Automatic cotton cleaning device for spinning machine suction box

An automatic cleaning and suction box technology, applied to spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of affecting the quality of spinning and the negative pressure of the negative pressure tube of the concentrated fiber weakening, etc., and achieves wide application and simple structure , Time-saving and labor-saving effect of cleaning flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

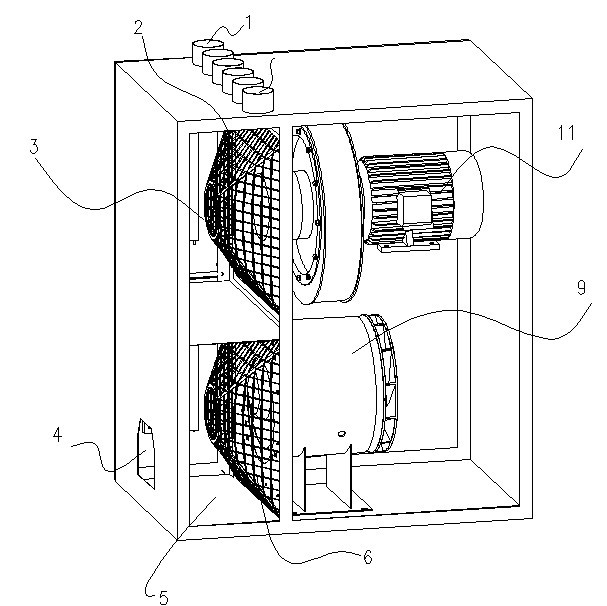

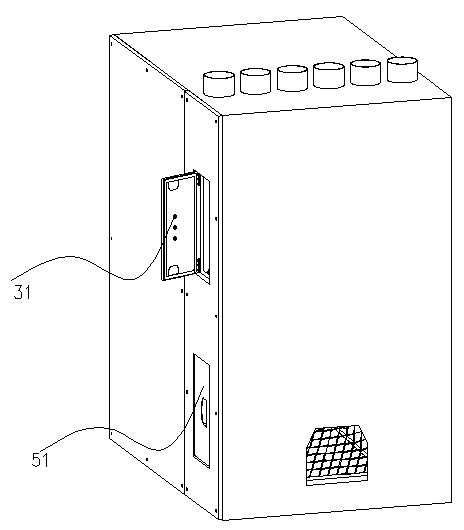

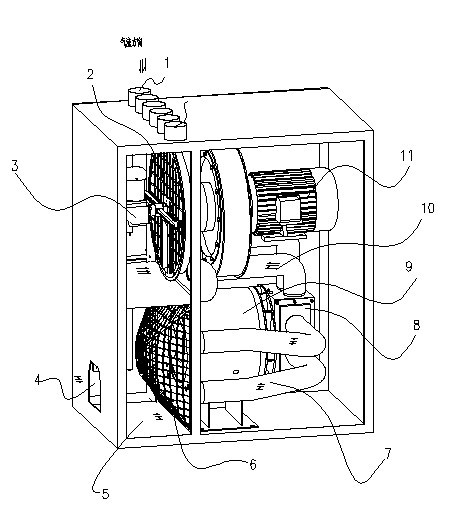

[0026] Such as image 3 , 4 As shown, an automatic cleaning device for the suction box of a textile machine is mainly composed of a cotton suction pipe (not shown in the figure), a flute pipe air collection pipe (not shown in the figure), a flute pipe air collection pipe air inlet 4, a broken end Strip suction box 5, broken strand filter screen 6, centrifugal fan 9, fiber accumulation negative pressure pipe (not shown in the figure), negative pressure air collection pipe (not shown in the figure), negative pressure air collection pipe air inlet 1 , Negative pressure suction box 3, fluffy filter screen 2, negative pressure centrifugal fan 11 are formed.

[0027] The above-mentioned flower cleaning device also includes an automatic flower cleaning conveying pipe 10 , a negative pressure valve, an automatic flower cleaning suction pipe 7 , a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com