Cleaning device for roving and spinning unit yarn bin guide rail

A technology of cleaning device and joint yarn warehouse, which is applied in textiles and papermaking, can solve the problems of potential safety hazards, easy sticking of filter screens, and deterioration of working environment by flying dust, so as to achieve strong operational reliability, improve production efficiency, and ensure spinning The effect of yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

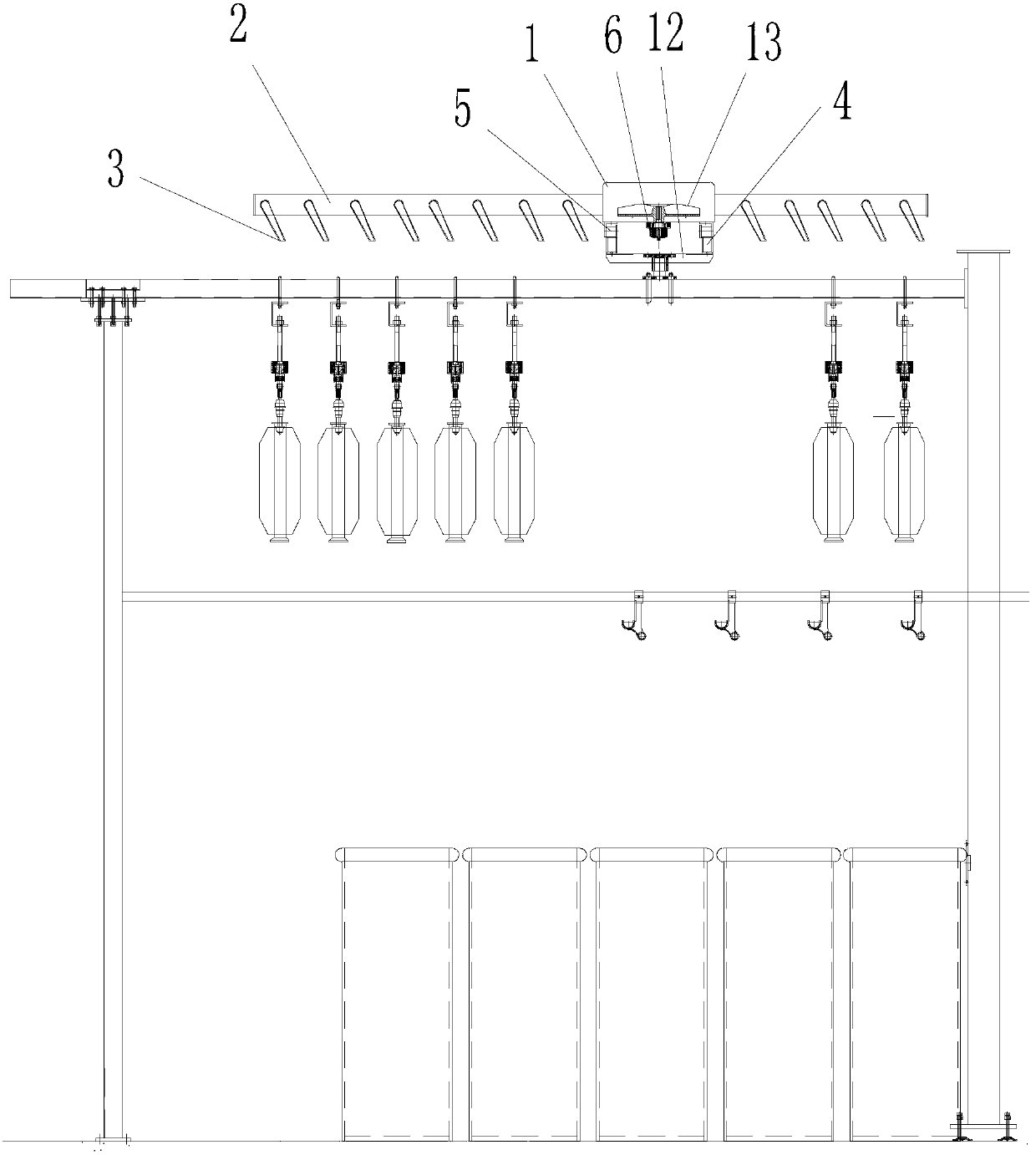

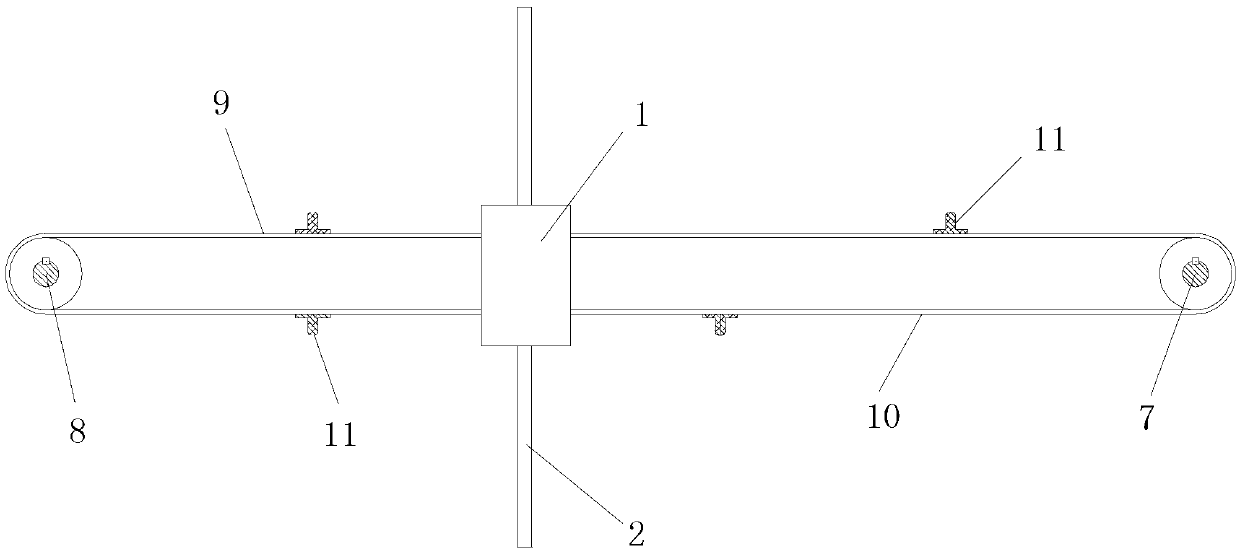

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0023] Figure 1 and figure 2 As shown, a thick and thin yarn storehouse guide rail cleaning device includes two parallel guide rails 4 installed on the yarn storehouse beam 12 and a blower mechanism that can slide along the guide rails 4. The blower mechanism includes a fan 1 and a The air ducts 2 on both sides of the fan 1, the bottom of the air duct 2 are evenly distributed with several oblique blowing nozzles 3, and the cleaning device for the guide rail of the thick and thin yarn warehouse also includes driving the blowing mechanism to slide along the guide rail 4 the drive mechanism.

[0024] The fan 1 includes an impeller 13, the bottom of the fan 1 is provided with first, second and third pulleys, the second pulley 6 is provided with a drive shaft, and the impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com