A method for preparing porous hollow titanium dioxide nanotubes

A technology of titanium dioxide and nanotubes, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of uncertainty in the silk production process, difficulty in forming coaxial Taylor cones, and difficulty in industrial application, etc., to achieve Good application prospects, ensuring stability, and simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

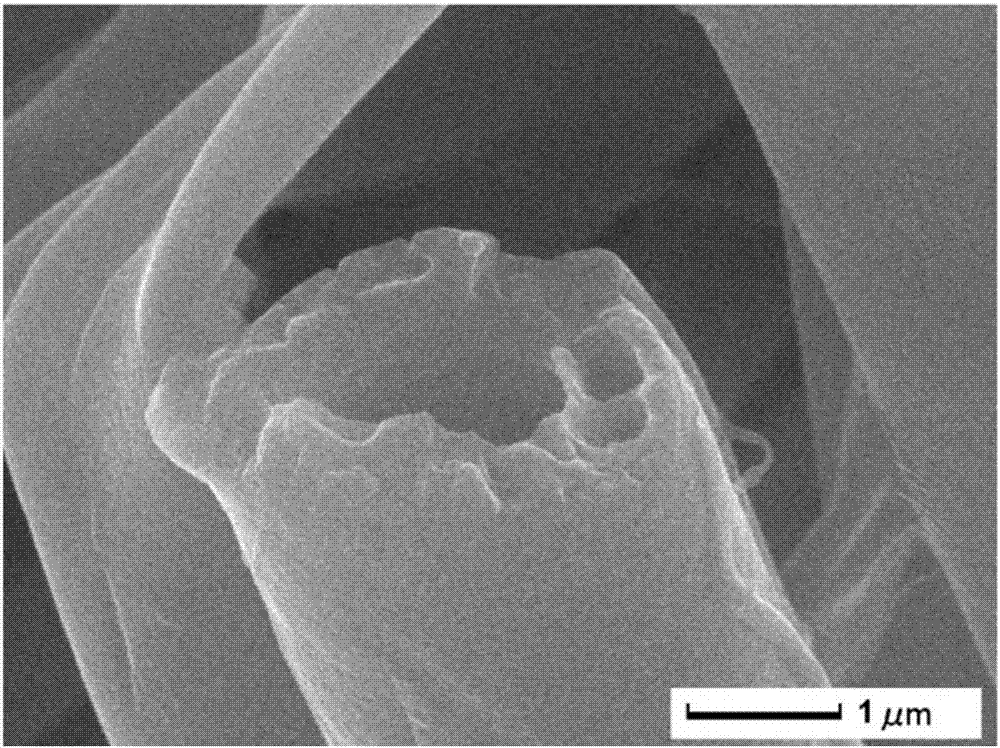

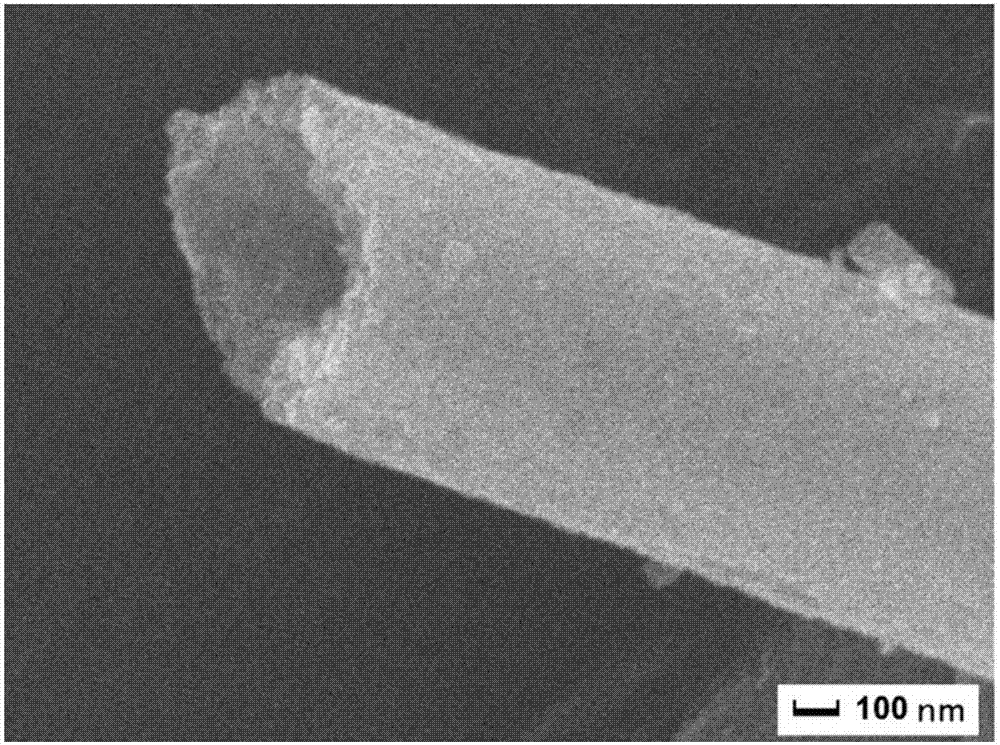

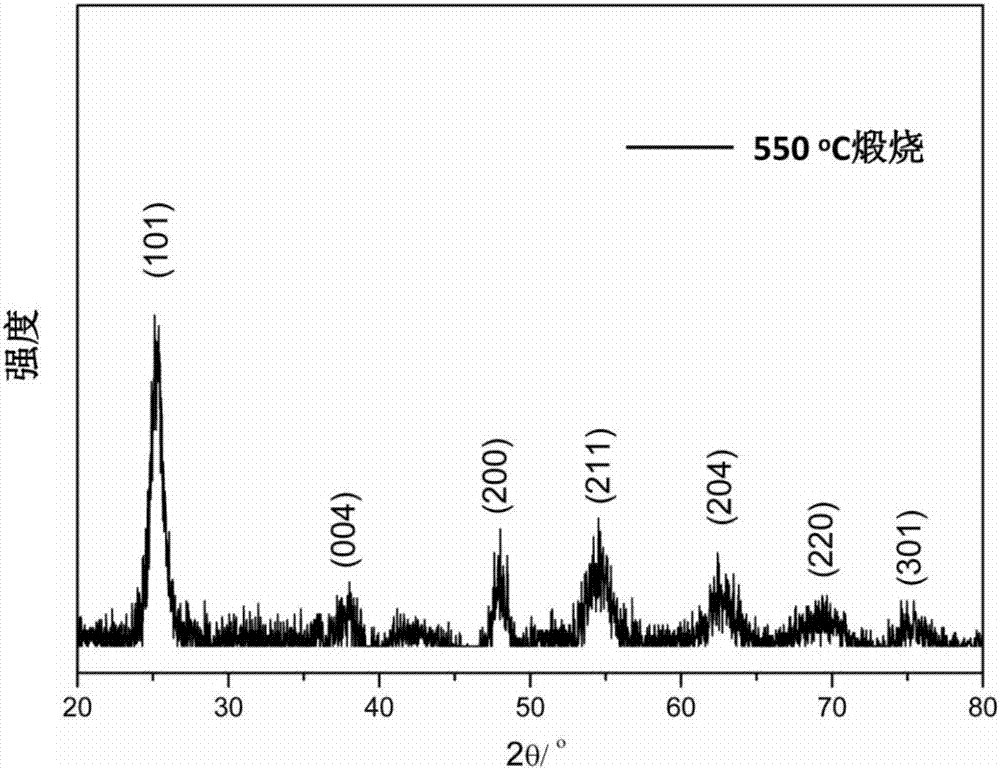

[0043] An embodiment of the method for preparing porous hollow titania nanotubes of the present invention comprises the following steps:

[0044] (1) Take 3g of polyvinylpyrrolidone (PVP) and 30ml of absolute ethanol and add them to a 100ml Erlenmeyer flask, stir magnetically until a uniform solution is obtained (wherein the mass fraction of polyvinylpyrrolidone is 11%), add 4ml Glacial acetic acid, magnetically stirred to obtain a uniform transparent solution, then added 4ml tetrabutyl titanate, magnetically stirred until a transparent and clear solution was obtained, then added 4ml sesame oil and 8ml n-hexane, magnetically stirred for 12 hours.

[0045] (2), use the spinning solution prepared in step (1) to carry out uniaxial electrospinning through a uniaxial electrospinning device to obtain nanofibers, and the spinning parameters are as follows: the feeding speed of the spinning solution is 0.8mL / h, and the voltage is 11kV, the receiving distance is 12cm, the outside tempe...

Embodiment 2

[0050] An embodiment of the method for preparing porous hollow titania nanotubes of the present invention comprises the following steps:

[0051] (1), get 2g polyvinyl alcohol and 30ml dehydrated alcohol and join in the Erlenmeyer flask of 100ml, stir magnetically until obtaining uniform solution (wherein, the mass fraction of polyvinyl alcohol is 8%), add 6ml glacial acetic acid, magnetically stir to obtain Uniform and transparent solution, then add 6ml tetrabutyl titanate, stir magnetically until a transparent and clear solution is obtained, then add 6ml sesame oil and 12ml n-hexane, stir magnetically for 12 hours.

[0052] (2), use the spinning solution prepared in step (1) to carry out uniaxial electrospinning through a uniaxial electrospinning device to obtain nanofibers, and the spinning parameters are as follows: the feeding speed of the spinning solution is 1.2mL / h, and the voltage is 7kV, the receiving distance is 12cm, the outside temperature is 30°C, and the humidit...

Embodiment 3

[0057] An embodiment of the method for preparing porous hollow titania nanotubes of the present invention comprises the following steps:

[0058] (1), take 2.5g polyvinylpyrrolidone and 30ml N,N-dimethylformamide and join in the conical flask of 100ml, stir magnetically until obtaining homogeneous solution (wherein, the mass fraction of polyvinylpyrrolidone is 8% ), add 6ml of glacial acetic acid, stir magnetically to obtain a uniform transparent solution, then add 6ml isopropyl titanate, stir magnetically until a transparent and clear solution is obtained, then add 6ml sesame oil and 10ml n-hexane, and stir magnetically for 12 hours.

[0059] (2), use the spinning solution prepared in step (1) to carry out uniaxial electrospinning through a uniaxial electrospinning device to obtain nanofibers, and the spinning parameters are as follows: the feeding speed of the spinning solution is 1.0mL / h, and the voltage is 9kV, the receiving distance is 12cm, the outside temperature is 31°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com