Cone yarn carrying steering mechanism

A technology of steering mechanism and yarn package, which is applied to conveyor objects, transportation and packaging, textiles and papermaking, etc., can solve the problems of low conveying efficiency, damage to package yarn, and heavy labor, and achieve simple structure, avoid damage, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

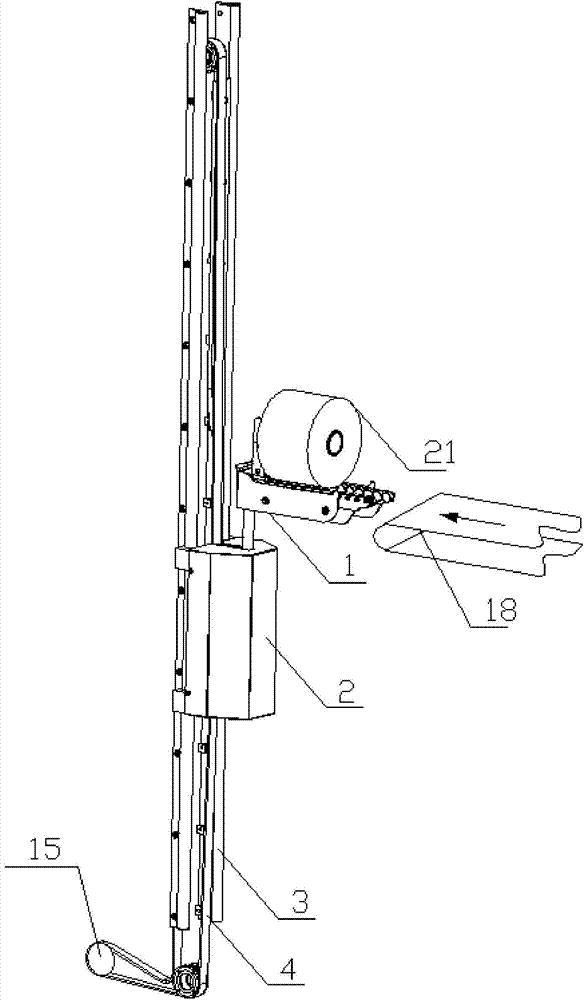

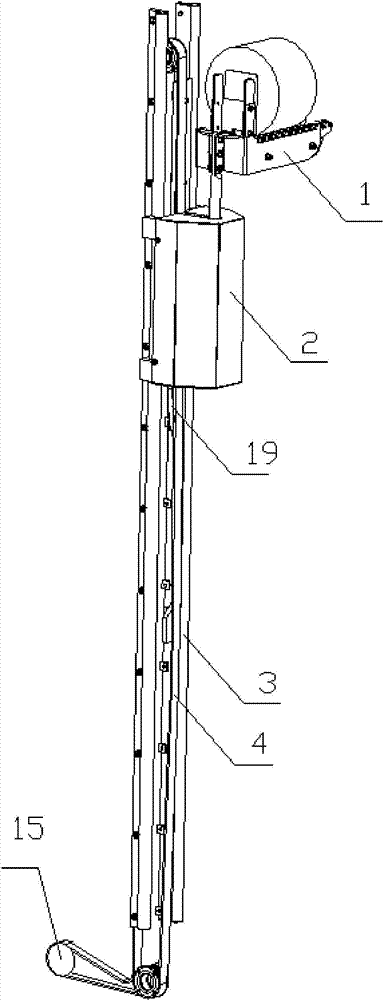

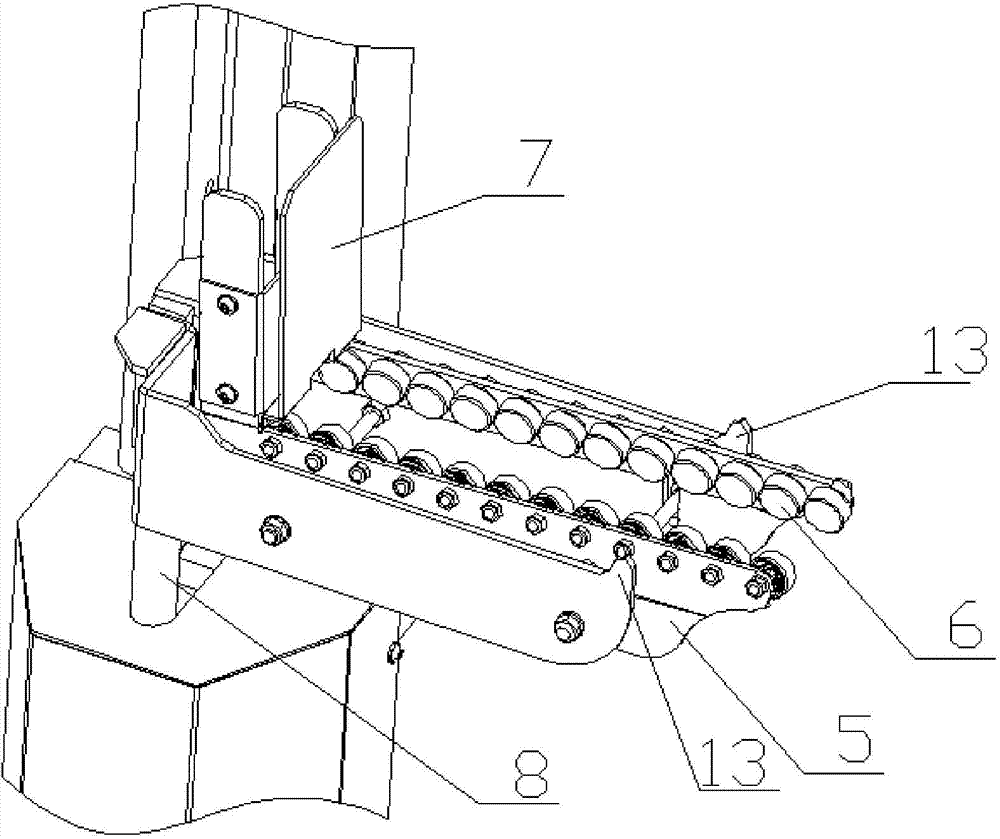

[0025] Embodiment: a bobbin transfer and steering mechanism, including a frame, a bobbin holding mechanism 1, a steering transmission mechanism 2 and a driving mechanism, wherein: a bobbin holding mechanism 1 is formed with a bobbin that can just accommodate the bobbin 21 The supporting part can just connect with the end of the conveyor belt 18 of the package yarn output device. The lower end of the package yarn supporting mechanism 1 is fixedly connected with a steering shaft 8, which can rotate around the vertical axis and is inserted in the steering transmission mechanism 2. Above, the steering transmission mechanism 2 can be vertically lifted and installed on the frame, the driving mechanism drives the steering transmission mechanism 2 to lift, and the steering transmission mechanism 2 can drive the steering shaft 8 to rotate back and forth by 90°.

[0026] This mechanism is applied to the equipment in the spinning process, such as winding, air-jet spinning or air-jet spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com