Spinning nozzle

A technology of spinning nozzle and spinning hole, which is applied in the field of inserted tubular porous spinning nozzle, which can solve the problems of abnormal production and loss of concentricity, etc., and achieve the effects of easy assembly, guaranteed spinning quality and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

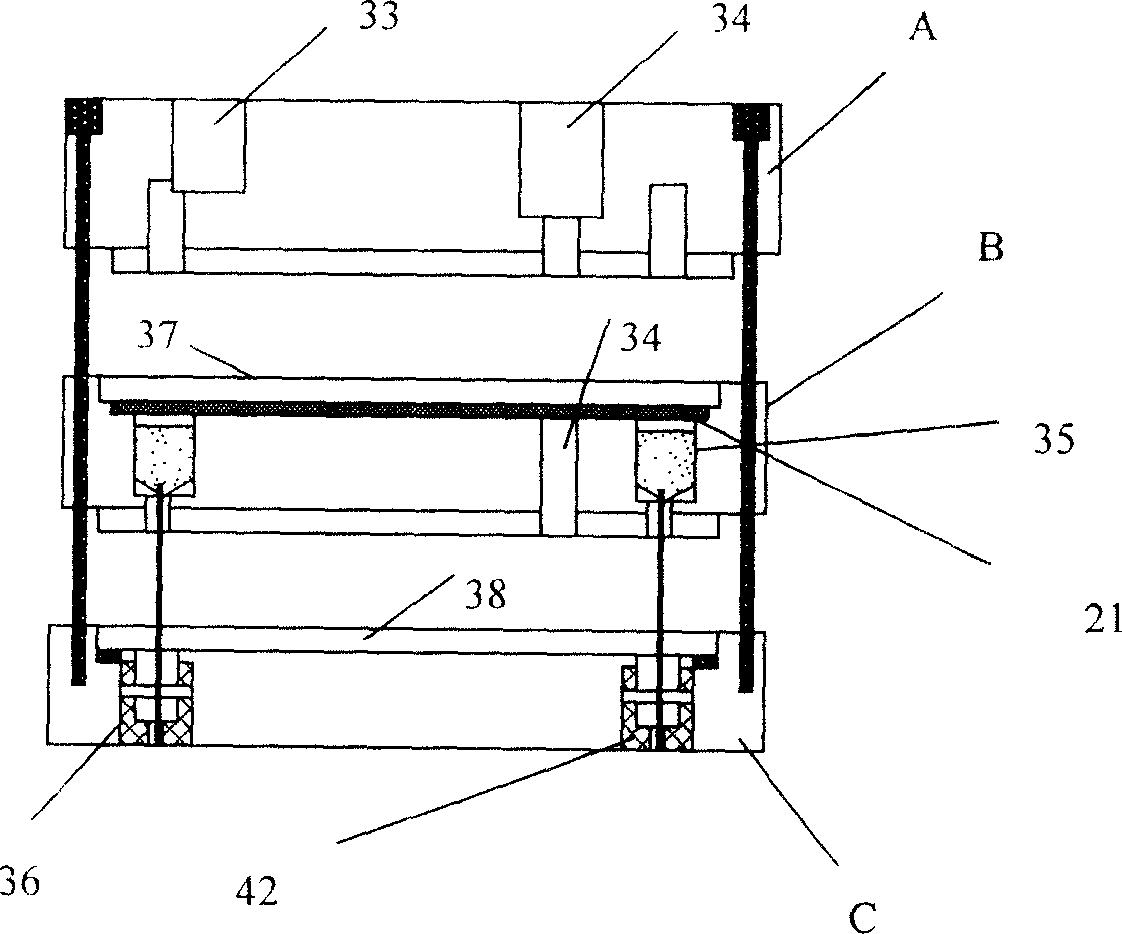

[0018] The following is based on figure 1 -4 Describe in detail the specific structure of the spinneret of the present invention.

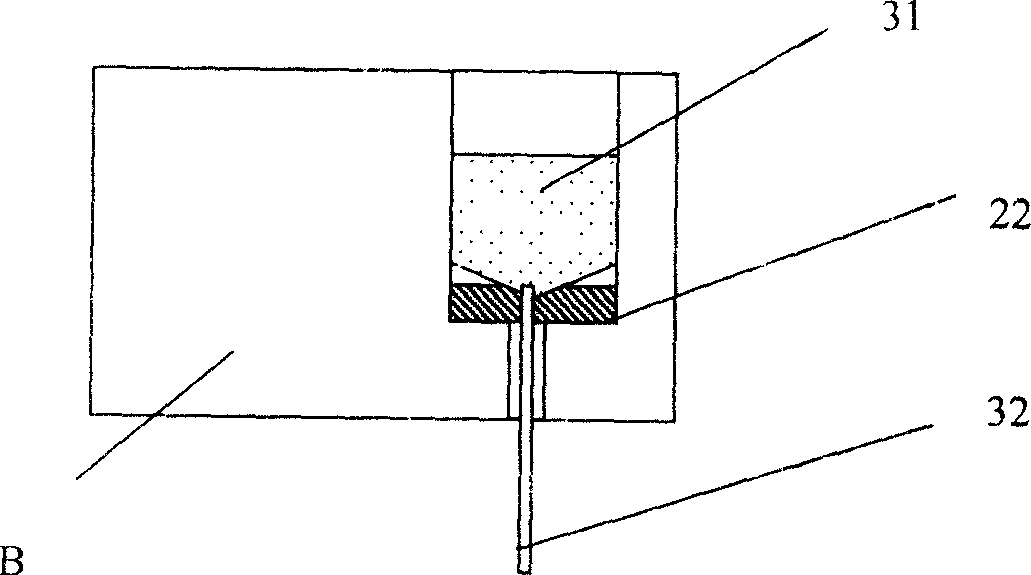

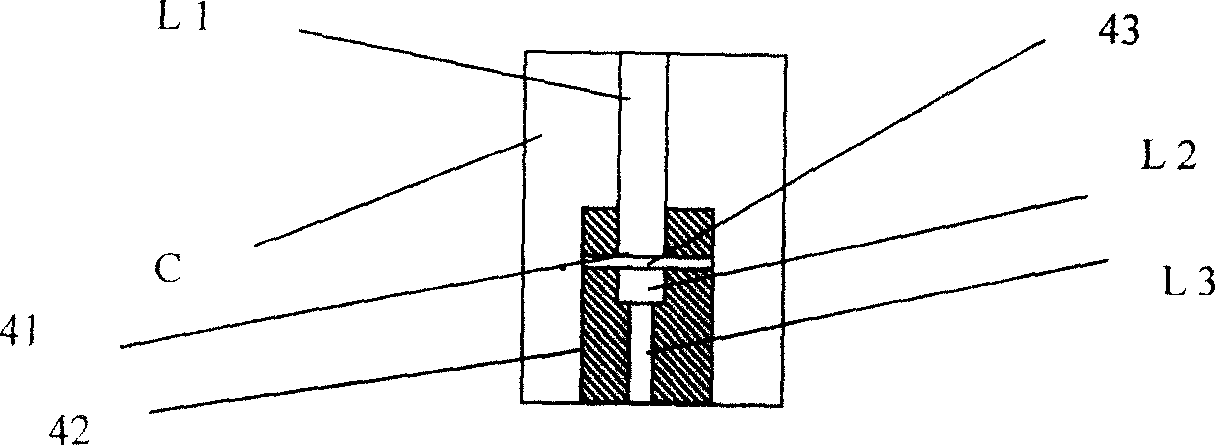

[0019] Such as figure 1 As shown, the spray head of the present invention is composed of upper assembly A, middle assembly B, and lower assembly C as a whole. Such as figure 1 As shown, the upper component A is provided with a core liquid hole 33 and a liquid material hole 34; the middle component B is provided with a liquid material hole 34 and a socket hole 35, and the socket 31 of the insertion tube is embedded in the socket hole 35. The top of the intermediate assembly B is provided with a core liquid tank 37; the lower assembly C is provided with a spinneret hole 36, and a cylinder 42 is arranged in the spinneret hole 36, and the middle of the cylinder 42 is perforated for the insertion tube 32 to pass through. A liquid material tank 38 is arranged on the top.

[0020] More specifically, the insertion tube may be a needle for injection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com