Patents

Literature

51results about "Titanium compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

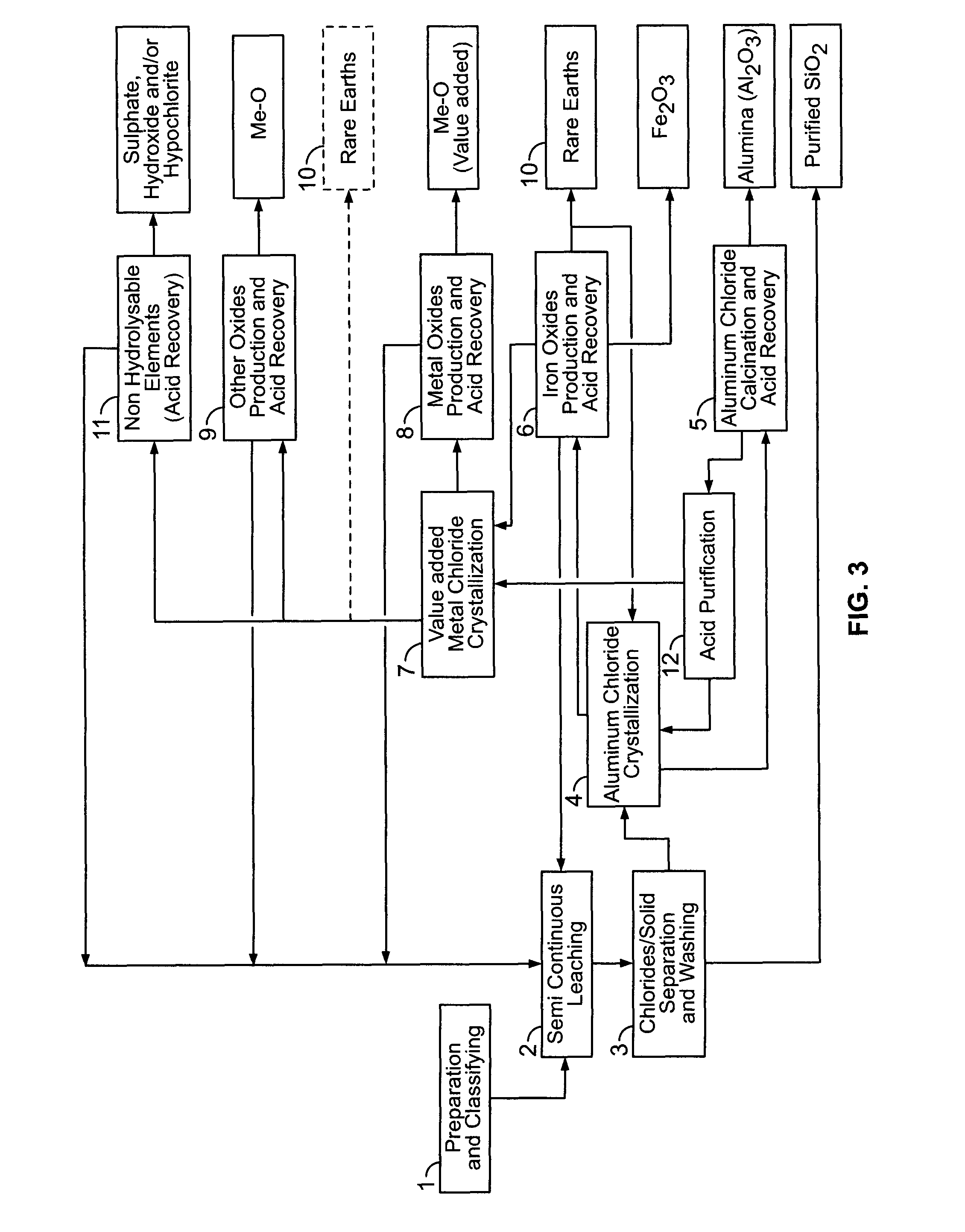

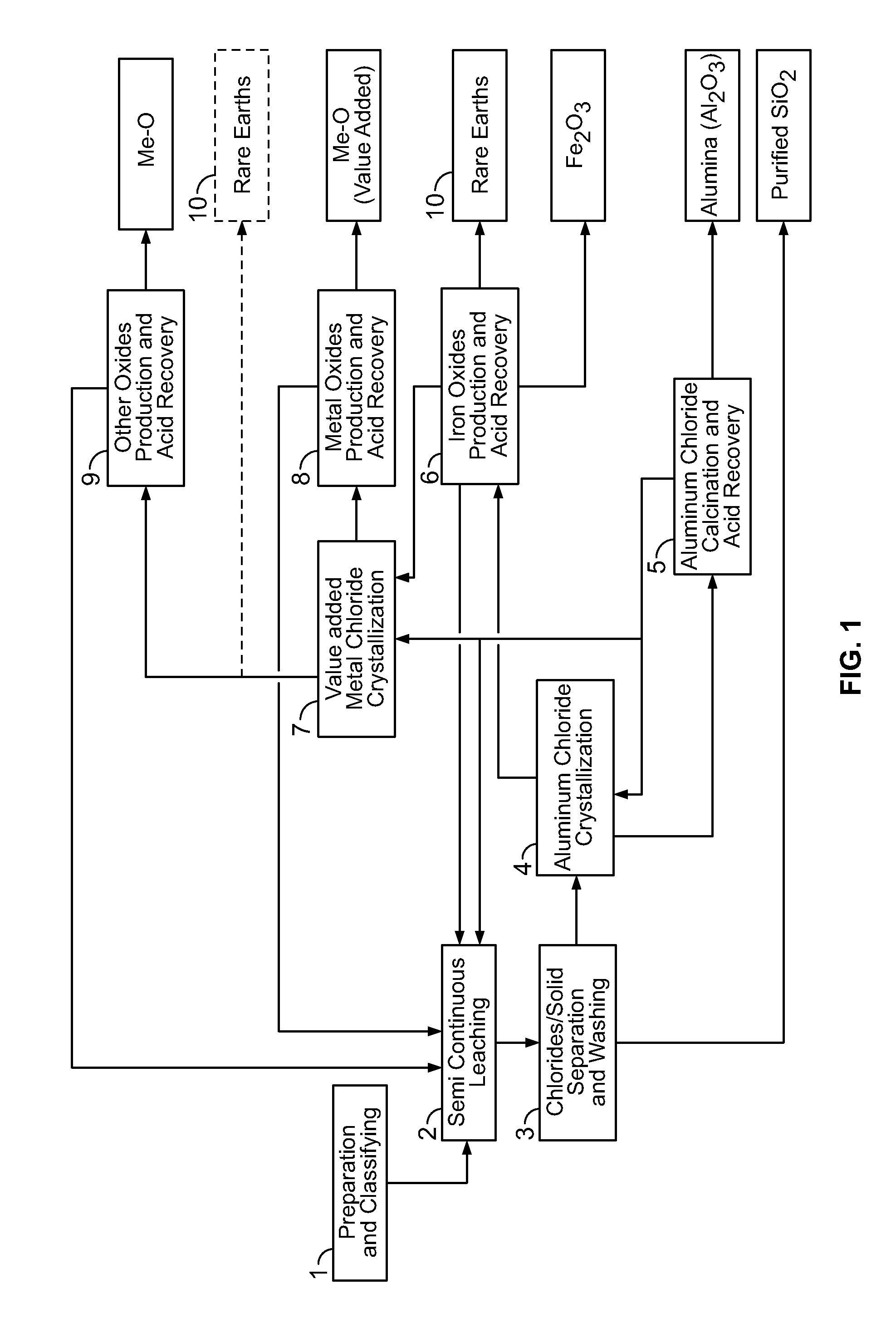

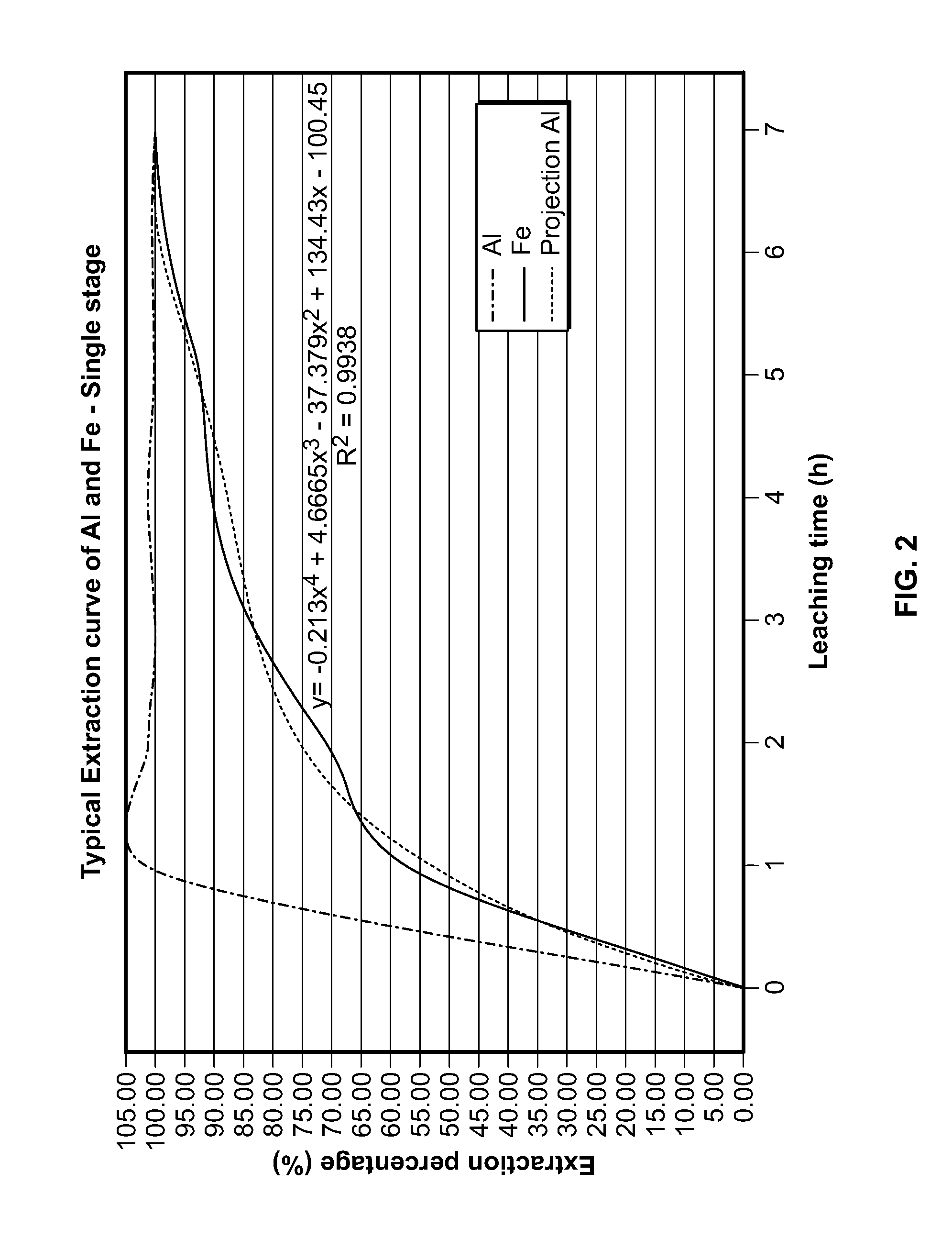

Processes for treating red mud

ActiveUS20140369907A1Simple and efficientLow costAluminium compoundsSolvent extractionPregnant leach solutionRare-earth element

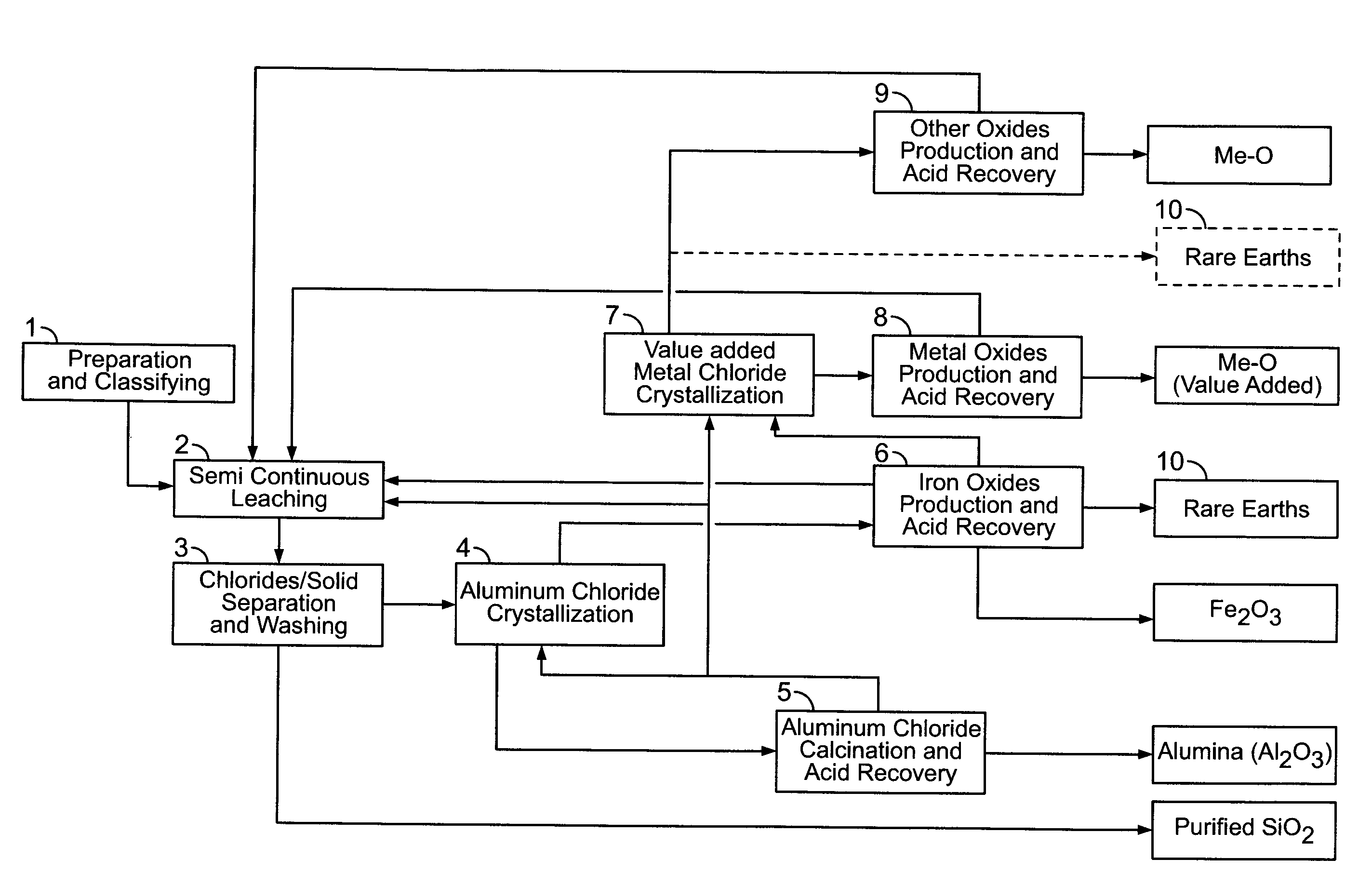

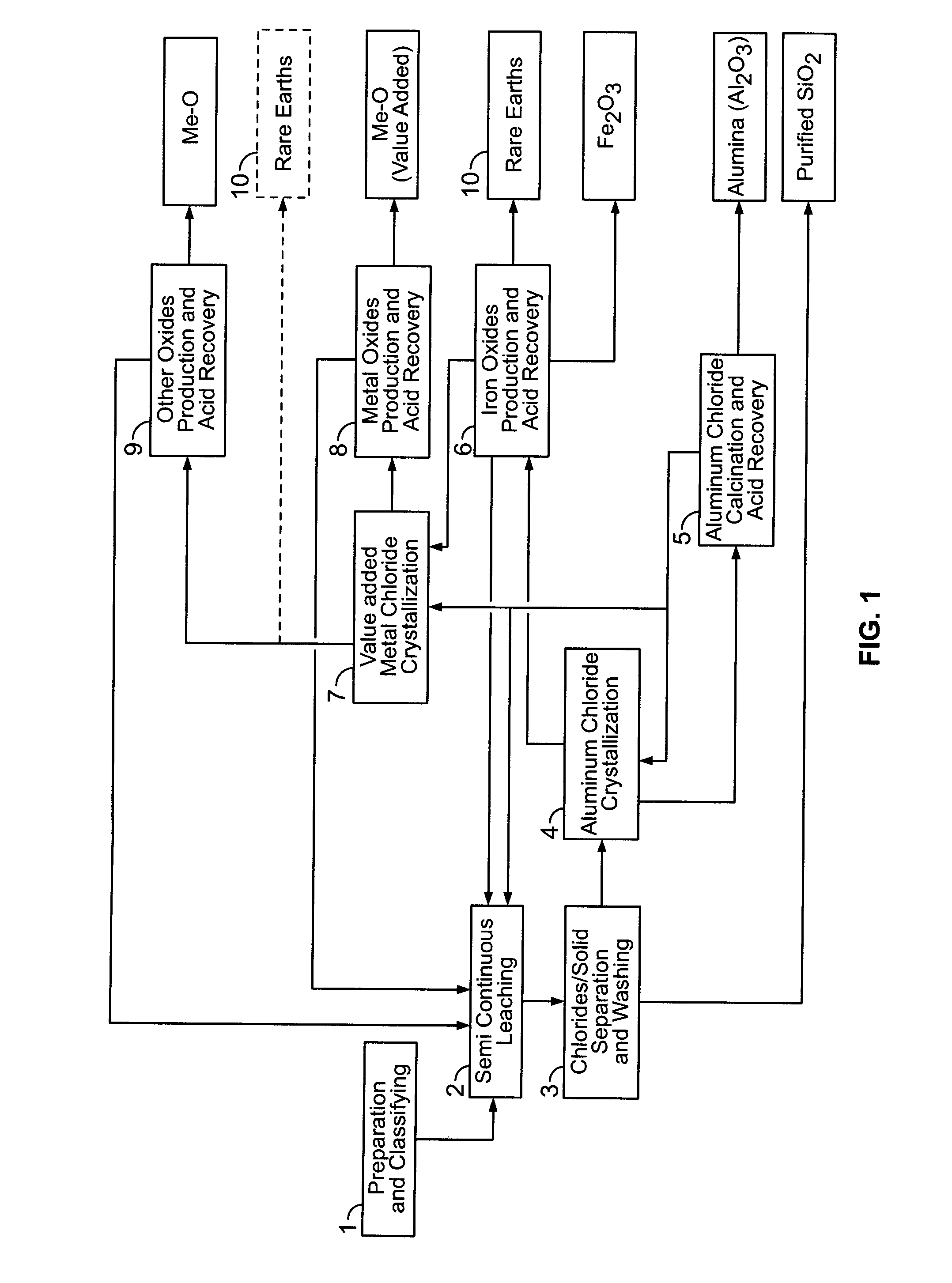

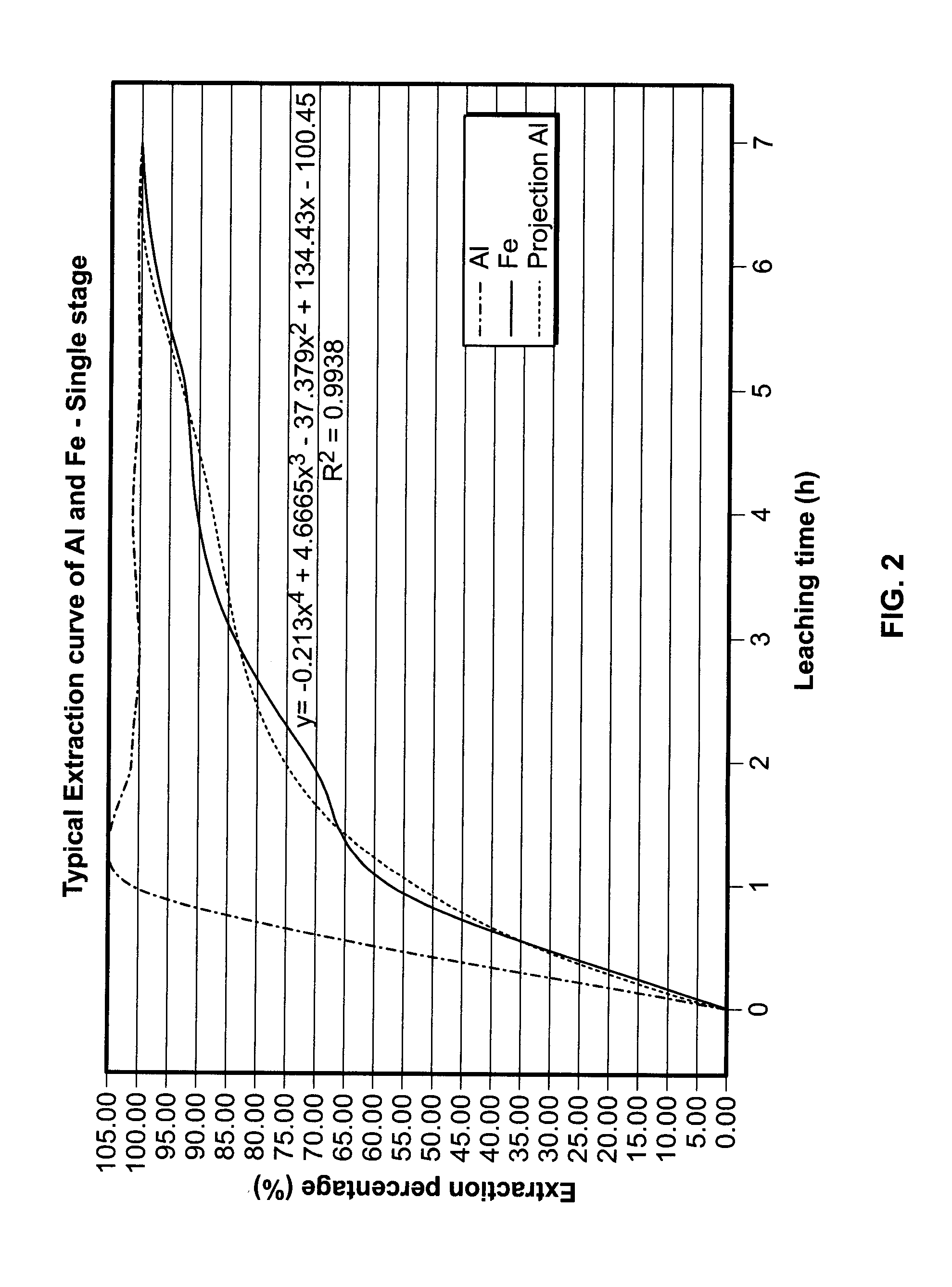

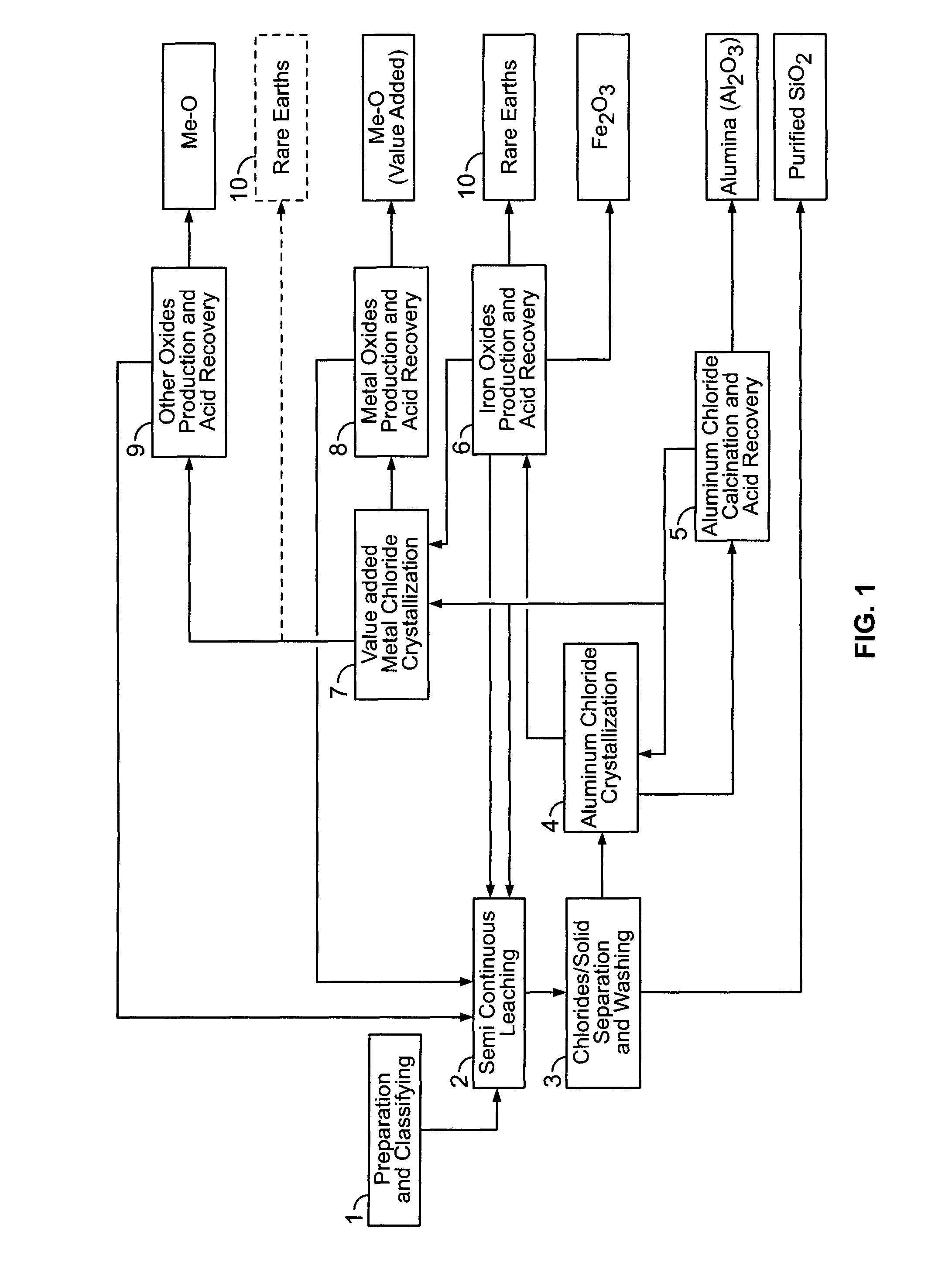

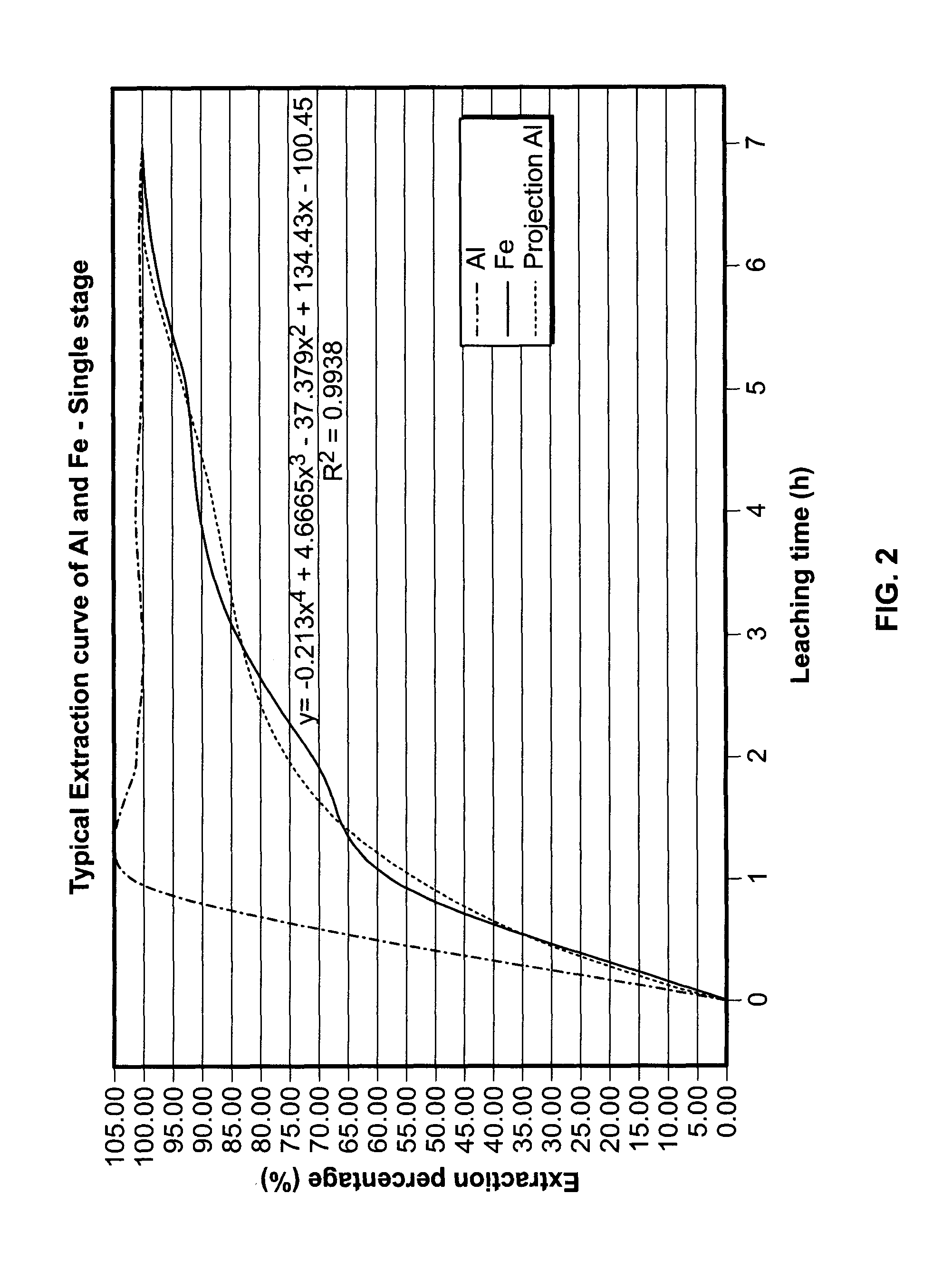

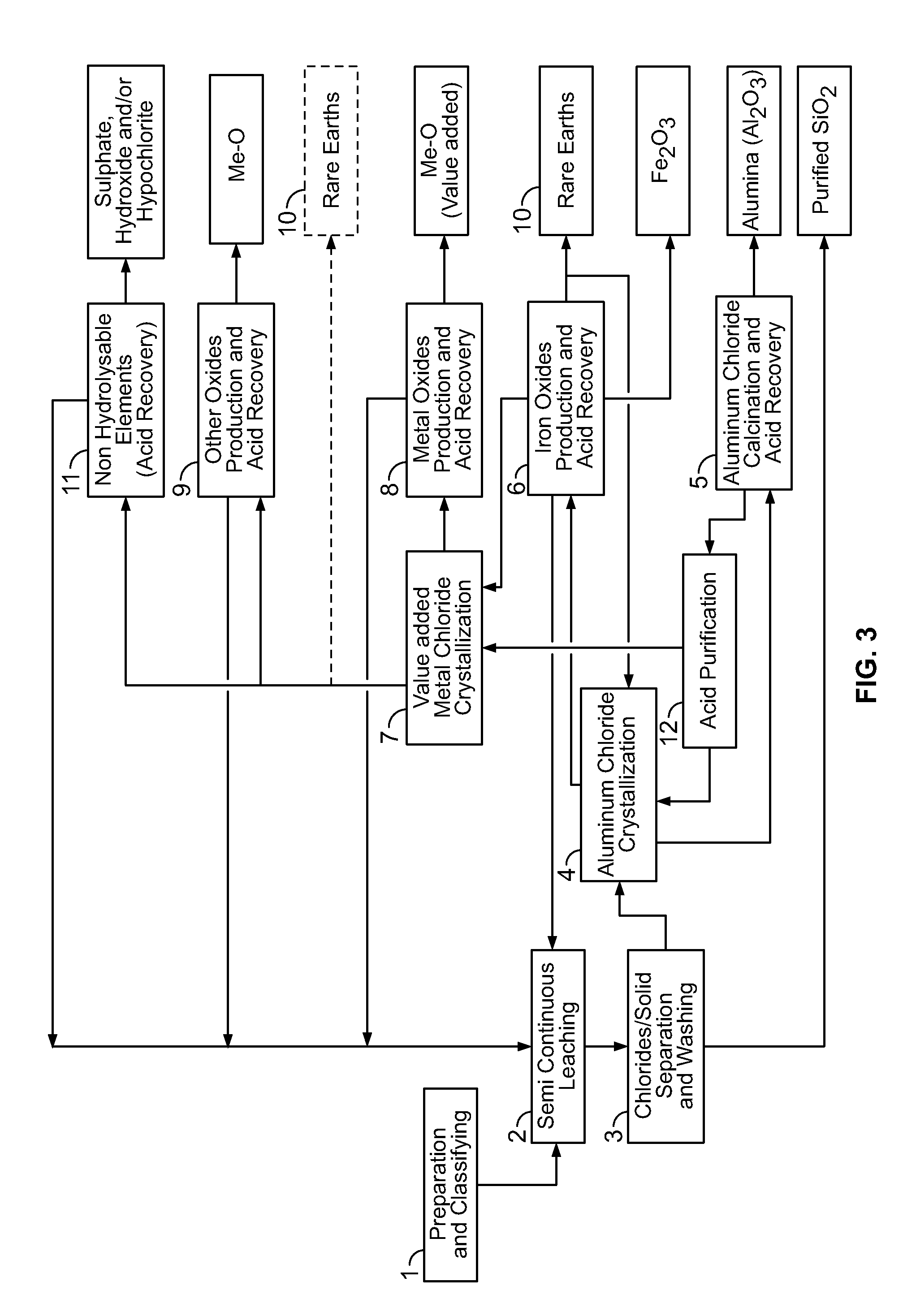

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

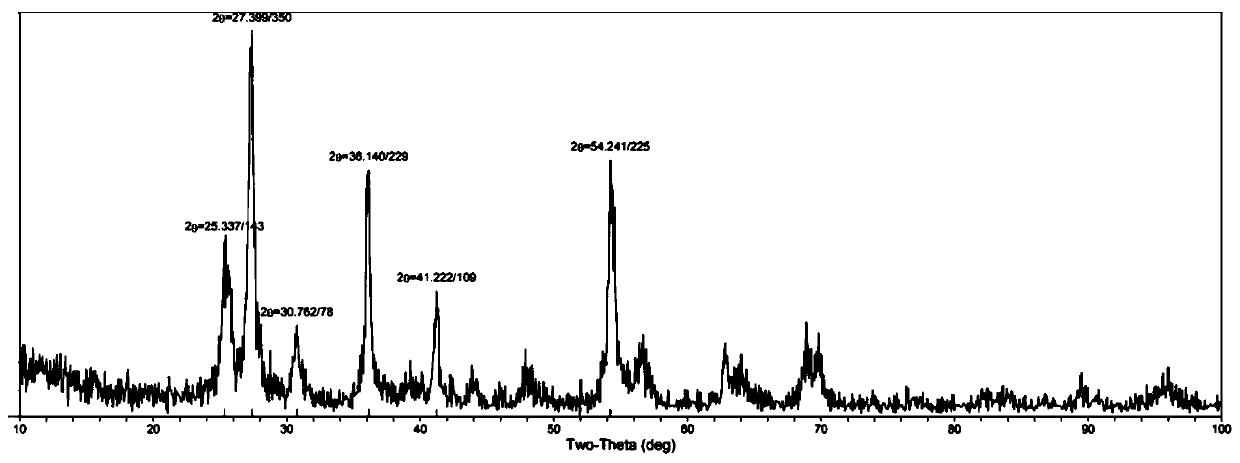

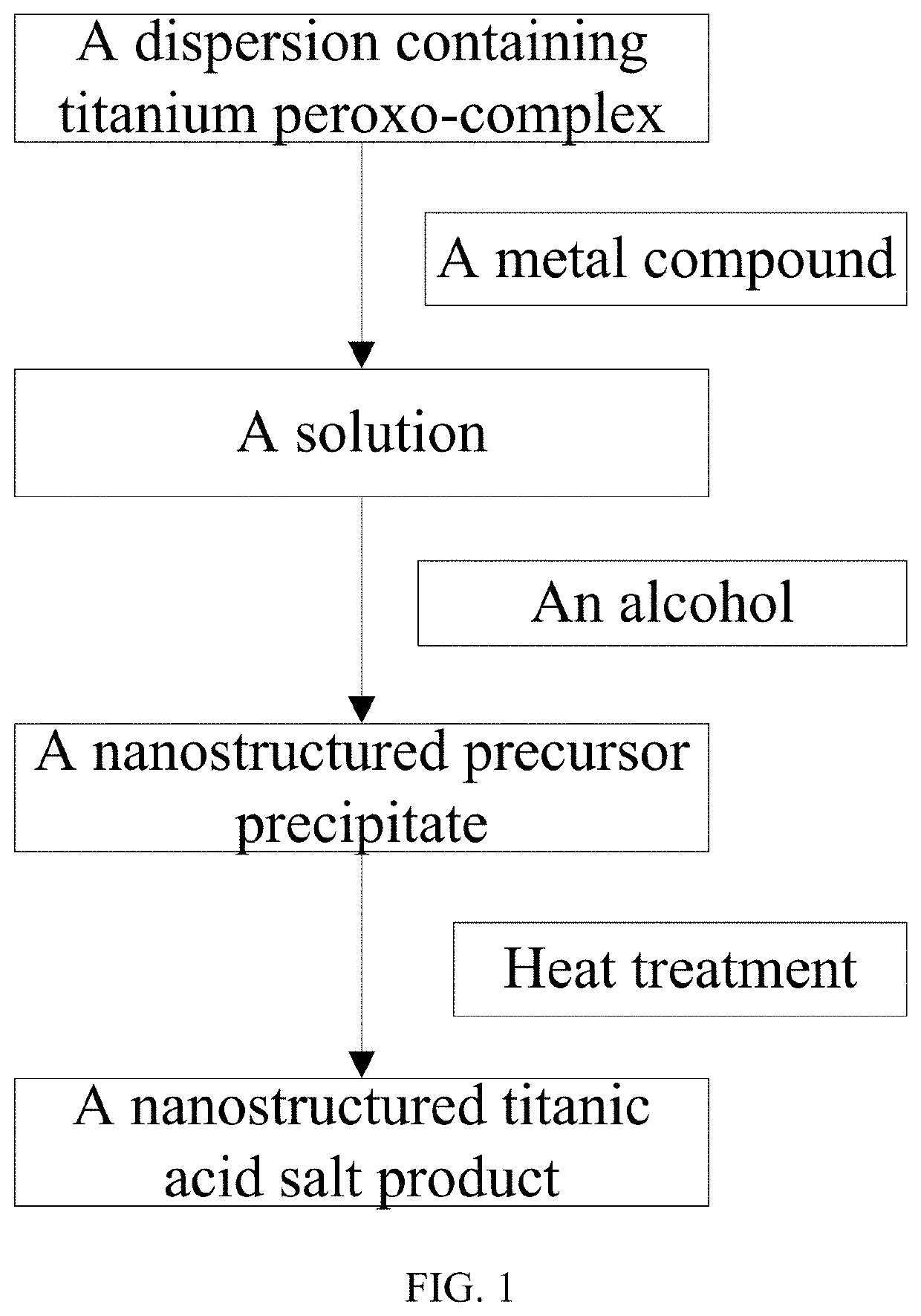

Titanate having a nanometer structure and preparing method and application thereof

ActiveCN109019675ASimple preparation processEase of large-scale industrial productionMaterial nanotechnologyAlkaline earth titanatesAlcoholTitanium

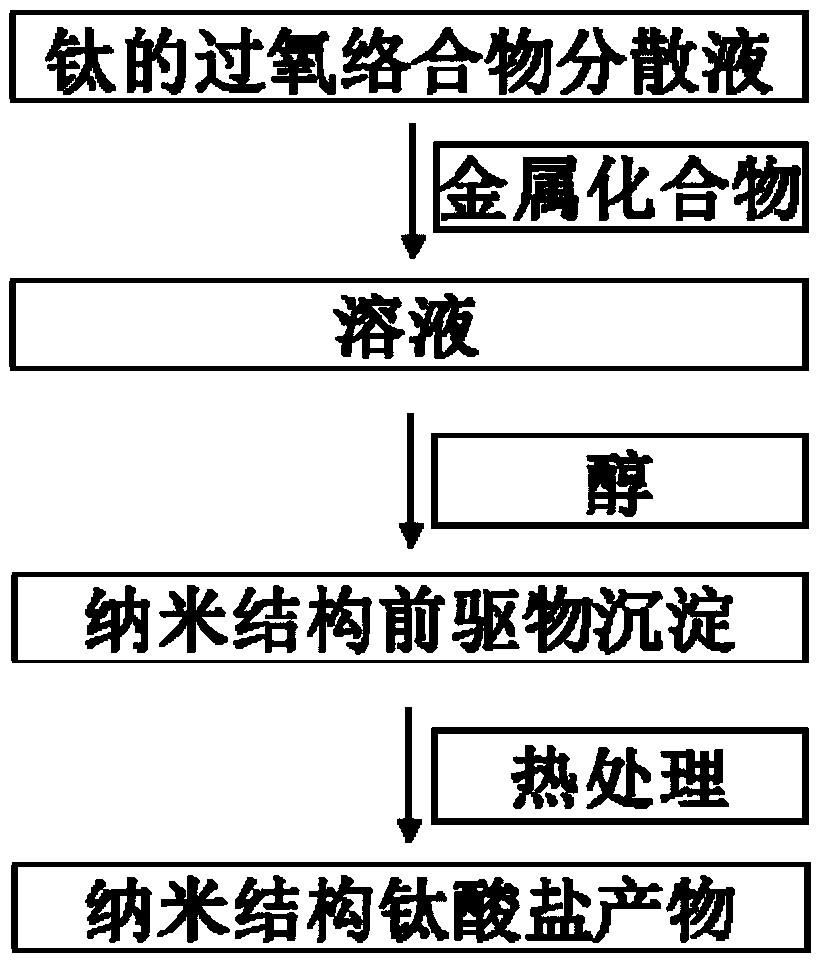

A titanate having a nanometer structure and a preparing method and application thereof are provided. The method include S1) preparing a dispersion containing a titanium peroxy complex; S2) slowly adding a metal compound into the dispersion to form a solution; S3) adding an alcohol into the solution at room temperature and under atmospheric pressure to promote generation of a titanate precursor precipitate having a nanometer structure, and performing separation to obtain the precursor; and S4) drying the precursor, and performing thermal treatment to obtain the titanate product having a nanometer structure. The titanate preparing method having a simple process and easily controllable process parameters and susceptible to large-scale industrial production is provided.

Owner:PETROCHINA CO LTD

Processes for treating red mud

ActiveUS9023301B2Simple and efficientLow costAluminium compoundsNickel compounds preparationRare-earth elementRed mud

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

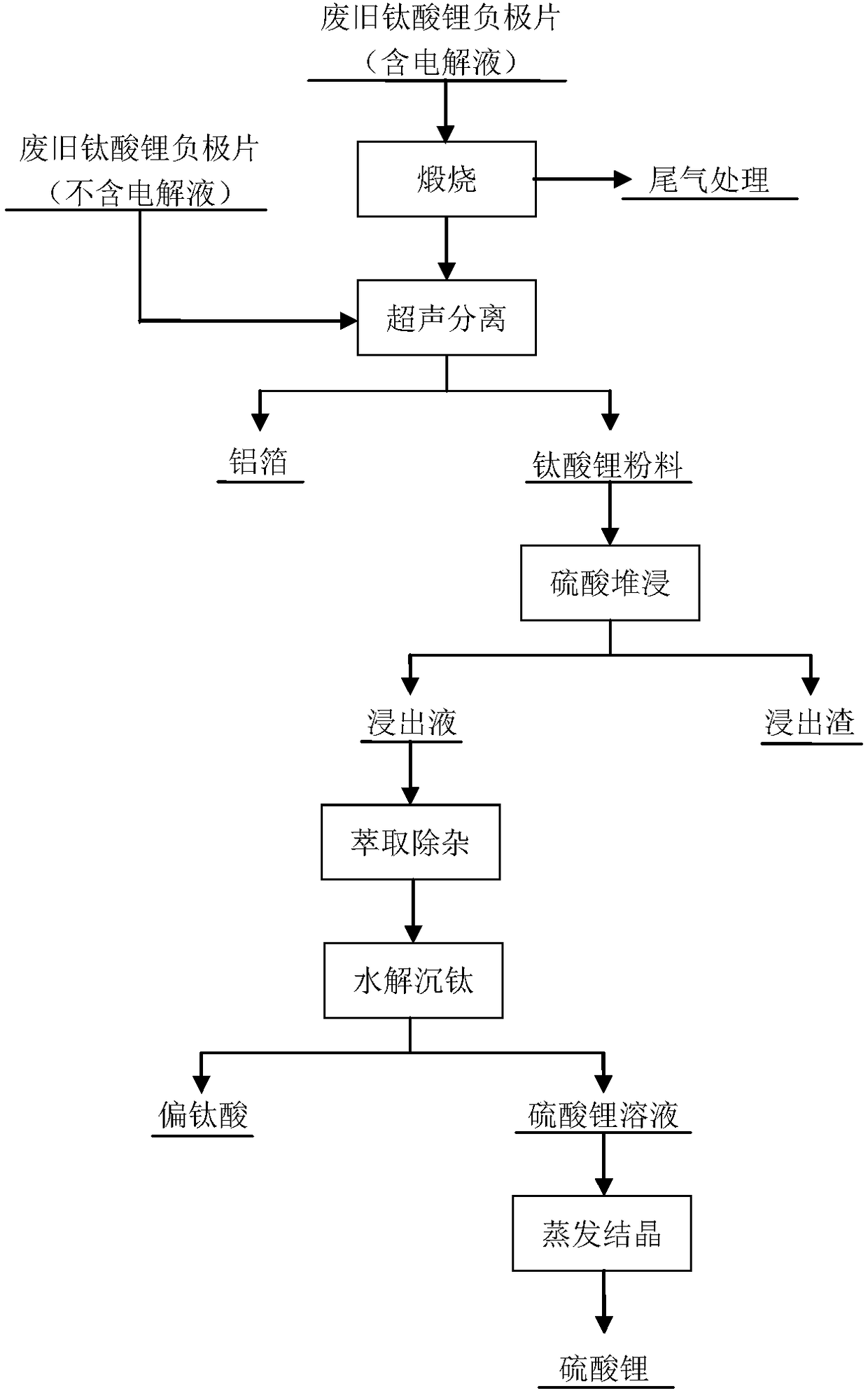

Method for recovering waste lithium titanate negative electrode sheet

InactiveCN108190922AEfficient separationAvoid the impact of subsequent processesWaste accumulators reclaimingTitanium compounds preparationRecovery methodShielding gas

The invention discloses a method for recovering a waste lithium titanate negative electrode sheet. The method comprises the following steps: under a protection gas, calcining a waste lithium titanatenegative electrode sheet containing an electrolyte to obtain a lithium titanate negative electrode sheet; carrying out ultrasonic vibration on the lithium titanate negative electrode sheet or a wastelithium titanate negative electrode sheet which does not contain an electrolyte to enable lithium titanate powder to fall off from aluminum foil; adding concentrated sulfuric acid into the lithium titanate powder, carrying out stirring, and carrying out sealing and standing, adding water, then carrying out heating and stirring, and carrying out filtering to obtain a leachate; adjusting the pH value of the leachate and then carrying out multi-stage extraction to obtain a water phase containing titanium and lithium ions; concentrating the water phase containing the titanium and the lithium ions,and carrying out precipitation after hydrolysis to obtain metatitanic acid and a lithium sulfate solution; and carrying out evaporating crystallization on the lithium sulfate solution to obtain lithium sulfate. The method for recovering the waste lithium titanate negative electrode sheet provided by the invention can be used to separate and purify metals of aluminum, titanium, lithium and the like in the waste lithium titanate negative electrode sheet, has short process, high efficiency, excellent separation, simple operation, greenness and environmental friendliness, and has strong social values and considerable economic benefits.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Processes for treating red mud

ActiveUS20150275330A1Simple and efficientLow costAluminium compoundsNickel compounds preparationPregnant leach solutionRare-earth element

Owner:AEM TECH INC

Recovery method of waste SCR denitration catalyst

ActiveCN110817944AGood removal effectImprove permeabilityAlkaline earth titanatesTungsten compounds preparationPtru catalystTungstate

The invention belongs to the field of non-ferrous metal recovery, and particularly relates to a recovery method of a waste SCR denitration catalyst. The recovery method comprises the steps of pretreatment, TiO2 separation, extraction and purification, titanium recovery, vanadium recovery, tungsten / molybdenum recovery and the like. The recovery method is capable of recycling a several precious recovery products such as V2O5, ammonium tungstate / ammonium molybdate and BaTiO3 from the waste SCR denitration catalyst. The invention provides an effective technical scheme, and efficient resource utilization of the waste SCR denitration catalyst can be realized.

Owner:北京华电光大环境股份有限公司

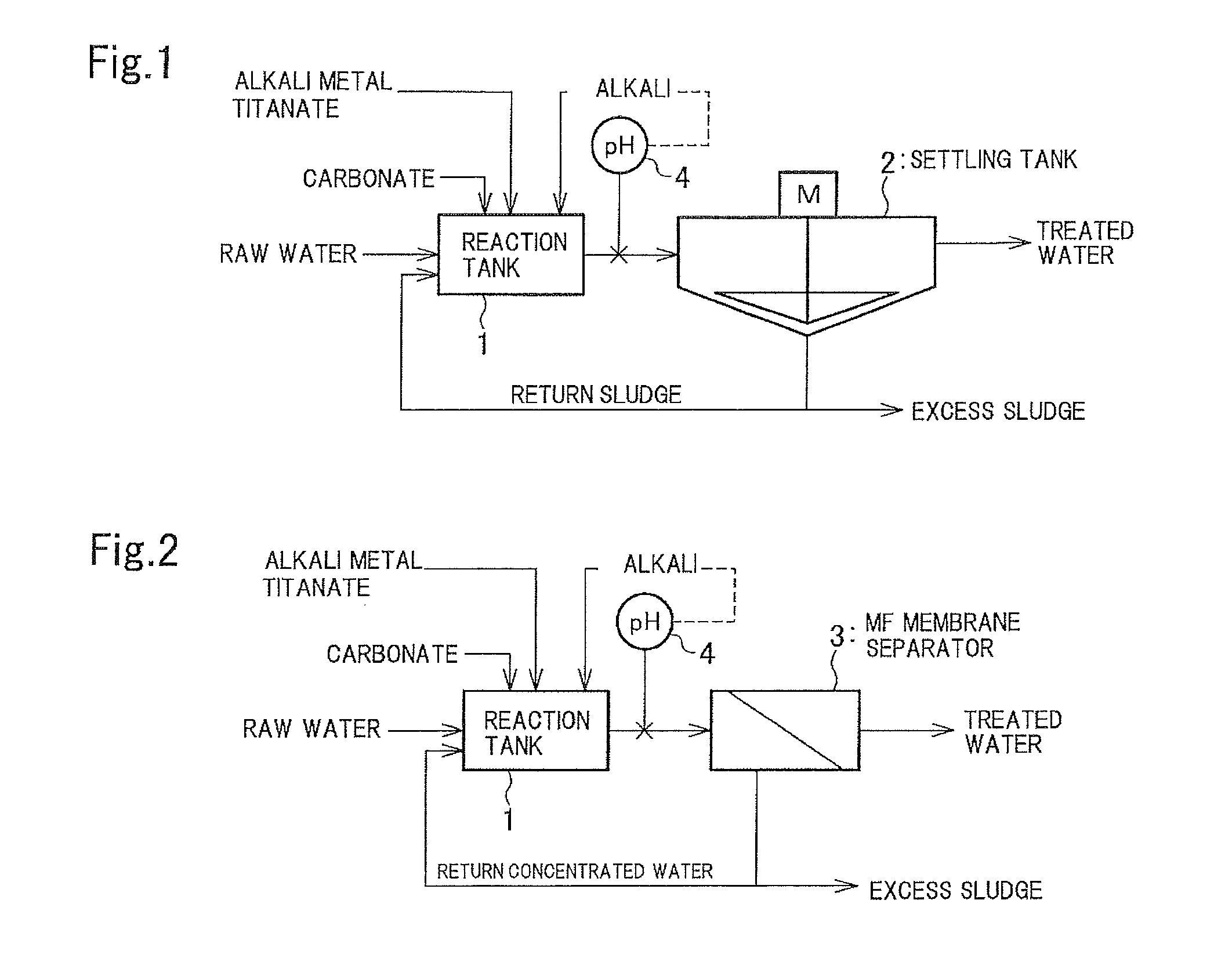

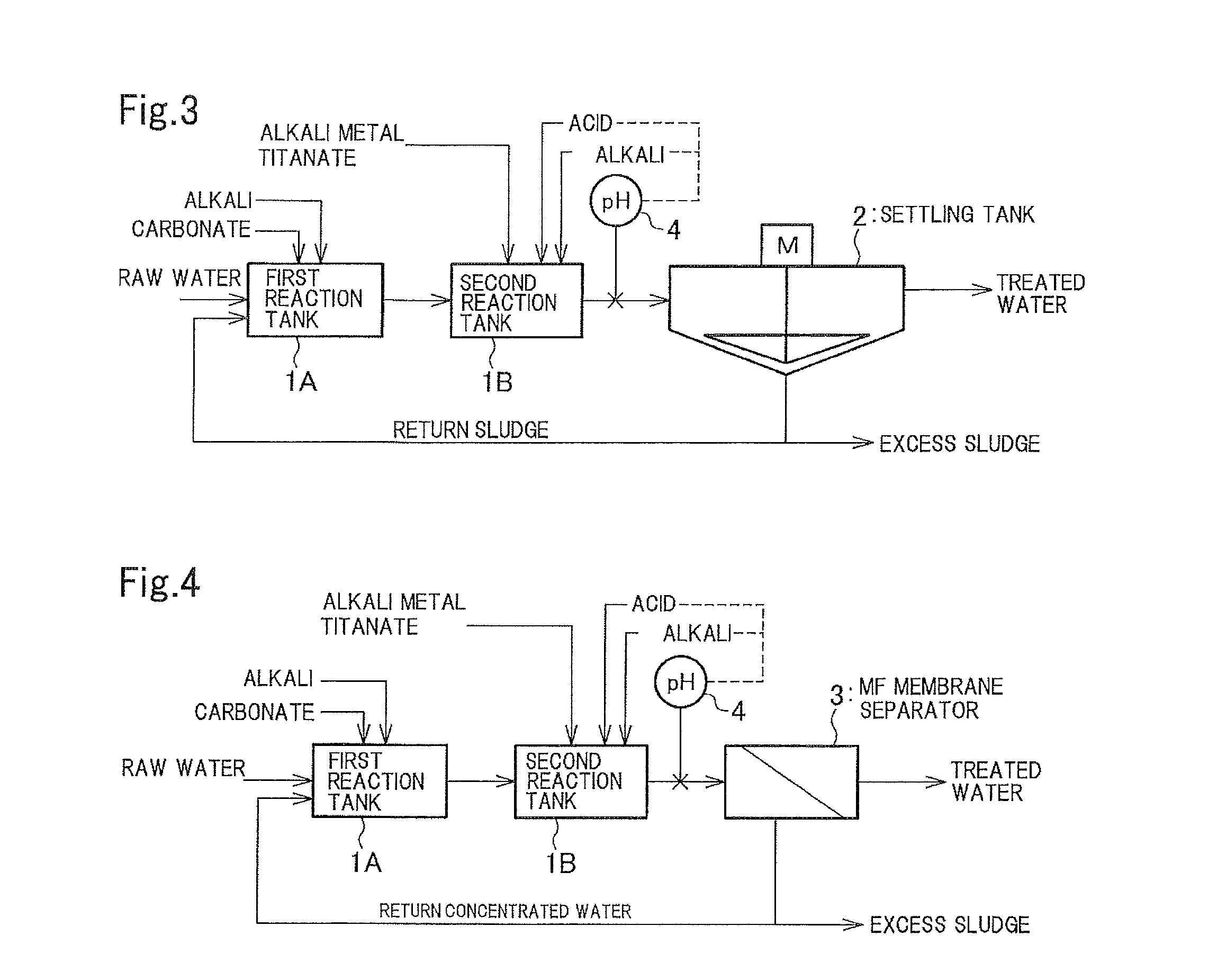

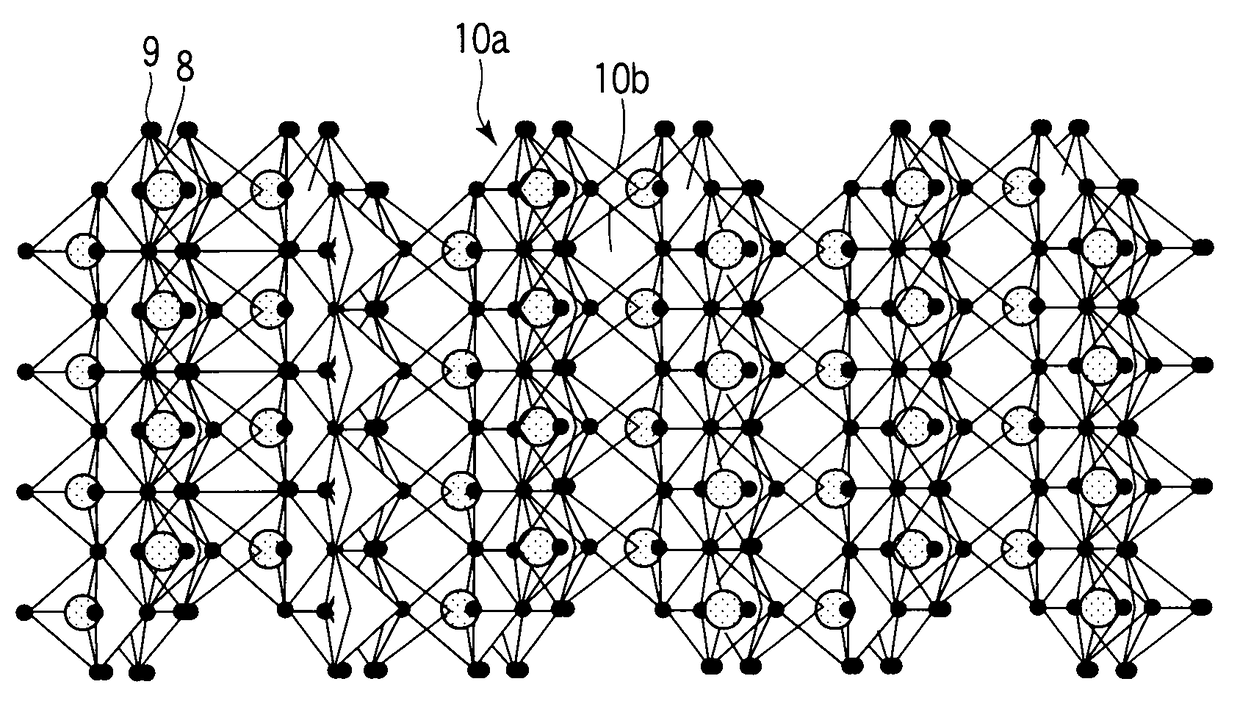

Method and apparatus for treating wastewater containing radioactive strontium

InactiveUS20150136704A1Reduce radiation doseEfficient removalAlkali titanatesSeawater treatmentStrontiumTreated water

Radioactive strontium is efficiently removed from wastewater containing radioactive strontium. In a treatment method for radioactive strontium-containing wastewater, wastewater containing radioactive strontium and a powdery alkali metal titanate are mixed in a stirrer-equipped reaction tank by stirring such that radioactive strontium in the wastewater is adsorbed on the powdery alkali metal titanate, followed by subjecting the powdery alkali metal titanate having radioactive strontium adsorbed thereon to solid-liquid separation. The radiation dose of treated water can be effectively reduced in such a manner that a powder of an alkali metal titanate is directly added to radioactive strontium-containing wastewater and is dispersed therein and therefore radioactive strontium is efficiently removed by adsorption.

Owner:KURITA WATER INDUSTRIES LTD +1

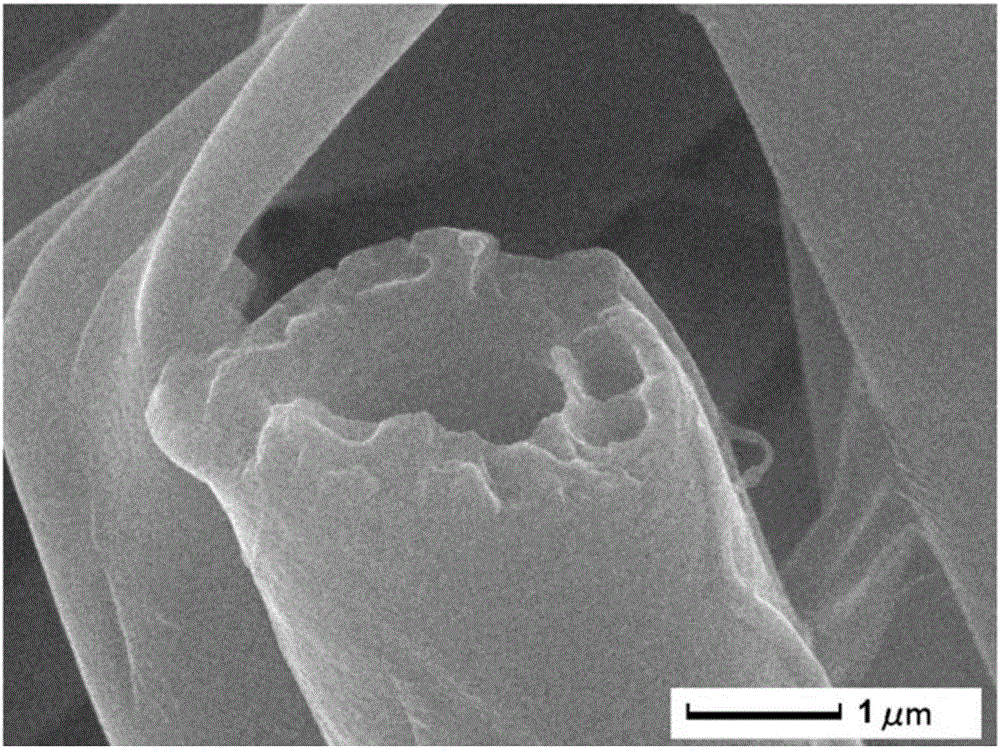

Method for preparing porous hollow titanium dioxide nanotubes

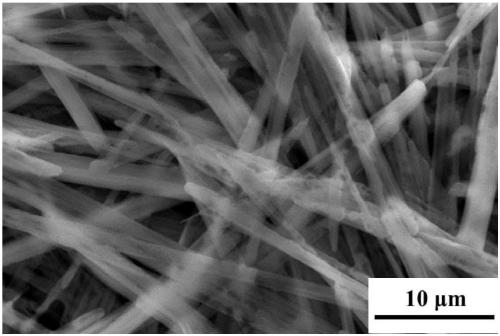

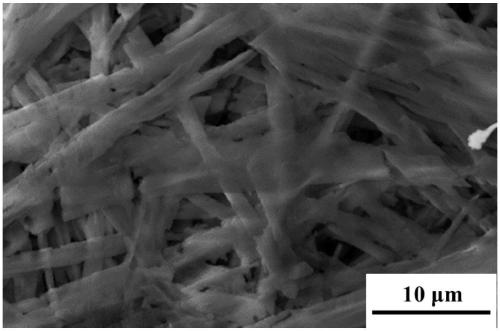

ActiveCN106186058ALarge specific surface areaReduce sensitivityElectro-spinningNanotechnologyFiberElectrospinning

The invention discloses a method for preparing porous hollow titanium dioxide nanotubes. The method comprises the steps of 1, dissolving a polymer spinning carrier, an anti-hydrolysis agent, disperse phase, a disperse phase cosolvent and a titanium dioxide precursor in a solvent while stirring to form a spinning solution; 2, conducting electrostatic spinning on the spinning solution obtained in step 1 through an electrostatic spinning device to obtain nanofiber; 3, aging the nanofiber obtained in step 2, and then conducting extraction to obtain hollow nanofiber; 4, calcinating the hollow nanofiber obtained in step 3 to obtain the porous hollow titanium dioxide nanotubes. The method is easy to operate, sensitivity to external conditions during spinning is reduced, silk production is stable, needle blocking does not occur easily, large-scale production can be achieved easily, and the porous hollow titanium dioxide nanotubes prepared with the method have a pure phase and a high specific surface area.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

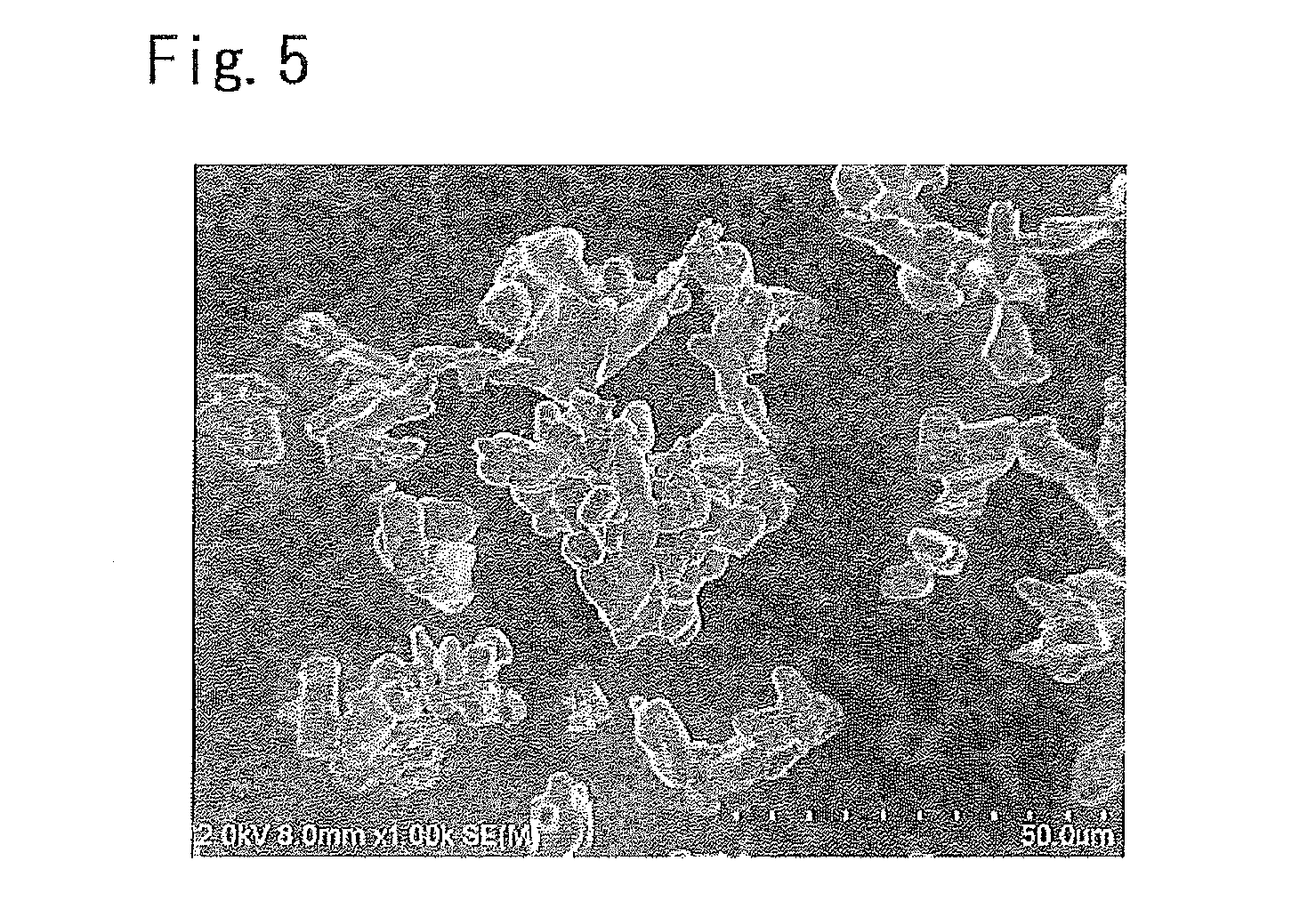

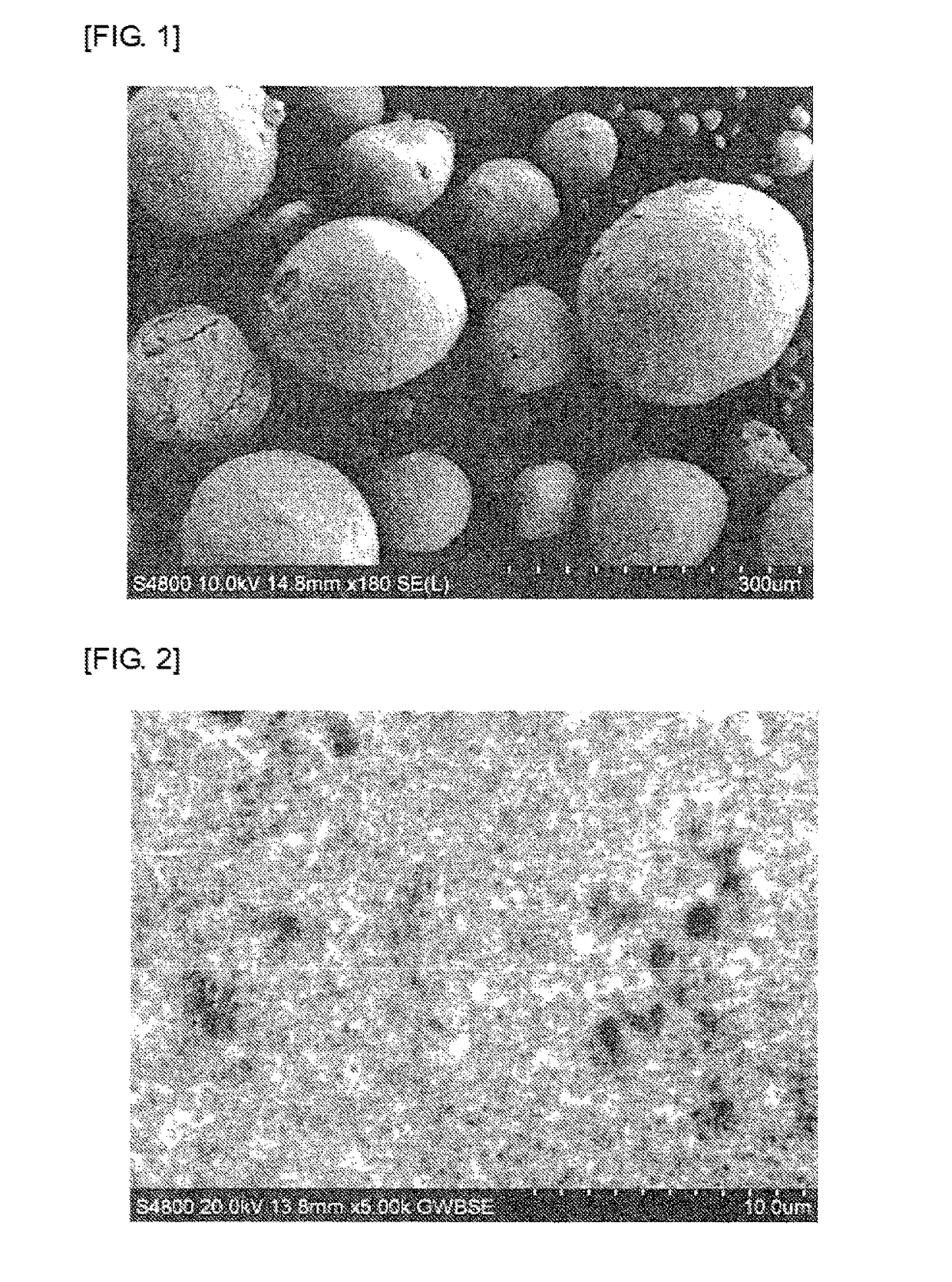

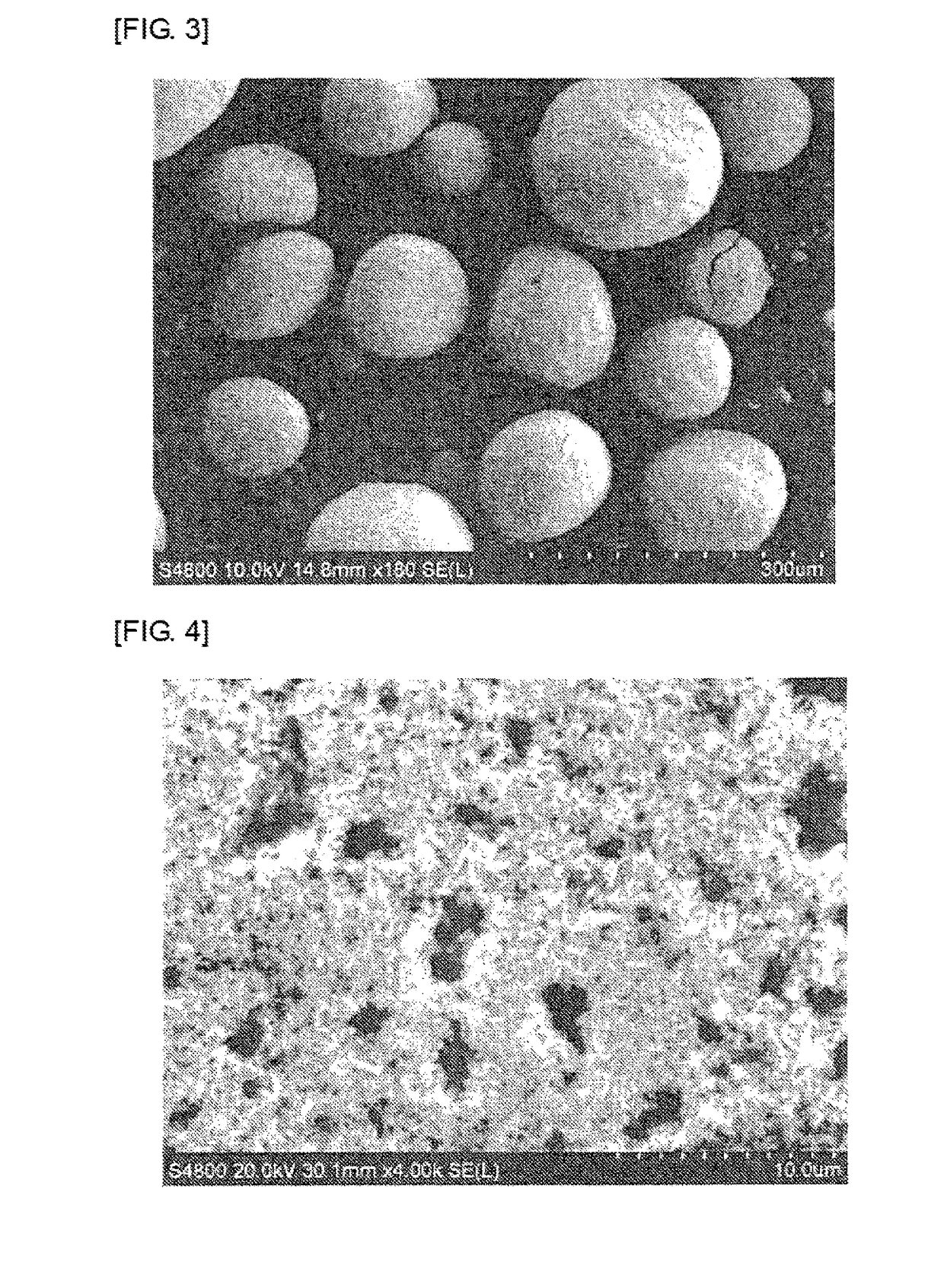

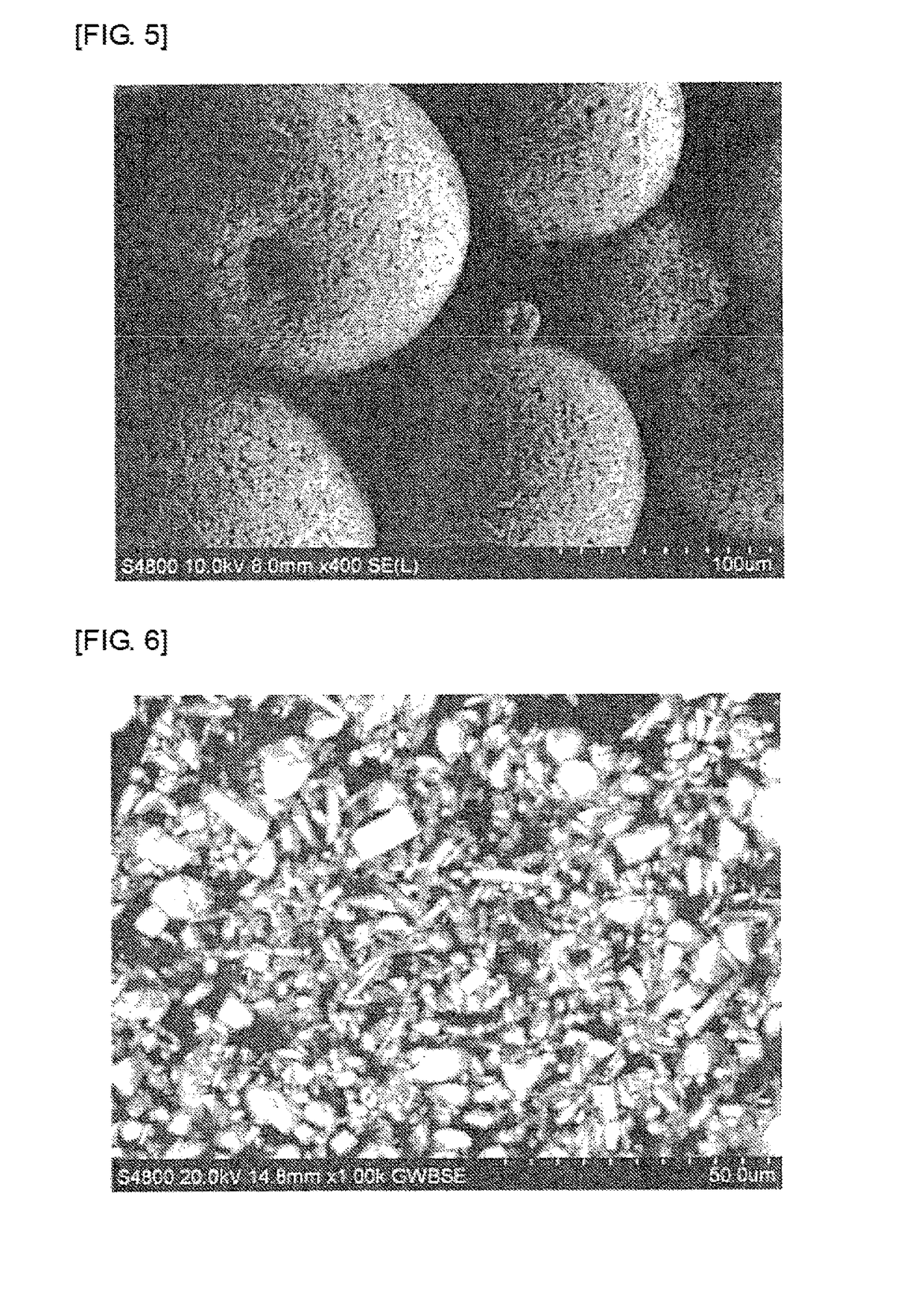

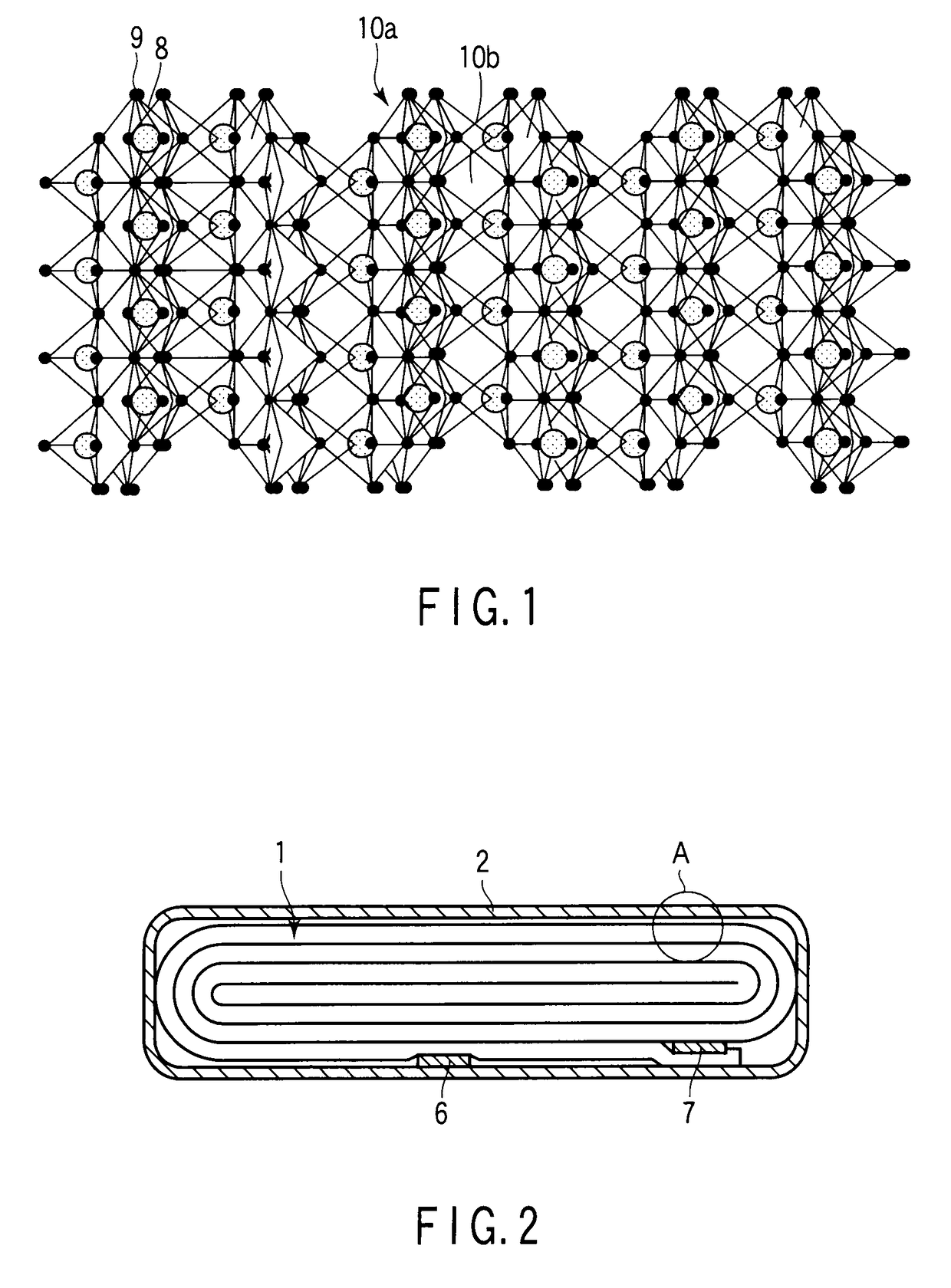

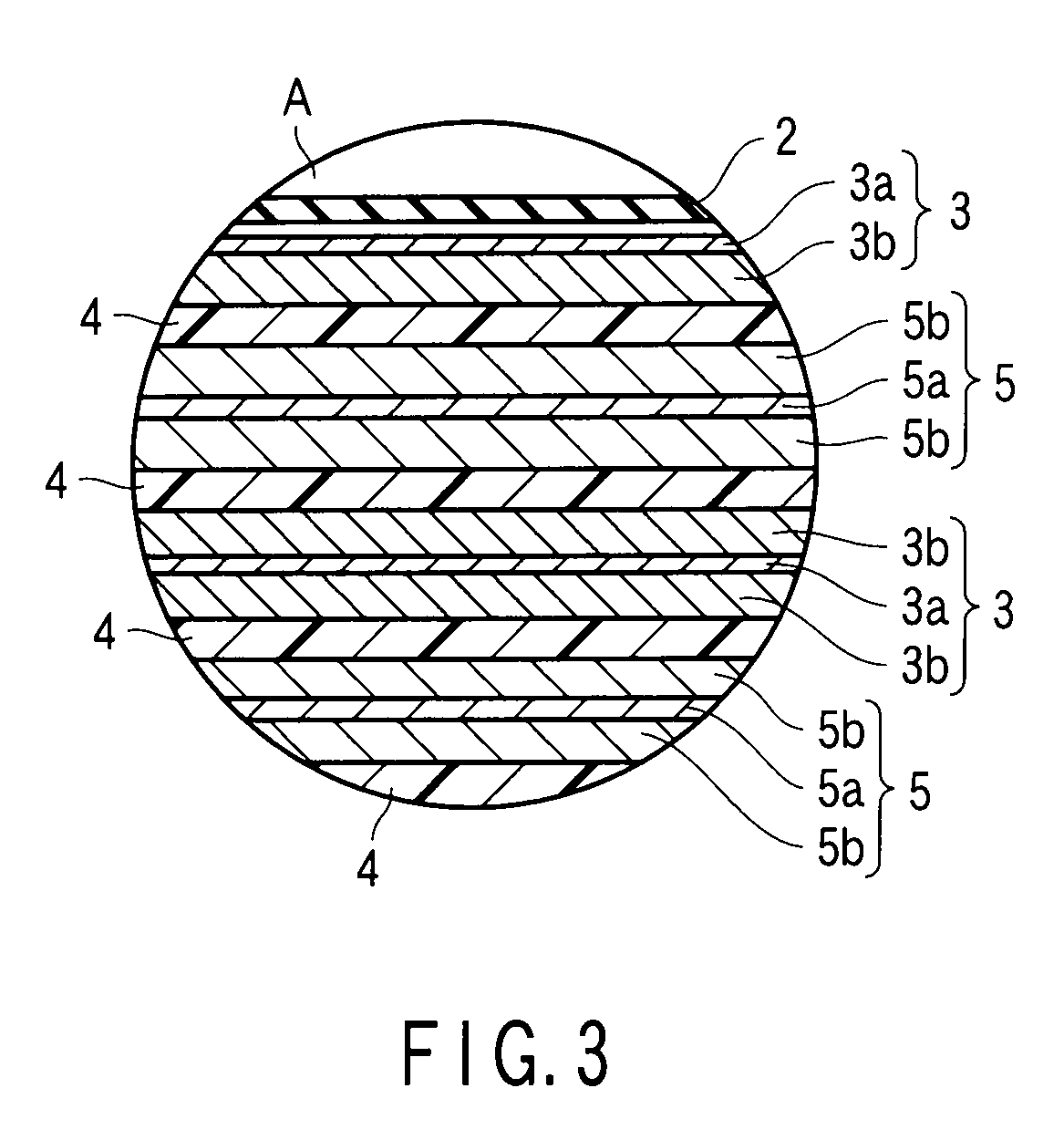

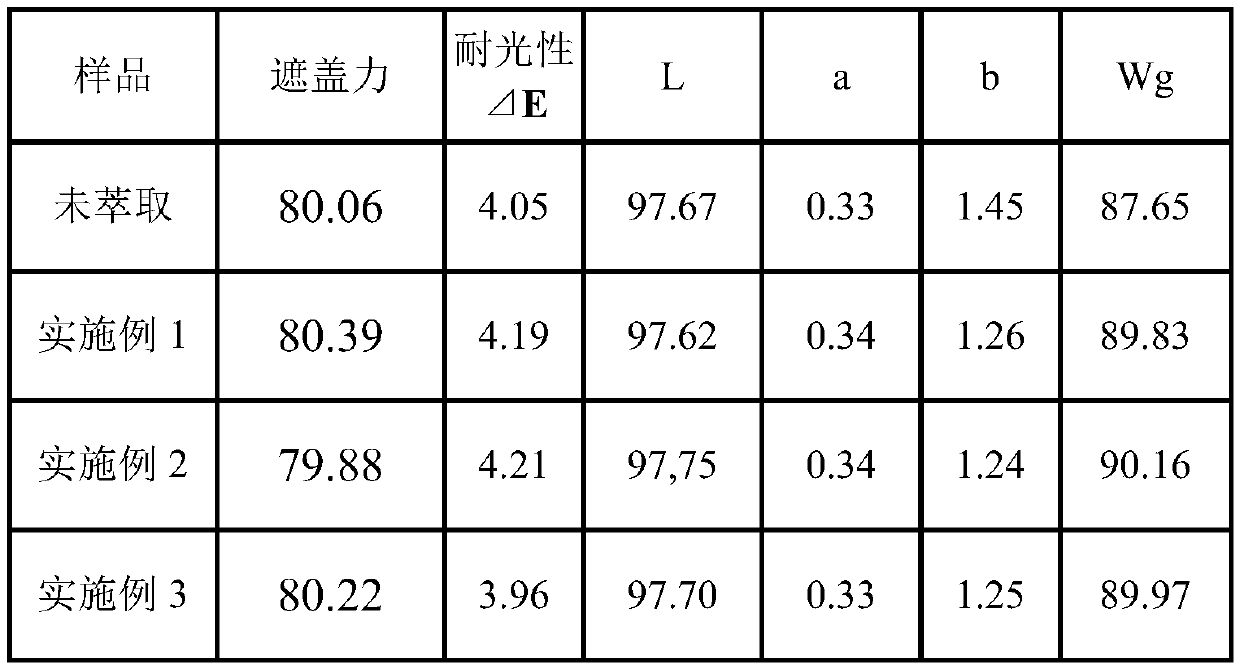

Porous titanate compound particles and method for producing same

ActiveUS20170291855A1Excellent fade resistanceAlkali titanatesOther chemical processesPore diameterMaterials science

Provided axe porous titanate compound particles capable of giving excellent fade resistance when used in a friction material, a resin compound and a friction material each containing the porous titanate compound particles, and a method for producing the porous titanate compound particles. Porous titanate compound particles are each formed of titanate compound crystal grains bonded together and have a cumulative pore volume of 5% or more within a pore diameter range of 0.01 to 1.0 μm.

Owner:OTSUKA CHEM CO LTD

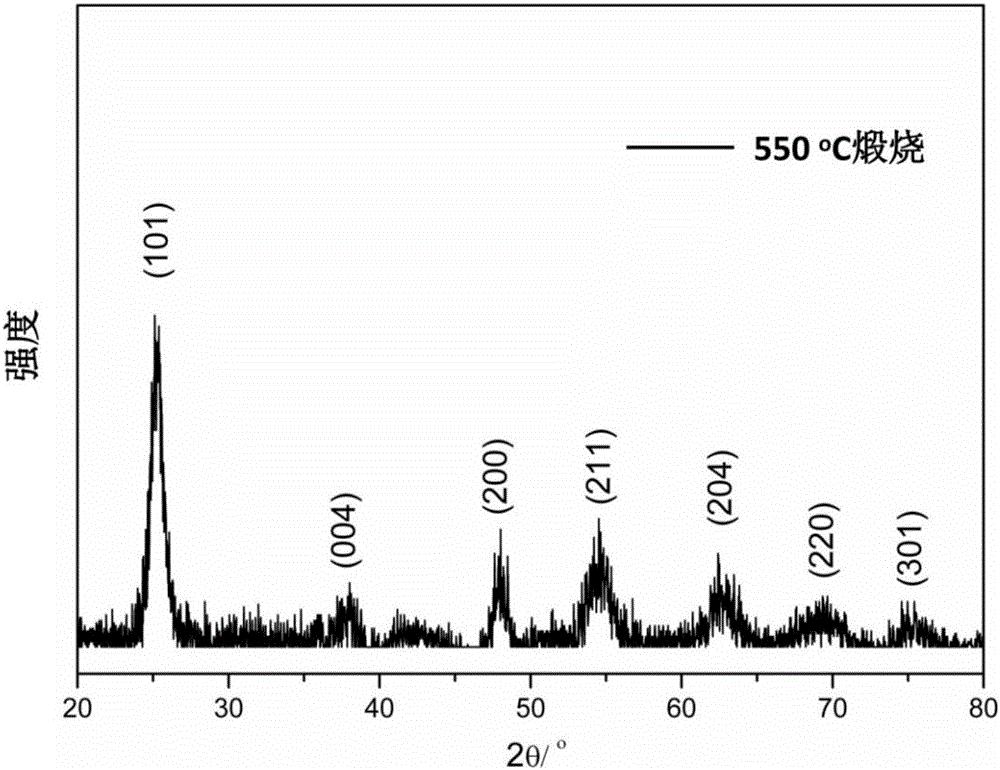

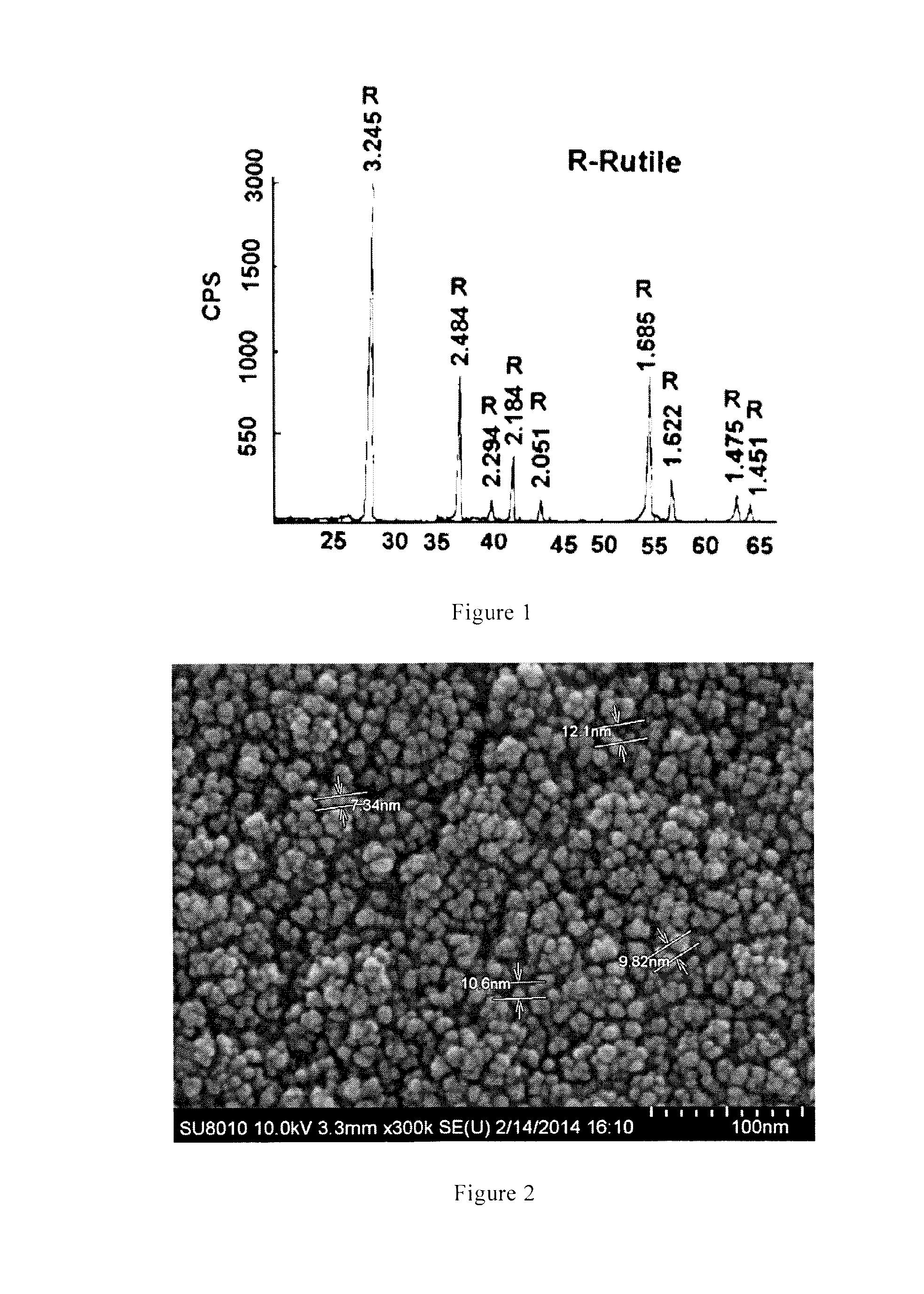

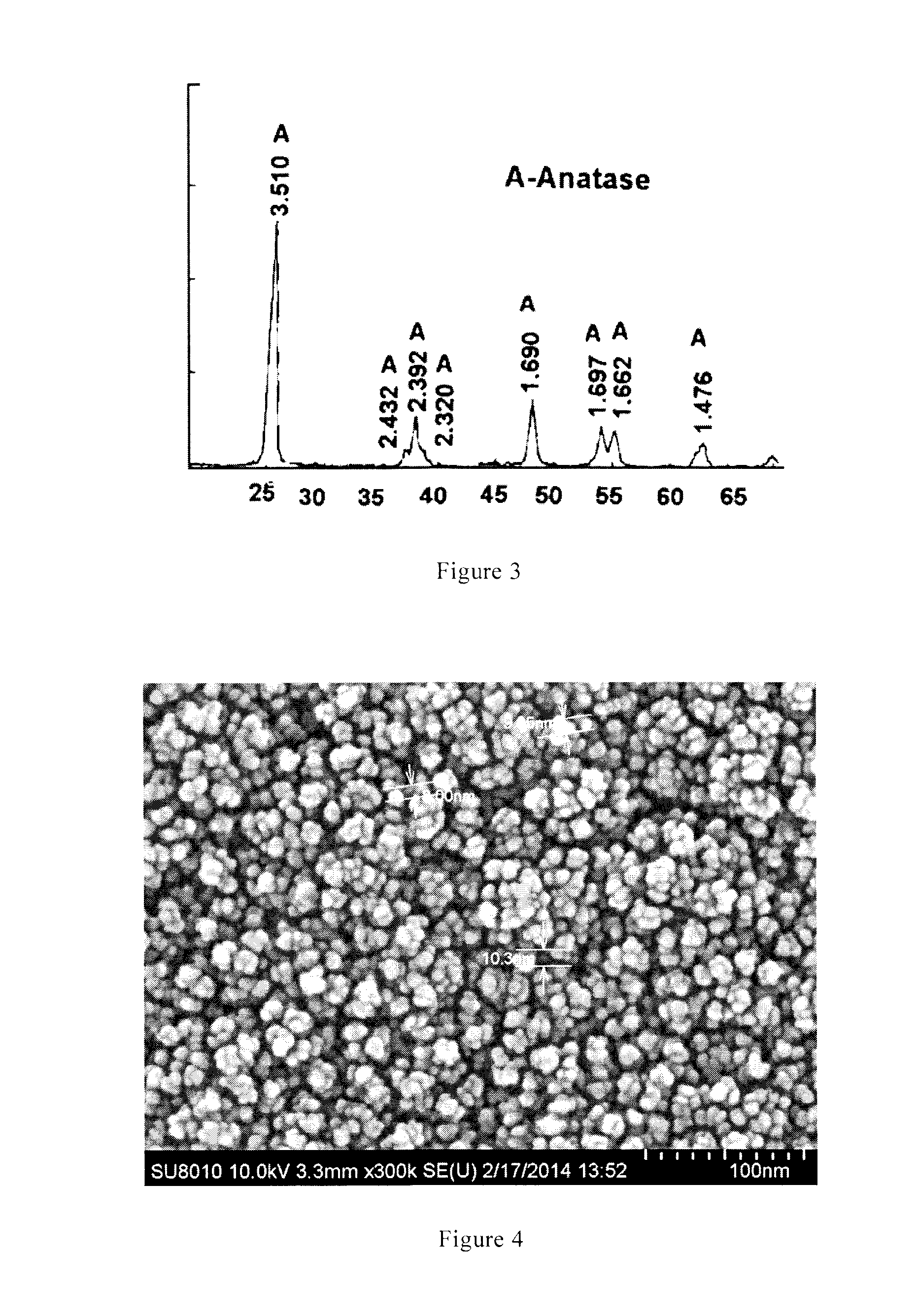

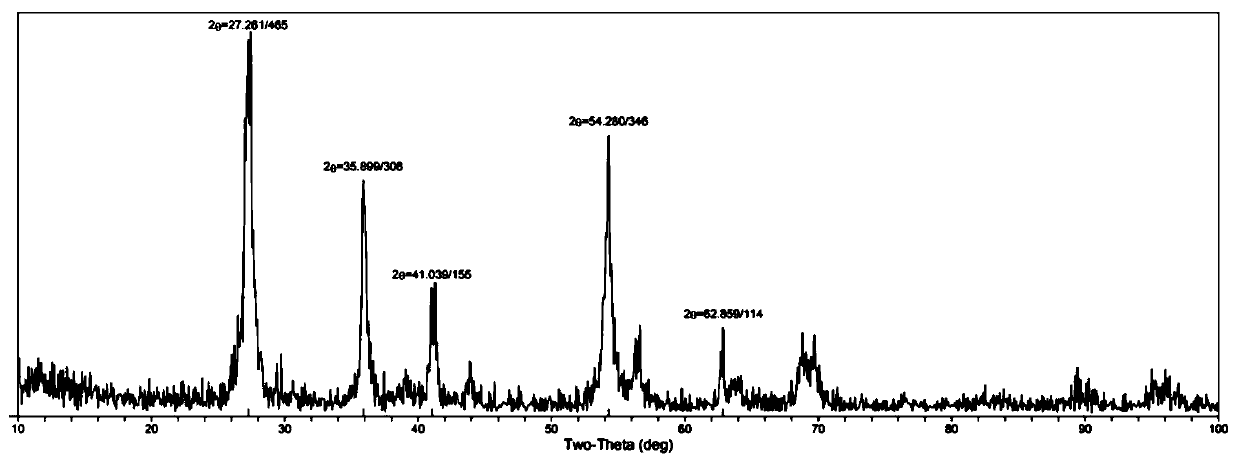

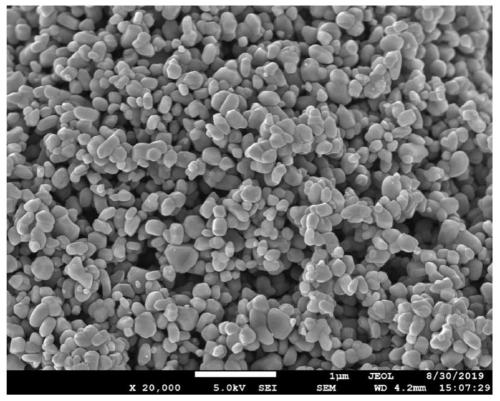

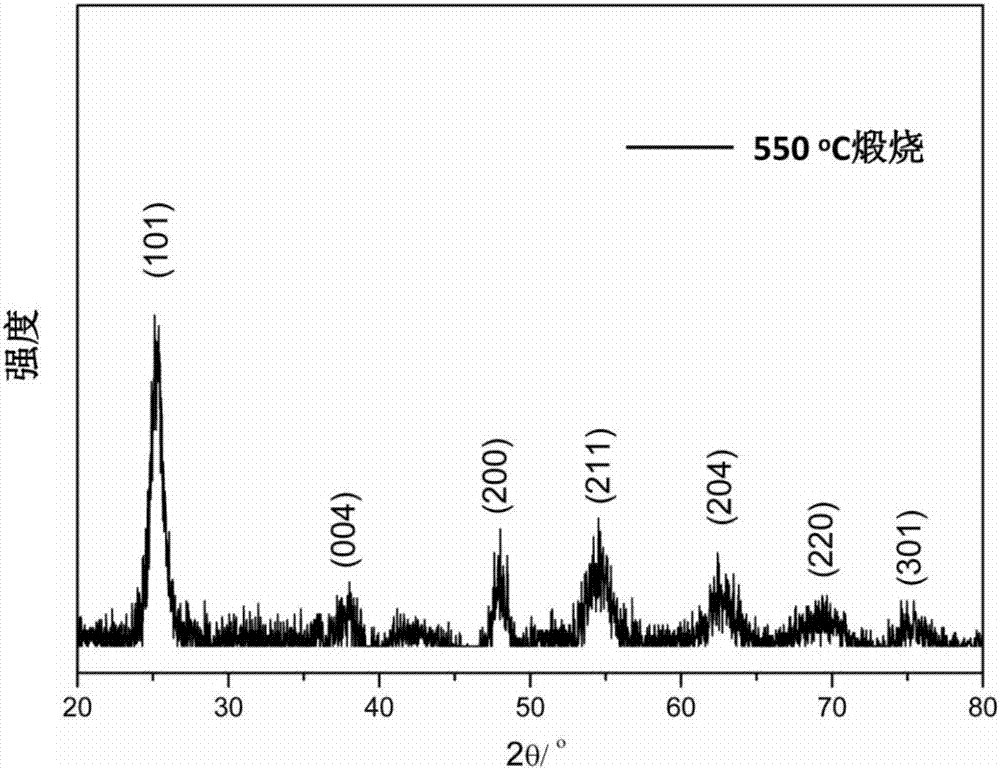

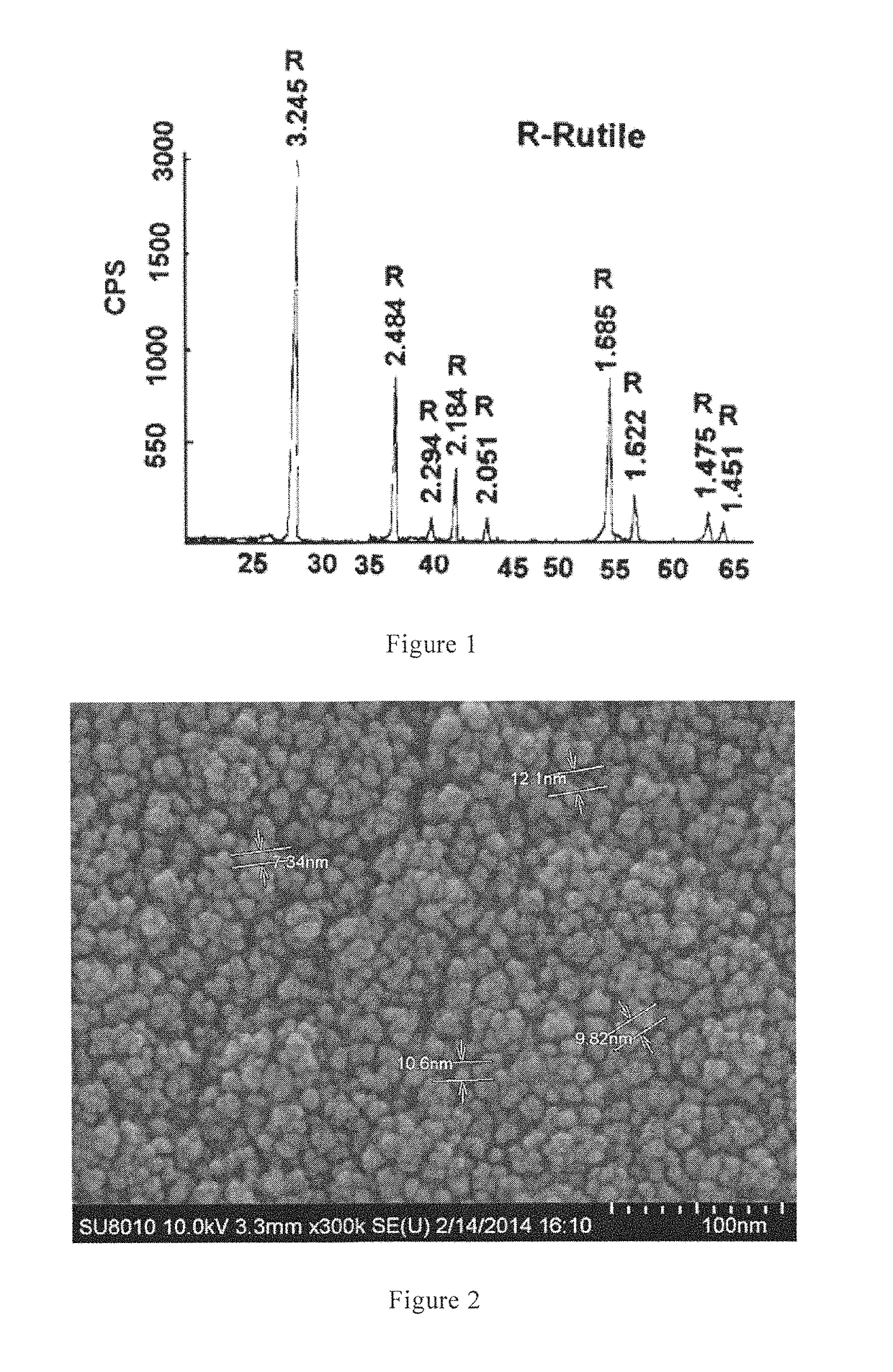

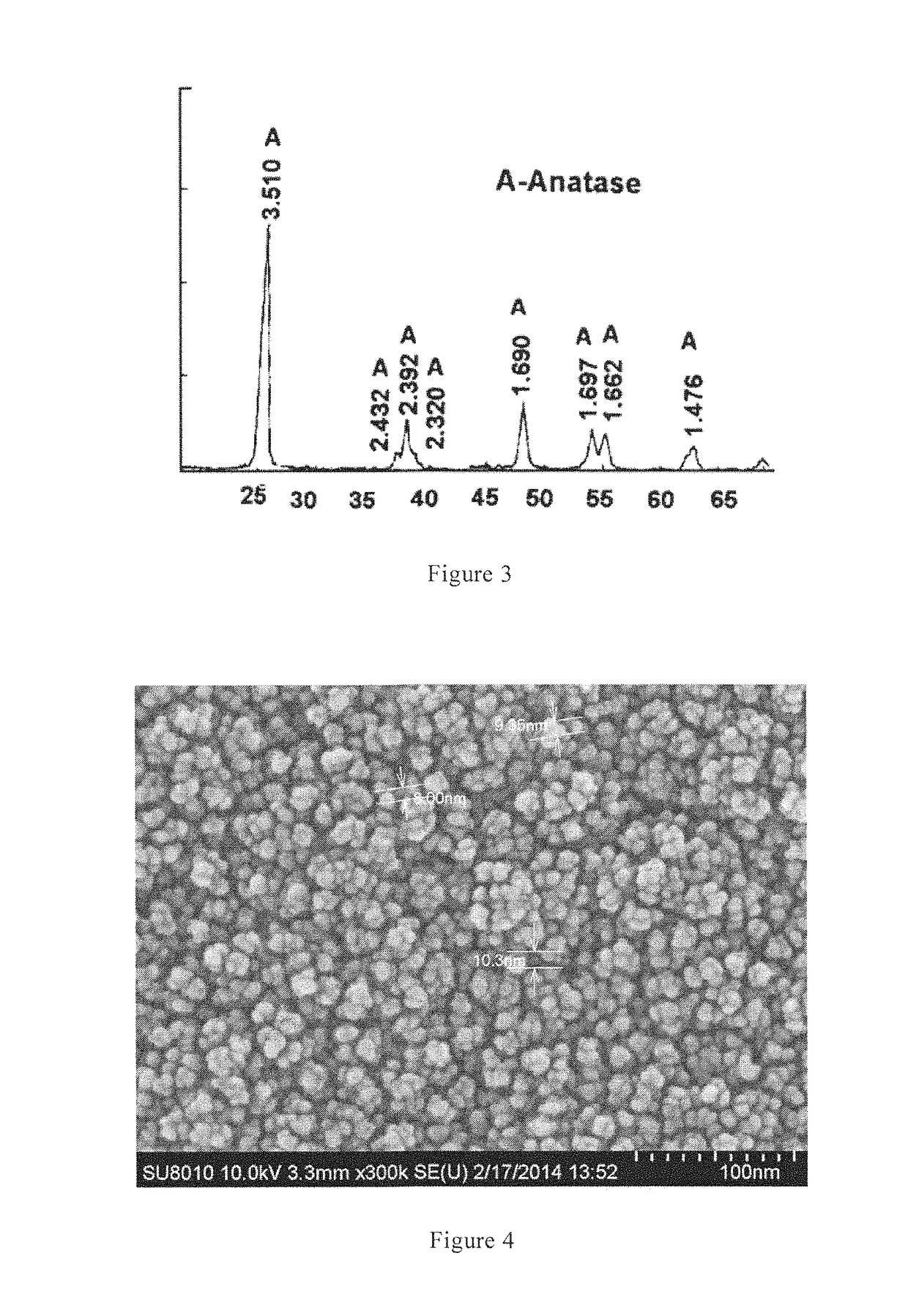

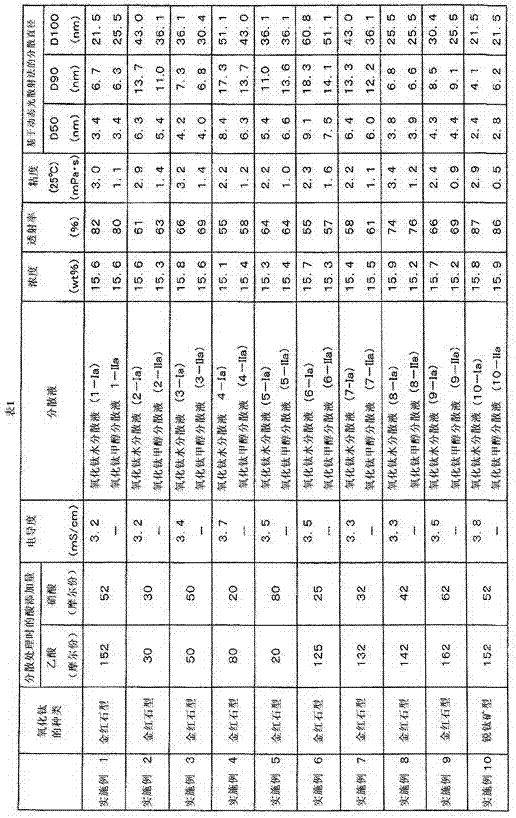

Method for Preparing Nanometer Titanium Dioxide

ActiveUS20170050863A1High dissolution rateReduce concentrationMaterial nanotechnologyTitanium dioxideTitanium ionHydrolysis

The present invention belongs to the field of preparation technique of inorganic, functional material and provides a method for preparing nanometer titanium dioxide which comprises the following steps: (1) dissolving ilmenite powder using hydrochloric acid to obtain a raw ore solution; (2) eliminating the iron element in the raw ore solution to obtain a final solution containing titanium ions (3) heating the final solution for hydrolysis to obtain a hydrolyzed product containing titanium dioxide; and (4) calcining the obtained hydrolyzed product to obtain nanometer titanium dioxide. The present invention has the advantages that the raw materials can be easily obtained, the energy consumption is low, both rutile type titanium dioxide and anatase type titanium dioxide can be produced, and the product has high purity, small particle diameter, narrow particle diameter distribution and good dispersibility.

Owner:ZIBO SHENGTAI COMPOSITE MATERIAL TECH

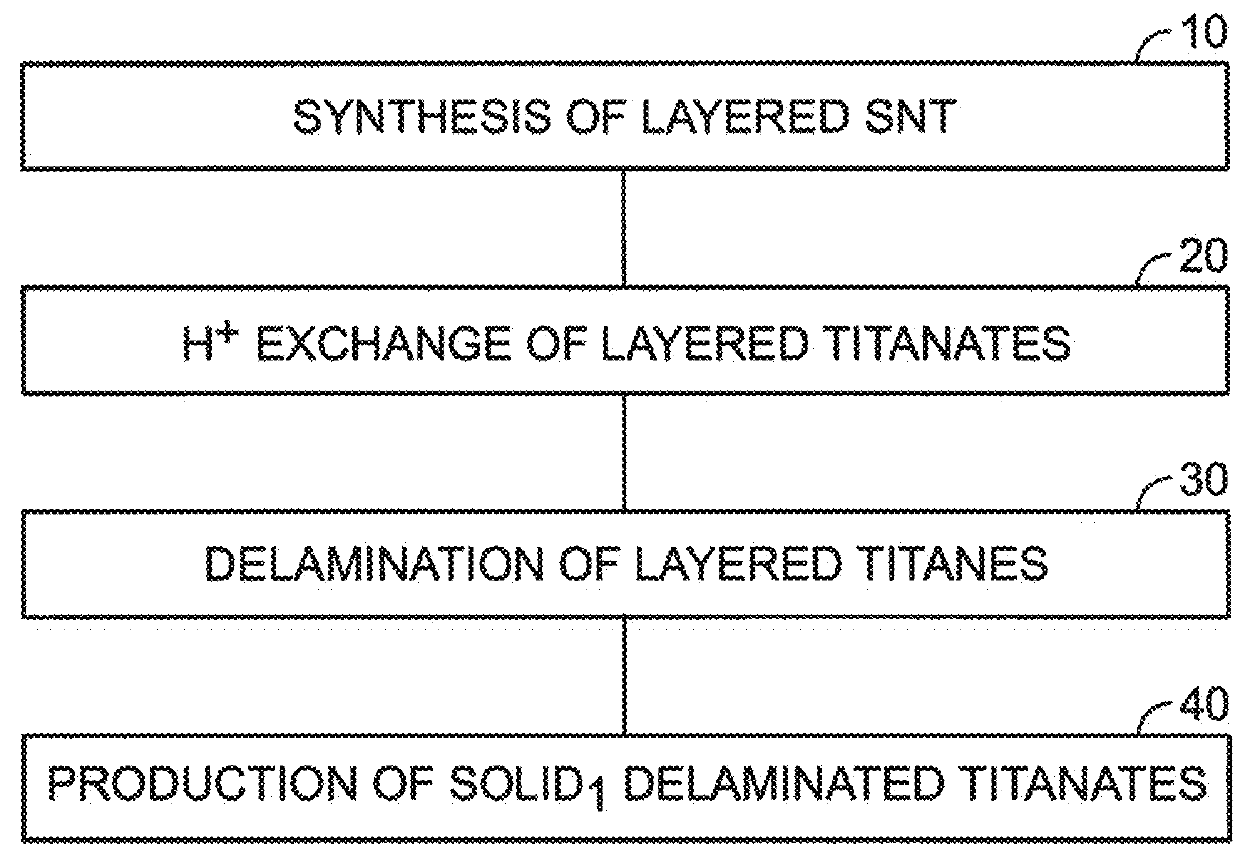

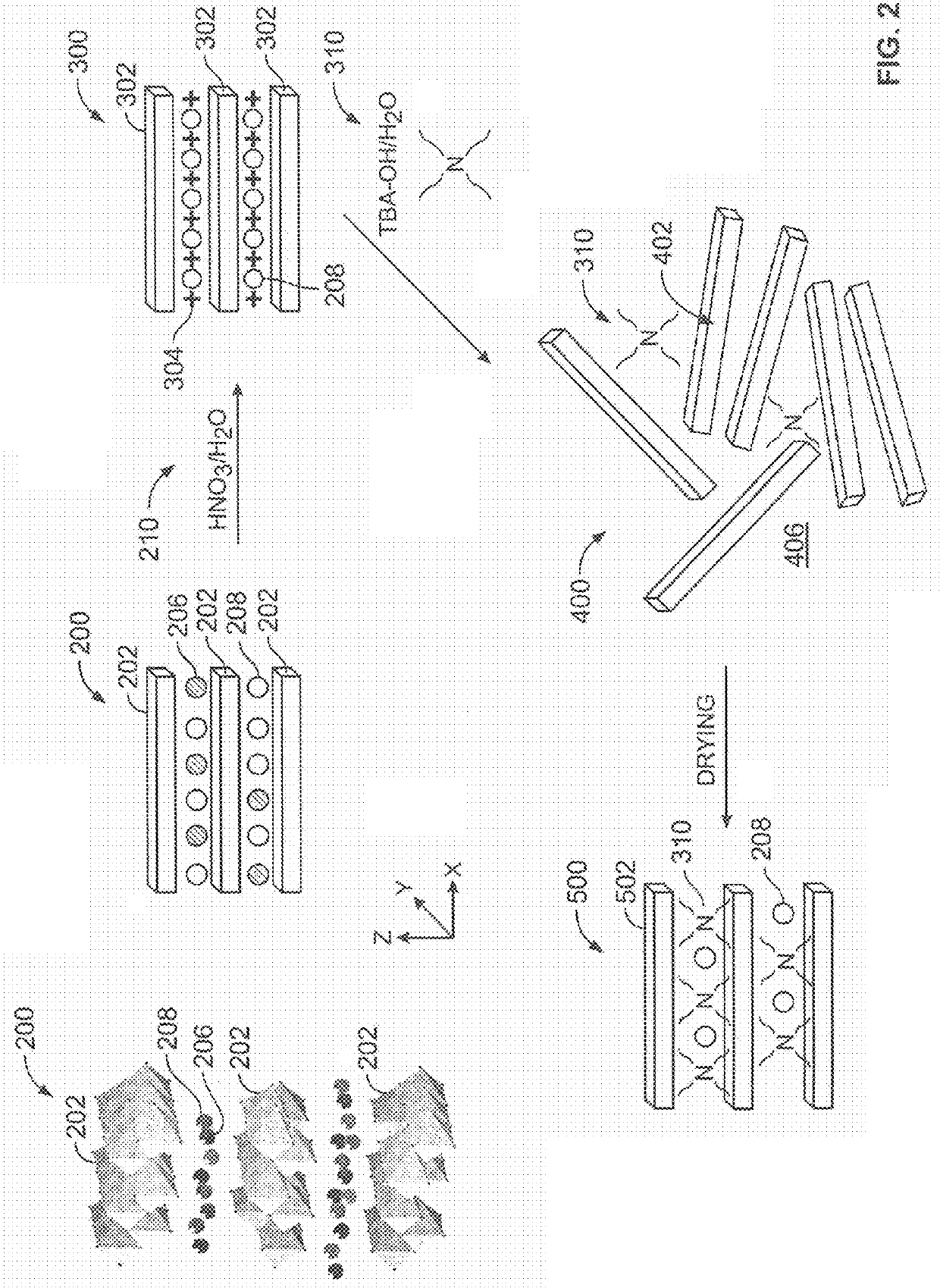

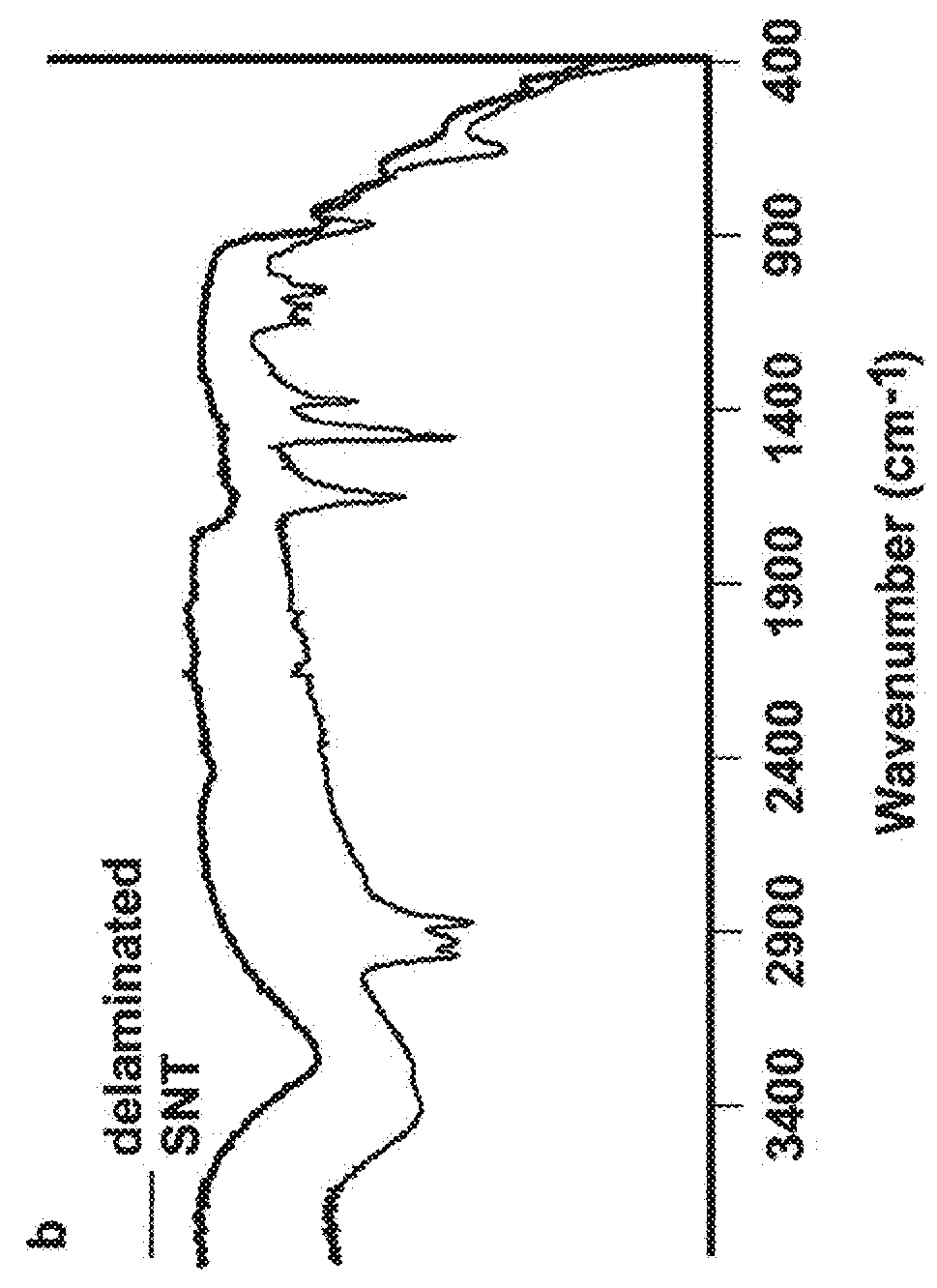

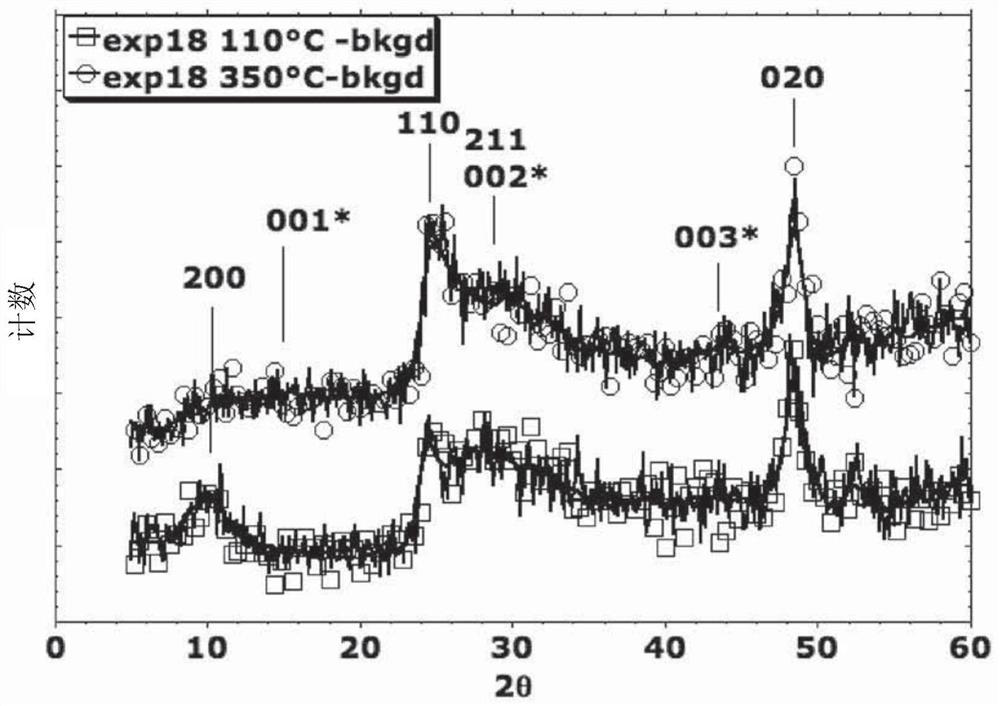

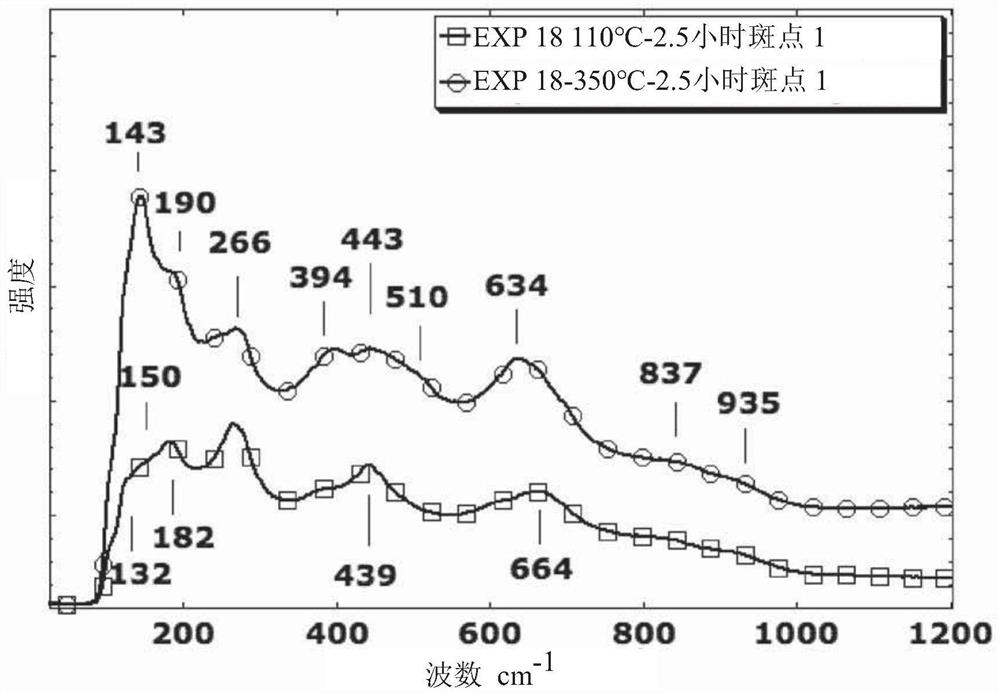

Delaminated sodium nonatitanate and a method for producing delaminated sodium nonatitanate

ActiveUS9249166B1Increase surface areaAlkaline earth titanatesAlkali titanatesHydrothermal synthesisSodium titanate

A hydrothermal synthesis method of making a delaminated titanate is disclosed. The delaminated titanate has a unique structure or morphology. The delaminated titanate is first formed by forming at a low temperature a layered sodium nonatitanate (SNT), which may be referred to as layered sodium titanate. The layered SNT has a unique morphology. The layered SNT is then synthesized into a delaminated titanate having a unique morphology.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

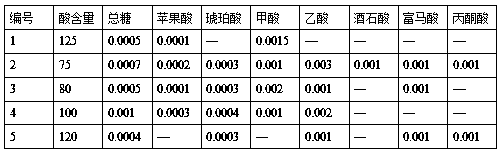

Novel hydrophobic eutectic solvent separation and purification system of weak protonic acid, and method for purifying weak protonic acid

ActiveCN111359258AHigh purityHigh yieldIron compounds preparationHydrogen sulfidesPhysical chemistryNetwork structure

The invention relates to the technical field of biology and chemical engineering, and concretely relates to a novel hydrophobic eutectic solvent separation and purification system of a weak protonic acid, and a method for purifying the weak protonic acid. The novel hydrophobic eutectic solvent separation and purification system of the weak protonic acid consists of a hydrogen bond donor, and a hydrogen bond receptor and an accelerant which are in a eutectic solvent; the weak protonic acid in a raw material solution is used as a hydrogen bond donor; and functional groups existing in the hydrogen bond receptor and the accelerant in the eutectic solvent interact with the weak protonic acid to form the novel hydrophobic eutectic solvent separation and purification system with a linear, planaror multi-dimensional network structure. The system and the method have the advantages of simple process, low energy consumption, high recovery rate, environmental friendliness, less pollution and thelike.

Owner:山东金原德丰科技开发有限责任公司

Rutile metatitanic acid and titanium dioxide, and preparation methods thereof

PendingCN111453768AImprove qualityReduce energy consumptionFerric oxidesTitanium dioxidePhysical chemistryChloride

The invention provides rutile metatitanic acid and titanium dioxide, and preparation methods thereof, belonging to the technical field of pigment preparation. The preparation method of rutile metatitanic acid comprises the following steps: hydrolyzing a mixed solution of a seed crystal solution and a ferrotitanium solution at 90-100 DEG C, and keeping the temperature to obtain a mixed solution containing metatitanic acid, ferrous chloride and hydrochloric acid, wherein the seed crystal solution is obtained by curing a part of the ferrotitanium solution at 90-100 DEG C, iron ions in the ferrotitanium solution are divalent iron ions, the content of Ti<4+> in the ferrotitanium solution is 100-200 g / L in terms of TiO2, and a iron-titanium ratio is 0.1-0.3. The rutile metatitanic acid is prepared by adopting the method. The preparation method of the titanium dioxide comprises the preparation method of the rutile type metatitanic acid, and comprises a step of calcining the metatitanic acid.The titanium dioxide is prepared by using the method. The rutile metatitanic acid is prepared by the method, and the method is simple in process and low in reaction energy consumption and can preparehigh-quality titanium dioxide .

Owner:福建富仕新材料有限责任公司

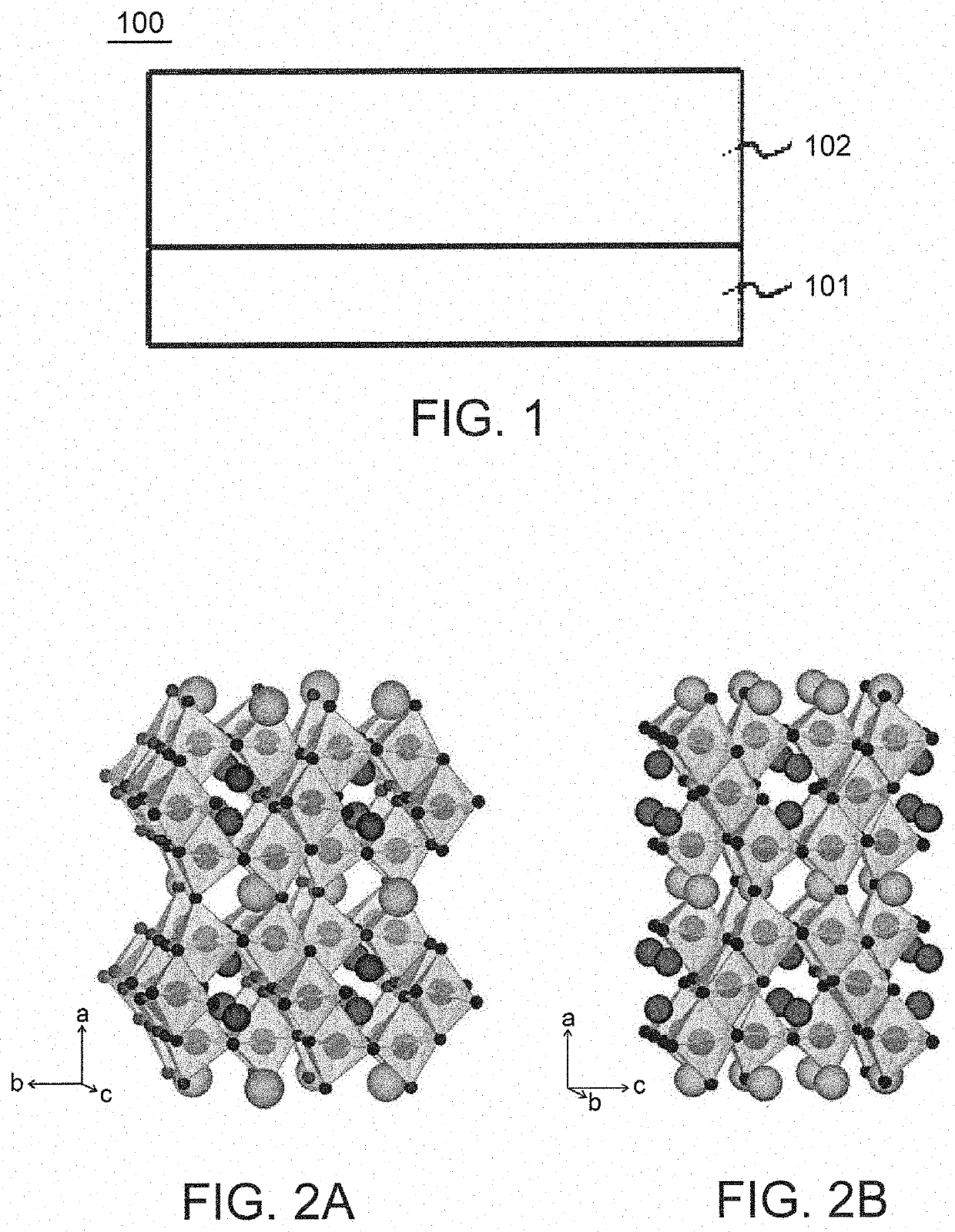

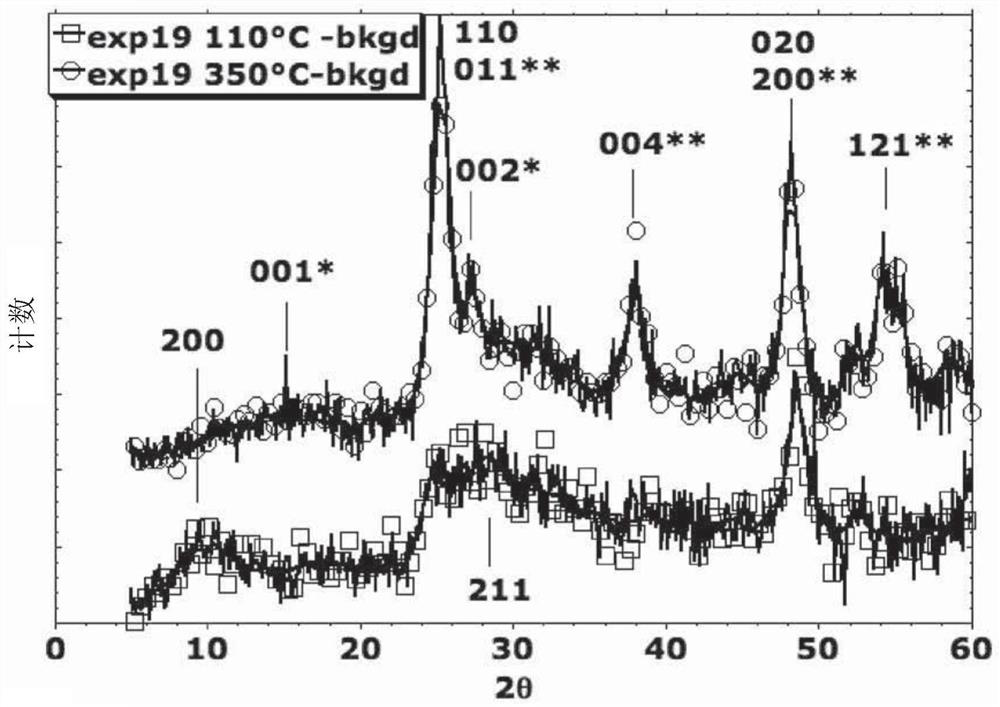

Negative electrode active material containing a titanium oxide compound having a crystal structure of monoclinic system titanium dioxide

A negative electrode active material according to one embodiment includes a titanium oxide compound having a crystal structure of monoclinic system titanium dioxide. The titanium oxide compound is modified by at least one kind of ion selected from the group consisting of an alkali metal cation, an alkali earth metal cation, a transition metal cation, a sulfide ion, a sulfuric acid ion and a chloride ion.

Owner:KK TOSHIBA

Recovery method of titanium oxydichloride waste liquid

PendingCN111170361AHigh whitenessGood hueInorganic pigment treatmentTitanium oxides/hydroxidesEnvironmental engineeringTitanium

The invention discloses a recovery method of titanium oxydichloride waste liquid. The recovery method comprises the following steps: extraction: oxidizing iron ions in the titanium oxydichloride wasteliquid, adding an organic extraction agent to the titanium oxydichloride waste liquid, and carrying out countercurrent extraction to obtain a titanium oxydichloride solution with an iron ion contentof less than 3 ppm and an organic extraction phase with a high iron content; and reverse extraction: subjecting the organic extraction phase with high iron content to reverse extraction with water toallow ferric iron and hydrogen ions to enter a water phase so as to obtain an acidic water phase containing ferric iron and the organic extraction agent, wherein the organic extraction agent is recycled and can be reused in the extraction step.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Efficient waste SCR denitration catalyst recovery method

ActiveCN112960697AEfficient recyclingTungsten compounds preparationNanotechnologyPtru catalystProcess engineering

The invention relates to an efficient waste SCR denitration catalyst recovery method, and belongs to the field of non-ferrous metal recovery. The novel process for recovering the tungsten element from the waste SCR denitration catalyst is provided, the comprehensive benefits of titanium element recovery are greatly improved, and the process mainly comprises the steps of raw material pretreatment, tungsten element extraction, crude titanium slag recovery, tungsten element purification, zirconium tungstate recovery and the like. The process has the advantages of high product value, small loss of target recovered elements, low cost input and the like, and can realize efficient treatment of the waste SCR denitration catalyst.

Owner:北京华电光大环境股份有限公司

Nanostructured titanic acid salts and preparation process and use thereof

ActiveUS20200071183A1Easy to makeEasy to controlMaterial nanotechnologyAlkaline earth titanatesAlcoholTitanium

The present invention provides a nanostructured titanic acid salt and a preparation process and use thereof. The process comprises preparing a dispersion containing titanium peroxy complex; slowly adding a metal compound to the dispersion containing the titanium peroxy complex to form a solution; adding an alcohol to the solution under normal temperature and normal pressure to produce the nanostructured titanic acid salt precursor precipitate in the solution, and separating the precipitate to obtain the titanic acid salt precursor; drying the precursor, and then heat treating it to obtain the nanostructured titanic acid salt product. The present invention provides a process for preparing a titanic acid salt with simple preparation process, easy control for process parameters and easy large-scale industrial production.

Owner:PETROCHINA CO LTD

Extraction of lithium from brine

ActiveUS20180222760A1Reduce and eliminate impurityIon-exchange process apparatusAlkali titanatesLithium chlorideSorbent

A process for the extraction of lithium from a brine, wherein a solution of the brine is contacted with a titanate adsorbent such that lithium ions are adsorbed thereon whilst rejecting substantially all other cations. The adsorbent is provided in the form of either a hydrated titanium dioxide or a sodium titanate. The process in turn produces a substantially pure lithium chloride solution

Owner:INNEOVATION PTY LTD

A method for preparing porous hollow titanium dioxide nanotubes

ActiveCN106186058BReduce sensitivityLess prone to cloggingElectro-spinningNanotechnologyFiberElectrospinning

The invention discloses a method for preparing porous hollow titanium dioxide nanotubes. The method comprises the steps of 1, dissolving a polymer spinning carrier, an anti-hydrolysis agent, disperse phase, a disperse phase cosolvent and a titanium dioxide precursor in a solvent while stirring to form a spinning solution; 2, conducting electrostatic spinning on the spinning solution obtained in step 1 through an electrostatic spinning device to obtain nanofiber; 3, aging the nanofiber obtained in step 2, and then conducting extraction to obtain hollow nanofiber; 4, calcinating the hollow nanofiber obtained in step 3 to obtain the porous hollow titanium dioxide nanotubes. The method is easy to operate, sensitivity to external conditions during spinning is reduced, silk production is stable, needle blocking does not occur easily, large-scale production can be achieved easily, and the porous hollow titanium dioxide nanotubes prepared with the method have a pure phase and a high specific surface area.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Extraction of lithium from brine

ActiveUS10626020B2Reduce and eliminate impurityIon-exchange process apparatusAlkali titanatesHydration reactionLithium chloride

A process for the extraction of lithium from a brine, wherein a solution of the brine is contacted with a titanate adsorbent such that lithium ions are adsorbed thereon whilst rejecting substantially all other cations. The adsorbent is provided in the form of either a hydrated titanium dioxide or a sodium titanate. The process in turn produces a substantially pure lithium chloride solution.

Owner:INNEOVATION PTY LTD

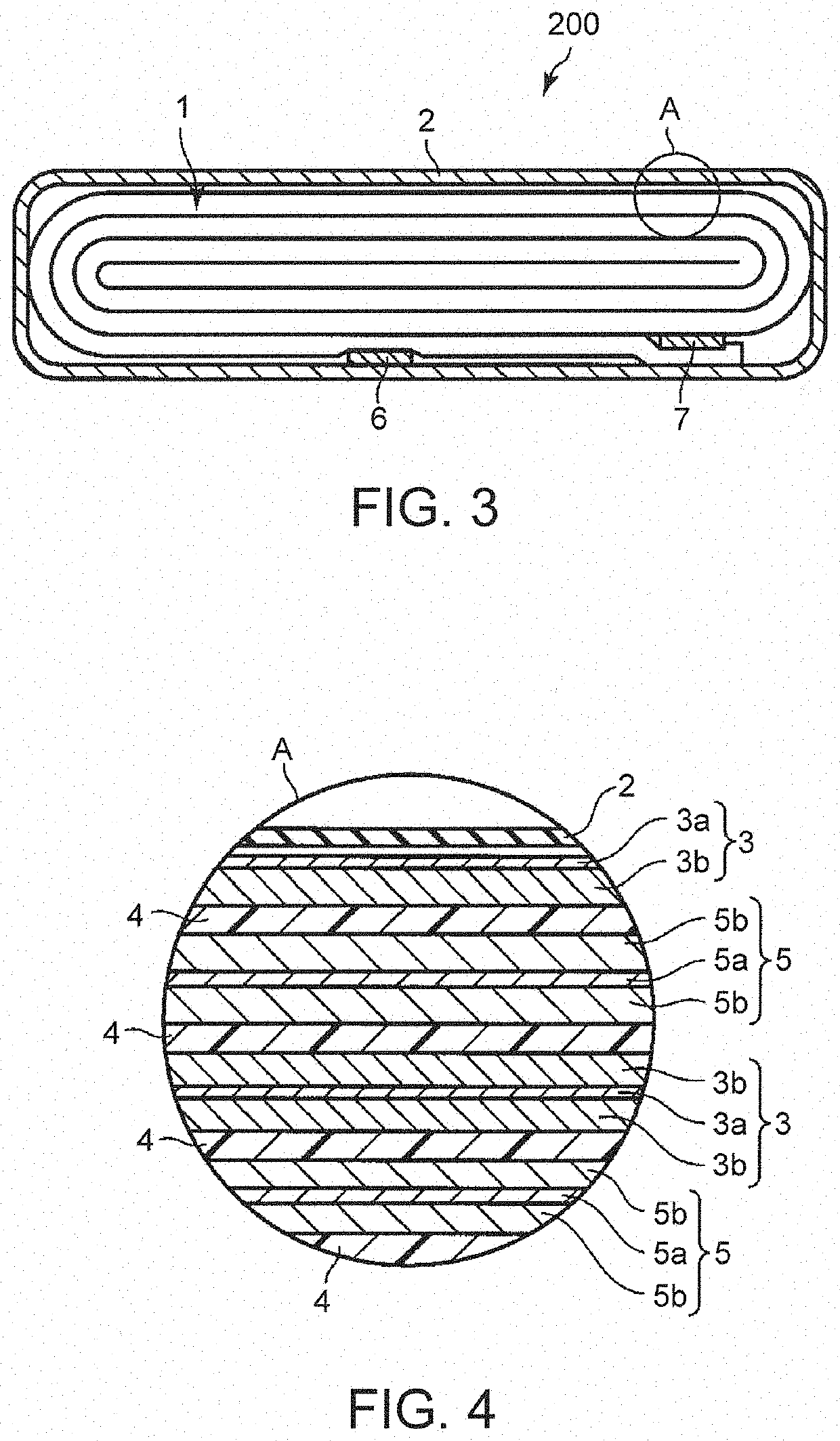

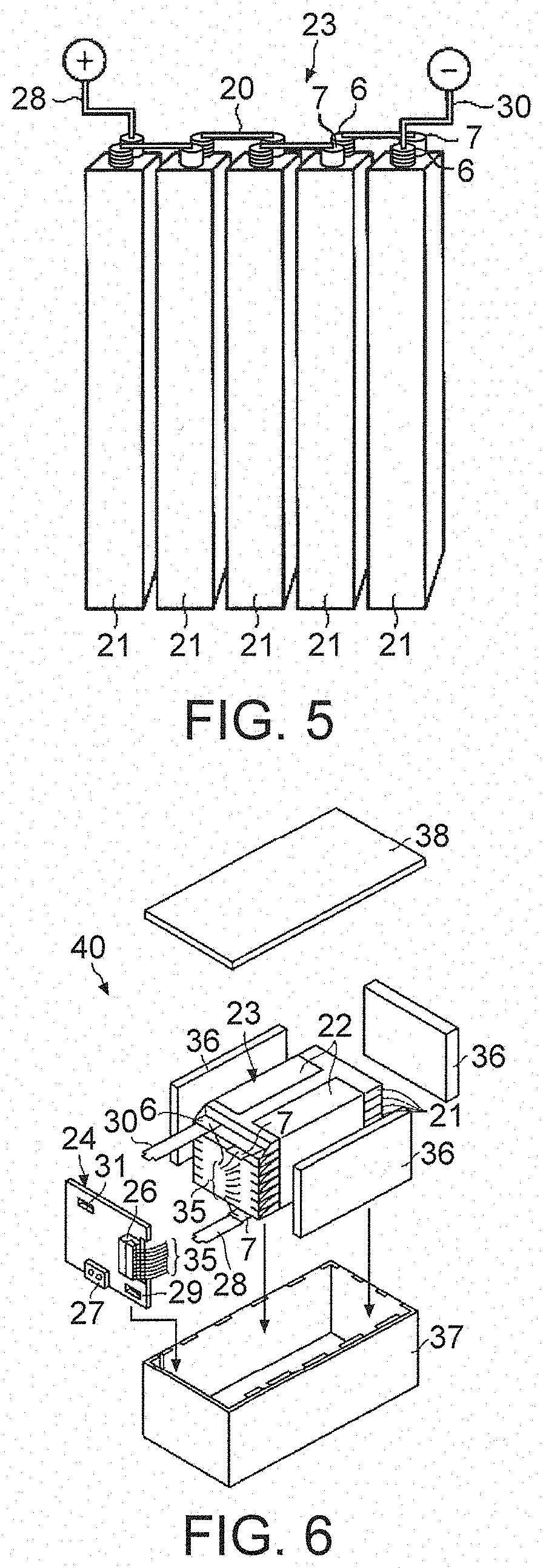

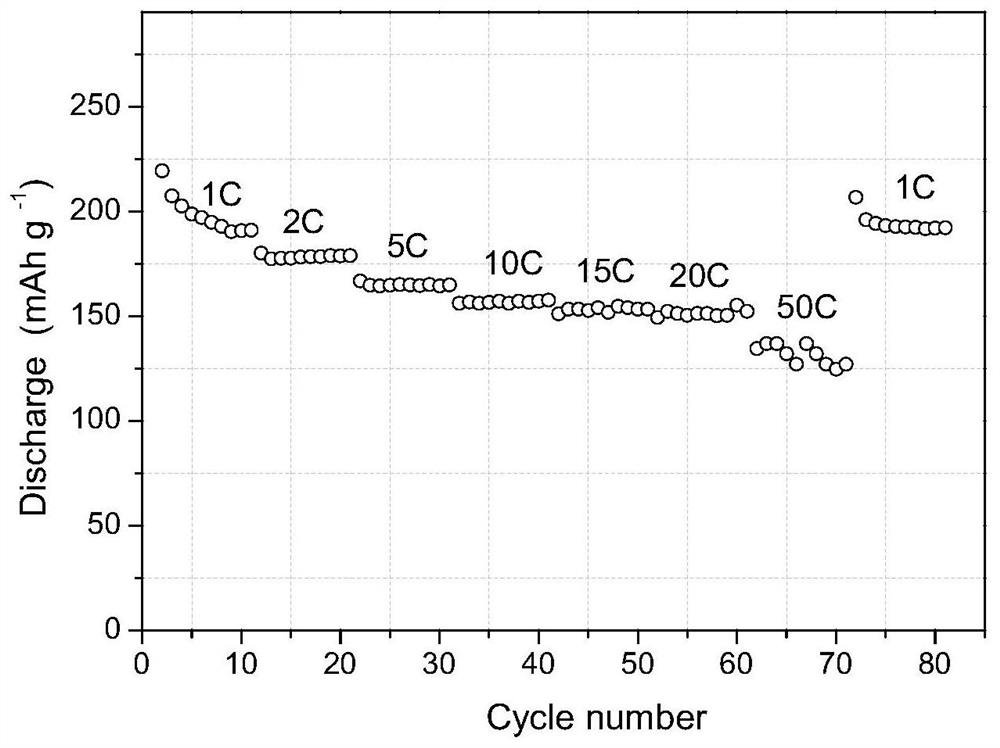

Electrode for a secondary battery, secondary battery, battery pack and vehicle

ActiveUS20200044235A1Easy inputExcellent output propertyAlkali titanatesNegative electrodesCrystal systemEngineering

An electrode for a secondary battery comprises a current collector; and an active material-containing layer has active materials which comprise titanium-containing composite oxide having an orthorhombic crystal structure and represented by a general formula Li2+aM12−bTi6−cM2dO14+δ;wherein the active material-containing layer has intensity ratio Ia / Ib in an X-ray diffraction pattern of the active material-containing layer, the Ia and the Ib are obtained by powder X-ray diffraction method using Cu-Kα ray, the intensity ratio is within a range of 0.5≤Ia / Ib≤2, the Ia is the strongest intensity of a diffraction peak among diffraction peaks appearing within a range of 42°≤2θ≤44°, and the Ib is the strongest intensity of a diffraction peak among diffraction peaks appearing within a range of 44°<2θ≤48°.(M1 is at least one selected from the group consisting of Sr, Ba, Ca, Mg, Na, Cs, Rb and K, M2 is at least one selected from the group consisting of Zr, Sn, V, Nb, Ta, Mo, W, Y, Fe, Co, Cr, Mn, Ni and Ala is within a range of 0≤a≤6b is within a range of 0≤b<2c is within a range of 0≤c<6d is within a range of 0≤d<6δ is within a range of −0.5≤δ≤0.5.)

Owner:KK TOSHIBA +1

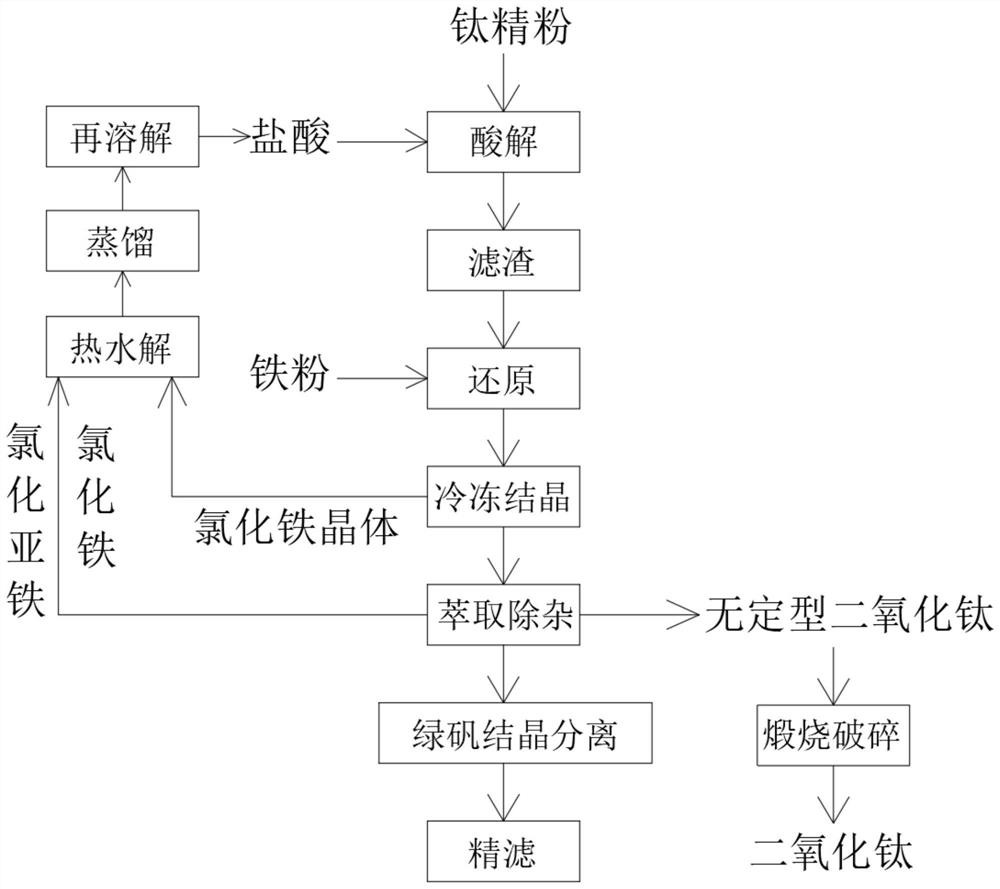

Preparation method of titanium dioxide for polyester chemical fiber extinction

PendingCN112694123AGood optical performanceStrong covering powerNanotechnologyBulk conveyorsPolyesterFiber

The invention discloses a preparation method of titanium dioxide for polyester chemical fiber extinction. The preparation method comprises the following steps: crushing titanium concentrate, mixing the crushed titanium concentrate with hydrochloric acid, carrying out acidolysis, filtering out residues, adding iron powder into the residual titanium oxychloride solution to reduce, crystallizing the solution by freezing, extracting to remove impurities, and hydrolyzing to obtain amorphous titanium dioxide; calcining and crushing to obtain titanium dioxide powder; ferric chloride crystals generated in the crystallization process, ferrous chloride generated in the extraction process and a ferric chloride solution are subjected to pyrohydrolysis, distillation and redissolution to obtain regenerated hydrochloric acid, and the regenerated hydrochloric acid is supplemented into the acidolysis process; compared with titanium dioxide prepared through a traditional process, titanium dioxide prepared through the preparation method has more excellent optical performance, covering power, decoloration power and weather resistance, hydrochloric acid can be recycled in the preparation process, three-waste emission of a factory is effectively reduced, and environmental protection is facilitated.

Owner:福州钛发科技有限公司 +1

Aerogel type rare earth composite thermal insulation material and preparation method thereof

ActiveCN112794334AOvercome deficienciesMaterial nanotechnologyLanthanum oxide/hydroxidesThermal insulationSilicic acid

The invention belongs to the technical field of thermal insulation materials, and particularly relates to an aerogel type rare earth composite thermal insulation material and a preparation method thereof. The product developed by the invention comprises silicon dioxide aerogel; a polydopamine layer is adsorbed on the surface of the pore wall of the silicon dioxide aerogel pore, and a rare earth oxide is adsorbed on the surface of the polydopamine layer; and the pore size distribution range of pores of the silicon dioxide aerogel is 20-40 nm. In addition, the material also comprises nano polyacrylate particles, and the nano polyacrylate particles are dispersed in pores of the silicon dioxide aerogel; and the composite material further comprises titanium dioxide aerogel. The preparation method comprises the following steps: mixing and dispersing tetraethoxysilane, absolute ethyl alcohol and dopamine-coated aluminum oxide particles, dropwise adding ammonia water, introducing air after the ammonia water is dropwise added, standing for aging, adjusting the pH value, carrying out ultrasonic impregnation, adding a rare earth salt solution, adjusting the pH value, washing, and drying to obtain the aerogel type rare earth composite thermal insulation material.

Owner:北京宇乾能源科技有限责任公司

Method for preparing nanometer titanium dioxide

The present invention belongs to the field of preparation technique of inorganic functional material and provides a method for preparing nanometer titanium dioxide which comprises the following steps: (1) dissolving ilmenite powder using hydrochloric acid to obtain a raw ore solution; (2) eliminating the iron element in the raw ore solution to obtain a final solution containing titanium ions; (3) heating the final solution for hydrolysis to obtain a hydrolyzed product containing titanium dioxide; and (4) calcining the obtained hydrolyzed product to obtain nanometer titanium dioxide. The present invention has the advantages that the raw materials can be easily obtained, the energy consumption is low, both rutile type titanium dioxide and anatase type titanium dioxide can be produced, and the product has high purity, small particle diameter, narrow particle diameter distribution and good dispersibility.

Owner:ZIBO SHENGTAI COMPOSITE MATERIAL TECH

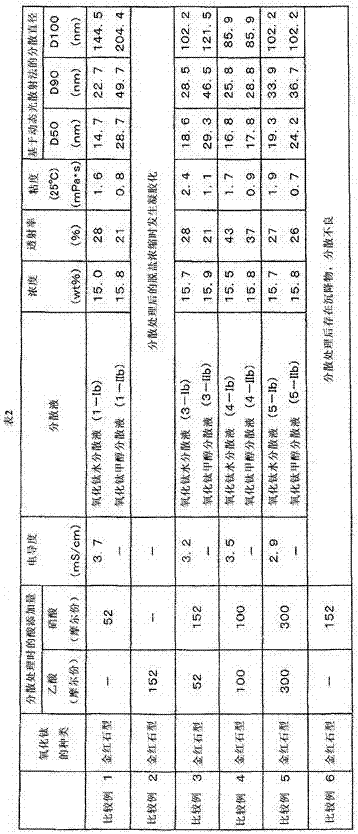

Production method for liquid dispersion of titanium oxide particles

ActiveCN107250048AEnsure transparencyMaintain dispersion diameterNanotechnologyTitanium dioxideAcetic acidAlcohol

The present invention provides a production method for an aqueous dispersion of titanium oxide particles, the production method comprising: a first step (a) in which an aqueous slurry of titanium oxide particles is subjected to wet dispersion in a stirred media mill or a high-pressure dispersion device and in the presence of 15-250 mol parts of acetic acid and 15-90 mol parts of nitric acid with respect to 100 mol parts of titanium oxide, and a pre-washing aqueous dispersion of titanium oxide particles is obtained; and a second step (b) in which the pre-washing aqueous dispersion of titanium oxide particles obtained in the first step (a) is washed. The present invention further provides a production method for a liquid dispersion of titanium oxide particles in alcohol, the production method comprising a third step (c) in which the carrier fluid of the aqueous dispersion of titanium oxide particles obtained in the second step (b) is replaced with an alcohol solvent.

Owner:SAKAI CHEM IND CO LTD

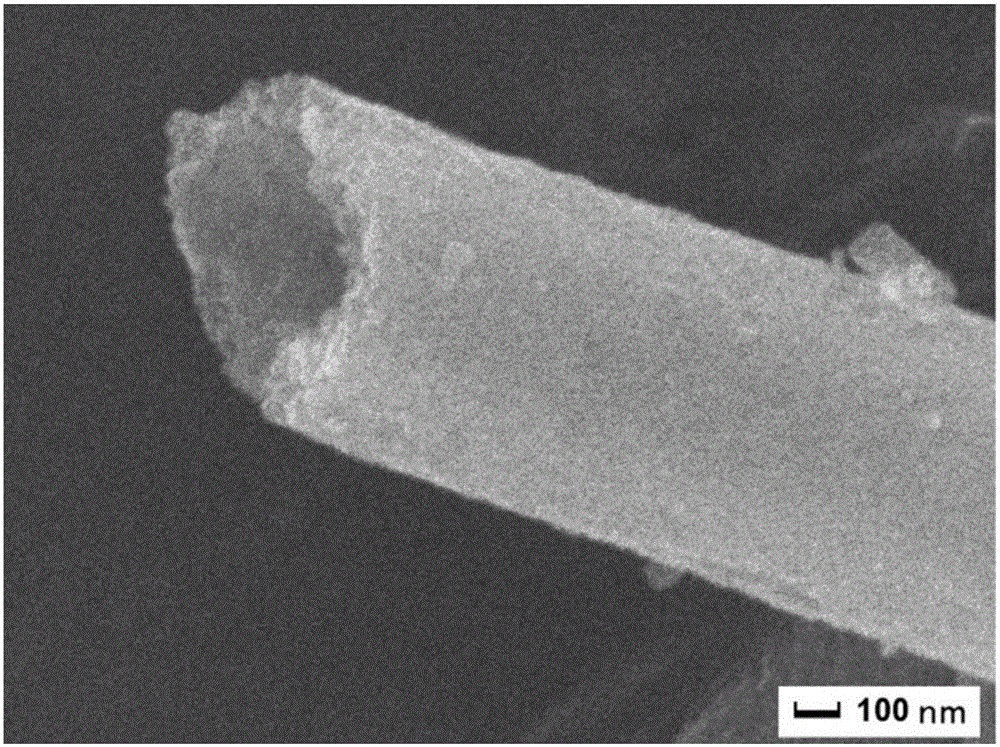

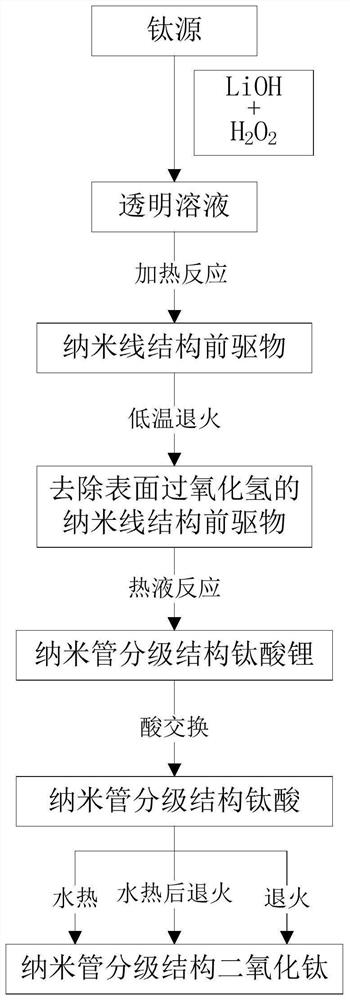

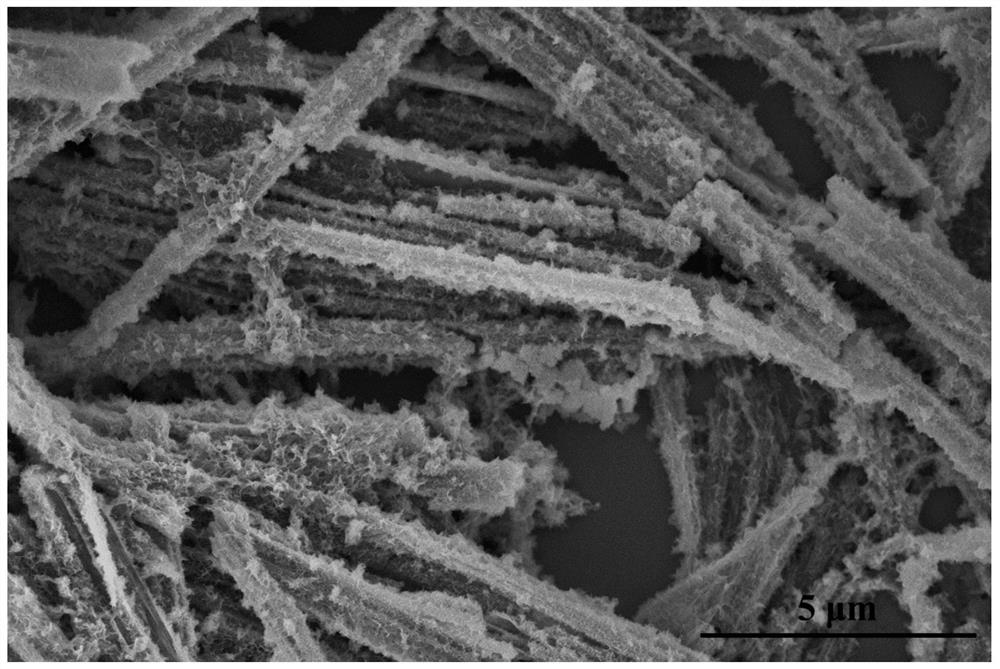

A kind of preparation method of nanotube hierarchical structure lithium titanate and its application and product

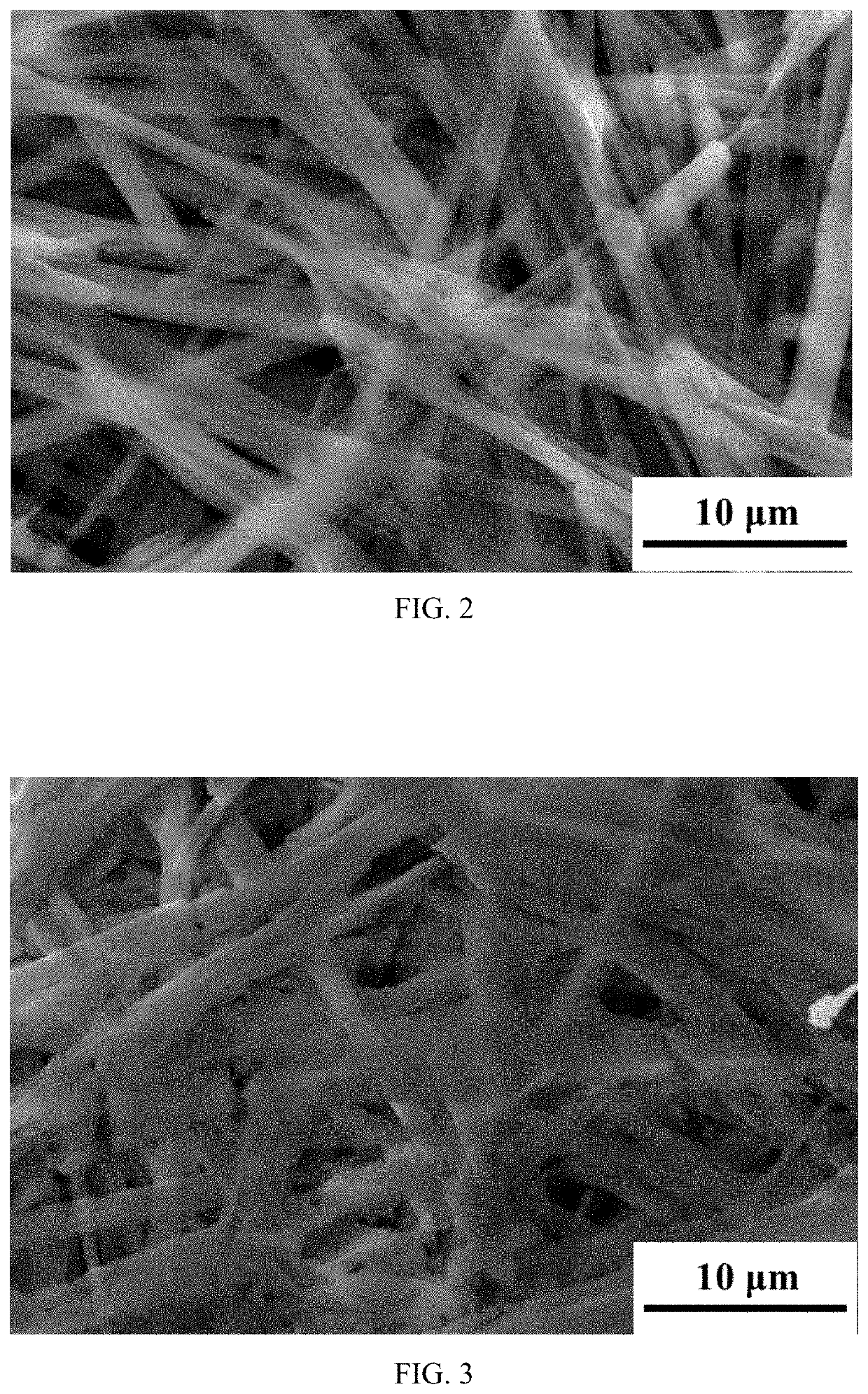

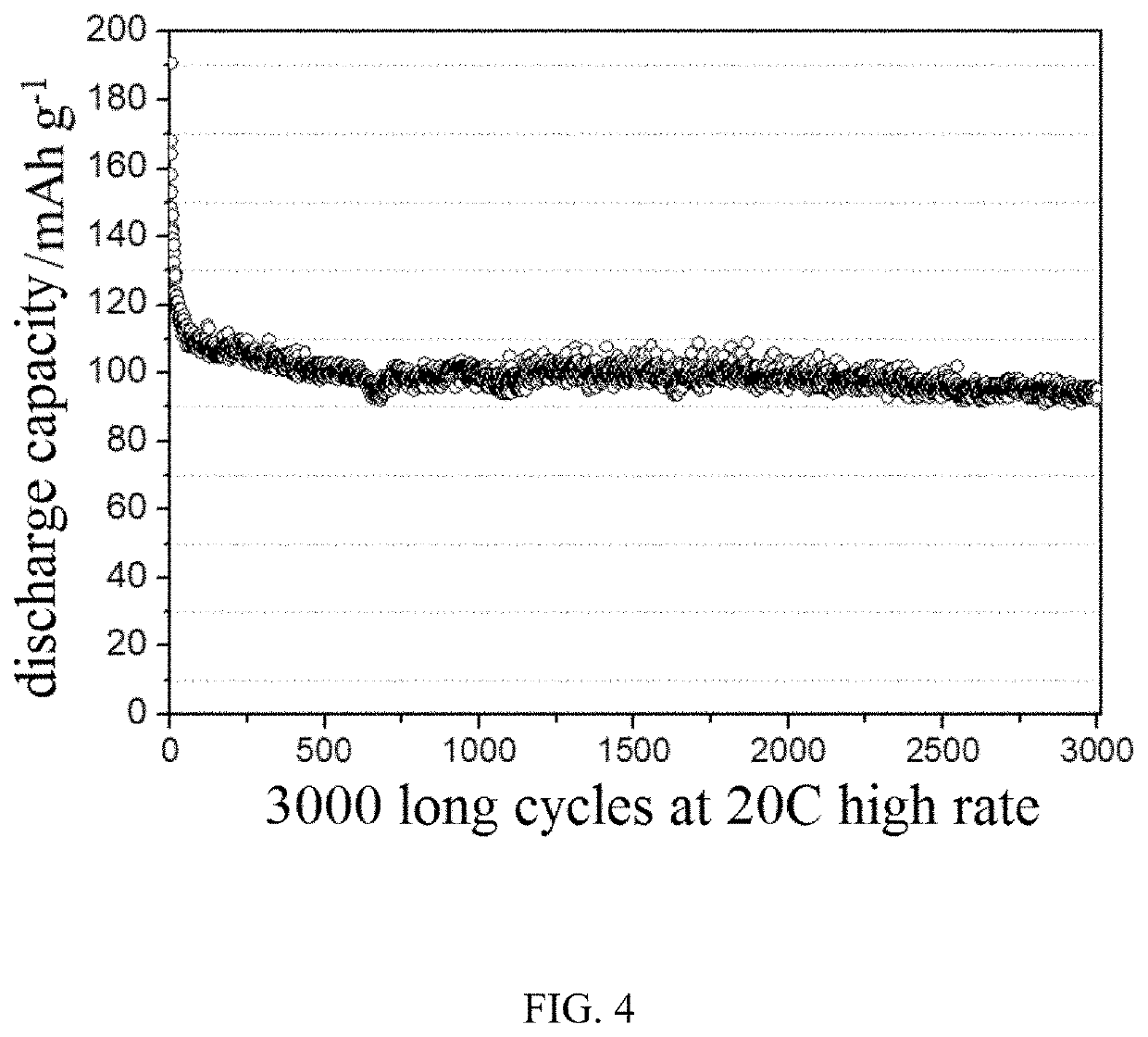

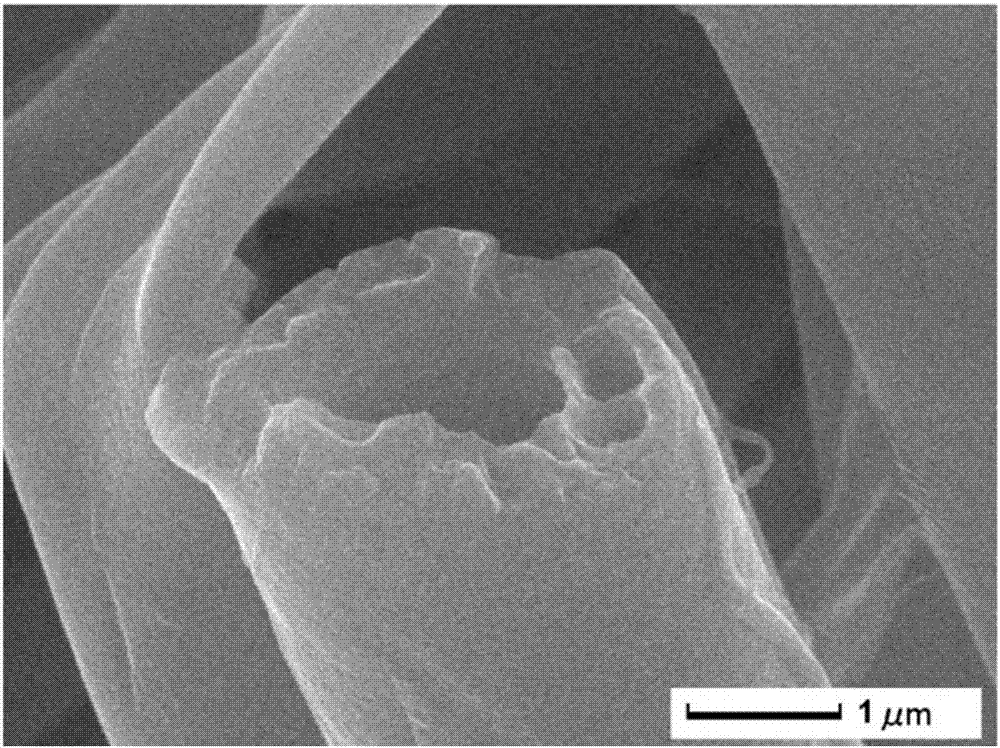

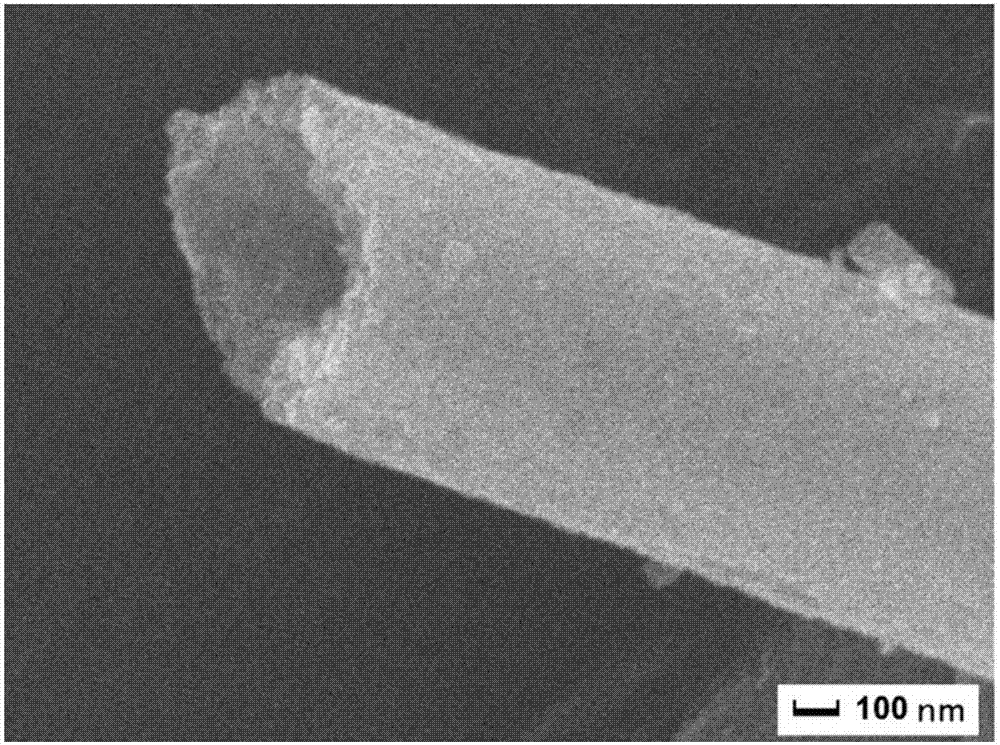

ActiveCN109279649BLarge specific surface areaIncrease the active siteMaterial nanotechnologyAlkali titanatesNanowireLithium hydroxide

The invention provides a preparation method of nanotube hierarchical structure lithium titanate, application and products thereof. The preparation method of nanotube hierarchical structure lithium titanate comprises the following steps: S1, dispersing the titanium source in an aqueous hydrogen peroxide solution containing lithium hydroxide, and stirring to obtain a mixed solution; S2, heating and reacting the mixed solution obtained in step S1 to obtain a nanometer Linear structure precursor; S3, separate and dry the nanowire structure precursor obtained in step S2; S4, perform low temperature annealing treatment on the separated and dried nanowire structure precursor; S5, subject step S4 to low temperature The annealed nanowire-like structure precursor is subjected to hydrothermal reaction to obtain nanotube hierarchical structure lithium titanate. The method of the invention has simple preparation process, easy control of process parameters and easy large-scale industrial production.

Owner:PETROCHINA CO LTD

Manufacture of titanium dioxide structures

PendingCN113490642ALarge specific surface areaLow agglomeration potentialMaterial nanotechnologyAlkali titanatesTitaniumMaterials science

The present invention relates to a method for manufacturing a structure of a titanium compound selected from the group consisting of sheets, wires and tubes. The present invention also relates to intermediate products and structures comprising titanium dioxide obtainable by the method. The invention provides an improved method giving improved yield as well as other advantages.

Owner:蒂奥泰克公司

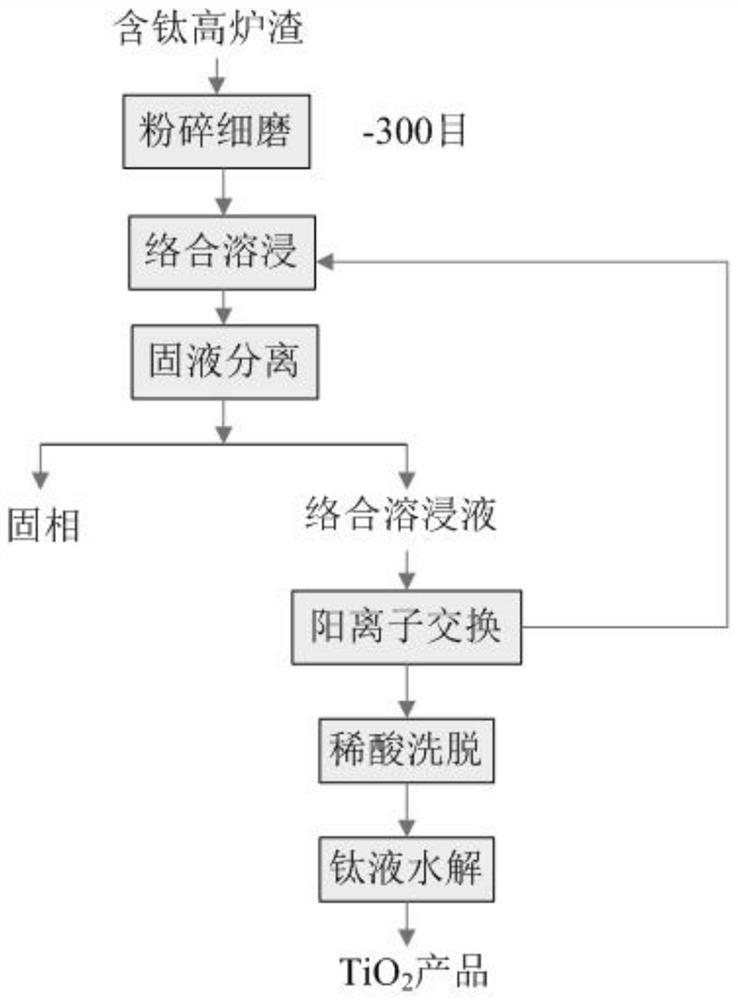

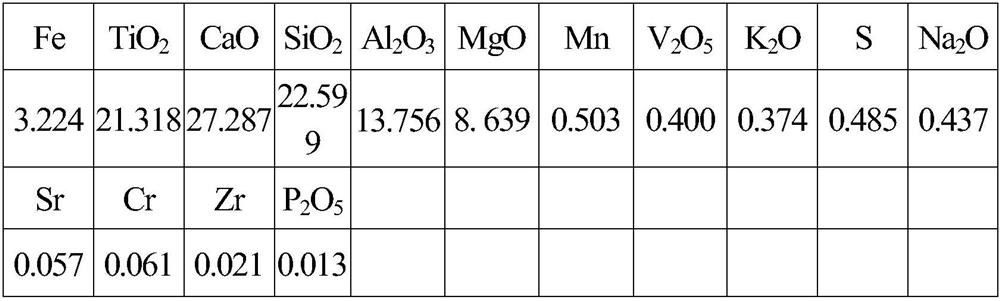

Method for producing titanium dioxide by extracting titanium dioxide from titanium-containing blast furnace slag

ActiveCN111573725BHigh purityCraft briefTitanium dioxideTitanium compounds preparationSlagPhysical chemistry

The invention discloses a method for extracting titanium dioxide from titanium-containing blast furnace slag to produce titanium dioxide, comprising the following steps: A. drying the blast furnace slag and grinding it into powder; B. adding ascorbic acid and sulfuric acid to the blast furnace slag powder and stirring evenly C. solid-liquid separation, and wash the filter cake with ascorbic acid to obtain ascorbic acid complex solution; D. utilize cation exchange resin to absorb titanium ions in the ascorbic acid complex solution; E. elution the cation resin with dilute sulfuric acid, And the eluent is hydrolyzed to obtain titanium dioxide. The present invention aims at the deficiencies of the existing technology for extracting titanium from high-titanium blast furnace slag, combines the idea of leaching gold with sodium cyanide, adopts ascorbic acid complexation to leach blast furnace slag, selectively complexes and leaches titanium in blast furnace slag into the liquid phase, and then Liquid-solid separation, liquid-phase hydrolysis to produce titanium dioxide, and subsequent solid-phase recycling to realize high-value recycling of titanium in blast furnace slag, reduce the environmental burden of blast furnace slag, and promote the unification of economic and social benefits.

Owner:SICHUAN JUNHE ENVIRONMENTAL PROTECTION

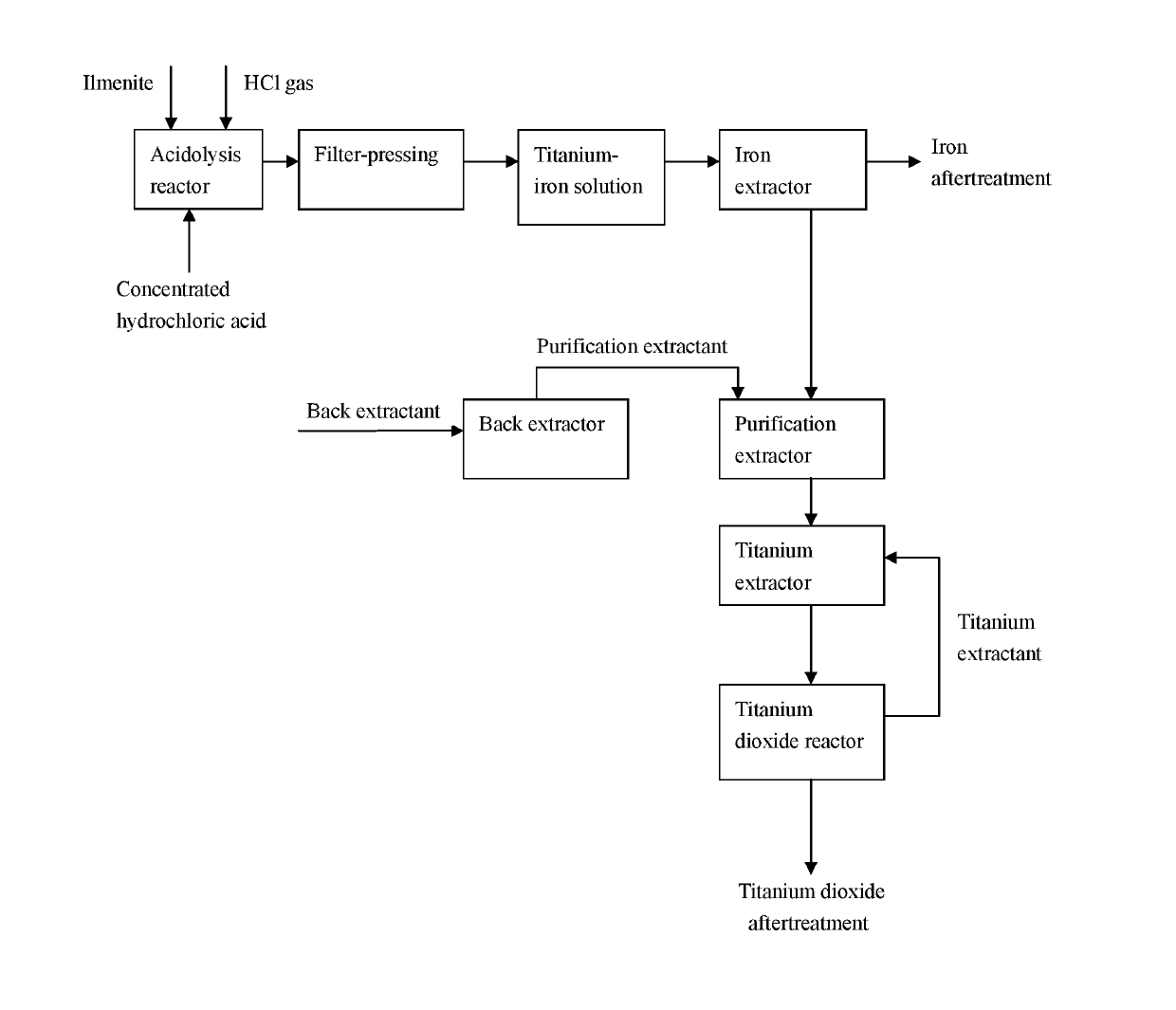

Preparation method for directly synthesizing titanium dioxide from titanium-rich organic phase prepared from ilmenite

ActiveUS10377639B2High yieldHigh dissolution rateIron compounds preparationTitanium dioxideIlmeniteTitanium ion

The present invention relates to a method for directly synthesizing titanium dioxide from a titanium-rich organic phase prepared from ilmenite, and more particularly to a method in which a titanium-rich acidolysis solution is obtained by an efficient ore dissolving technology, titanium ions are transferred to the organic phase by means of an effective titanium extractant to obtain a high-purity and titanium-rich organic phase, and then the titanium dioxide is directly synthesized in the organic phase. With this method, the dissolution rate of ilmenite can be effectively improved, the process flow is shortened and production costs are reduced, and titanium dioxide with high yield and high quality is obtained.

Owner:FUJIAN KUNCAI MATERIAL TECH CO LTD

A new system for separation and purification of hydrophobic eutectic solvent of weak protic acid and method for purifying weak protic acid

ActiveCN111359258BHigh purityHigh yieldIron compounds preparationHydrogen sulfidesChemical industryPhysical chemistry

The invention relates to the technical field of biology and chemical industry, specifically a new system for separation and purification of a hydrophobic deep eutectic solvent and a method for purifying a weak protonic acid. Composition of bond donor and hydrogen bond acceptor and accelerator in deep eutectic solvent; weak protonic acid in raw material solution as hydrogen bond donor; functional group and weak protonic acid existing in deep eutectic solvent hydrogen bond acceptor and accelerator Interaction to form a new hydrophobic deep eutectic solvent separation and purification system with linear, planar or multi-dimensional network structure, which has the advantages of simple process, low energy consumption, high recovery rate, green environmental protection, and less pollution.

Owner:山东金原德丰科技开发有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com