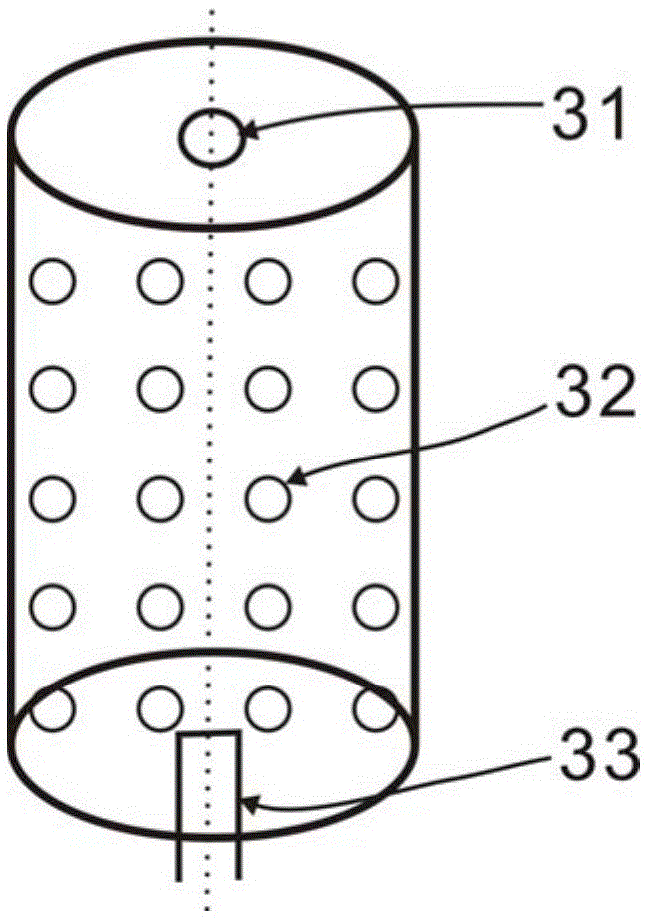

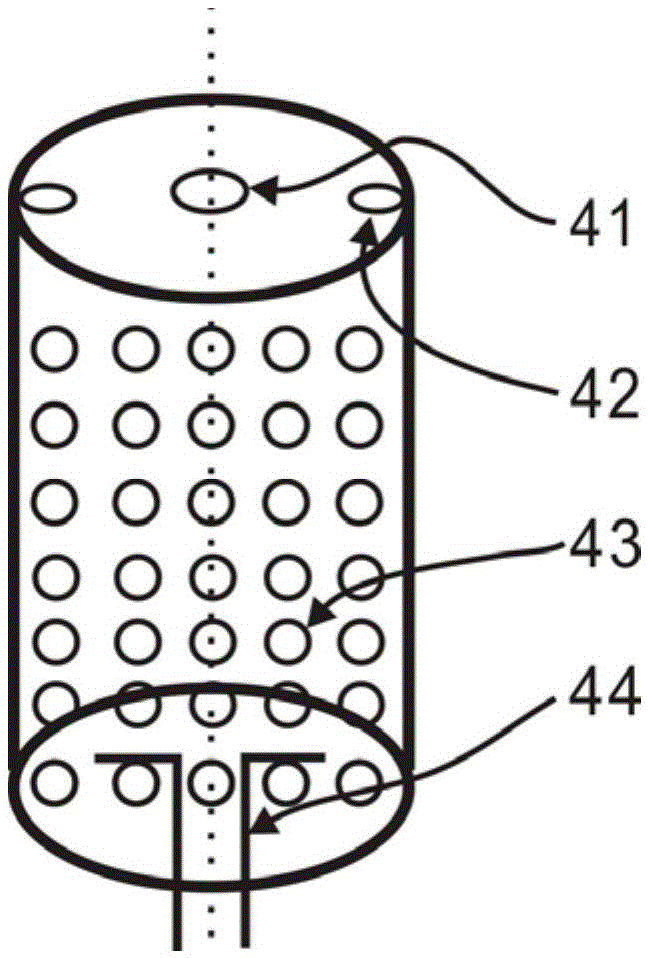

Bubble electrostatic spinning system for preparing composite fiber material

The invention discloses a bubble electrostatic spinning system for preparing a composite fiber material. A spinning cylinder and an air cylinder in an internal-external nested manner are adopted as spinning devices; different solutions are separated and conveyed to the closed spinning cylinder through a first liquid conveying pipeline; and the solutions are uniformly mixed through the rotation of the air cylinder to realize batch production. A liquid supply device is closed, the property change of the spinning solution is avoided, the spinning quality is guaranteed, and environmental pollution is reduced. The spinning holes in the spinning cylinder are designed in equal-interval vertical axial arrangement, and mutual influence of bubbles generated at any adjacent spinning holes is effectively avoided; and meanwhile, at least one vent hole stays on the same horizontal plane with the spinning holes so as to guarantee normal spinning at each spinning hole and improve the yield of the micro-nano composite fiber material. A receiving device is arranged in a roller manner and circles the spinning cylinder, so that the fiber receiving area is effectively increased, and continuous batch production is possible.

Owner:SUZHOU UNIV

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

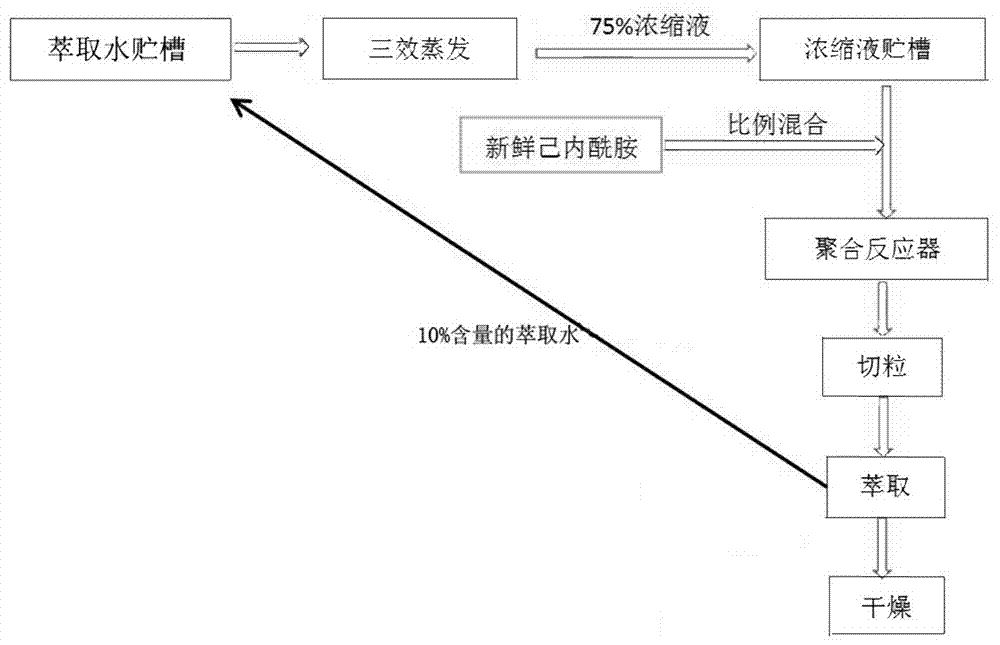

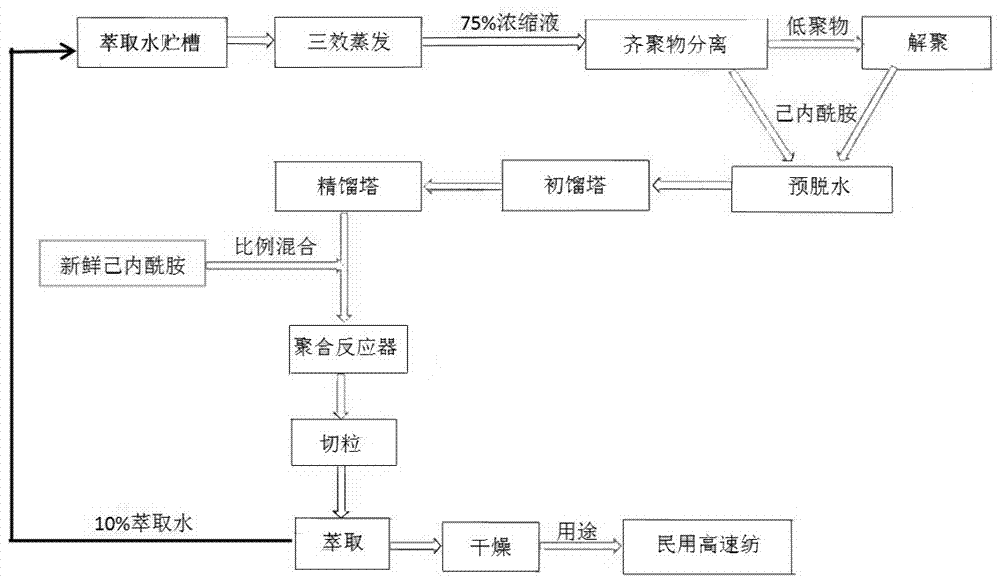

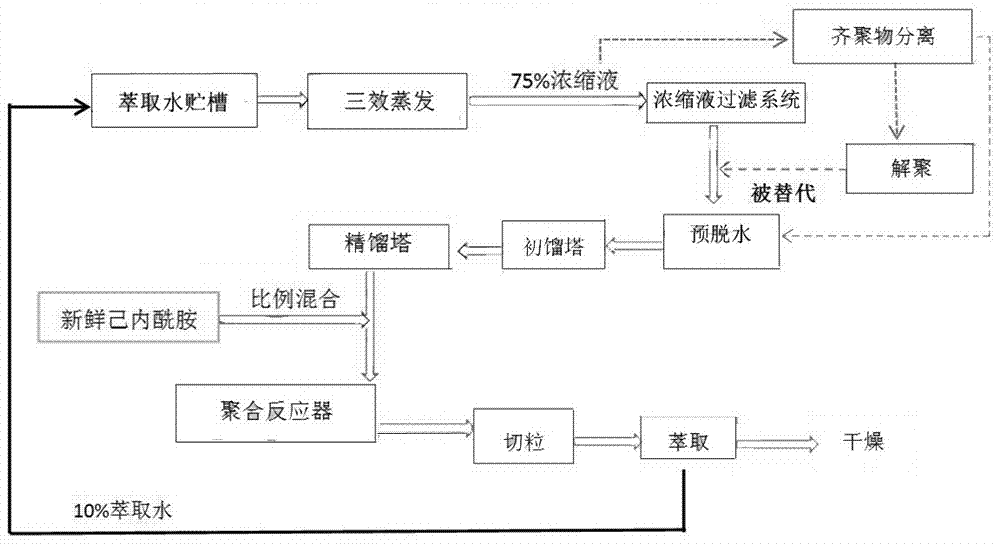

Method used for recycling caprolactam for PA6 polymerization production

ActiveCN107400231AGuarantee continuous and stable operationGuarantee the quality of spinningMonocomponent polyamides artificial filamentDistillationFiltration

The invention relates to a method used for recycling caprolactam for PA6 polymerization production. The method comprises following steps: extraction water from extraction is subjected to triple effect evaporation concentration so as to obtain a concentrate, wherein the caprolactam content of the extraction water is about 10%; the concentrate is subjected to treatment using a filtration system, is delivered into a pre-dehydration column for dehydration, then is delivered into a primary distillation tower and a rectifying tower, and at last is subjected to mixing reaction with fresh caprolactam; and at last pelletizing, extracting, and drying are carried out so as to obtain PA6 slices. The method is capable of solving problems in the prior art that pipelines are always blocked, cleaning difficulty is high, energy consumption is large, and operation is not convenient, ensuring continuous stable operation of caprolactam recycling, ensuring the quality of recycled caprolactam is capable of satisfying requirements of high speed spinning slice production, and reducing production cost greatly without influencing slice spinning quality.

Owner:YANGMEI GRP TAIYUAN CHEM NEW MATERIAL

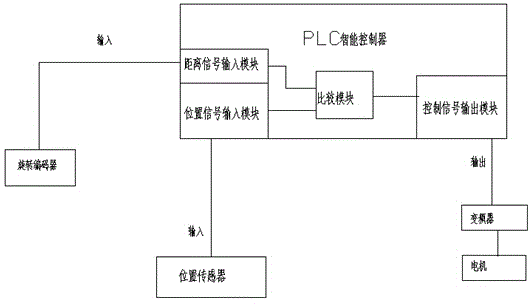

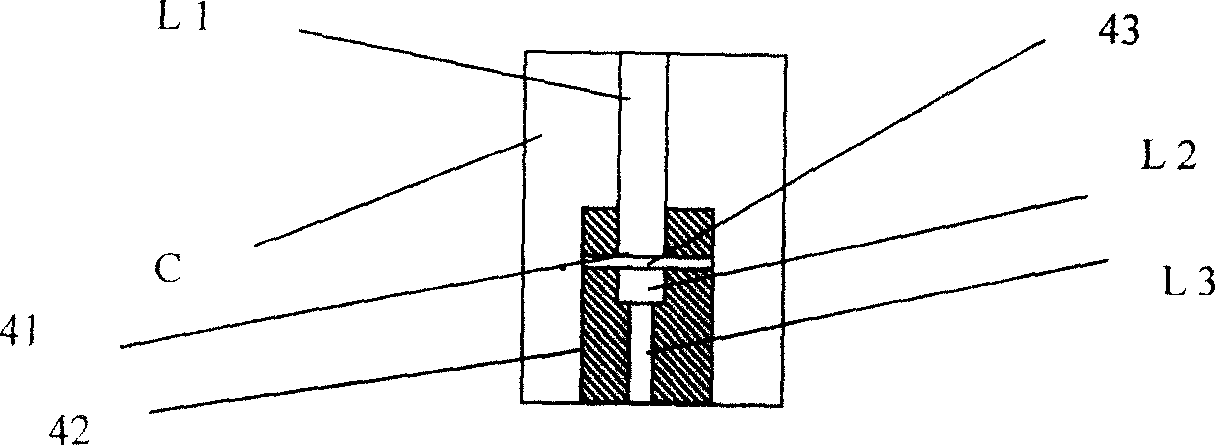

Intelligent control system for spun yarn forming

The invention relates to an intelligent control system for spun yarn forming. The intelligent control system comprises a signal acquisition unit, a control unit and an execution unit. The signal acquisition unit is used for collecting signals indicating whether a steel collar plate reaches an initial position, a yarn middle pull position, a pullback position and the highest position; the control unit is used for receiving the signals collected by the signal acquisition unit and outputting control signals after the collected signals are compared with set signals and judged; the execution unit is used for receiving the control signals output by the control unit and controlling ascending and descending of the steel collar plate according to the received control signals. According to the intelligent control system, whether the steel collar plate reaches the initial position, the yarn middle pull position, the pullback position and the highest position accurately can be precisely detected, it is guaranteed that each movement is precisely in place, and the defects brought by inaccurate positions are overcome.

Owner:YIBIN HUIMEI WORSTED TECH +1

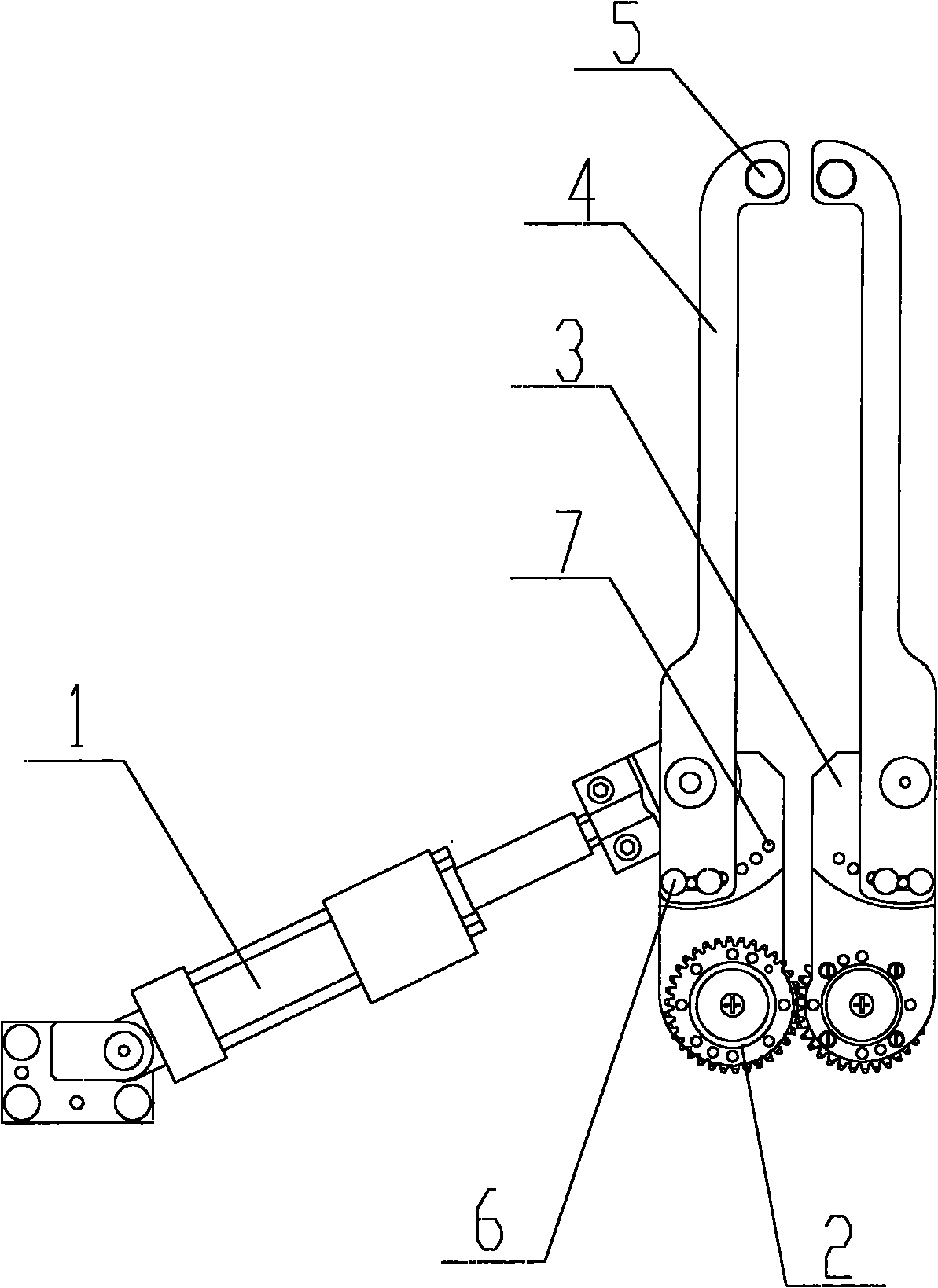

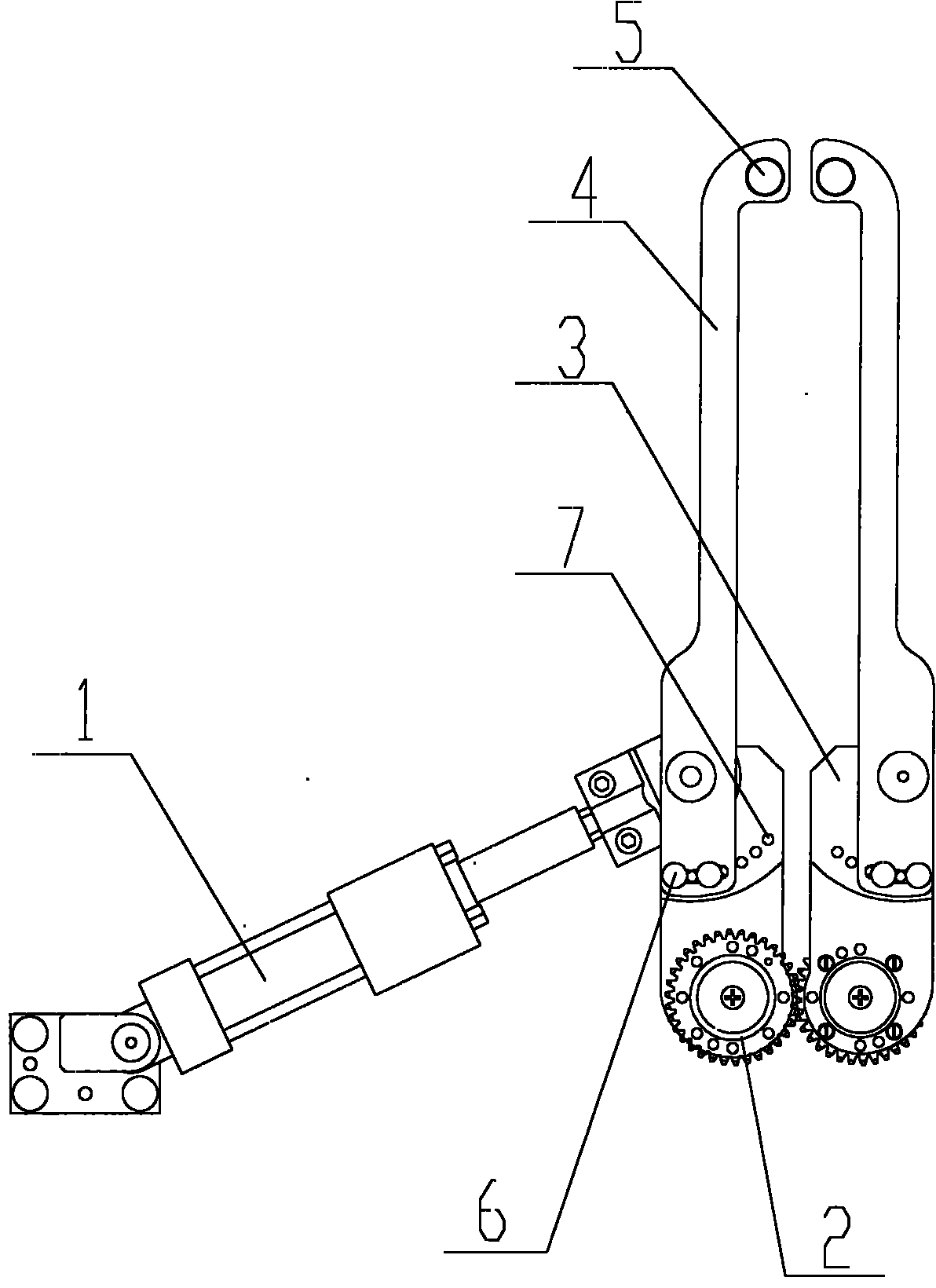

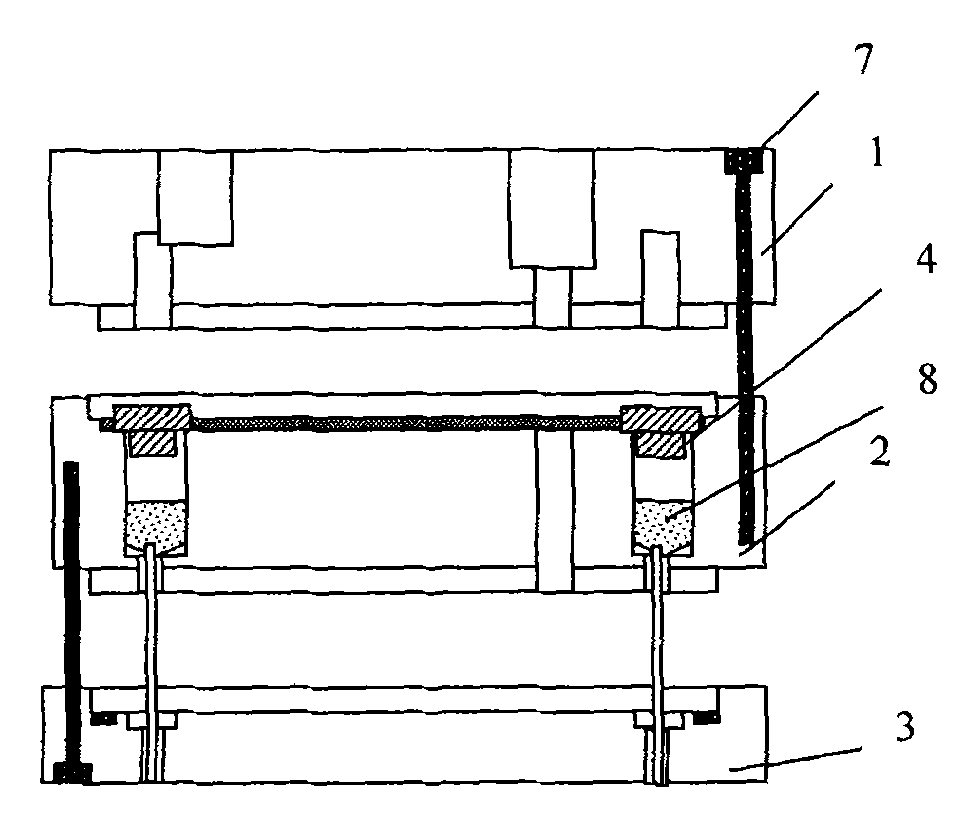

Blank centering device

InactiveCN101972818AGuarantee the quality of spinningAvoid bumpingMetal-working feeding devicesPositioning apparatusHydraulic cylinderNumerical control

The invention discloses a blank centering device. The blank centering device comprises a hydraulic cylinder with a piston rod, two gears, two gear mounting plates and two blank oscillating rods, wherein the two gears are meshed with each other and separately fixed on one end of each gear mounting plate, the other end of each gear mounting plate is hinged with one end of each blank oscillating rod through a hinge pin, a hole is formed on the other end of each blank oscillating rod; a material support rod is fixed in each hole and perpendicular to the corresponding blank oscillating rod; and the piston rod of the hydraulic cylinder is hinged with one blank oscillating rod through a hinge pin. The centering device can effectively solve the problem that the centering property is poor when the blank is arranged and clamped manually, and ensure the spinning quality of the spinned part; and the device can be used in the numerical control machine tools such as the numerical control lathe and the milling machine and have high adaptability.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Tail yarn head keeping device for tail yarn removing machine

ActiveCN104176563AReduce yarn end lengthImprove removal efficiencyFilament handlingDrinking strawYarn

The invention discloses a yarn head keeping device for a tail yarn removing machine. The yarn head keeping device comprises a sucking and breaking device, a driving device and a detecting device, wherein the sucking and breaking device comprises a negative pressure bin, a suction pipe, an exhaust pipe, an air pipe and a yarn guide plate; the negative pressure bin is fixedly mounted on a rack on one side at the inlet of the tail yarn removing machine; the lower end of the suction pipe is communicated with the negative pressure bin; the upper end of the suction pipe faces one side of a bobbin with the tail yarn; the two ends of the exhaust pipe are connected with the negative pressure bin and a lap waste box respectively; the two ends of the air pipe are connected with the negative pressure bin and the driving device respectively; the yarn guide plate is fixed on the rack on one side at the inlet of the tail yarn removing machine and positioned between the negative pressure bin and the bottom of the bobbin; the driving device comprises a two-way electromagnetic valve; the two-way electromagnetic valve is connected with the air pipe and a gas source respectively; the detection device comprises an optical fiber amplifier fixed at the lower part of the yarn guide plate. According to the tail yarn head keeping device, the lengths of kept tail yarn heads on the bobbin are basically consistent, the broken yarn heads can be conveniently found by the tail yarn removing machine, the tail yarn removing efficiency is improved and the spinning quality is guaranteed.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

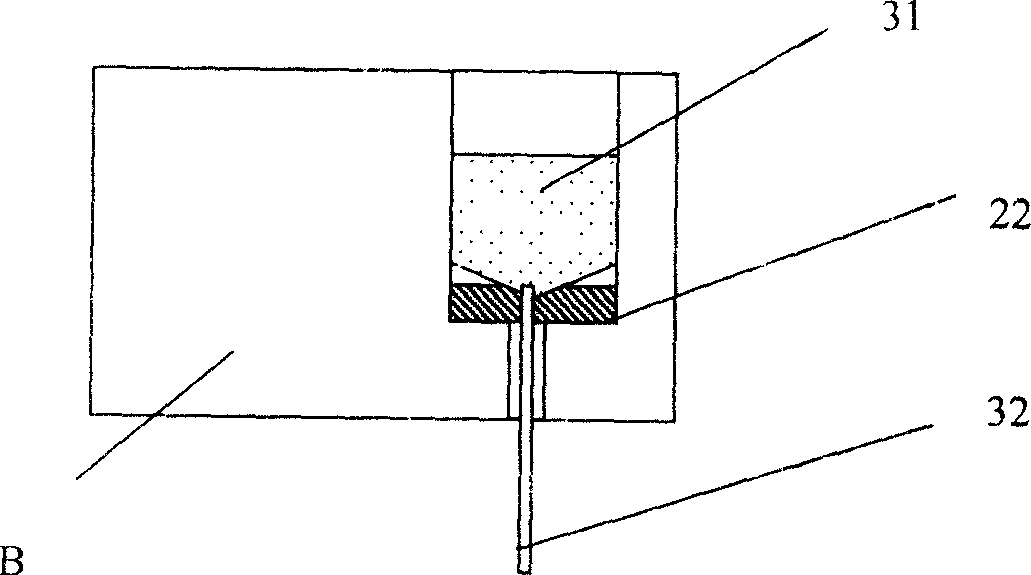

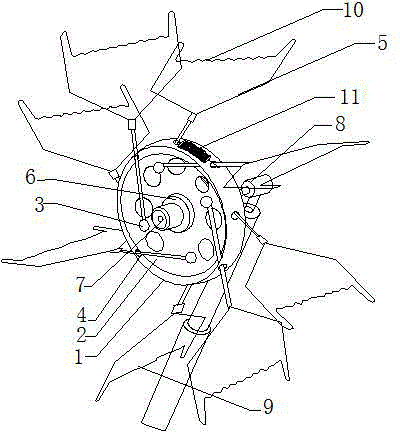

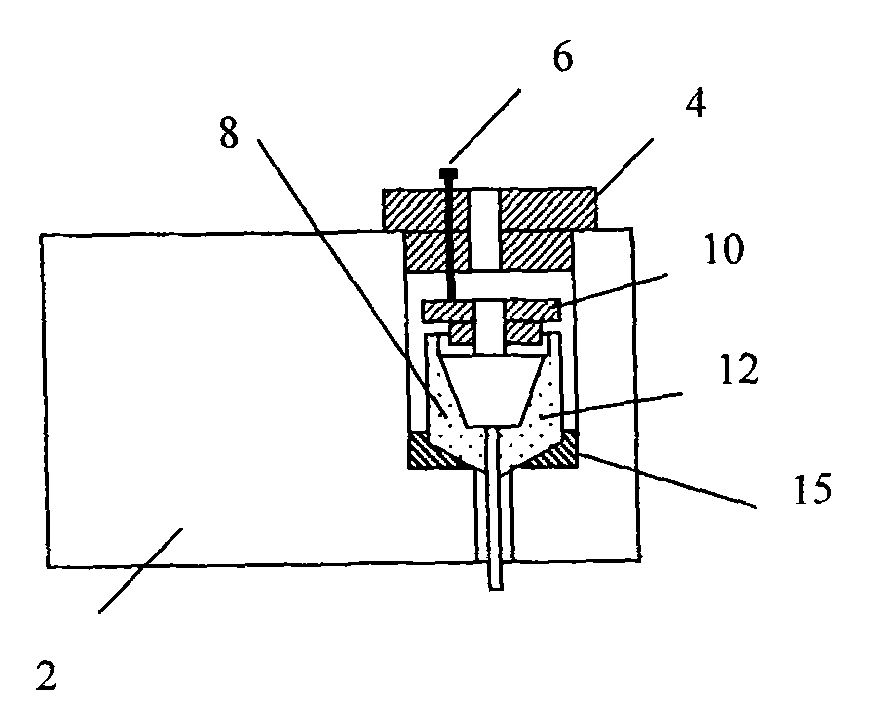

Spinning nozzle

InactiveCN101200815AEasy to disassemble and cleanEasy to useNew-spun product collectionHollow filament manufactureEngineeringFiber spinning

The invention relates to a chemical fiber spinning nozzle, in particular to an inserted pipe type porous spinning nozzle which is used for spinning hollow fiber. According to the inserted pipe type hollow fiber spinning nozzle provided by the invention, the nozzle includes an upper component, a middle component and a lower component. A core liquid hole and a liquid material hole are arranged on the upper component; a liquid material hole and a socket hole are arranged in the middle component; the socket hole is embedded in the socket of an inserted pipe; a spinneret hole is arranged on the lower component; a cylinder is arranged in the spinneret hole; a hole is arranged in the middle of the cylinder for the inserted pipe to pass through for the compulsory concentric location. According to the nozzle structure of the invention, the concentration of the nozzle is not needed to be regulated. Thus, the invention can be easily disassembled for cleaning whenever the spinning is finished. The assembly is easy. And the concentration of the nozzle is not needed to be regulated again. With convenient usage, the invention can guarantee the spinning quality and is beneficial to be used in the large scale production.

Owner:胡萍

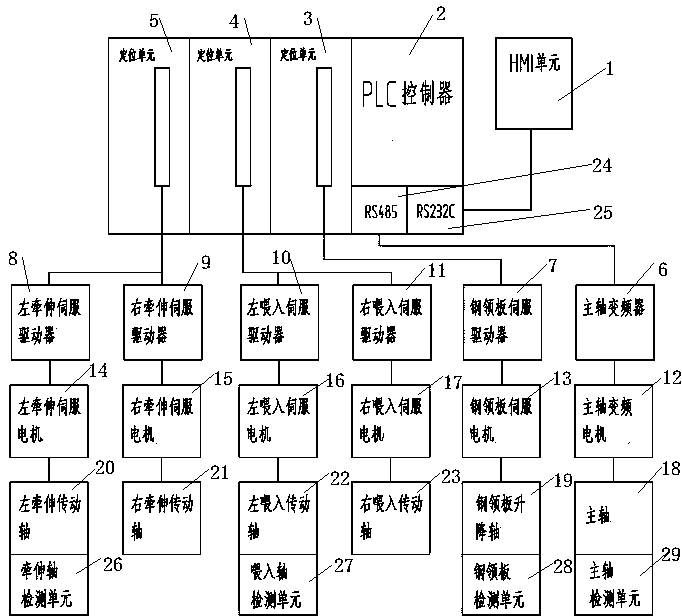

Variable-frequency and servo-linkage control system and method for spinning of spinning frame

InactiveCN110344147AHigh precisionQuality improvementTextile/flexible product manufactureTextiles and paperYarnFrequency changer

The invention relates to a variable-frequency and servo-linkage control system and method for spinning of a spinning frame. The system comprises a HMI (human machine interface) unit, a PLC (programmable logic controller), three positioning units, a spindle frequency converter, five servo drivers, a variable-frequency motor, five servo motors, five transmission shafts and four detection units, andthe PLC is connected with the HMI unit. The system solves the problems of unstable frequency converter open-loop control, uneven spun yarn levelness and inconsistent spun yarn forming tightness degreeand the like, spinning and forming accuracy, quality and uniformity are greatly improved, and spinning quality requirements can be met as for high-count, high-density and high-quality spinning. According the system, spinning accuracy and spinning quality are ensured, complicacy and high cost of a full-servo control method are avoided, and the novel control system and method is economical and practical.

Owner:山东同大机械有限公司

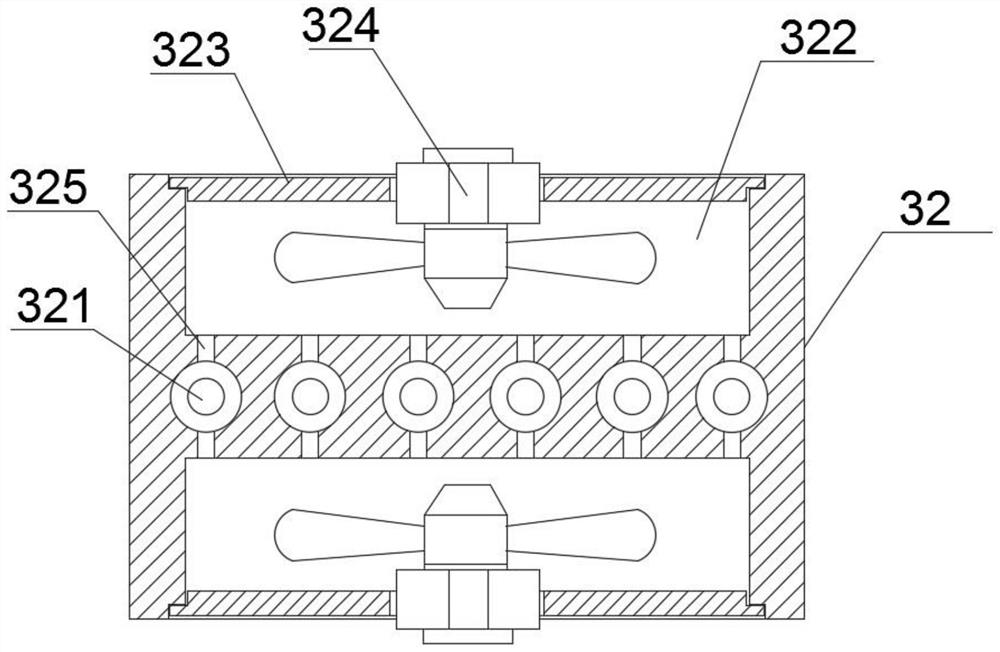

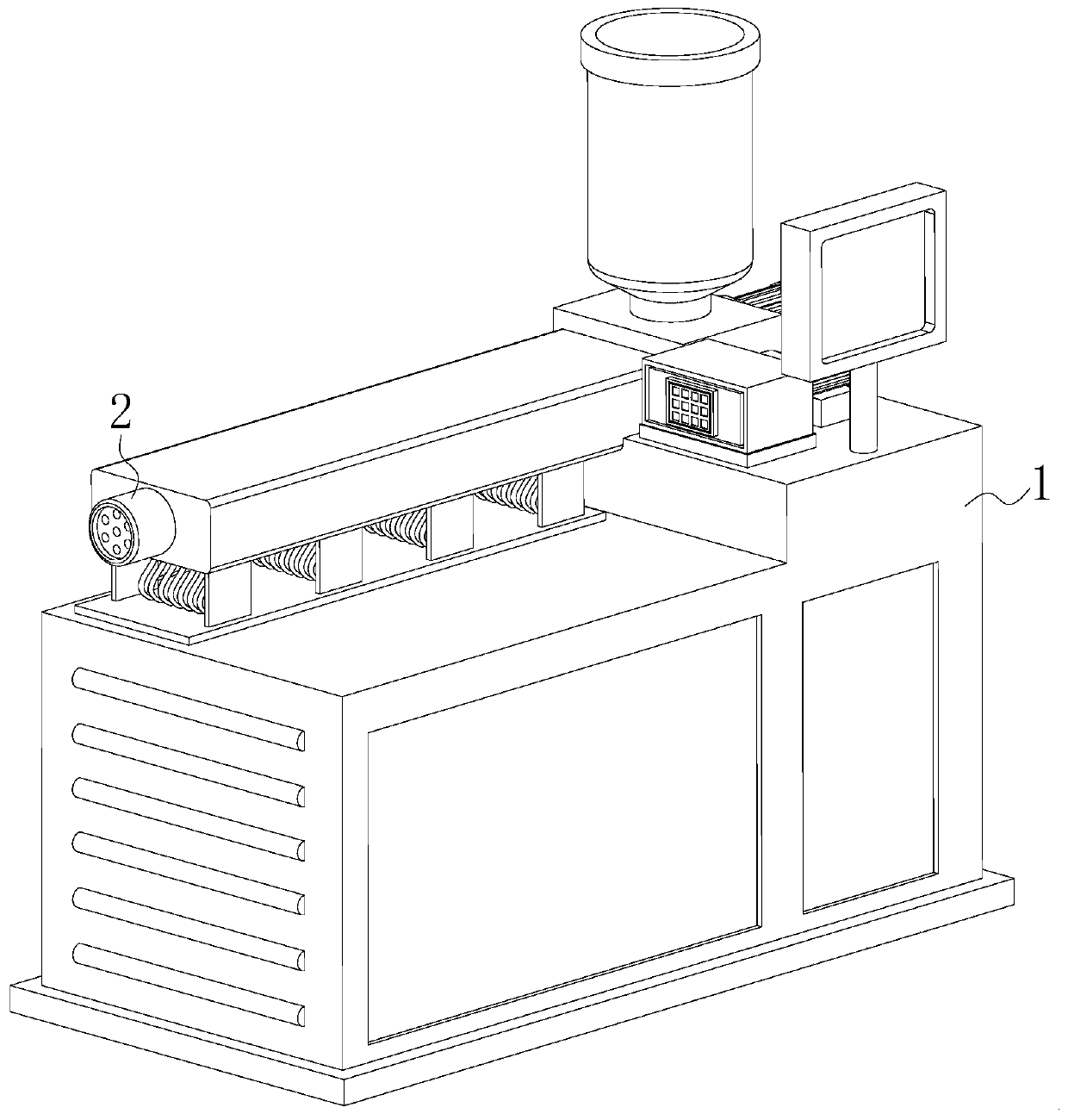

Polyglycolic acid wire-drawing equipment

ActiveCN111778572AGuarantee the quality of spinningNovel structureNew-spun product collectionFilament manufactureFiberGlycolic acid

The invention relates to polyglycolic acid wire-drawing equipment, which comprises a foundation bed, a first cooling device, a second cooling device and a rolling device, wherein the first cooling device, the second cooling device and the rolling device are arranged on the foundation bed; the rolling device comprises a reel frame and a rolling barrel rotatably arranged on the reel frame; the reelframe is provided with a third motor used for driving the rolling barrel to rotate; the lower end of the reel frame is provided with a collection cover of an arc-shaped structure; the collection coveris positioned below the rolling barrel; the bottom center of the collection cover is provided with an opening and is connected with a collection hopper; the bottom of the collection hopper is connected with an air pipe; one side of the lower end of the air pipe is connected with an exhaust fan; and the bottom end of the air pipe is connected with an impurity removal box. The rolling device is cooperated with the air pipe, the exhaust fan and the impurity removal box through the collection cover to remove impurities and short fibers on olyglycolic acid fibers, and the quality of the olyglycolic acid fibers is guaranteed.

Owner:ZHONG HONG NANO FIBER TECH DANYANG

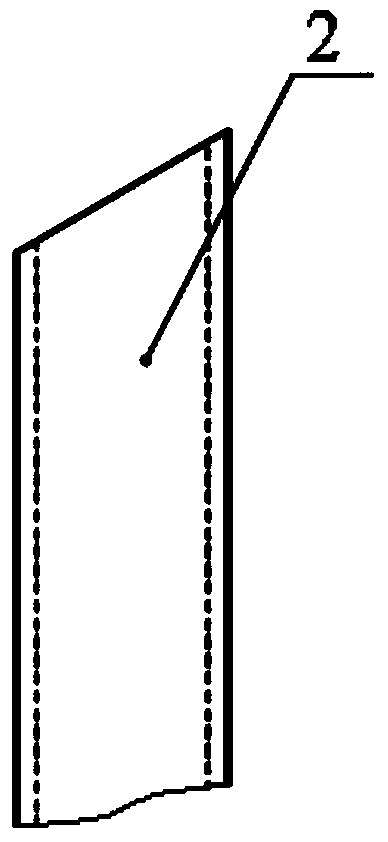

Reeling rack

InactiveCN105780238AEasy to operateIncrease tightnessLeasingOther manufacturing equipments/toolsYarnSpinning

The invention discloses a reeling rack which comprises a sleeve, wherein a separation plate is installed in the middle of the sleeve; studs are installed on the front side and the rear side of the separation plate respectively; multiple through holes are formed in a crossed manner at intervals on the sleeve walls located on the front and rear sides of the separation plate; reeling arms are installed on the inner side of the through holes; the inner sides of the reeling arms are fixed on the studs; a bearing is installed on the middle part of the separation plate; a spindle is installed on the inner side of the bearing; a rear bearing is installed on the rear side of the spindle; and a supporting shaft is installed on the bottom of the rear bearing. The reeling rack disclosed by the invention is characterized in that operations are simple; through crossed disposition of the front and rear through holes, multiple sets of reeling arms can be disposed, so that the shape of the reeling arms can further approach a round shape, tightness of yarn winding is increased, and spinning quality is ensured; automatic adjustment and driving can be carried out by a power motor according to spinning speeds; the height of a yarn installation place can be adjusted by a telescopic rod; and yarns can be supplied uniformly by yarn grasping grains, and an elastic tensioning mechanism can become more compact.

Owner:TIANJIN HAOSHI CARPET

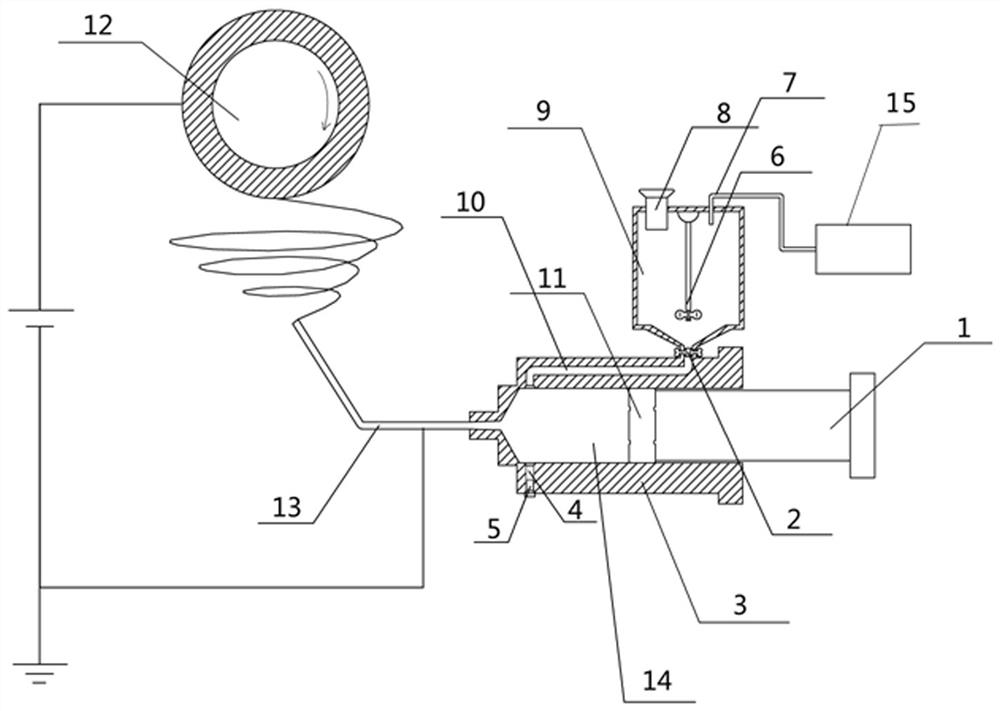

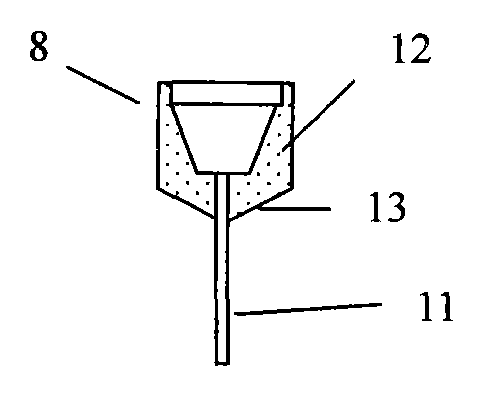

Electrostatic spinning injection device with liquid preparation function

The invention discloses an electrostatic spinning injection device with a liquid preparation function. The electrostatic spinning injection device comprises an injection cylinder (3), an injection push rod (1), a needle (13), a liquid preparation cylinder (9) and a vacuum pump, the needle (13) is arranged at the end of the injection cylinder (3), the injection push rod (1) is arranged in the injection cylinder (3), and a pipe plug (11) is arranged at the end of the injection push rod (1), one end of the liquid preparation cylinder (9) is connected with the vacuum pump, the other end of the liquid preparation cylinder (9) is communicated with a cavity of the injection cylinder (3) through a liquid guide pipe (10), and a ball valve (2) is arranged at the outlet end of the liquid preparationcylinder (9). By means of the electrostatic spinning injection device, a liquid preparation device and an injection device are combined into a whole, the manpower process is saved, and the quality ofspinning products is improved.

Owner:HUNAN INSTITUTE OF ENGINEERING

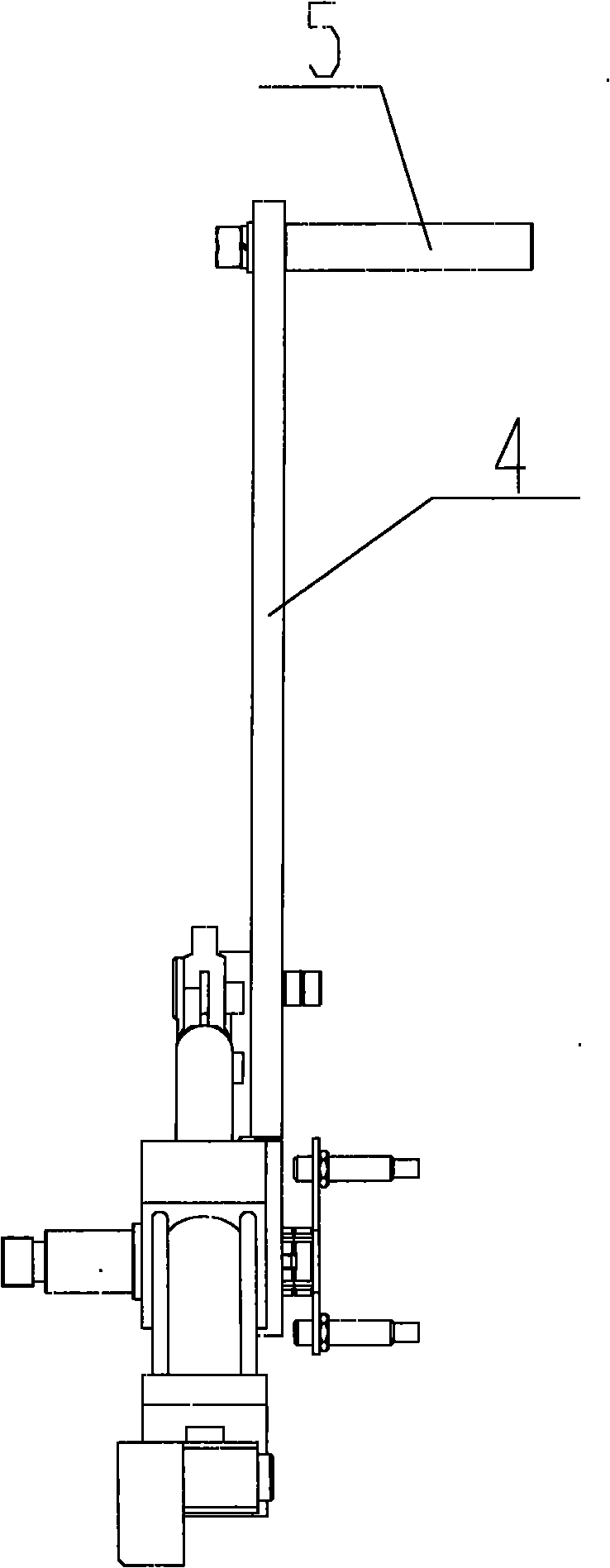

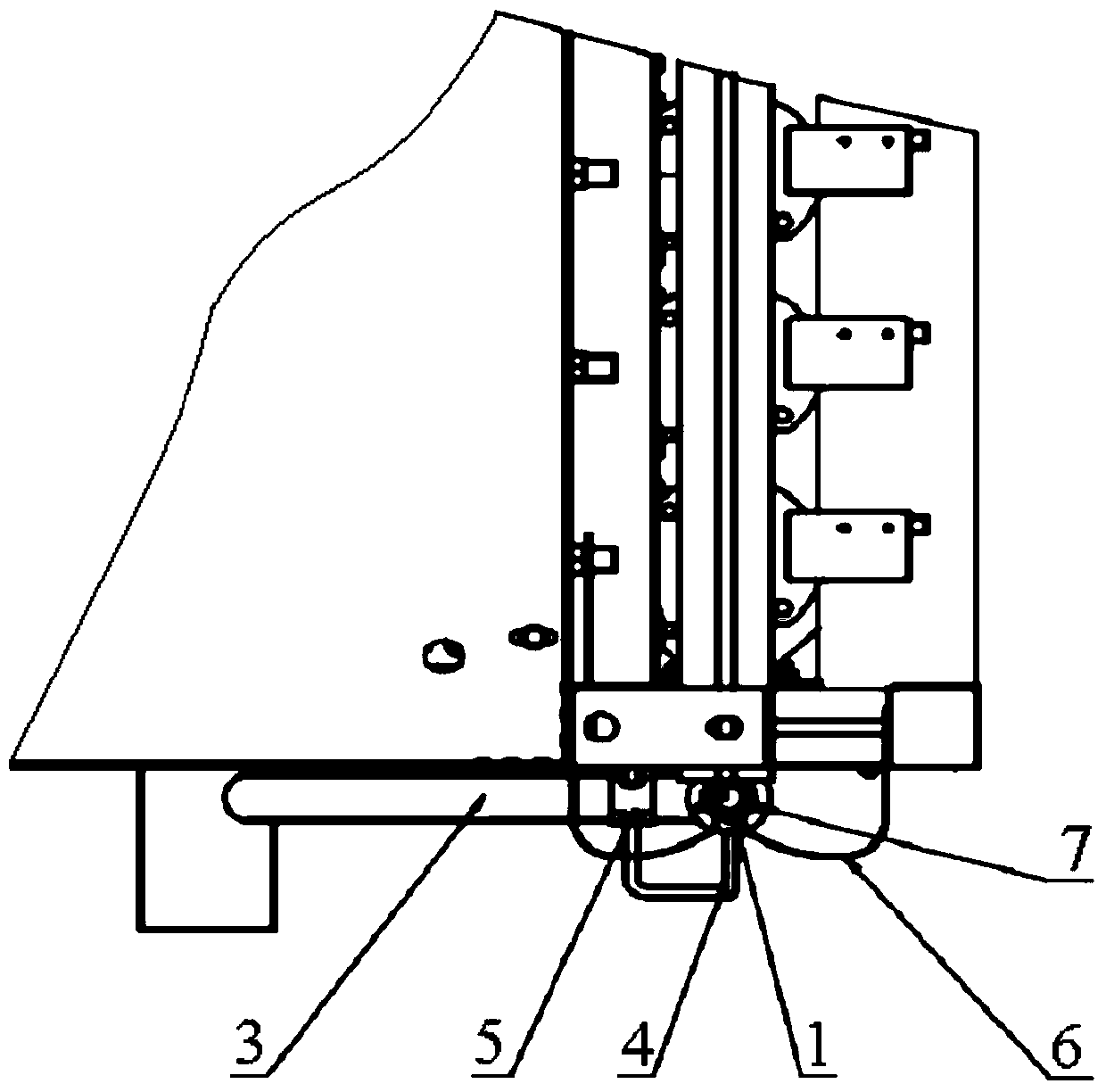

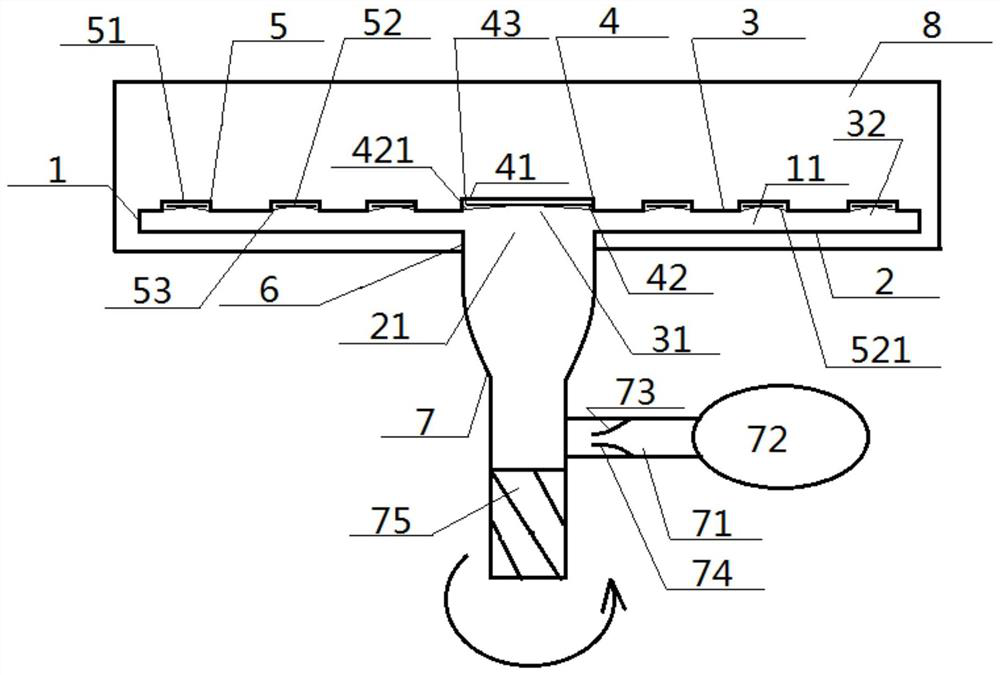

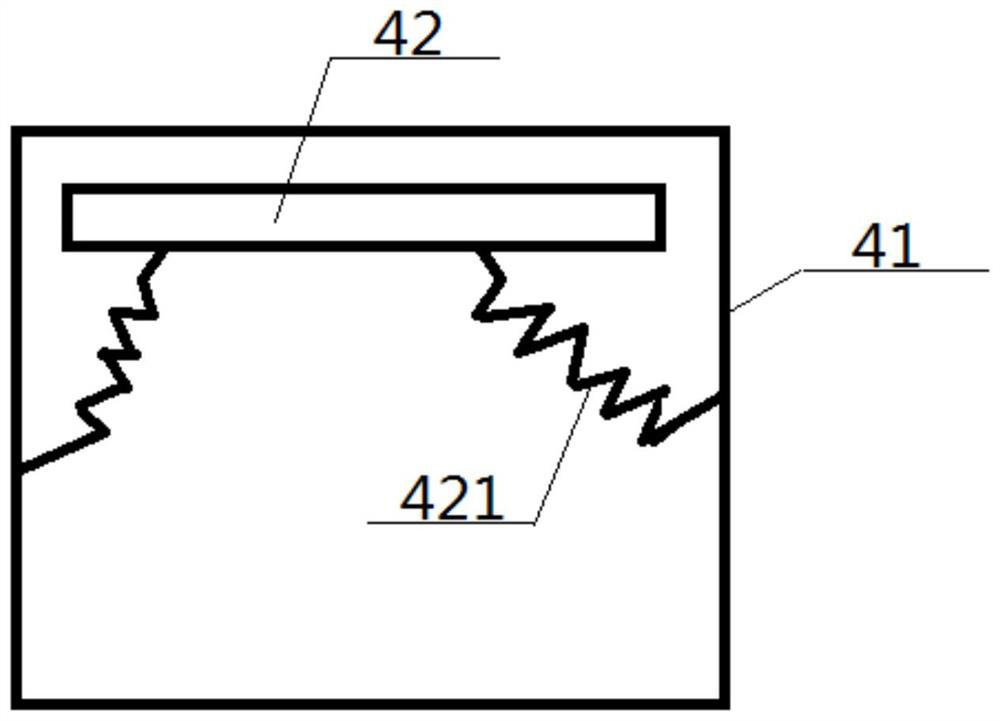

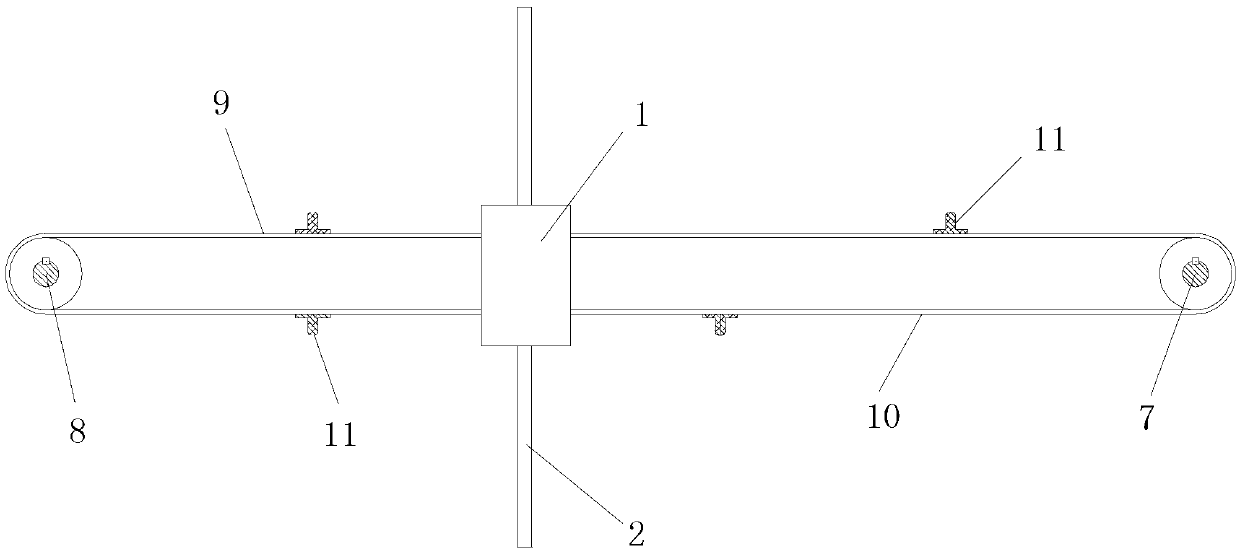

Traversing Mechanism of Air Spinning Machine

ActiveCN103603098BSimple structureEasy for daily maintenanceContinuous wound-up machinesOpen-end spinning machinesDrive shaftEngineering

The invention discloses a transversing mechanism of an airflow spinning machine. The transversing mechanism of the airflow spinning machine comprises a base; a supporting block is arranged under the base; the middle of the base is provided with a driving motor; the portions of the base, which are arranged on the bilateral sides of the driving motor, are provided with a support or installing holes, wherein the support or the installing holes are used for installing the transversing mechanism; an output shaft of the driving motor is vertically downward to penetrate the base and a driven shaft which is parallel to the output shaft is driven through a first transmission mechanism; one end of the driven shaft is upward to penetrate the base; a pair of push rods which are arranged in a parallel mode are driven by the driven shaft end which is located on the base through a second transmission mechanism; the push rods are arranged at the upper end of the base. According to the transversing mechanism of the airflow spinning machine, the integral structure is simplified, the daily repair and maintenance is convenient, the transversing speed is uniform, the work is smooth, the spinning quality is high, the noise is low, the safety is high, the transmission efficiency is high, the occupied space in a machine head is small, the transversing stroke is flexible and controllable, the transversing displacement is convenient to adjust, the service life is long, and the like.

Owner:江阴艾泰克机械制造有限公司

Hollow fiber spinning nozzle of insertion tube type

InactiveCN101935891AEasy to disassemble and cleanEasy to assembleHollow filament manufactureFilament/thread formingHollow fibreEngineering

The invention provides a hollow fiber spinning nozzle of an insertion tube type, comprising a bottom sheet, a middle sheet, an upper cover, a fastening bolt, an insertion tube fitting, a positioning base and a bolt. The fastening bolt connects the bottom sheet (1), the a middle sheet and the upper cover together so as to fix the whole framework of the nozzle; the insertion tube fitting is arranged in a hole of the middle sheet for spraying feed liquor, the positioning base is arranged in a hole of the middle sheet and connected with the middle sheet through threads, and the bolt is set to penetrate through the positioning base for positioning the insertion tube fitting. According to the nozzle structure of the invention, the concentricity of the nozzle is convenient to adjust so that the nozzle is convenient to take apart and clean and easy to assemble. The invention not only is convenient to use, but also can ensure the spinning quality, is favorable to being useding in mass production, can be conveniently to replaced with syringe needles of different specifications and be used for spinning bilayer or multi-layer composite hollow fiber and multi-core hollow fiber or processing a spinning nozzle with 1-36 holes or more.

Owner:吕剑阳

Broken end suction device of tail yarn removing machine

The invention discloses a broken end suction device of a tail yarn removing machine. The broken end suction device comprises a broken end suction component and a driving unit, wherein the driving unit comprises a driving motor and a fan; the driving motor and the fan are both arranged in the tail yarn removing machine; the broken end suction component comprises a suction nozzle and a first suction pipe; one end of the first suction pipe is fixedly connected with the suction nozzle, and the other end of the first suction pipe is communicated with a second suction pipe on the tail yarn removing machine; and the second suction pipe is connected with an exhaust opening of the fan. The broken end suction device can suck the broken ends on a spool under the condition that the tail yarn spool moves; the cotton yarns are snapped under the combined action of suction force and pulling force; the broken end length of the tail yarn is reduced; the tail yarn removing machine can conveniently search the tail yarn broken ends; and the tail yarn removing efficiency is improved.

Owner:CMT HICORP MACHINERY QINGDAO

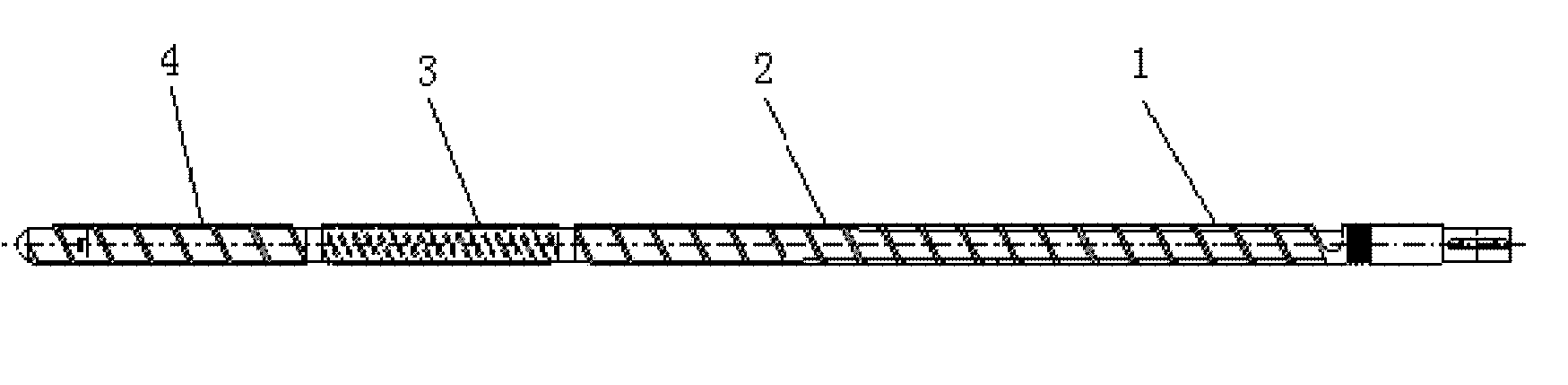

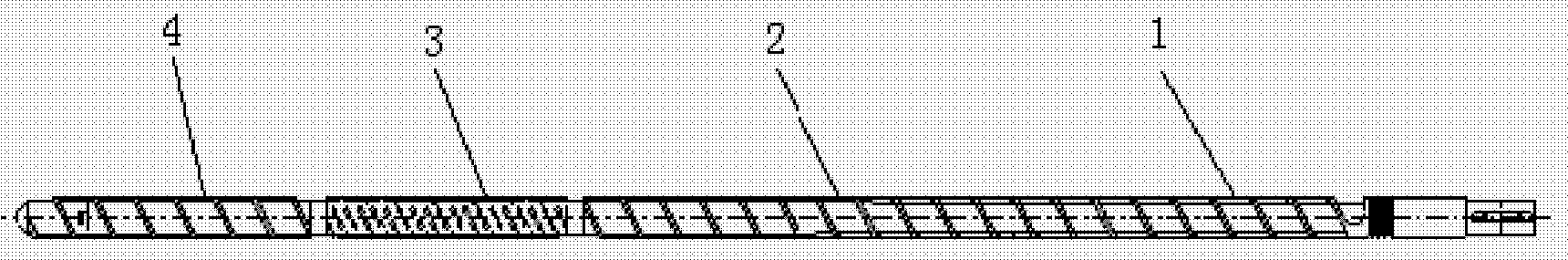

Extruder screw

InactiveCN102534819AIncrease chance of blendingImproved phase heat exchangeFilament forming substance formingSolid phasesEngineering

The invention discloses an extruder screw. The extruder screw sequentially comprises a feeding section, a compression section, a mixing section and a metering section, wherein a flow dividing element is arranged on the surface of the mixing section; and the mixing section is positioned between the compression section and the metering section. By the extruder screw, the flow direction of a melted melt pushed through a spiral groove of the compression section is changed, the mixing probability of fluid is increased, a heat exchange effect of a solid phase and a liquid phase is improved, the unmelted solid agglomerate can be refined, melted and homogenized, subsequent spinning can be performed, and spinning quality can be ensured.

Owner:BEIJING CHONGLEE MACHINERY ENG

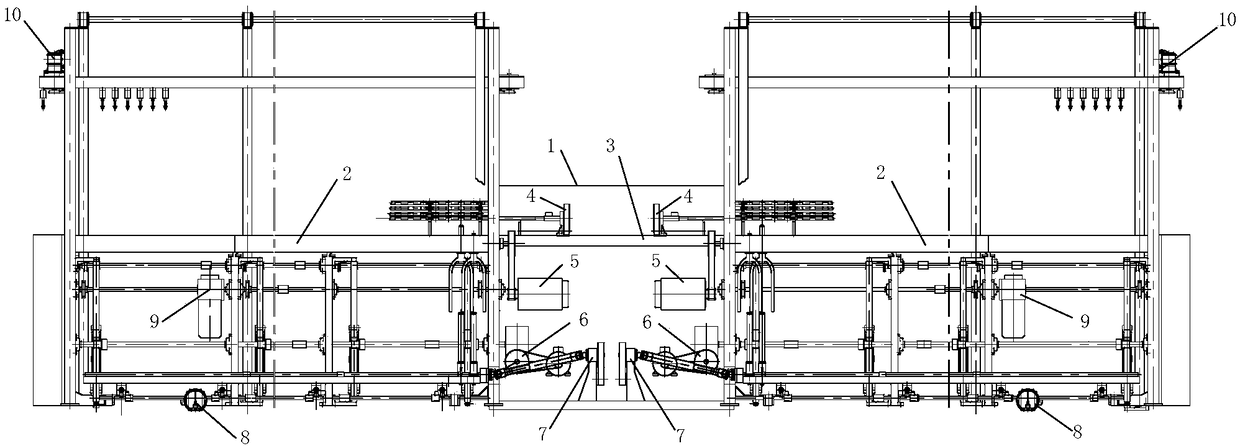

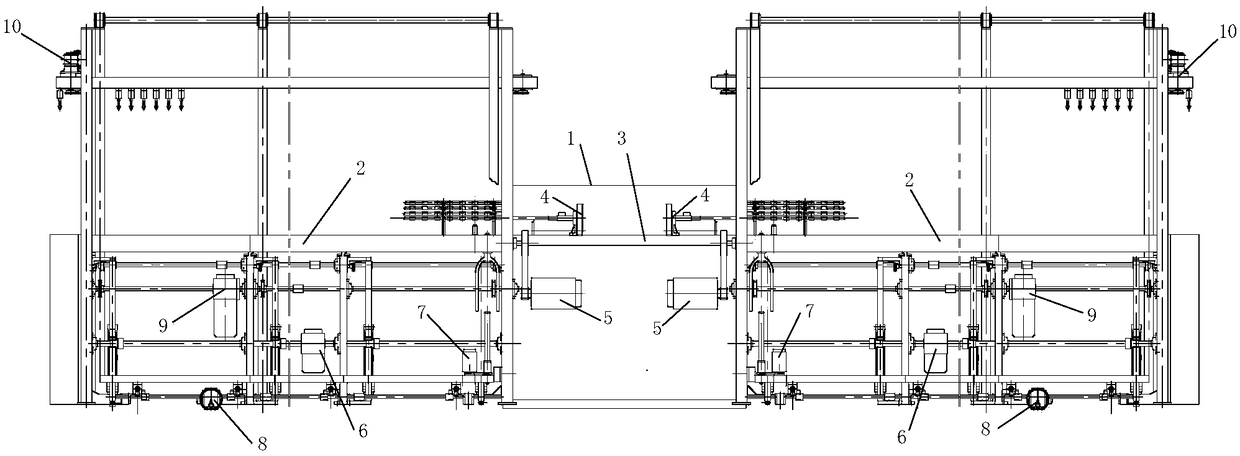

Combined type roving frame

The invention provides a combined type roving frame. The combined type roving frame comprises a power output mechanism and two sets of spinning mechanisms. The two ends of the power output mechanism and the spinning mechanisms are connected into a whole. The power output mechanism is provided with two sets of power output monomers. One set of spinning mechanism adapts to one set of power output monomer. A set of air drafting dust collection device is arranged on the two sets of spinning mechanisms. The power output mechanism further comprises a supporting frame. The two ends of the supportingframe and the spinning mechanisms are connected into a whole respectively, and the two sets of power output monomers are symmetrically placed on the supporting frame. The combined type roving frame isprovided with the two sets of spinning mechanisms, each set of spinning mechanism adapts to one set of power output monomer, the power output monomers independently provide power for the two sets ofspinning mechanisms and do not affect each other, rough yarn of different varieties can be separately spun by the two sets of spinning mechanisms, and rough yarn of the same varieties can be spun at the same time. The spindle number of the two sets of spinning mechanisms is two times that of an original roving frame, the single-machine yield of the roving frame can be greatly increased, and the production efficiency of the roving frame can be greatly improved.

Owner:CMT HICORP MACHINERY QINGDAO

Production method of superfine high count yarn

ActiveCN103526350BImprove spinning efficiencyIncrease speedContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a production method of superfine high count yarn. According to the technology, fiber sequentially goes the procedure of cotton grabbing, dedusting, heavy article impurity removing, cotton opening, cotton condensing, cotton combing, strip combining and rotor spinning yarn. The quality of superfine high count yarn reaches the quality of ring spinning. The production method of superfine high count yarn has the characteristics of high speed, high yield, large coiling block, short technology of rotary spinning, ensures spinning quality and improves the spinning speed at the same time.

Owner:YIBIN WEILUO TEXTILE

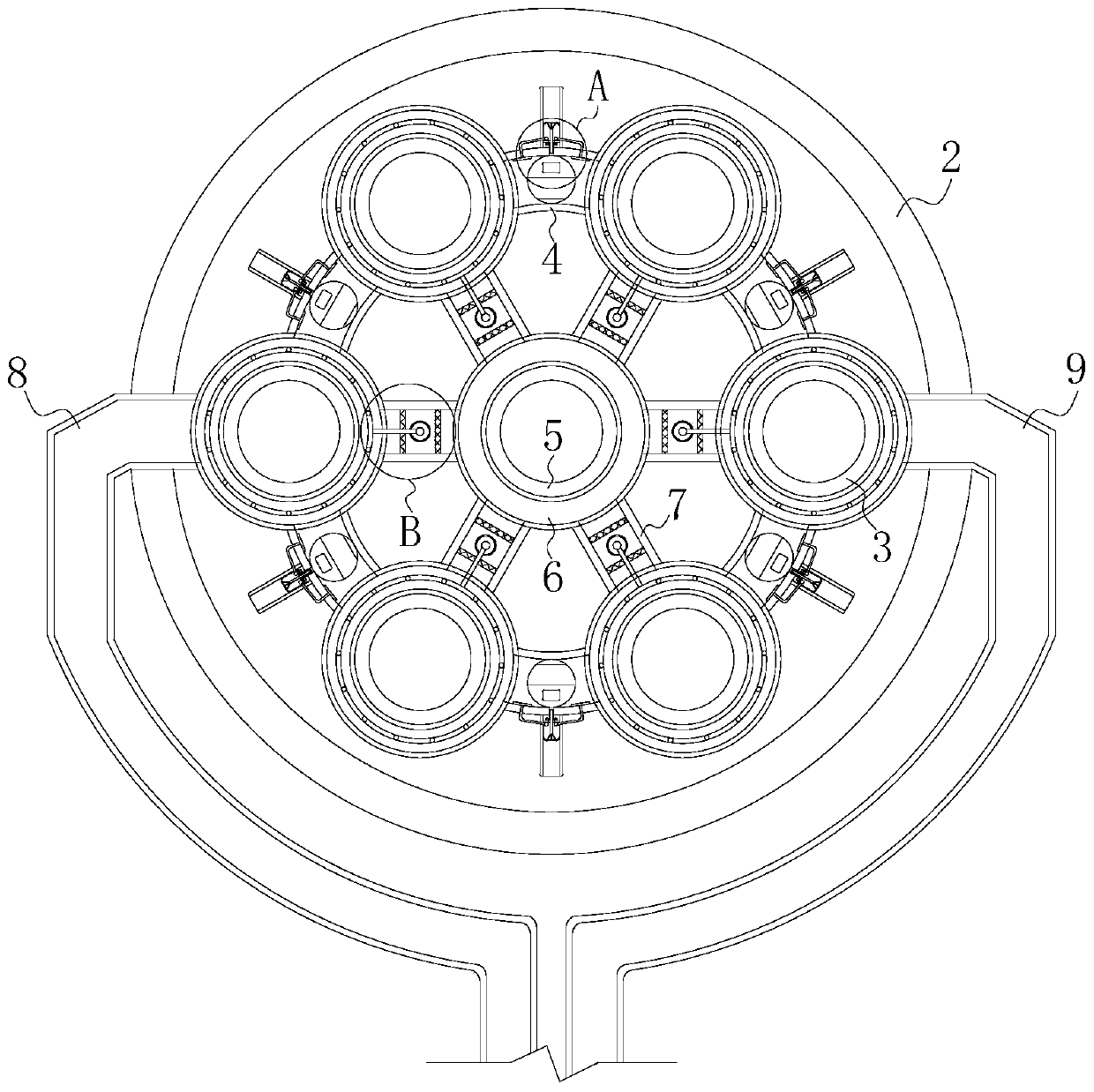

Supporting floating type centrifugal spinning device and using method thereof

PendingCN114197065AIncrease productionImprove dispersionSpinnerette packsArtificial thread manufacturing machinesPhysicsEngineering

A supporting floating type centrifugal spinning device comprises a liquid containing bottom shell, a liquid containing top shell, a main spray head and a plurality of secondary spray heads, a liquid containing inner cavity is defined by the liquid containing bottom shell, a side wall outer shell and the liquid containing top shell, a main liquid opening and a plurality of secondary liquid openings are formed in the middle of the liquid containing top shell, and the main spray head comprises a main spray cylinder and a main floating piece; the bottom end of the main spraying barrel is communicated with the liquid containing inner cavity through a main liquid opening, and an arc-shaped main slit is formed between a main floating piece floating on the portion, close to the top end of the main spraying barrel, in the main spraying barrel and the main spraying barrel; the secondary spray head comprises a secondary spray cylinder and a secondary floating piece, the bottom end of the secondary spray cylinder is communicated with the liquid containing inner cavity through a secondary liquid opening, and an arc-shaped secondary slit is formed between the secondary floating piece floating on the portion, close to the top end, in the secondary spray cylinder and the secondary spray cylinder; the main floating piece is connected with the inner wall of the main spraying barrel through a main supporting wire, and the secondary floating piece is connected with the inner wall of the secondary spraying barrel through a secondary supporting wire. According to the design, the yield is high, dispersity is high, adjustability is high, and the spinning effect is good.

Owner:WUHAN TEXTILE UNIV

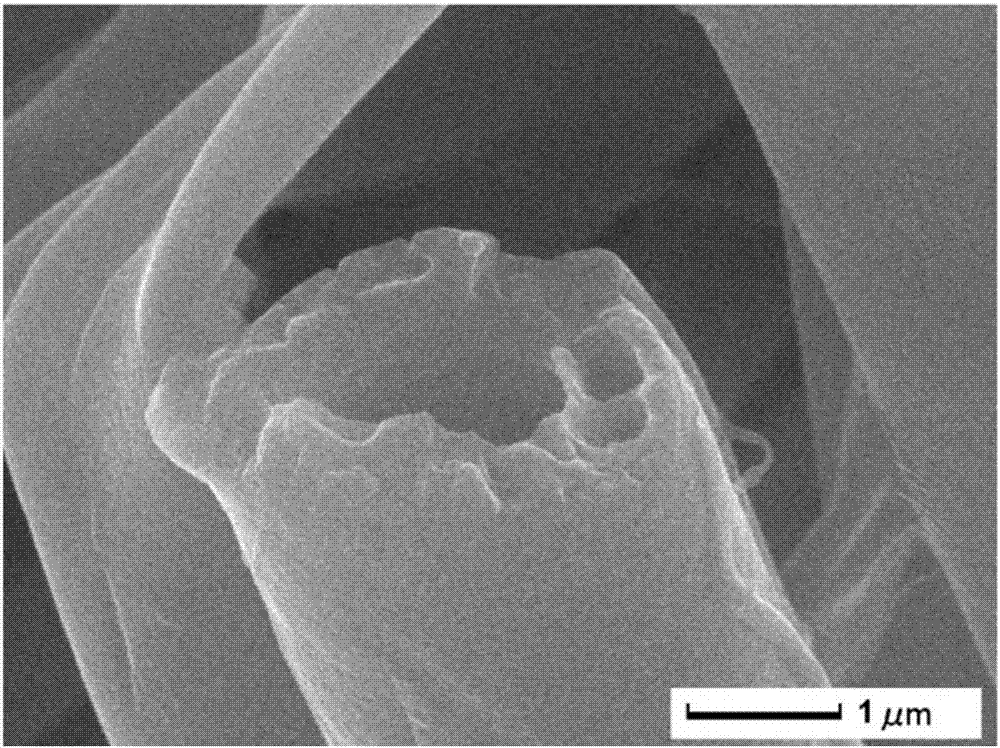

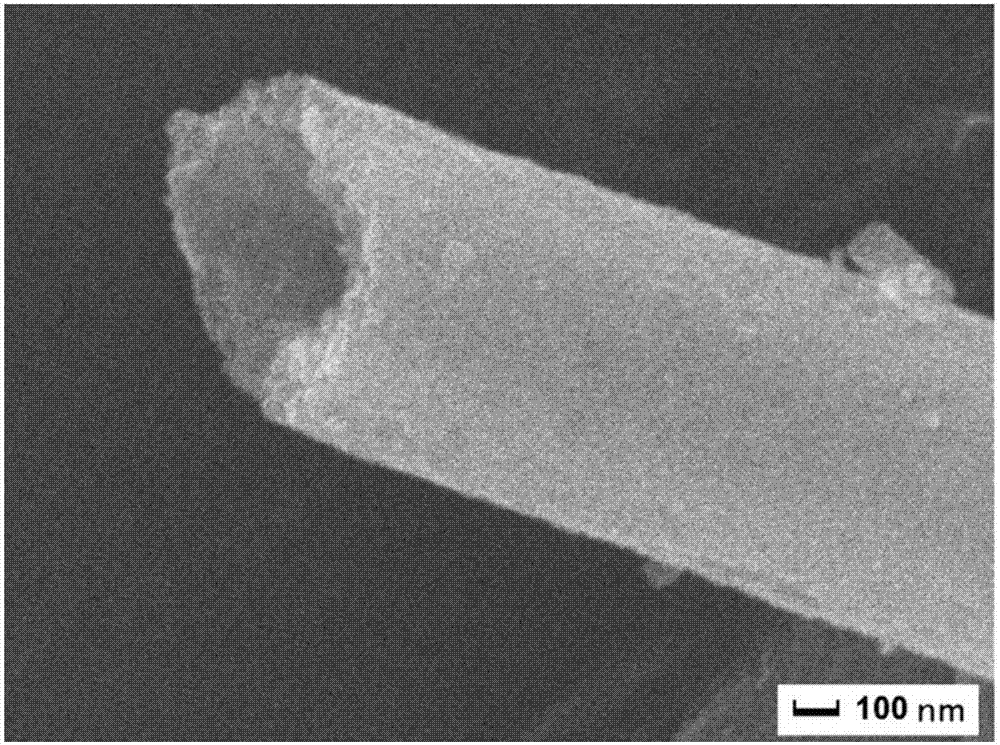

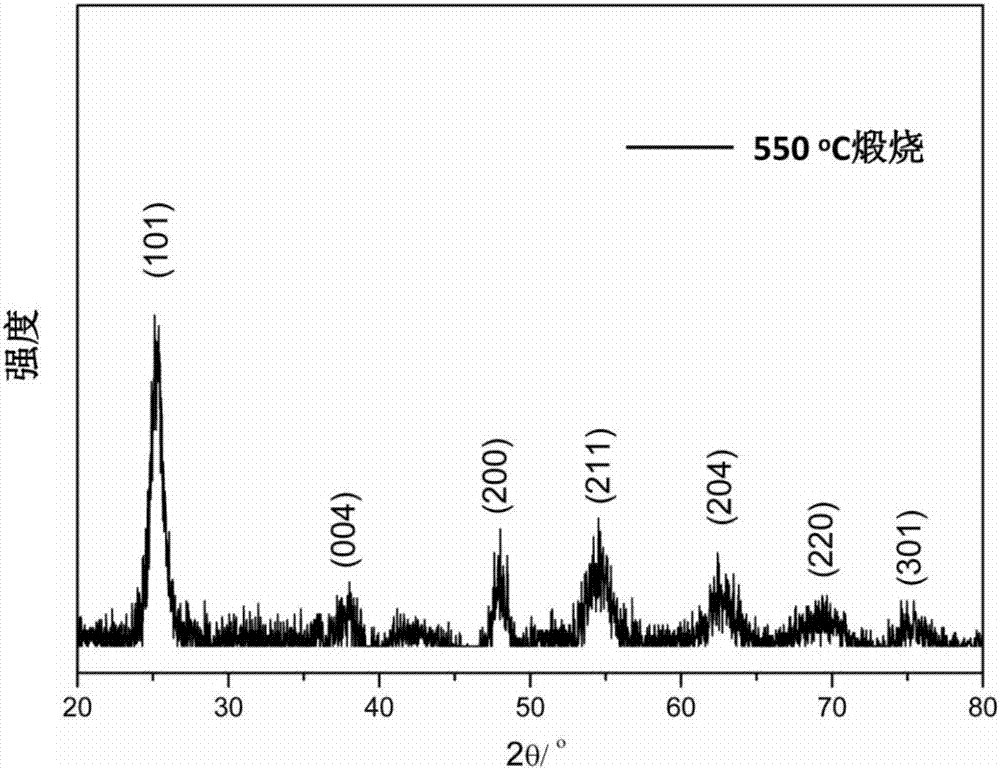

A method for preparing porous hollow titanium dioxide nanotubes

ActiveCN106186058BReduce sensitivityLess prone to cloggingElectro-spinningNanotechnologyFiberElectrospinning

The invention discloses a method for preparing porous hollow titanium dioxide nanotubes. The method comprises the steps of 1, dissolving a polymer spinning carrier, an anti-hydrolysis agent, disperse phase, a disperse phase cosolvent and a titanium dioxide precursor in a solvent while stirring to form a spinning solution; 2, conducting electrostatic spinning on the spinning solution obtained in step 1 through an electrostatic spinning device to obtain nanofiber; 3, aging the nanofiber obtained in step 2, and then conducting extraction to obtain hollow nanofiber; 4, calcinating the hollow nanofiber obtained in step 3 to obtain the porous hollow titanium dioxide nanotubes. The method is easy to operate, sensitivity to external conditions during spinning is reduced, silk production is stable, needle blocking does not occur easily, large-scale production can be achieved easily, and the porous hollow titanium dioxide nanotubes prepared with the method have a pure phase and a high specific surface area.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Cleaning device for roving and spinning unit yarn bin guide rail

The invention discloses a cleaning device for a roving and spinning unit yarn bin guide rail. The cleaning device comprises two parallel guide rails which are installed on a yarn bin beam and a blowing mechanism which can slide along the guide rails, wherein the blowing mechanism comprises a fan and air pipes which are arranged on the two sides of the fan, and a plurality of inclined blowing nozzles are uniformly distributed on the bottom ends of the air pipes. The cleaning device for the roving and spinning unit yarn bin guide rail further comprises a drive mechanism which drive the blowing mechanism to slide along the guide rails. By the cleaning device, the labor and labor cost for cleaning are lowered, the production efficiency is increased, and the spinning quality is ensured; and the cleaning device has the advantages of simplicity in structure, convenience in installation and maintenance, low energy consumption, good cleaning effect and strong operation reliability.

Owner:CMT HICORP MACHINERY QINGDAO

Production equipment of fiber-grade polypropylene

The invention discloses production equipment of fiber-grade polypropylene and relates to the technical field of chemical fiber production. The production equipment of the fiber-grade polypropylene comprises a machine body, wherein the machine body comprises a single-screw extruder and a discharging barrel mounted at a discharging port of the single-screw extruder, six conduits connected with the discharging end of the single-screw extruder are fixedly connected in the discharging barrel at equal intervals in a surrounding manner, every two adjacent conduits are communicated through a swan neck, a middle barrel is fixedly connected at the axis of the inner wall of the discharging barrel, and the middle barrel and the conduits are sleeved with water cooling pipes. According to the productionequipment of fiber-grade polypropylene, when spinning temperature is too high, water temperature increases synchronously, so that a flow control mechanism is driven to enable a flow ball to rotate, the flow ball gradually rotates and the pore diameter gradually increases to increase flow of water in the swan necks, the operation rate of a water cooling system is increased, and the water cooling heat exchange method is enhanced by increasing the water flow speed.

Owner:范儒毅

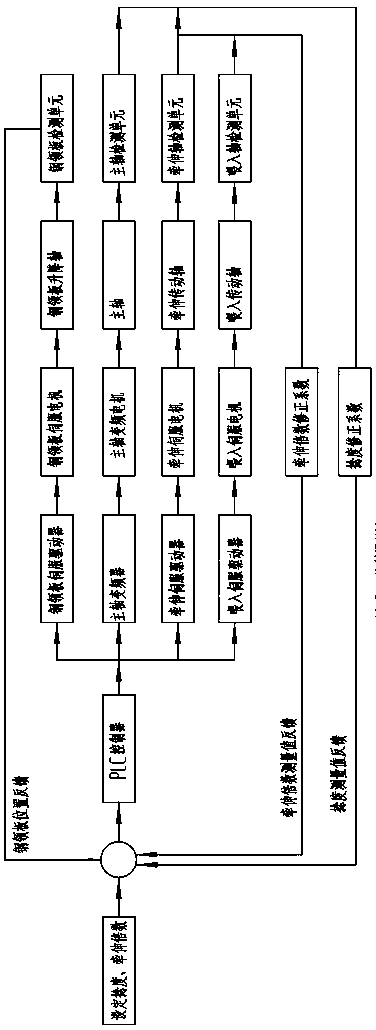

Control system of semi-continuous and high-speed spinning machine

InactiveCN103409827AAdequate responseIncrease spinning speedWet spinning methodsControl systemControl engineering

The invention relates to a control system of a semi-continuous and high-speed spinning machine. The control system comprises a central control module, a glue supply control module, a thread-line forming control module, a spinning control module and a winding control module, wherein the central control module is respectively connected with the glue supply control module, the thread-line forming control module, the spinning control module and the winding control module; the spinning control module controls formed thread-lines to walk to a spinning roller which is transversely arranged relative to an operation face of a spinning surface, and the formed thread-lines surround the spinning roller; the spinning control module controls a spinning device to draft, solidify and disacidify the thread-lines by controlling rotation of the spinning roller, and in the processes of drafting, solidifying and disacidifying the thread-lines, the spinning control module controls a washing device to wash the formed thread-lines; the spinning control module controls the formed thread-lines which are drafted, solidified, disacidified and washed to be guided out of the spinning roller to the interior of a hopper. The control system of the semi-continuous and high-speed spinning machine improves the spinning speed, ensures response and walking path of the thread-lines and also ensures the full response of the thread-lines.

Owner:YIBIN HIEST FIBER +2

Spinning assembly for multi-component fiber

PendingCN111101212AShorten the lengthAvoid interactionSpinning solution de-aeratingFilament/thread formingEngineeringMaterials science

The invention discloses a spinning assembly for a multi-component fiber, and belongs to melt spinning equipment. The spinning assembly comprises a box body, a spinneret plate, a melt distribution plate, a melt filtering cylinder and a box body cover, wherein the spinneret plate is arranged at the bottom of a box body cavity, and spinneret plate capillary spinneret holes are formed in the spinneretplate; the melt distribution plate is stacked above the spinneret plate, and is provided with melt distribution holes, and a melt distribution groove is formed in the bottom of the melt distributionplate; the melt filtering cylinder is arranged in the box body cavity and is supported on the melt distribution plate, and comprises a first melt filtering cavity, a second melt filtering cavity and athird melt filtering cavity; the box body cover is fixed with the top surface of the box body, and the box body cover is provided with a first component melt lead-in hole, a second component melt lead-in hole and a third component melt lead-in hole; the left end of the first component melt lead-in hole communicates with the upper part of the first melt filtering cavity; the left end of the secondcomponent melt lead-in hole communicates with the upper part of the second melt filtering cavity; the left end of the third component melt lead-in hole communicates with the upper part of the third melt filtering cavity; and the first component melt lead-in hole, the second component melt lead-in hole and the third component melt lead-in hole extend into the right side surface of the box body cover and communicate with the outside. Mutual influence caused by different component melt temperatures can be avoided, and the spinning quality is ensured.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com