Tail yarn head keeping device for tail yarn removing machine

A technology for clearing machine and tail yarn, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc. problems, achieve good twist breaking and loosening effect, improve removal efficiency, and ensure spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

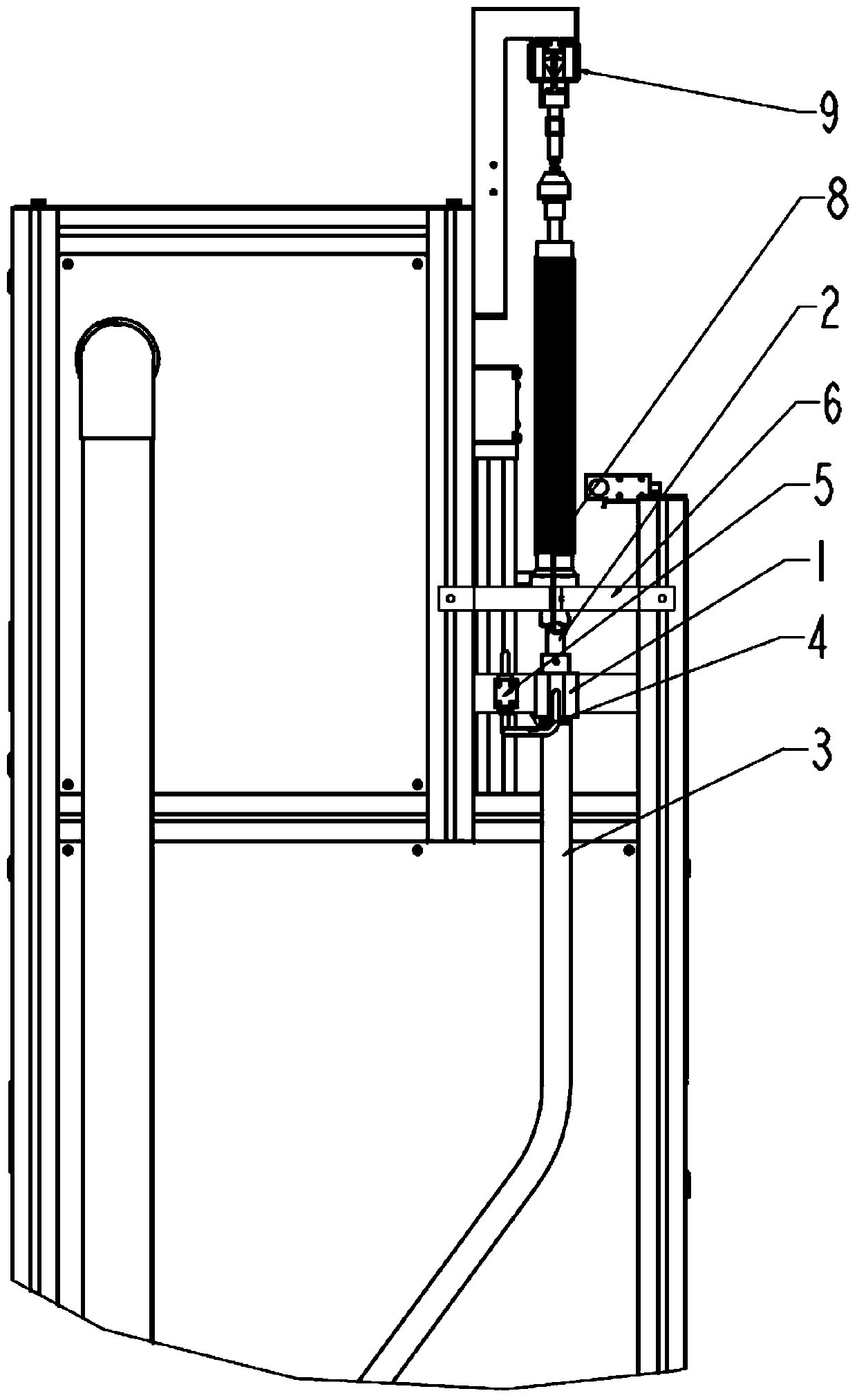

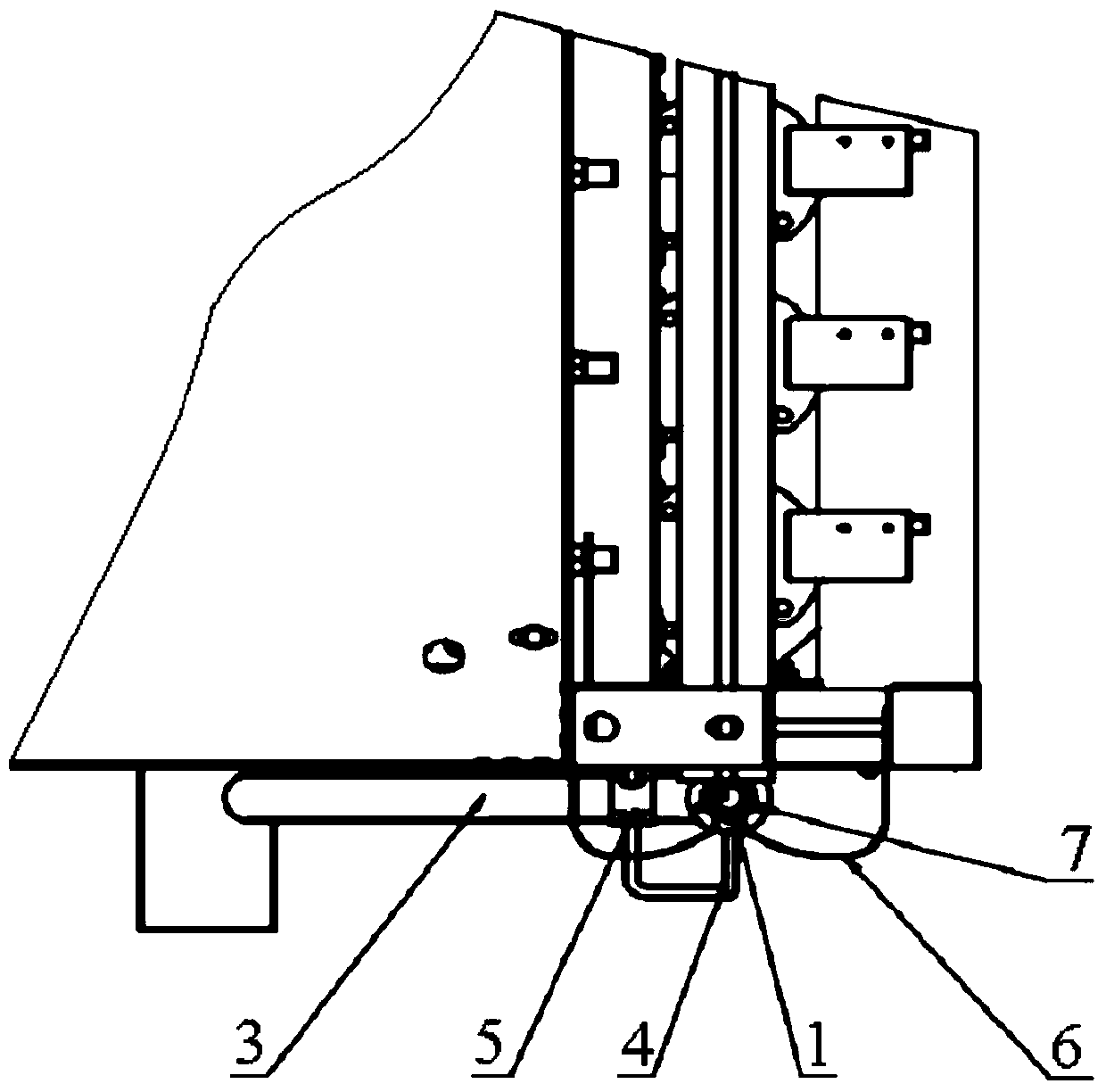

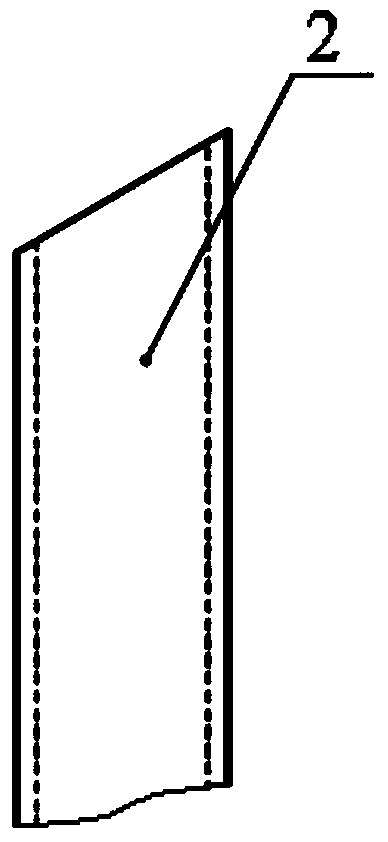

[0018] Such as figure 1 with figure 2 As shown, the present invention is a tail yarn removal device for a tail yarn retention device, which includes a suction device, a driving device and a detection device. The suction device includes a negative pressure chamber 1, a suction pipe 2, an exhaust pipe 3, an air pipe 4 and a yarn guide plate 6, and the negative pressure chamber 1 is fixedly installed on a frame at the entrance side of the tail yarn removal machine. The lower end of the suction pipe 2 communicates with the negative pressure chamber 1, such as Figure 3-1 with Figure 3-2 As shown, the suction pipe 2 is a circular tube, and the upper end is a port with a slope. In use, the port faces the side of the bobbin tube 8 with tail yarn, and the port of the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com