Electrostatic spinning injection device with liquid preparation function

An electrospinning and injection device technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of long process, waste of manpower, and many processes, so as to reduce dripping, improve quality, and ensure Effect of spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

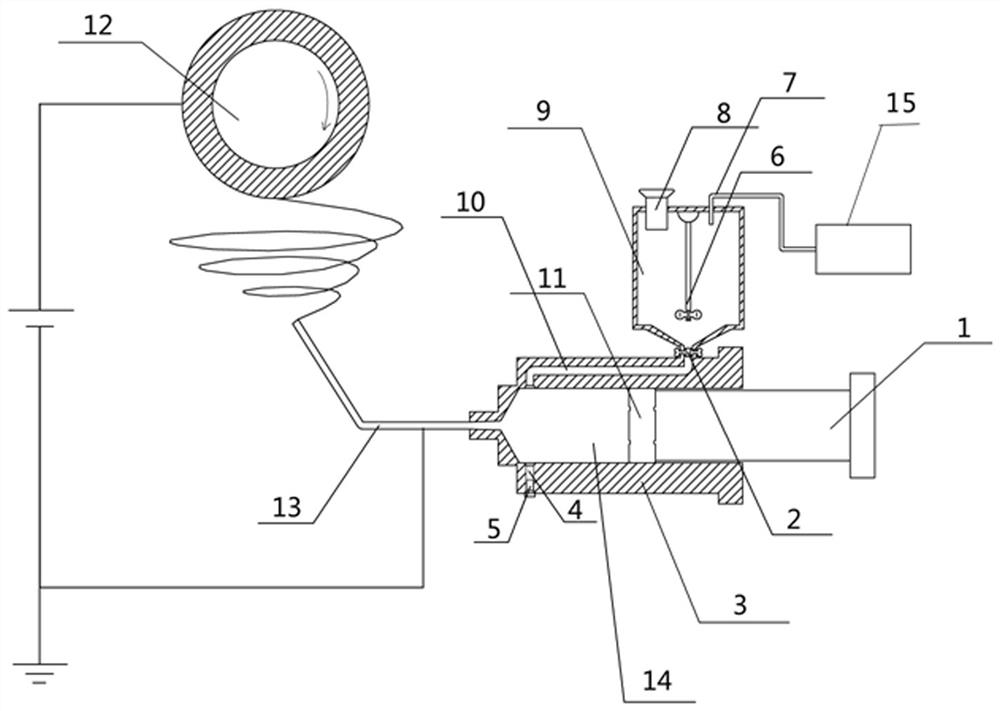

[0012] Such as figure 1 As shown, the present invention includes a syringe 3, an injection plunger 1, a needle 13, a liquid dispensing cylinder 9 and a vacuum pump 15. The end of the syringe 3 is provided with a needle 13, and the syringe 3 is provided with an injection plunger 1, and The end of the rod 1 is provided with a pipe plug 11, one end of the liquid dispensing cylinder 9 is connected with the vacuum pump 15, the other end is connected with the syringe cavity 14 through the catheter 10, and the outlet end of the liquid dispensing cylinder 9 is provided with a ball valve 2.

[0013] The dosing cylinder 9 can complete the configuration of the spinning solution. The spinning solution flows into the injection cylinder cavity 14 through the catheter 10 when the ball valve 2 is opened. The plug 11 is pushed by the injection plunger 1 to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com