Combined type roving frame

A roving frame and combined technology, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc., can solve the problem of out-of-synchronization of head and tail torsion in long-axis transmission, non-corresponding doffing time, color spinning and so on. Yarn incompatibility and other problems can be solved, so as to ensure the quality of spinning, improve production efficiency, and increase the output of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

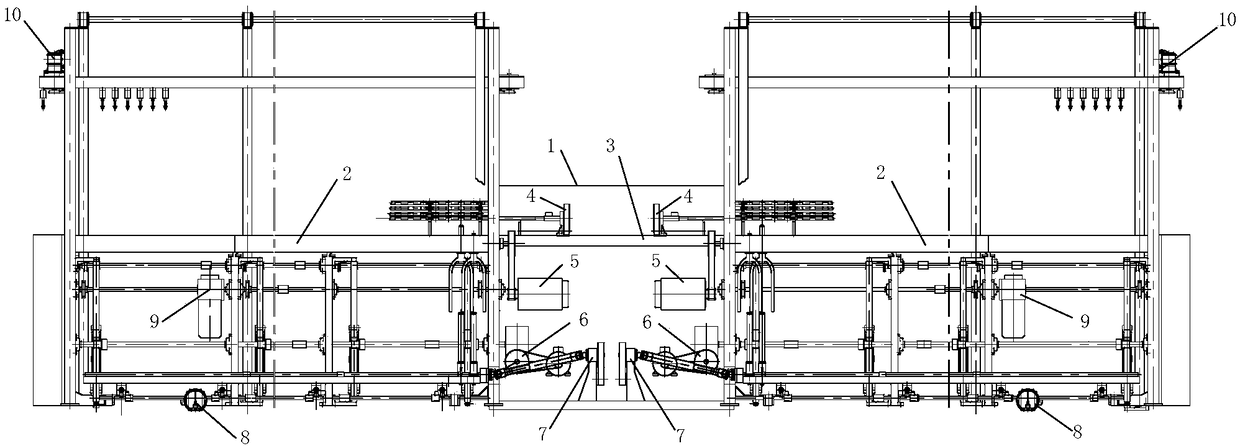

[0044] combine figure 1 , The combined roving frame includes a power output mechanism 1 and two sets of spinning mechanisms 2, and the two ends of the power output mechanism 1 are respectively connected with the spinning mechanism 2 as a whole.

[0045] The power output mechanism 1 has two sets of power output units, a set of spinning mechanism 2 is adapted to a set of power output units, and the power output unit independently provides power for a set of spinning mechanisms, and the two power output units are independent of each other. do not affect each other.

[0046] A set of air suction and dust collection devices are arranged on the two sets of spinning mechanisms.

[0047] The power output mechanism also includes a support frame 3, and the two ends of the support frame 3 are respectively integrated with the spinning mechanism.

[0048] Two sets of power output units are symmetrically placed on the support frame, and the power output units include a drafting transmissi...

Embodiment 2

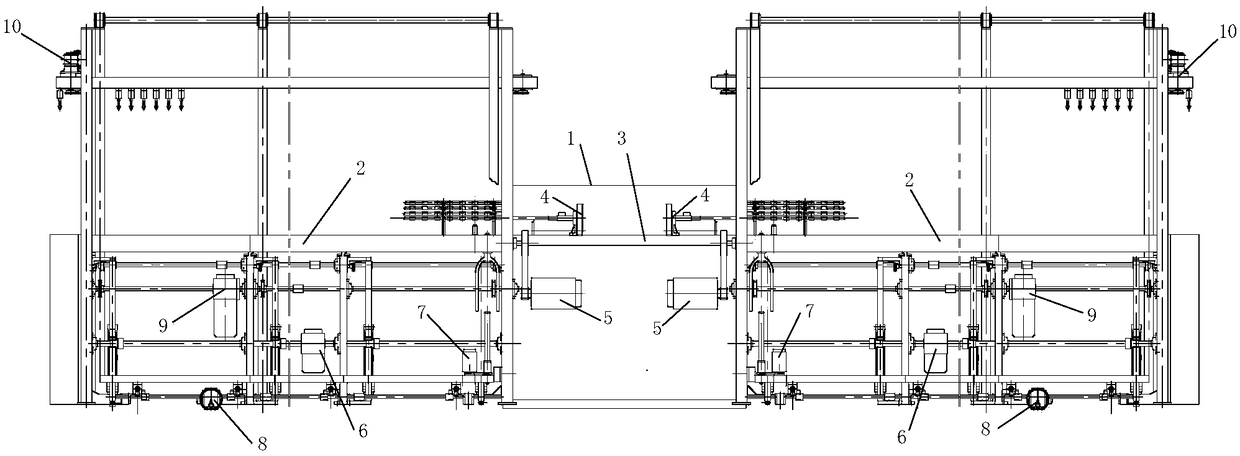

[0073] combine figure 2 , The combined roving frame includes a power output mechanism 1 and two sets of spinning mechanisms 2, and the two ends of the power output mechanism 1 are respectively connected with the spinning mechanism 2 as a whole.

[0074] The power output mechanism 1 has two sets of power output units, a set of spinning mechanism 2 is adapted to a set of power output units, and the power output unit independently provides power for a set of spinning mechanisms, and the two power output units are independent of each other. do not affect each other.

[0075] A set of air suction and dust collection devices are arranged on the two sets of spinning mechanisms.

[0076] The power output mechanism also includes a support frame 3, and the two ends of the support frame 3 are respectively integrated with the spinning mechanism.

[0077] Two sets of power output units are symmetrically placed on the support frame, and the power output units include a drafting transmiss...

Embodiment 3

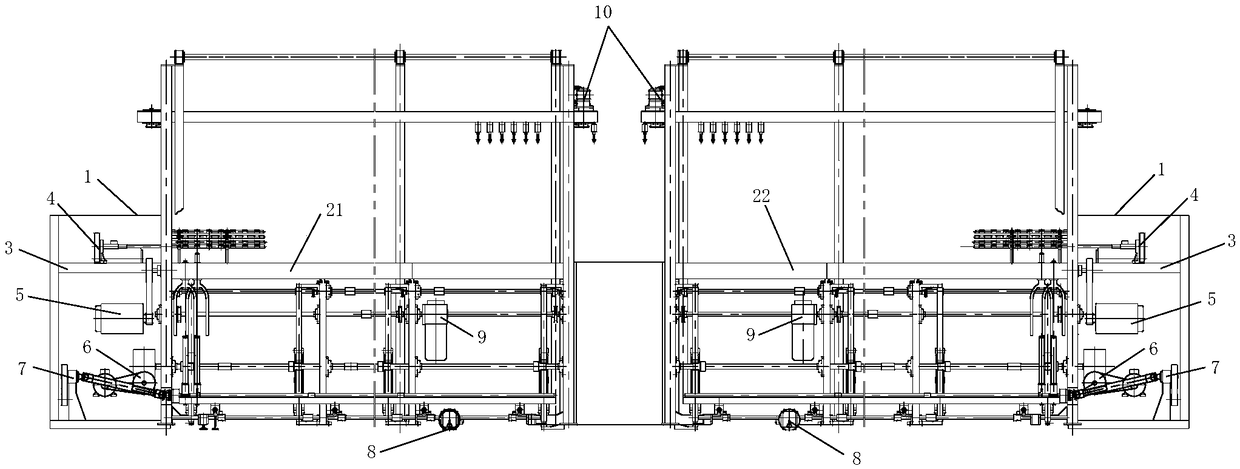

[0096] combine image 3 , a combined roving frame, including two sets of power output mechanisms 1 and two sets of spinning mechanisms 2, the two sets of spinning mechanisms are divided into a first spinning mechanism 21 and a second spinning mechanism 22, the right end of the first spinning mechanism 21 It is integrated with the left end of the second spinning mechanism 22, the left end of the first spinning mechanism is connected with a set of power output mechanism, and the right end of the second spinning mechanism is connected with another set of power output mechanism.

[0097] The power output mechanism has a set of power output monomers, and a set of spinning mechanisms is adapted to a set of power output monomers. The power output unit independently provides power for a set of spinning mechanisms, and the two power output units are independent of each other and do not affect each other.

[0098] Both the first spinning mechanism and the second spinning mechanism are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com