Method for recovering waste lithium titanate negative electrode sheet

A recovery method, lithium titanate technology, applied in the field of recovery of waste lithium titanate negative electrode, can solve the problems of difficult industrialization, high process requirements, large fluctuations in leaching rate, etc., to achieve the reduction of impurity metals, high purity, good The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

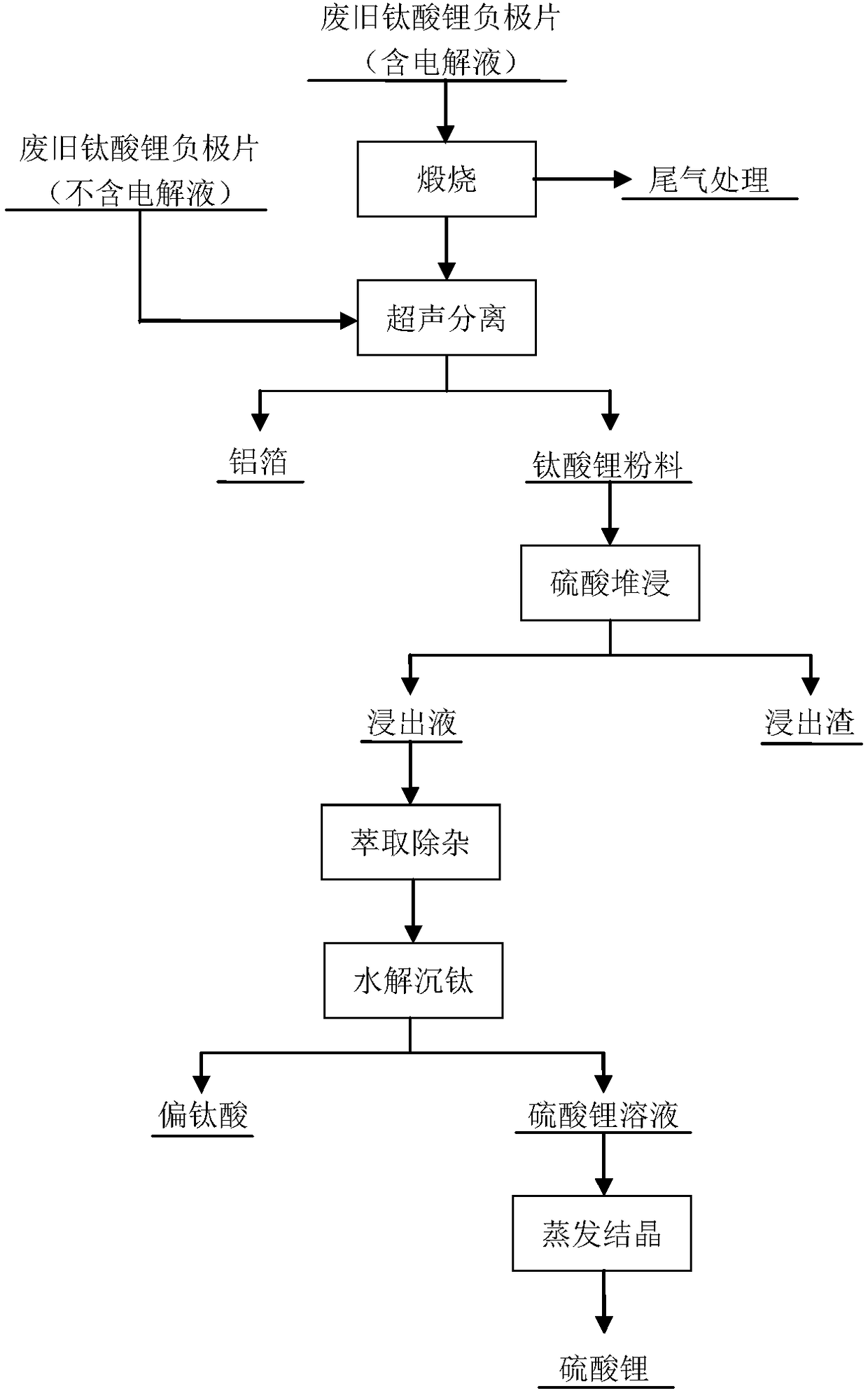

[0028] figure 1 For the flow chart of the recovery method of the waste and old lithium titanate negative plate that the present invention proposes; Refer to figure 1 , a kind of recovery method of waste lithium titanate negative plate that the present invention proposes, comprises the following steps:

[0029] S1. Calcination: Take the waste lithium titanate negative electrode sheet (including electrolyte) directly disassembled from the scrapped liquid-injected battery, put it into a tube furnace under nitrogen protection, and calcinate it at 350°C for 4 hours to obtain titanic acid Lithium negative electrode and tail gas, the tail gas is condensed and liquefied to recover organic matter, and the purified gas is mainly nitrogen, which is the protective gas introduced, and collected and recycled;

[0030] S2. Ultrasonic separation: place the lithium titanate negative plate obtained after calcination in S1 in an ultrasonic oscillator to vibrate and separate, the oscillation fre...

Embodiment 2

[0036] The recovery method of a kind of waste lithium titanate negative plate that the present invention proposes comprises the following steps:

[0037] S1. Calcination: Take the waste lithium titanate negative electrode sheet (including electrolyte) directly disassembled from the scrapped liquid-injected battery, put it into a tube furnace under the protection of helium gas, and calcinate it at 550°C for 2 hours to obtain titanic acid Lithium negative plate and exhaust gas, the exhaust gas is condensed and liquefied to recover organic matter, and the purified gas is mainly the protective gas helium, which is directly discharged;

[0038] S2. Ultrasonic separation: place the lithium titanate negative plate obtained after calcination in S1 in an ultrasonic oscillator to vibrate and separate, the oscillation frequency is 30KHz, and vibrate for 2h, so that the lithium titanate powder is separated from the aluminum foil;

[0039] S3. Sulfuric acid heap leaching: Add concentrated ...

Embodiment 3

[0044] The recovery method of a kind of waste lithium titanate negative plate that the present invention proposes comprises the following steps:

[0045] Take the waste lithium titanate negative plate that has not been injected and place it in an ultrasonic oscillator to vibrate and separate at a frequency of 40KHz for 1 hour to separate the lithium titanate powder from the aluminum foil; Add concentrated sulfuric acid at a mass ratio of 1:2, stir evenly, and place it sealed for 24 hours. After the concentrated sulfuric acid completely destroys the lithium titanate crystal lattice, add water. The weight ratio of lithium titanate powder to water is 1:5. Stir at 70°C for 2 hours, filter to obtain leaching residue and leach solution containing lithium and titanium metal; use ammonia water to adjust the pH of the leach solution to 3.5, filter, and use P204 and sulfonated kerosene to prepare the extraction agent for five-stage countercurrent extraction, wherein the saponification ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com