Patents

Literature

40results about How to "Excellent fade resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

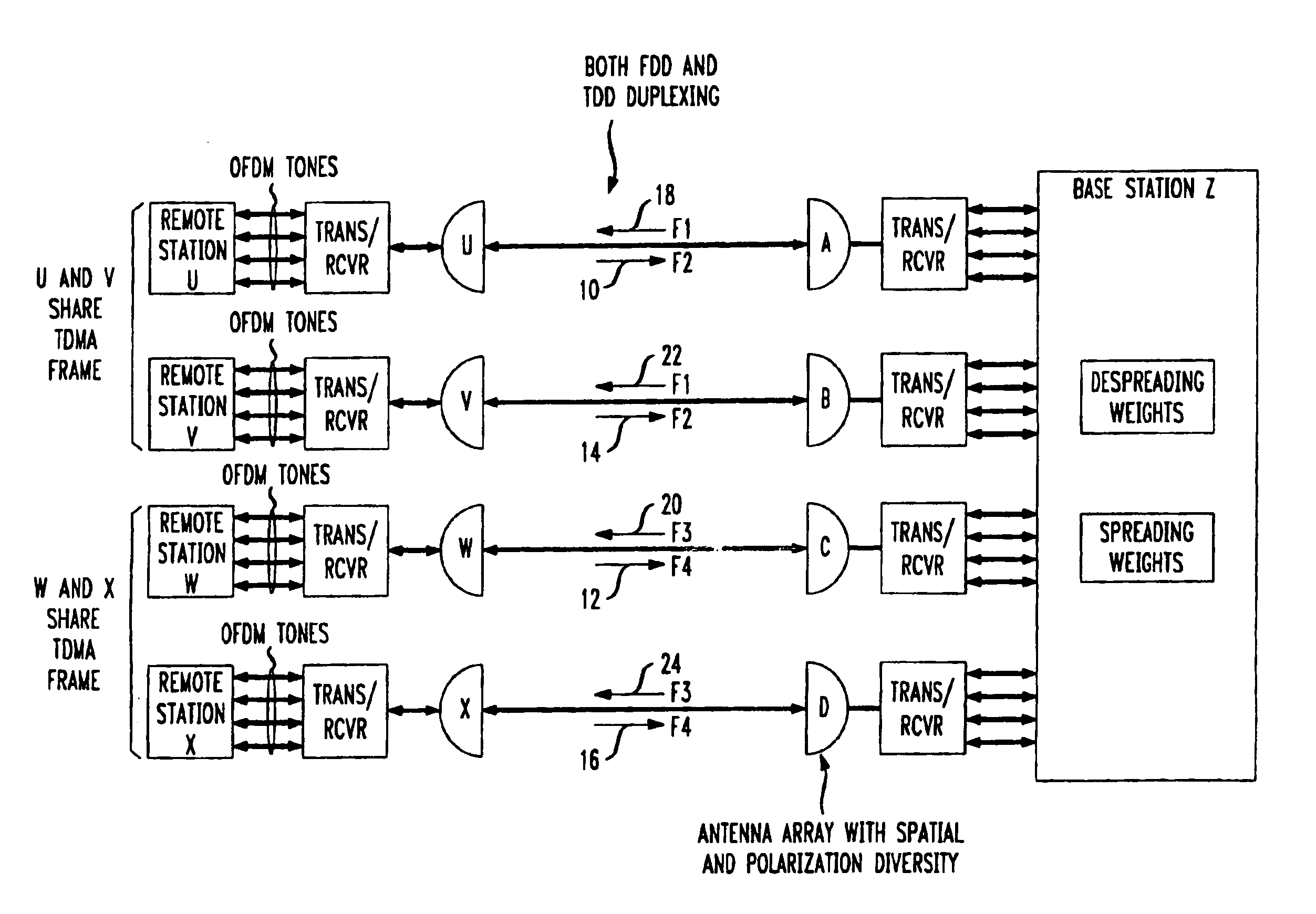

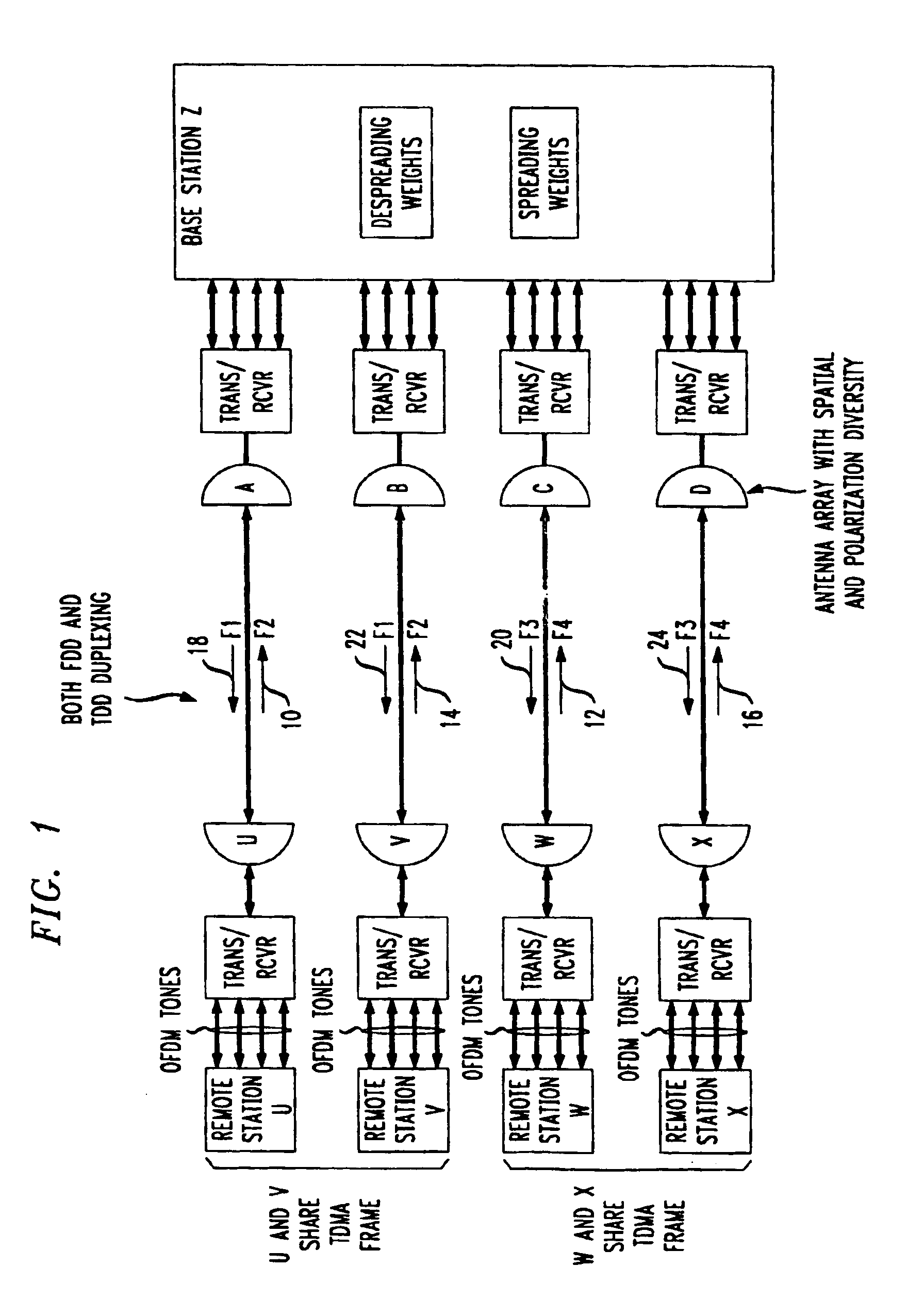

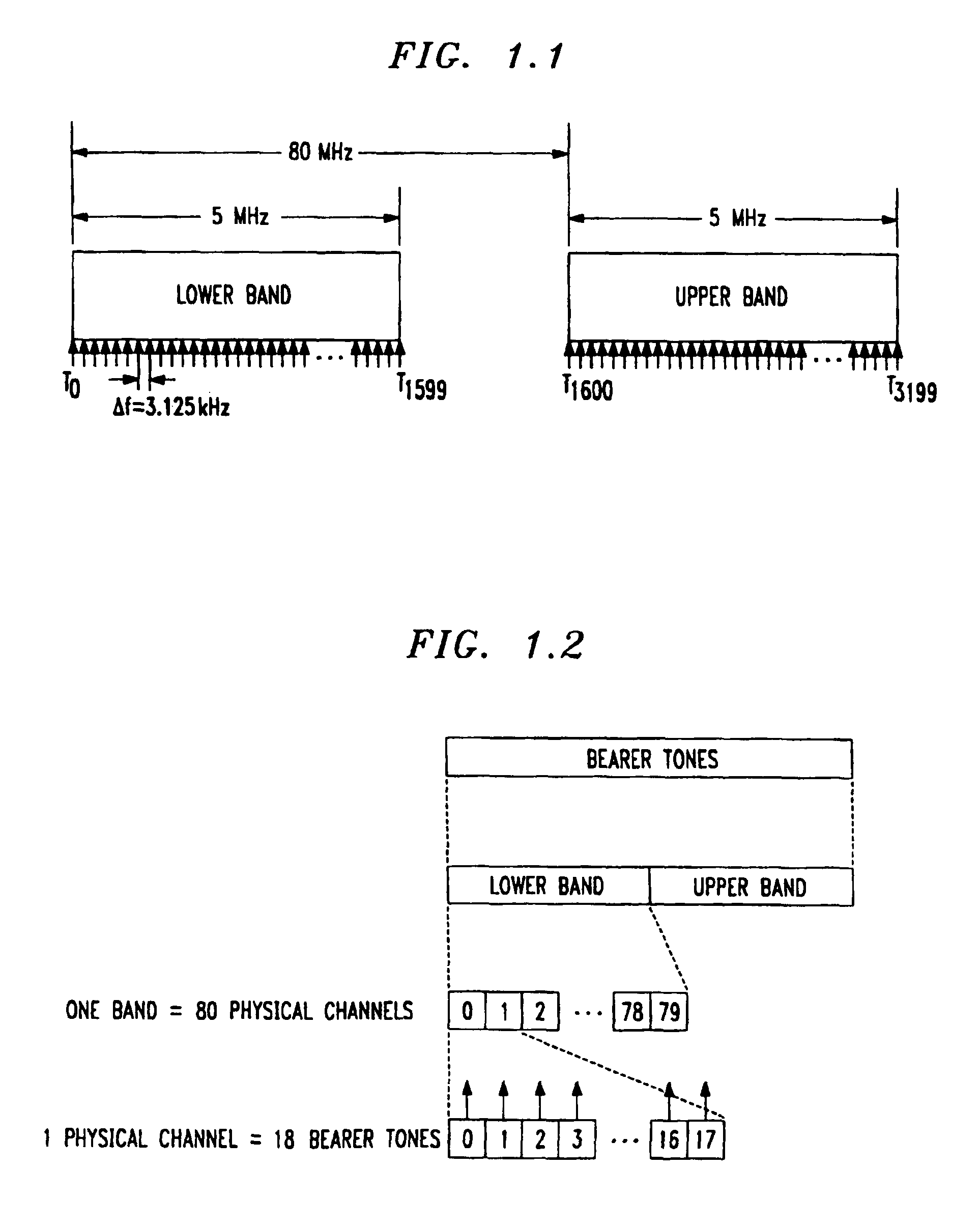

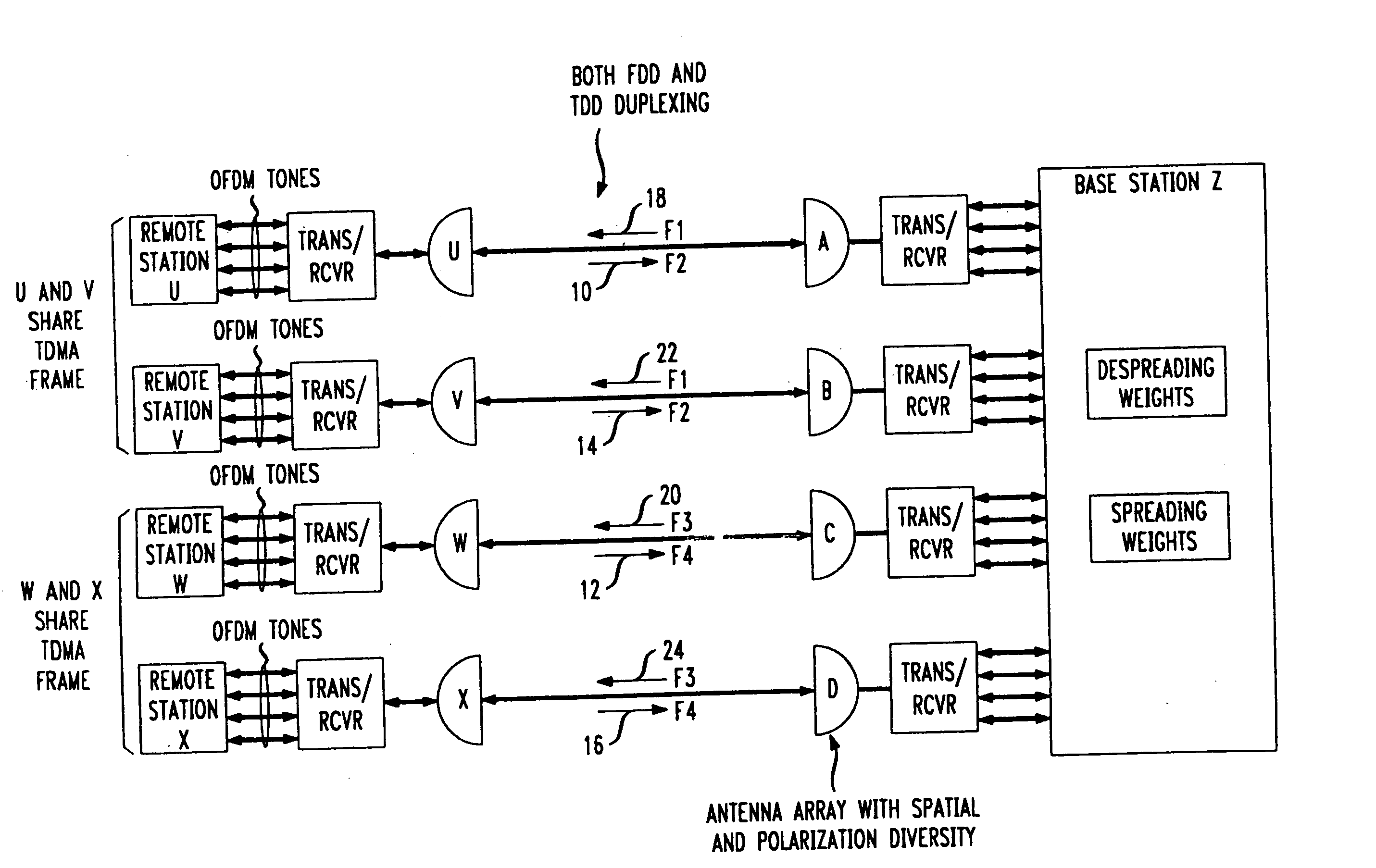

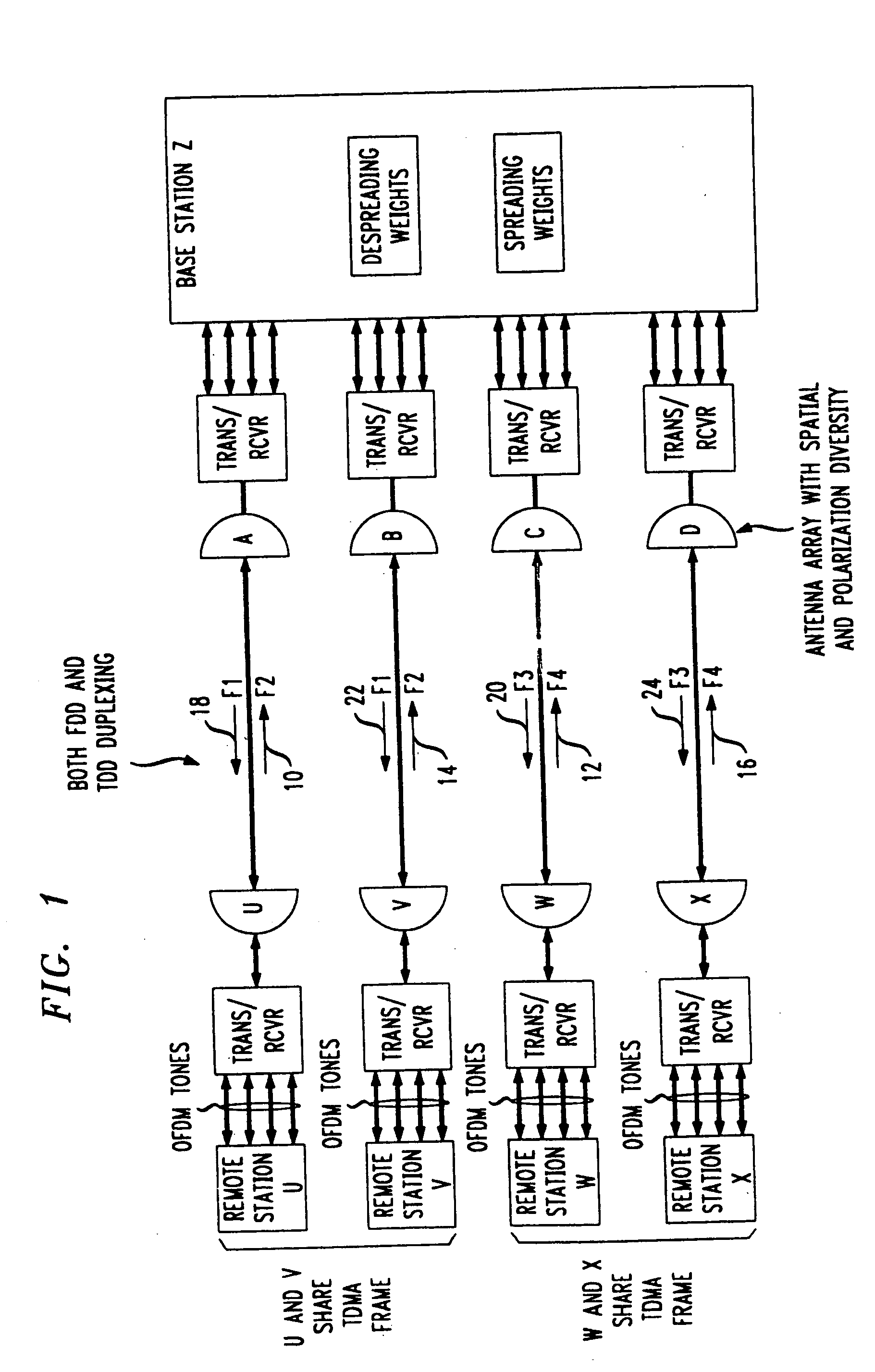

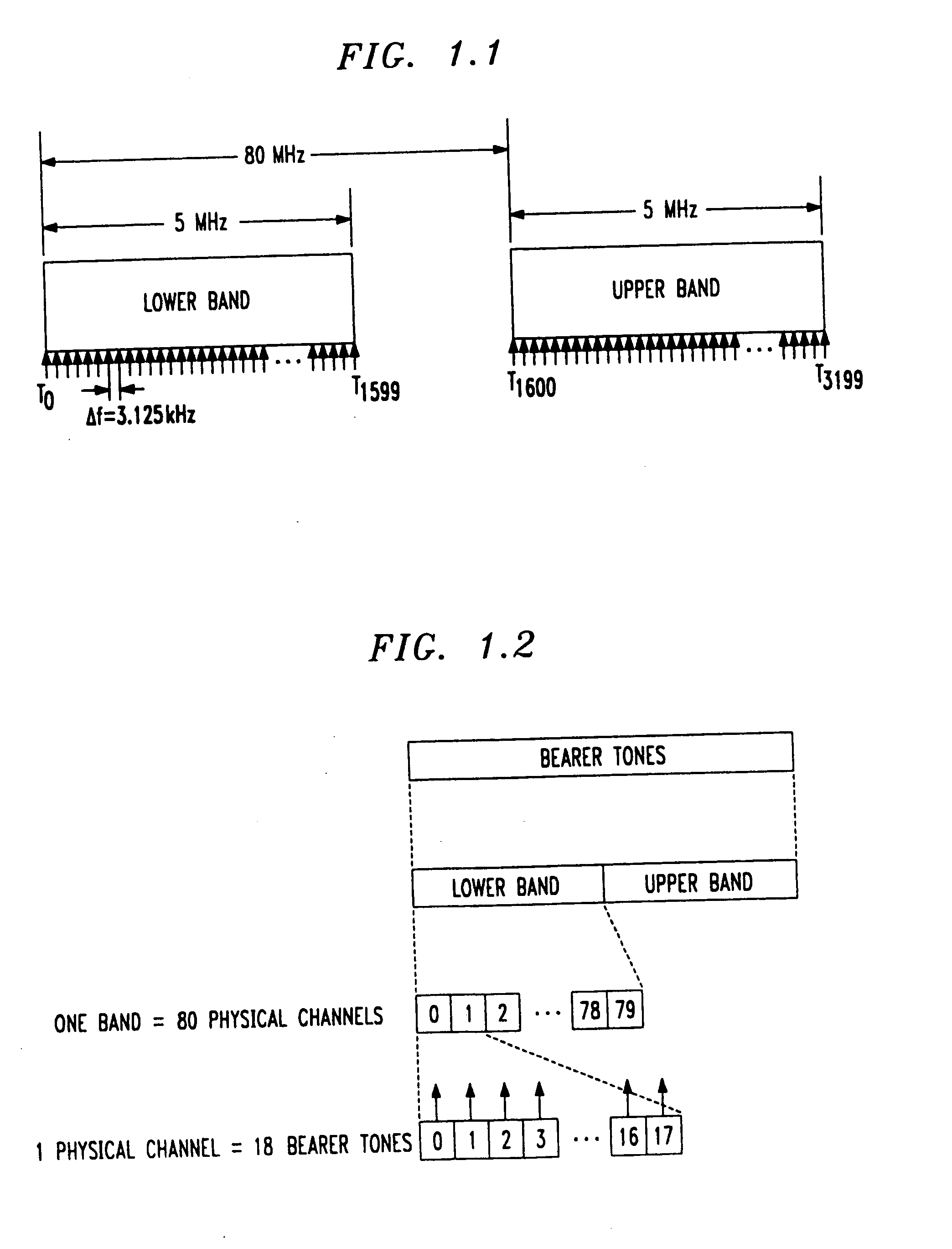

Method for frequency division duplex communications

InactiveUS6853629B2Improve bandwidth efficiencyQuality improvementSpatial transmit diversityModulated-carrier systemsTelecommunicationsPolarization diversity

The high quality PCS communications are enabled in environments where adjacent PCS service bands operate with out-of-band harmonics that would otherwise interfere with the system's operation. The highly bandwidth-efficient communications method combines a form of time division duplex (TDD), frequency division duplex (FDD), time division multiple access (TDMA), orthogonal frequency division multiplexing (OFDM), spatial diversity, and polarization diversity in various unique combinations. The method provides excellent fade resistance. The method enables changing a user's available bandwidth on demand by assigning additional TDMA slots during the user's session.

Owner:AT&T MOBILITY II LLC

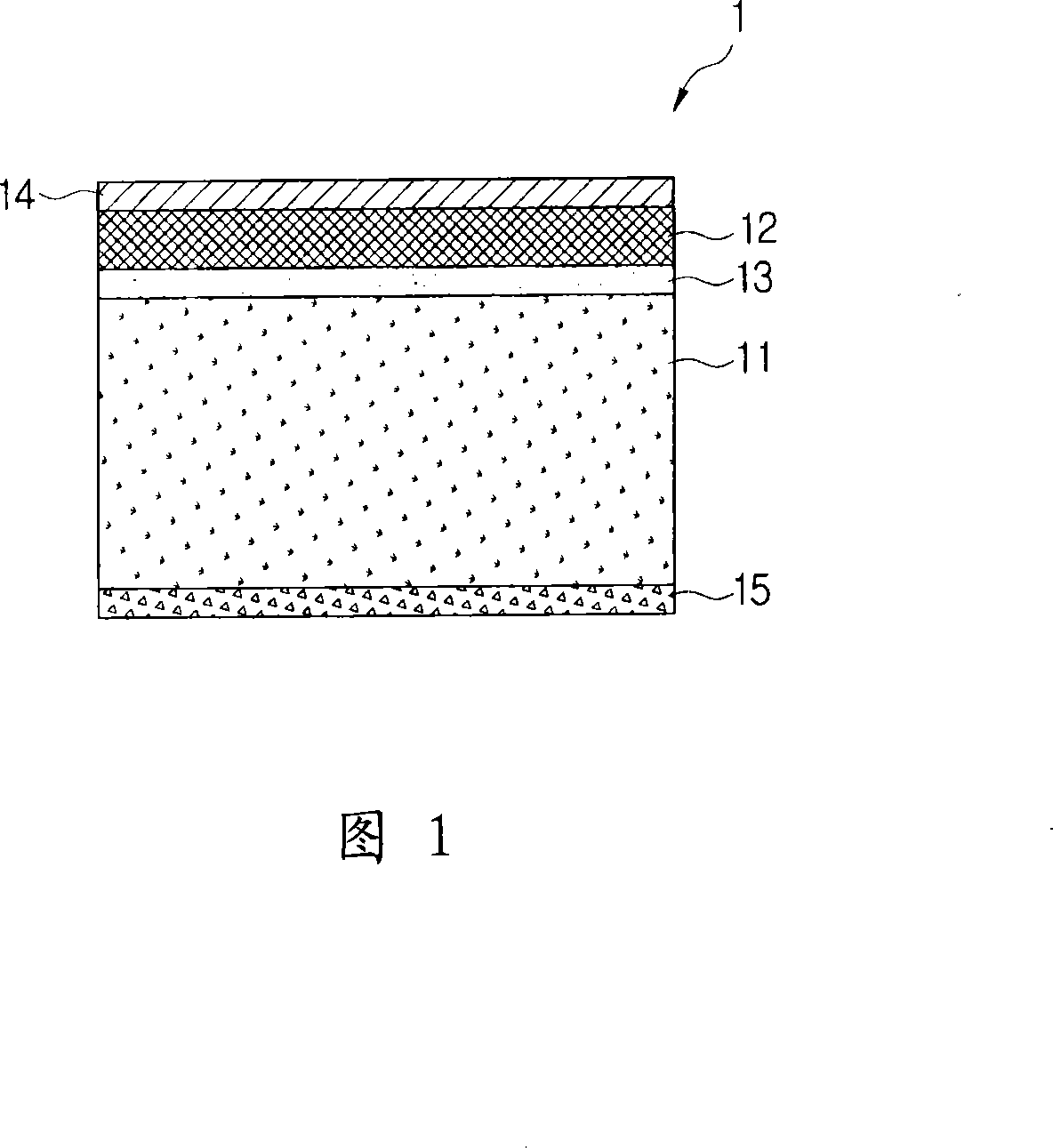

Concrete structure heavy-duty nano composite coating and protection method

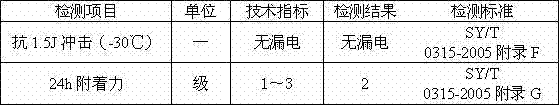

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Method for frequency division duplex communications

InactiveUS20050180349A1Improve bandwidth efficiencyQuality improvementSpatial transmit diversityPolarisation/directional diversityTelecommunicationsTime division multiple access

The high quality PCS communications are enabled in environments where adjacent PCS service bands operate with out-of-band harmonics that would otherwise interfere with the system's operation. The highly bandwidth-efficient communications method combines a form of time division duplex (TDD), frequency division duplex (FDD), time division multiple access (TDMA), orthogonal frequency division multiplexing (OFDM), spatial diversity, and polarization diversity in various unique combinations. The method provides excellent fade resistance. The method enables changing a user's available bandwidth on demand by assigning additional TDMA slots during the user's session.

Owner:AT&T MOBILITY II LLC

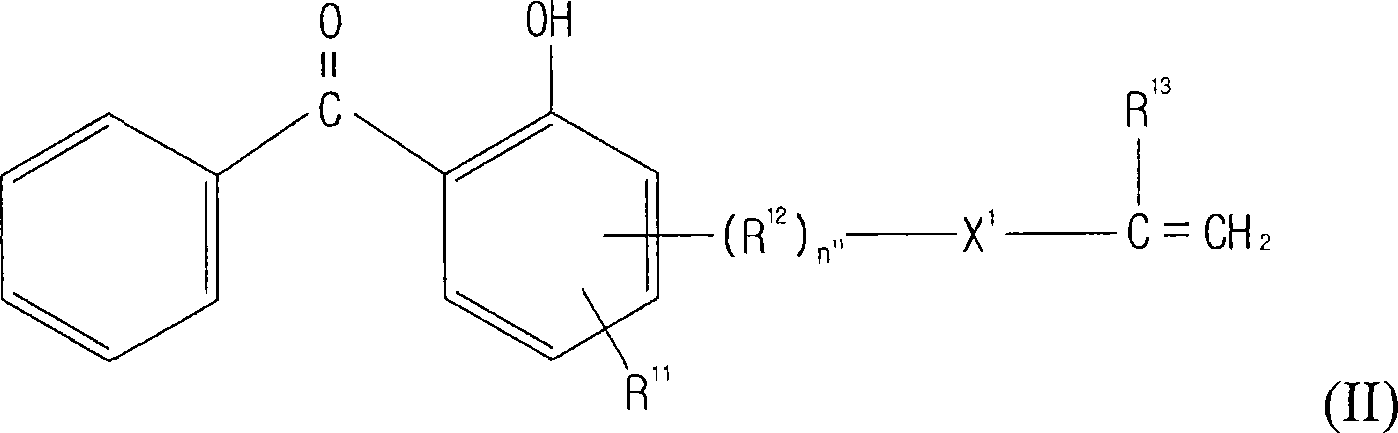

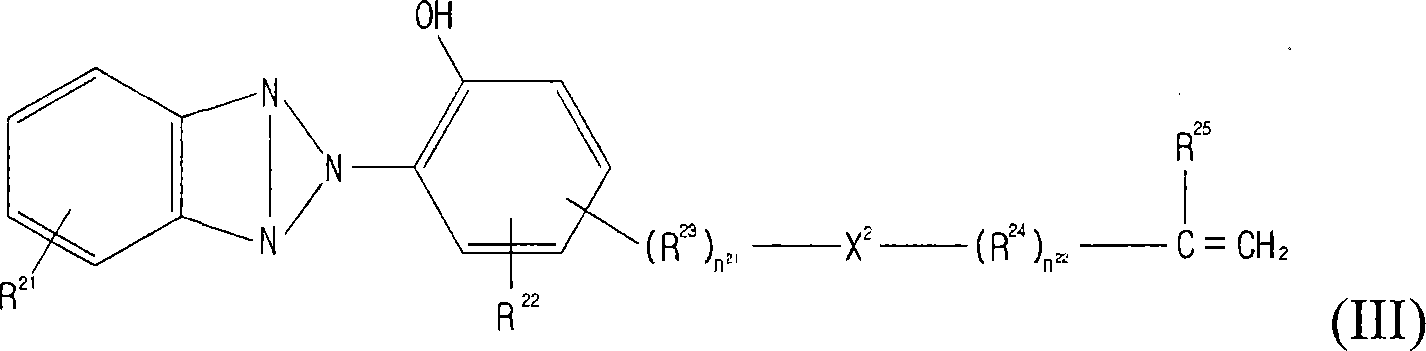

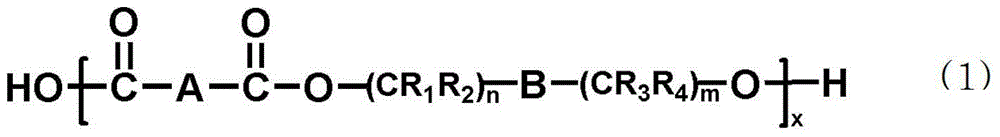

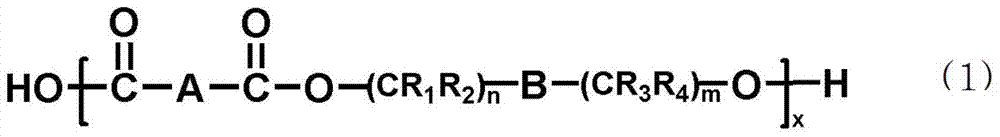

Composition for ink acceptable layer, a recording medium and method for preparing recording medium

InactiveCN101104351AGood light fastnessExcellent fade resistanceNon-fibrous pulp additionDuplicating/marking methodsSolventLightfastness

A composition for an ink acceptable layer has excellent light resistance and discoloration resistance while maintaining improved ink fixation properties and glossiness. A recording medium for an image forming apparatuses using the composition, and a method for preparing the recording medium are also provided. The composition for forming an ink acceptable layer according to an exemplary embodiment includes a fixing agent, an inorganic filler, a binder and a solvent. The fixing agent is a polymeric material containing UV-absorbing constituents.

Owner:SAMSUNG ELECTRONICS CO LTD

Copper-free ceramic friction material and preparation method thereof

InactiveUS20130203888A1Improve thermal conductivityImprove friction performanceNon-woven fabricsFriction liningFiberCarbon fibers

The invention discloses a copper-free ceramic friction material and a preparation method thereof. The friction material at least contains the following materials in mass content: 2-30% of alkaline earth-based metal compound and 2-30% of carbon fiber, wherein the alkaline earth-based metal compound is MxFeyTiOz, M is alkaline earth element Be, Mg, Ca, Sr or Ba, x is 0.2-2, y is 1-2, and z is 4-16. The friction material prepared according to the invention has excellent friction wear performance, high property of heat conductivity and excellent high temperature fading resistance. The temperature on the friction surfaces is effectively reduced during braking.

Owner:LU XIAOHUA +4

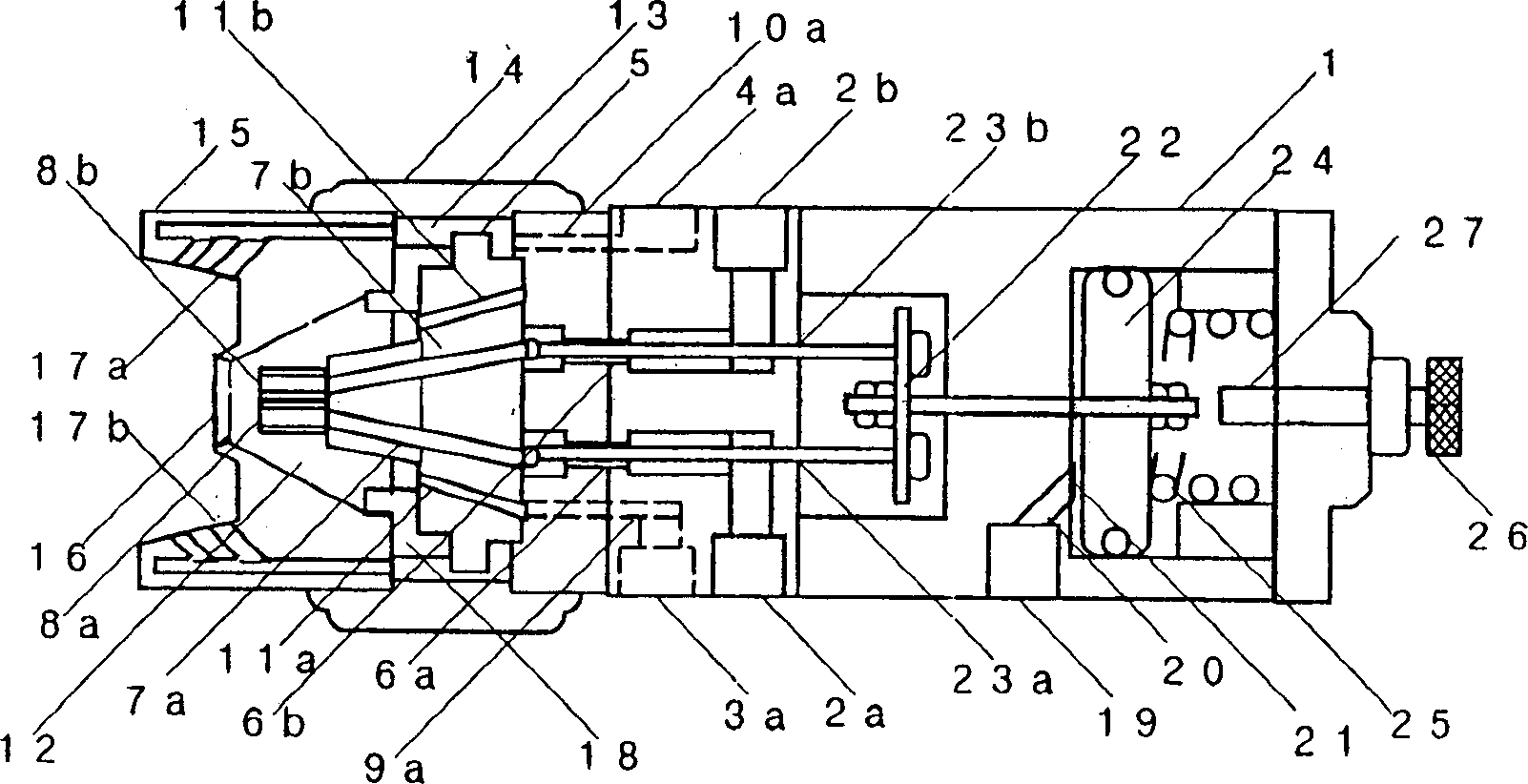

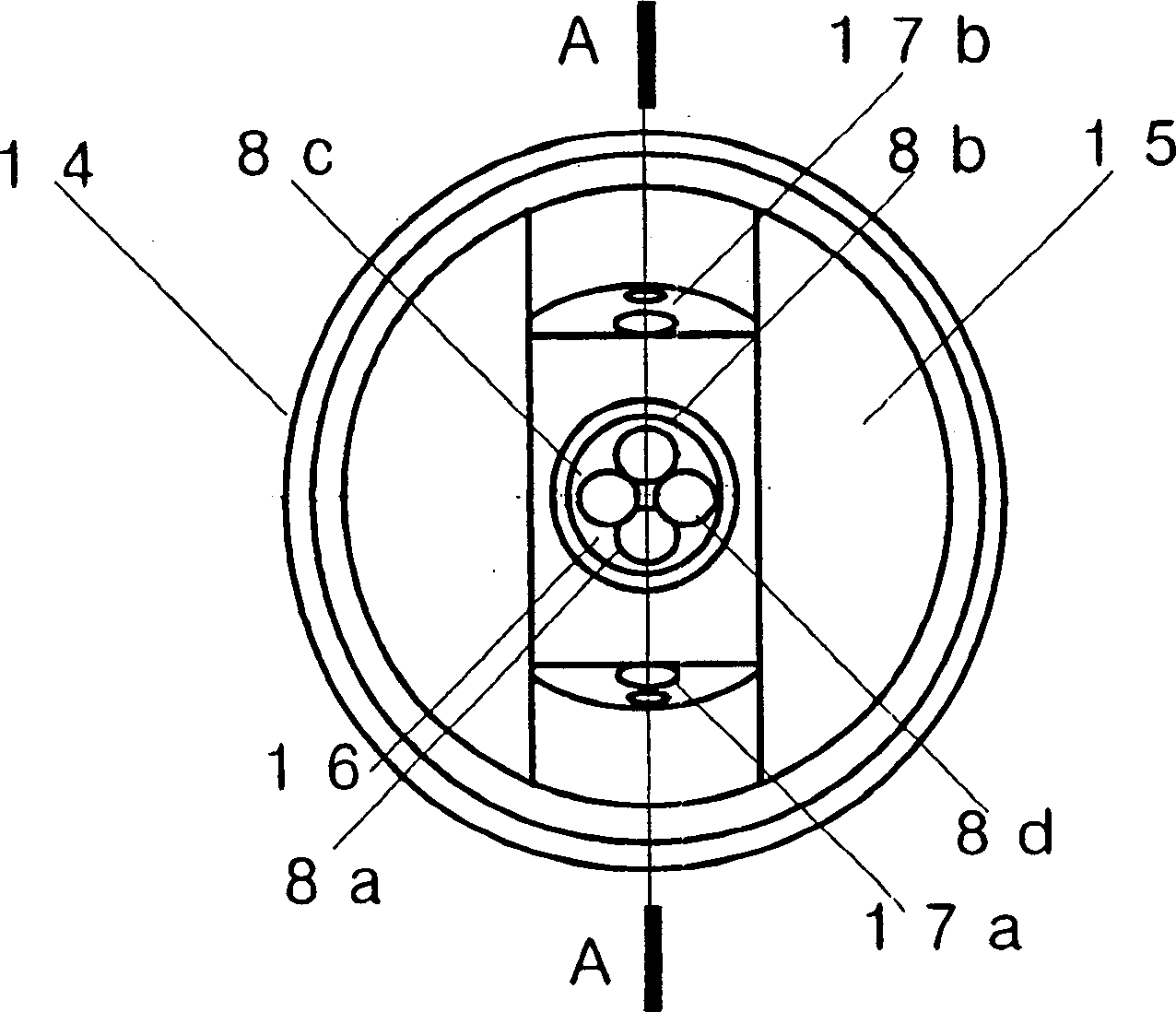

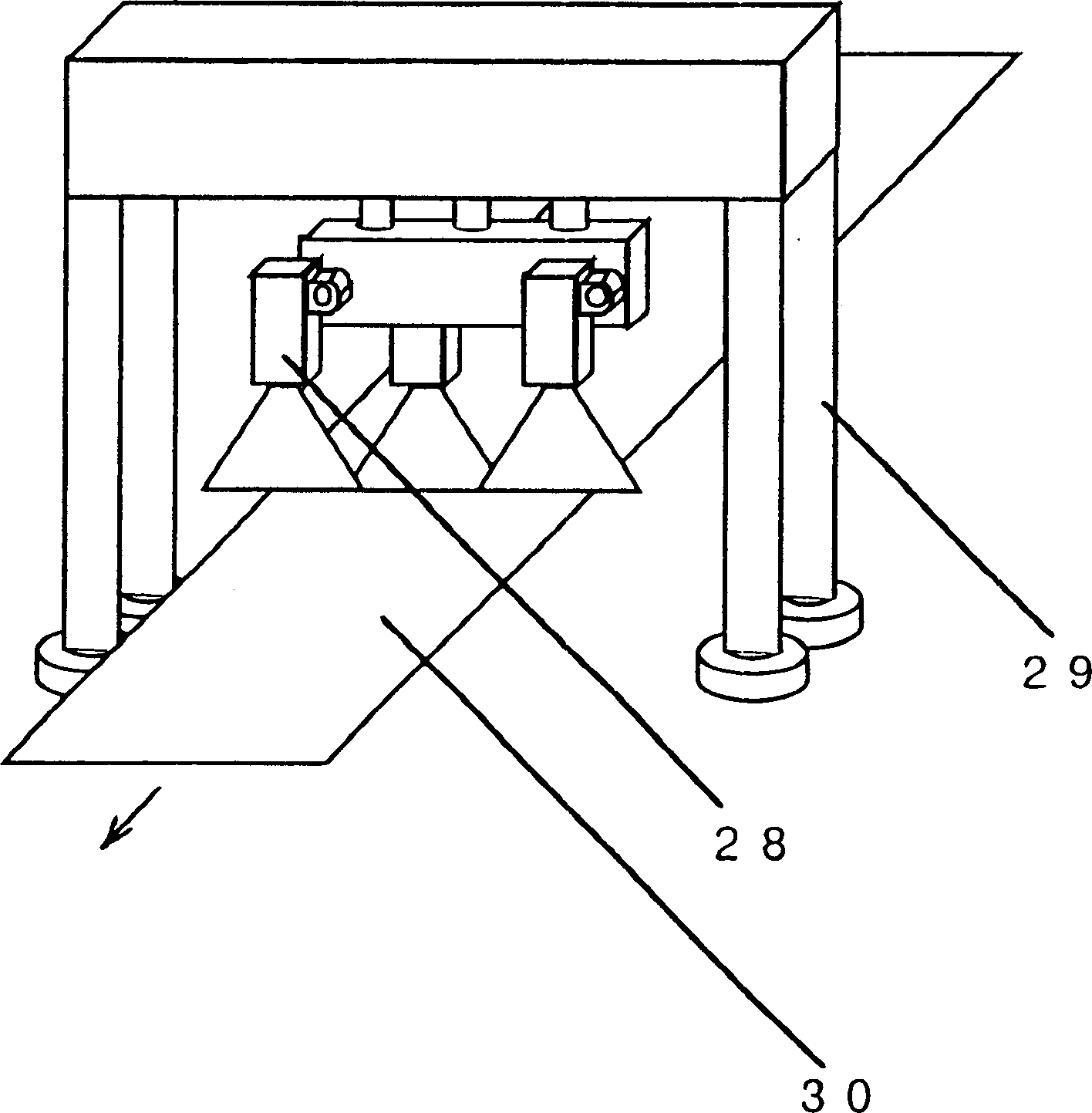

Multi-colour figure film forming method

InactiveCN1394693AImprove pollutionGood weather resistancePretreated surfacesLiquid spraying apparatusChemical compoundMelamine resin

The present invention provides a process for forming a matted multicolor pattern coating film having a 60 degree specular gloss of 10 or less by spray-coating and baking plural coating materials having different colors on a moving strip coated article, wherein the above respective coating materials are shrunk matted coating film-forming coating materials each comprising (A) a hydroxyl group-containing organic resin, (B) a low nuclidic methylated melamine resin, (C) a reaction mixture of 1 mole of a sulfonic acid compound and 1.5 mole or more of an amine compound and (D) a color pigment; and in carrying out spray coating, two or more spray-coating apparatuses having two or more coating material-discharging nozzles are used, and coating materials having coating colors which are different from each other are discharged from at least two coating material-discharging nozzles of the above respective spray-coating apparatuses to form a plural number of unit plural color spray patterns in which the above coating materials having different coating colors are present in a mixture.

Owner:KANSAI PAINT CO LTD

Friction material composition, friction material, and friction member

InactiveUS20170284491A1Excellent fade resistanceImprove wear resistanceOther chemical processesFriction liningCalcium carbonateMagnesium

A friction material composition includes a binder, organic filler, inorganic filler and fiber reinforcement, and does not contain copper or contains copper in an amount of 0.5 mass % or less. The inorganic filler is one or more selected from y alumina having an average particle size of 10 nm to 50 μm, dolomite having an average particle size of 1 to 20 μm, calcium carbonate having an average particle size of 1 to 20 μm, magnesium carbonate having an average particle size of 1 to 20 μm, manganese dioxide having an average particle size of 1 to 20 μm, zinc oxide having an average particle size of 10 nm to 1 μm, magnetite having an average particle size of 1.0 μm or less, cerium oxide having an average particle size of 0.5 to 5 μm, and zirconia having an average particle size of 5 to 50 nm.

Owner:JAPAN BRAKE IND CO LTD

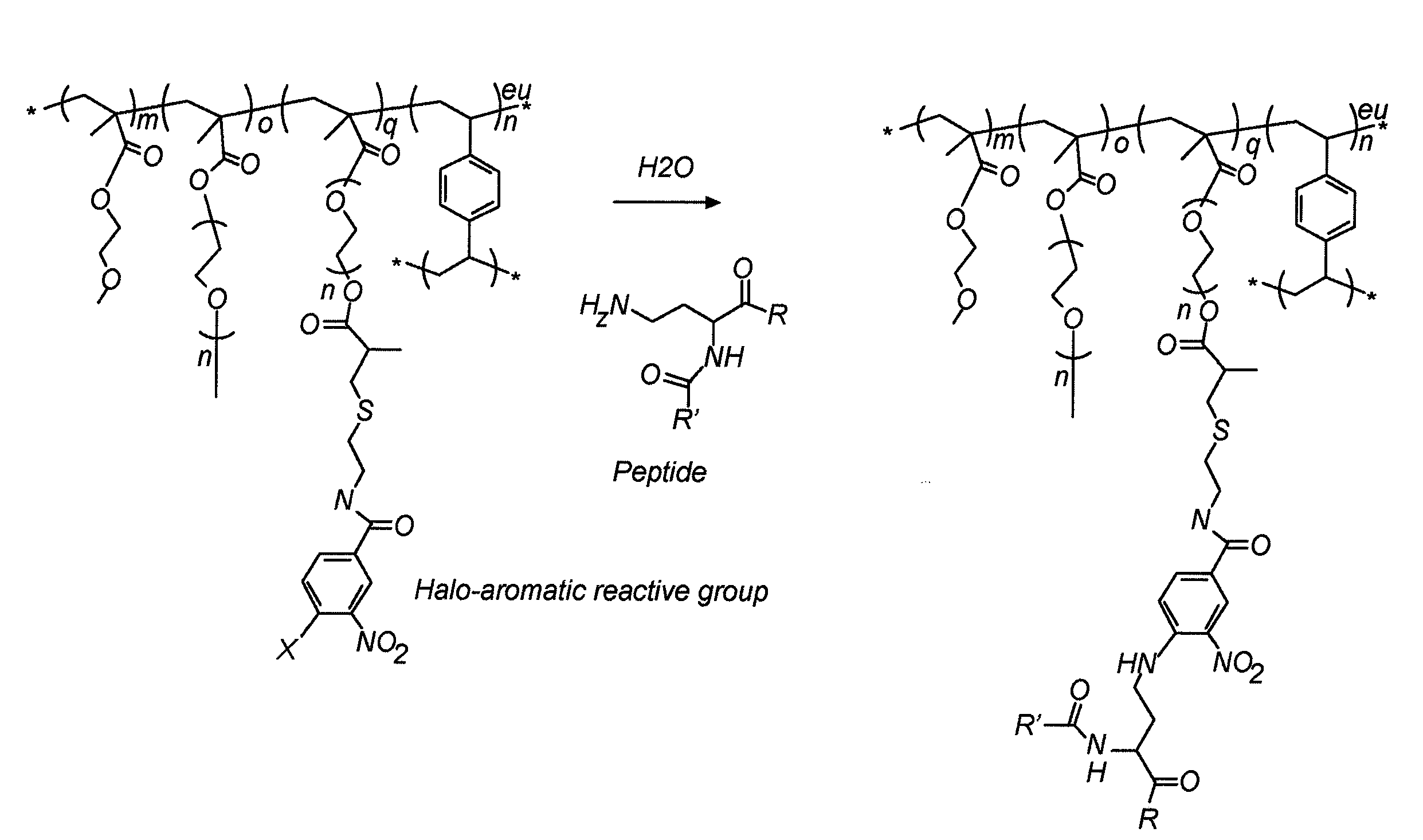

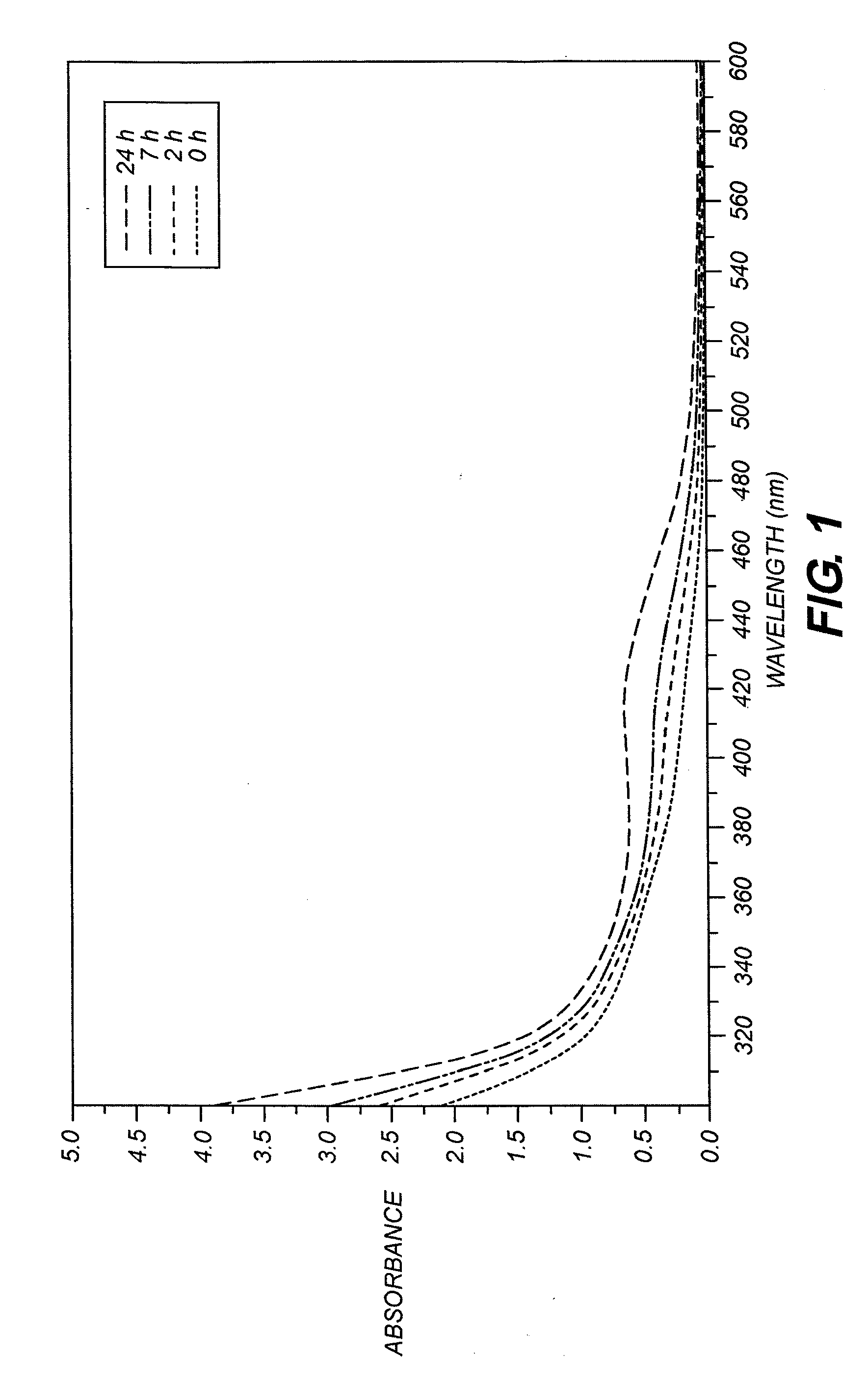

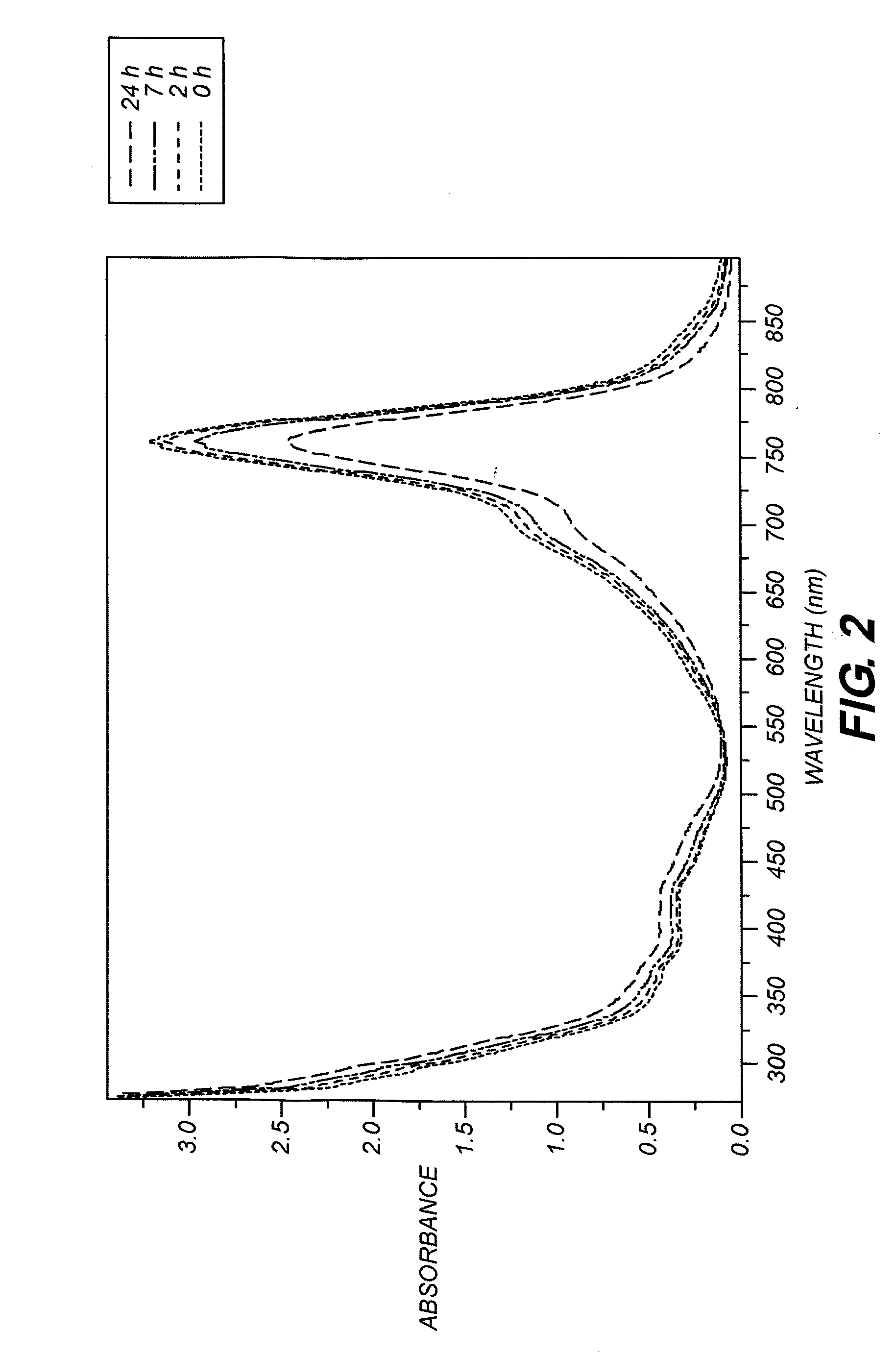

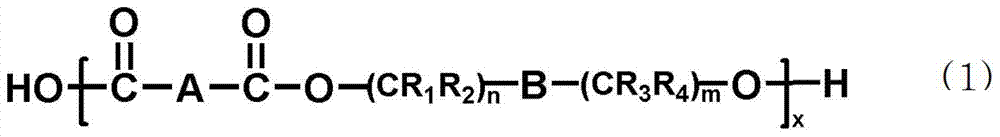

Molecular imaging probes based on loaded reactive nano-scale latex

InactiveUS20100034748A1Good fluorescence propertiesExcellent fade resistancePowder deliveryOrganic chemistryMethacrylateWater insoluble

The present invention relates to a loaded reactive nanoscale latex particle synthesized from mixture of monomers containing water insoluble monomers, at least two ethylenically functionalities monomers, halo-aromatic-polyethyleneglycol-methacrylate, polyethyleneglycolacrylate containing macromonomers, and up to 10 wt % other ethylenic monomers different from above monomers. The reactive halo-aromatic groups on the surface of latex particle are servable as linkers to react with peptides, antibodies, nucleic acids, ligands or other biomolecules.

Owner:CARESTREAM HEALTH INC

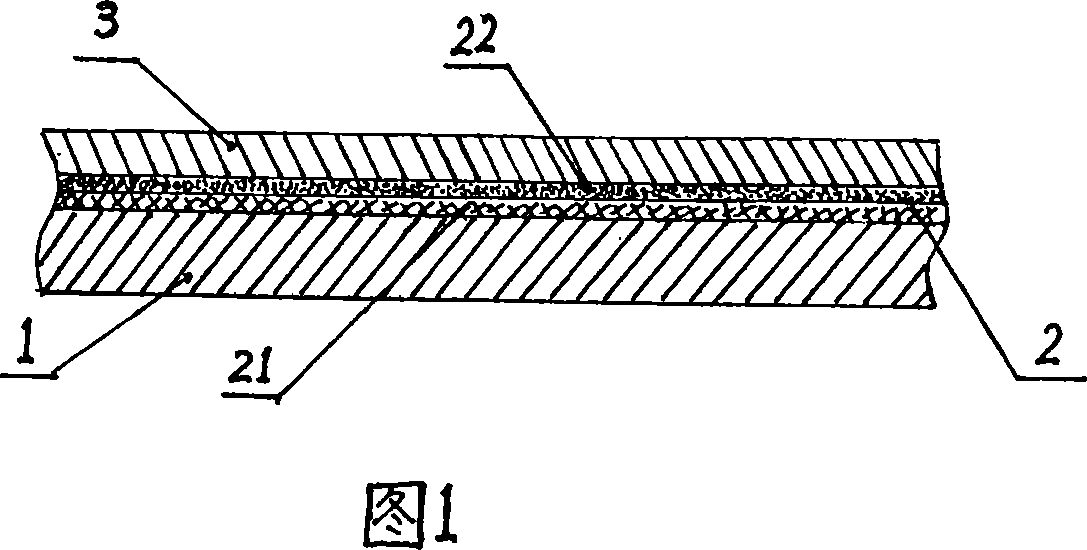

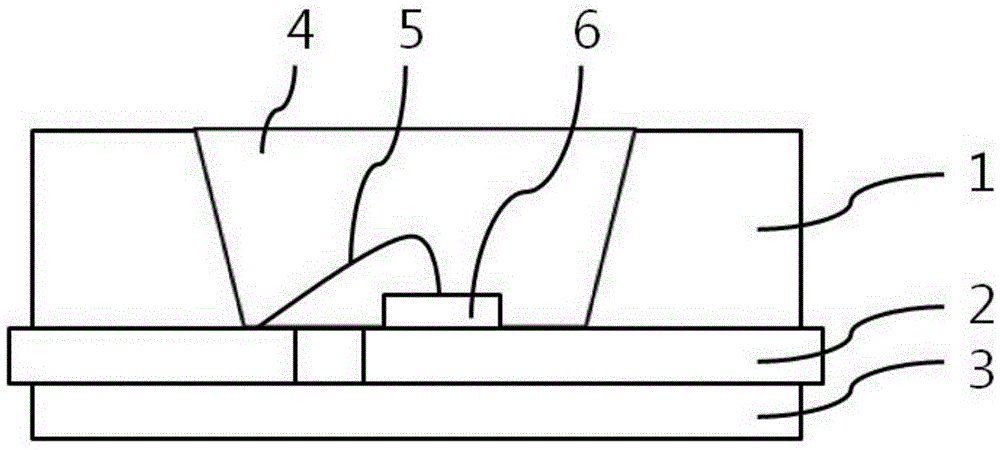

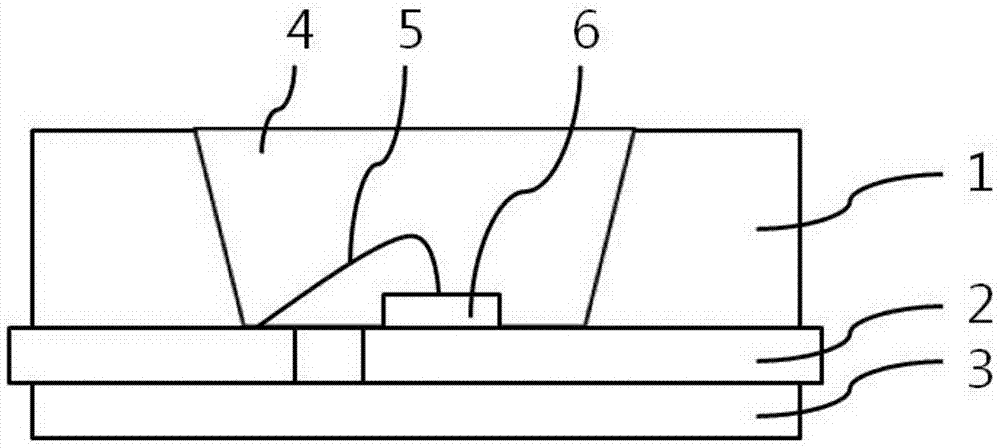

Light reflecting ceramic chip and preparation method thereof

InactiveCN101078200AHigh strengthImprove abrasion resistanceRefuge islandsTraffic signalsBrickThin layer

The invention relates to a reflection porcelain brick and the manufacturing method, characterized in that it comprises porcelain bottom layer (1), reflection refractive layer (2) and transparent face layer (3); the reflection refractive layer (2) is located between the porcelain bottom layer (1) and the transparent face layer (3); the bottom face of reflection refractive layer (2) is connected with the porcelain bottom layer (1) by sintering or bonding; the top face of reflection refractive layer (2) is connected with the bottom face of transparent layer (3) by sintering and bonding. The reflection refractive layer (2) comprises reflection thin layer (21) and refractive thin layer (22). The reflection thin layer (21) is compounded on the top surface of porcelain bottom layer (1) and the refractive thin layer (22) is compounded on the top surface of reflection thin layer (21). The carrier of invention is porcelain, which is provided with higher intensity and good anti-wear ability. And porcelain is the material with anti-aging and discoloration resistance. So the reflection porcelain brick is provided with good weather ability, anti-aging, good discoloration resistance ability and long service life. The invention is especially applied in places with bad circumstance, such as road and station so on where reflection caution is needed. The invention is provided with convenient construction, low cost and wide application range.

Owner:廖志强

Washing machine door special-purpose sealing ring

The invention discloses a washing machine door special-purpose sealing ring. The sealing ring comprises base rubber, a filler and additives. The base rubber comprises an ethylene propylene diene monomer and silica gel compound rubber. The other components comprise white carbon, talcum powder, StronWi TM, high flash point paraffin oil, diethylene glycol, a silane coupling agent, zinc oxide, a mildewproof agent, paraffin wax, black master batches, titanium dioxide, an antiager, an accelerator and a vulcanizing agent. Through combination of the base rubber containing the ethylene propylene diene monomer and silica gel compound rubber and the fillers and additives, the ethylene propylene diene monomer sealing ring has good low / high temperature resistance and aging resistance. Through use of physical inertia of the silica gel compound rubber, smell friendliness of the sealing ring is improved. The sealing ring has the advantages of fine feeling, excellent hot aging resistance and long service life.

Owner:DEZHOU HELIJIA RUBBER & PLASTIC PROD CO LTD

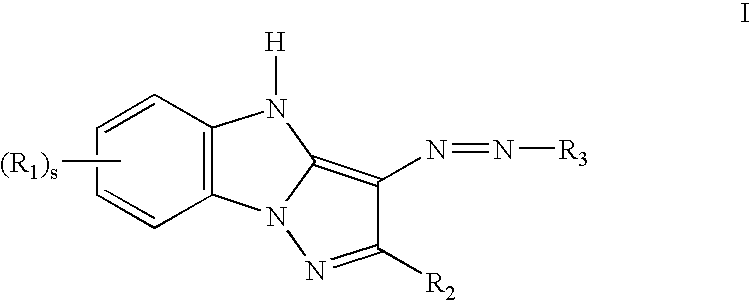

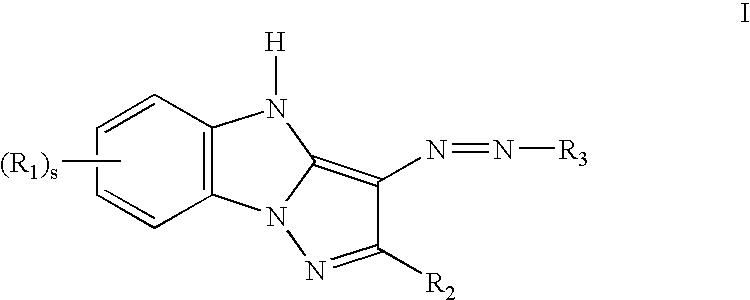

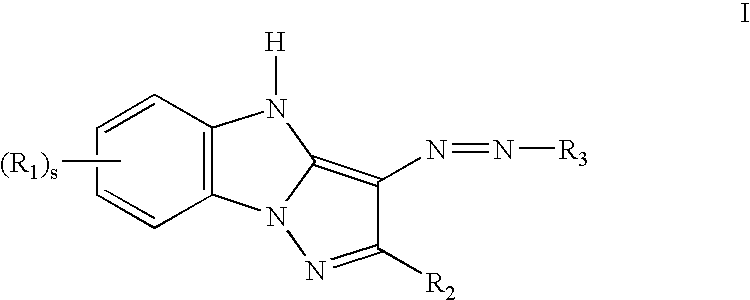

Solubilized dyes for inks

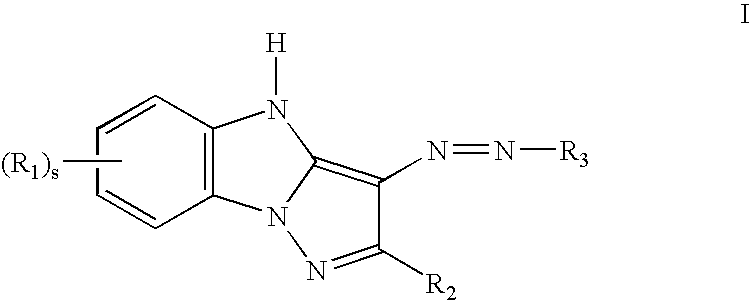

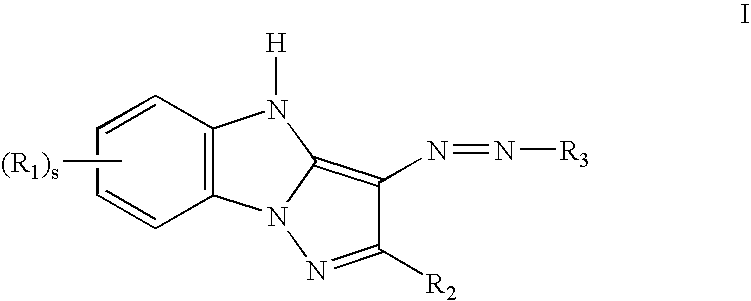

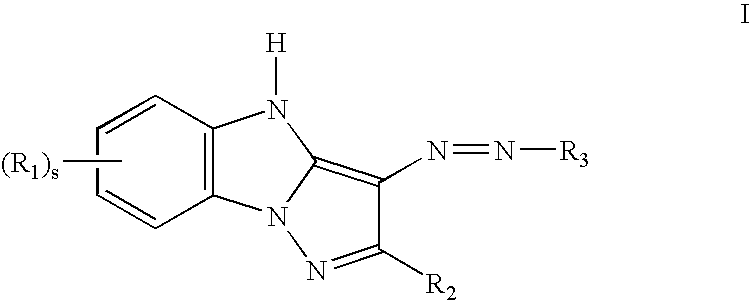

This invention relates to an ink composition comprising a dye represented by Formula I:whereinR1 is independently a non-metallic substituent;s is 0, 1, 2, 3, or 4;R2 is hydrogen or a non-metallic substituent;R3 is a substituted or unsubstituted aromatic or heterocyclic group with the proviso that if R3 is a quinoline moiety, the azo group is not bonded to the 5, 6, 7 or 8 position of the quinoline ring; wherein the dye must bear at least one ionizable group that is capable of imparting water solubility to the dye. It also relates to dyes which comprise a specific subset of the above dyes.

Owner:EASTMAN KODAK CO

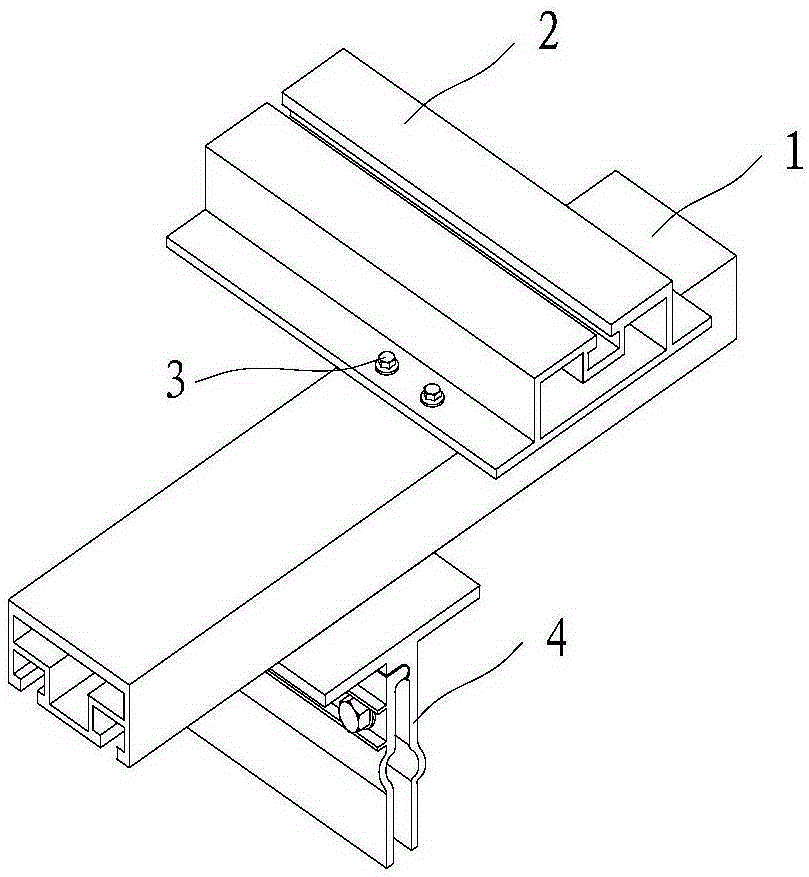

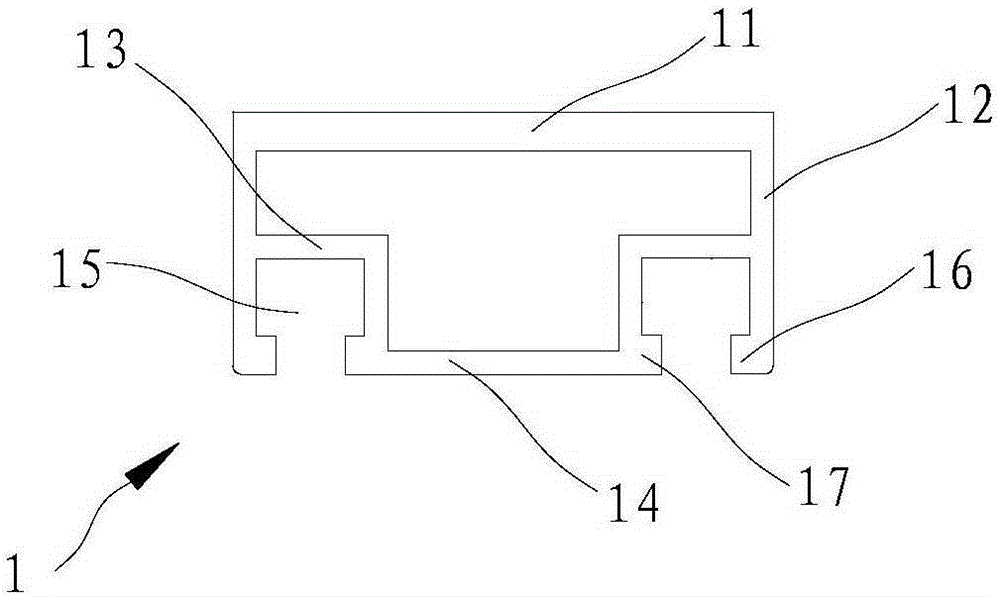

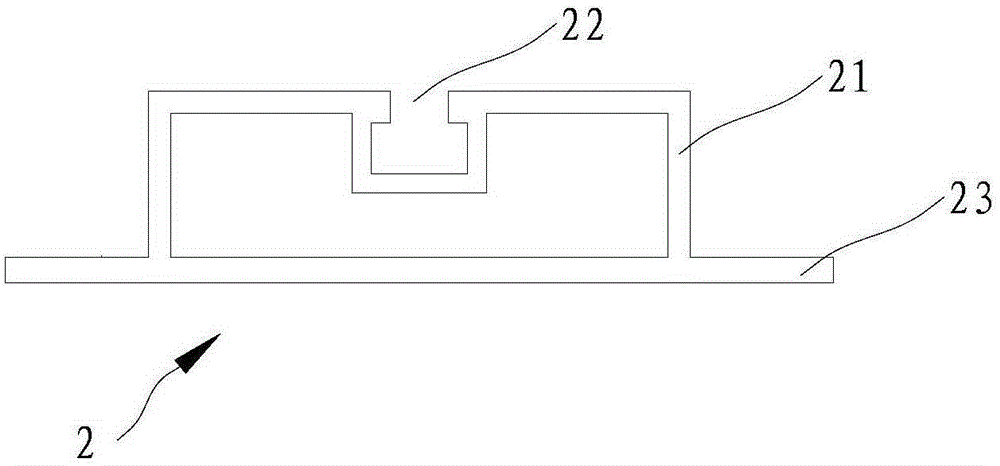

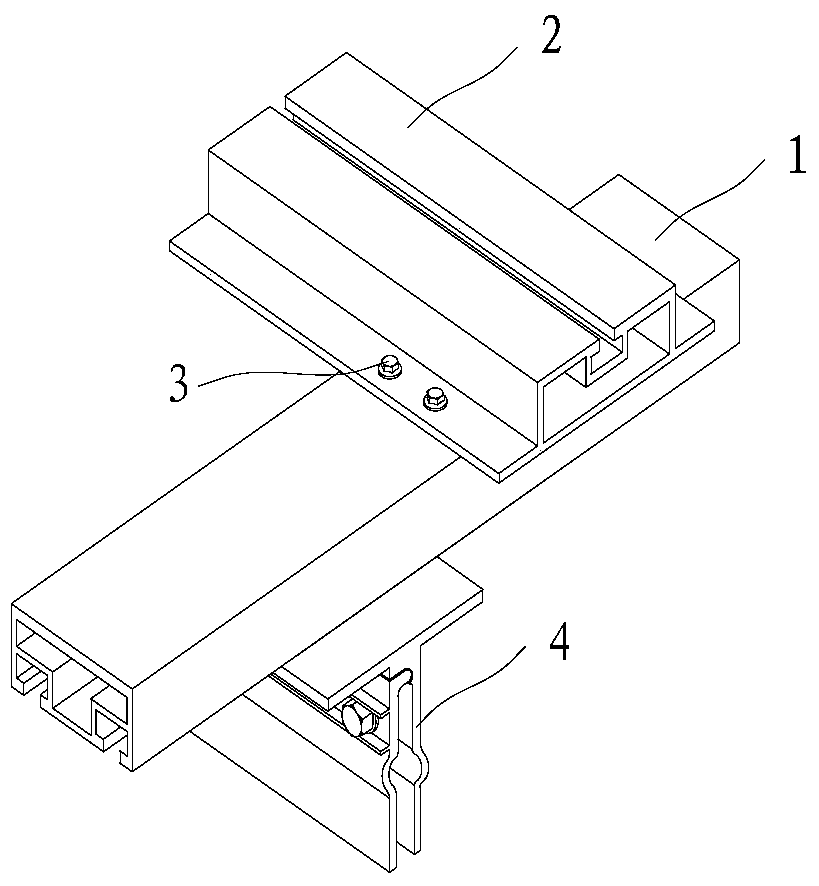

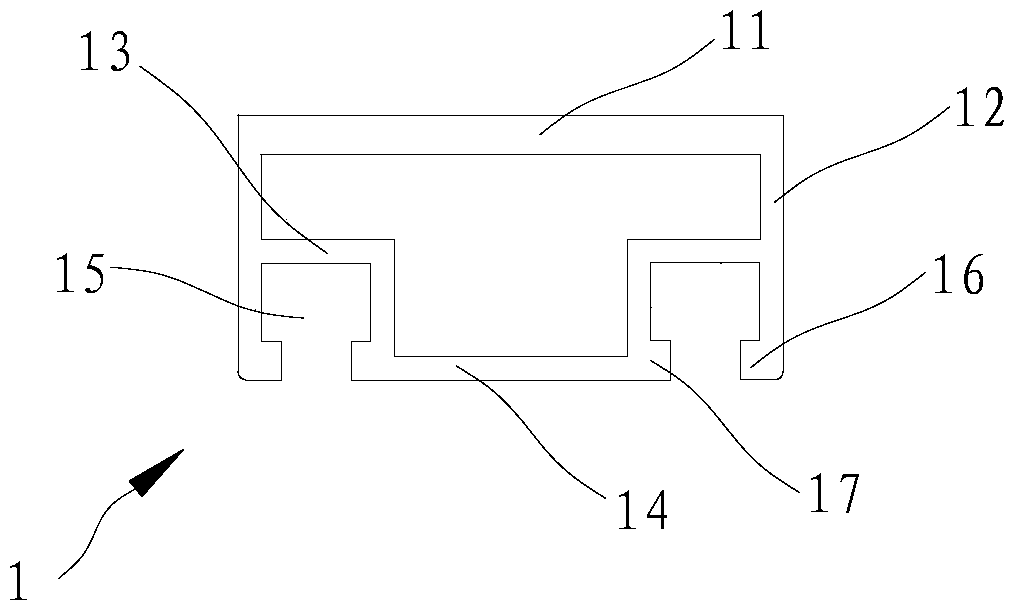

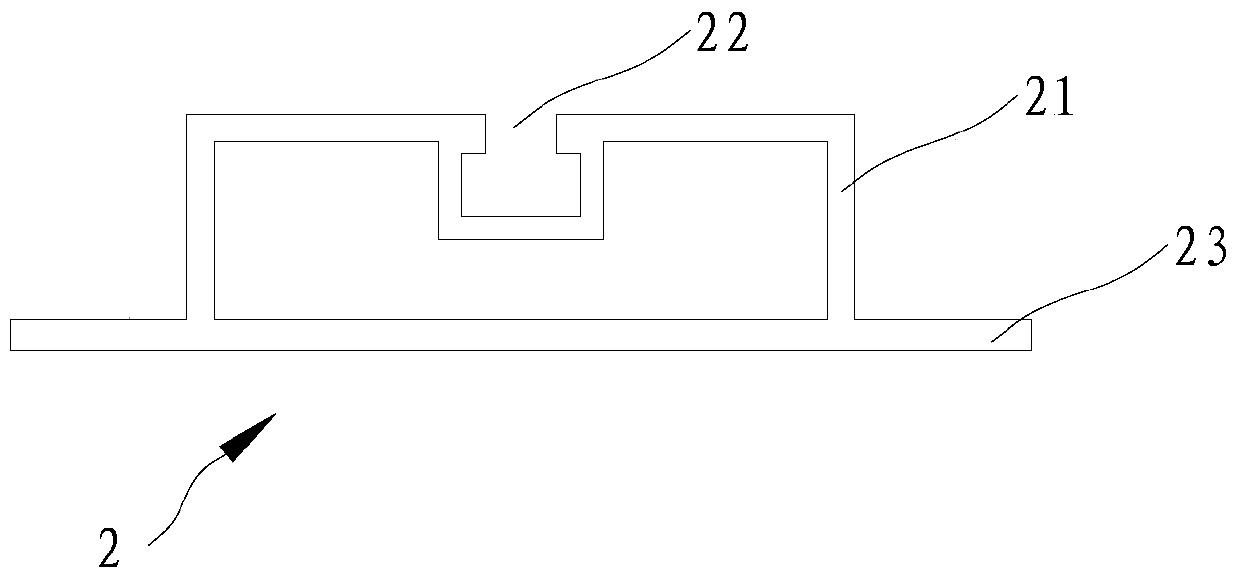

Keel structure and roof system

ActiveCN105155782AGuaranteed stabilityExcellent fade resistanceRoof covering using slabs/sheetsKeel structureEngineering

The invention discloses a keel structure and a roof system. The keel structure comprises a main keel, an auxiliary keel fixedly mounted on the main keel through a first fastening component and a clamp for supporting the main keel, wherein the main keel comprises a horizontal plate and two vertical plates respectively arranged on the two sides of the horizontal plate in parallel, and a groove is jointly enclosed by the horizontal plate and the two vertical plates; the main keel further comprises two circuitous plates which respectively project and extend into the groove from the vertical plates and then are respectively circuitously bent towards the inner side of the groove, and the two circuitous plates are fixedly connected through a connecting plate; first back-hooking parts are arranged at the ends, far from the horizontal plate, of the vertical plates, and second back-hooking parts are arranged at the ends, far from the vertical plates, of the circuitous plates; a mounting groove is jointly enclosed by the vertical plates, the circuitous plates, the first back-hooking parts and the second back-hooking parts; and the clamp is mounted below the main keel. The keel structure is particularly suitable for outer decoration panels made of high-weight materials, such as support stainless steel plates.

Owner:CHINA STATE DECORATION GRP

Wearable and abrasion resistant emulational artistic door with simulative wood grain

InactiveCN1730892AImprove surface propertiesExcellent abrasion and scratch resistanceNatural patternsDecorative surface effectsFiberLacquer

The present invention is one kind of antiwear imitation wooden artistic door. The present invention features the production process including kiln drying treatment of timber, making door frame with timber and high density fiber board, producing sound isolating honeycomb paper material, combining the honeycomb paper material to the frame to form blank, polishing, printing the wooden grains of walnut, bloodwood, cherry, maple, etc. on the blank, and roller coating water thinned primer, ink, transparent primer, transparent primer and scuff resistant transparent surface paint with roll coater on the surface. During the surface painting process, no curing agent, diluent and other harmful material are used, and the surface lacquer film has excellent surface performance, such as excellent antiwear performance, less fading, etc.

Owner:昆明红塔木业有限公司

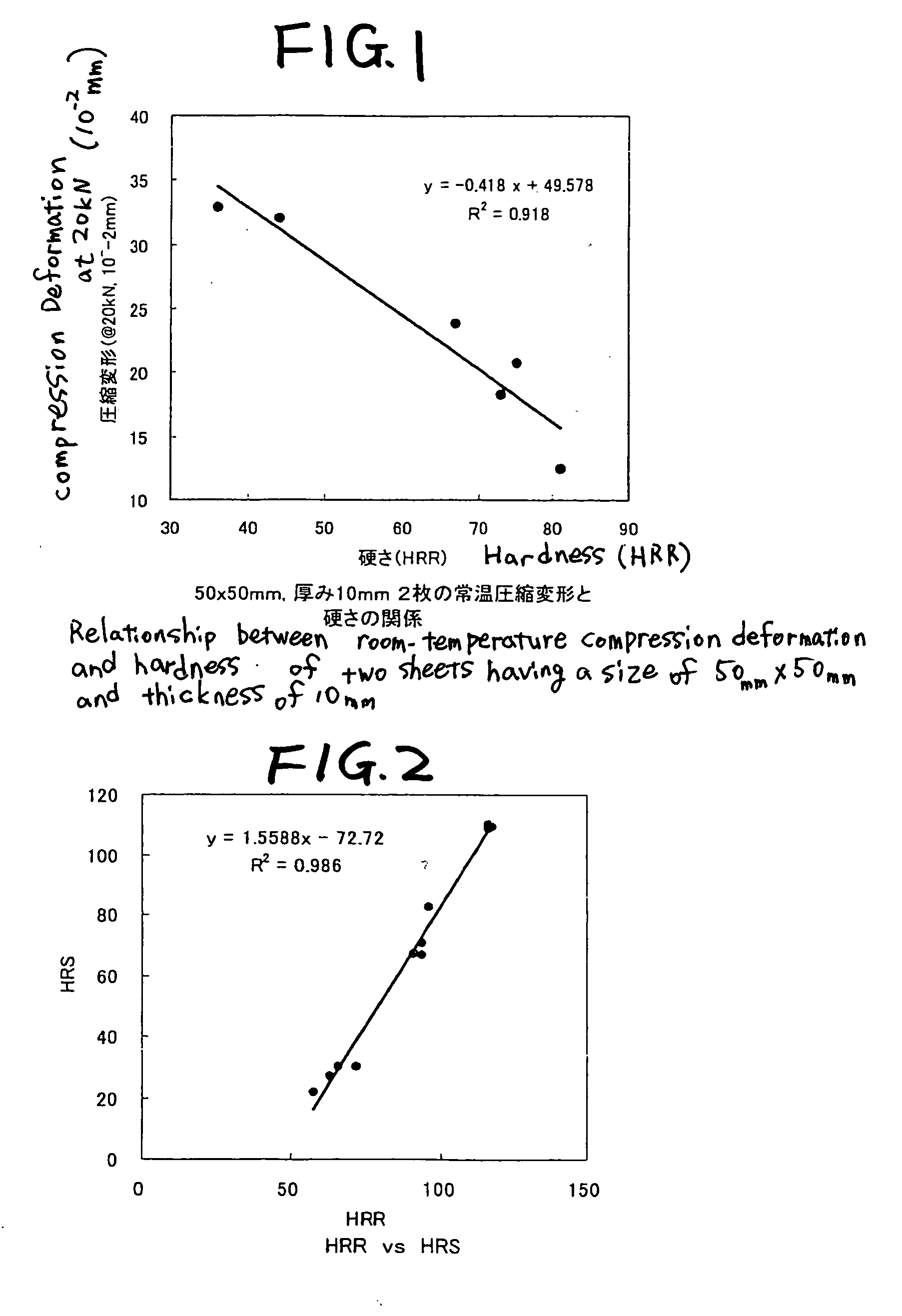

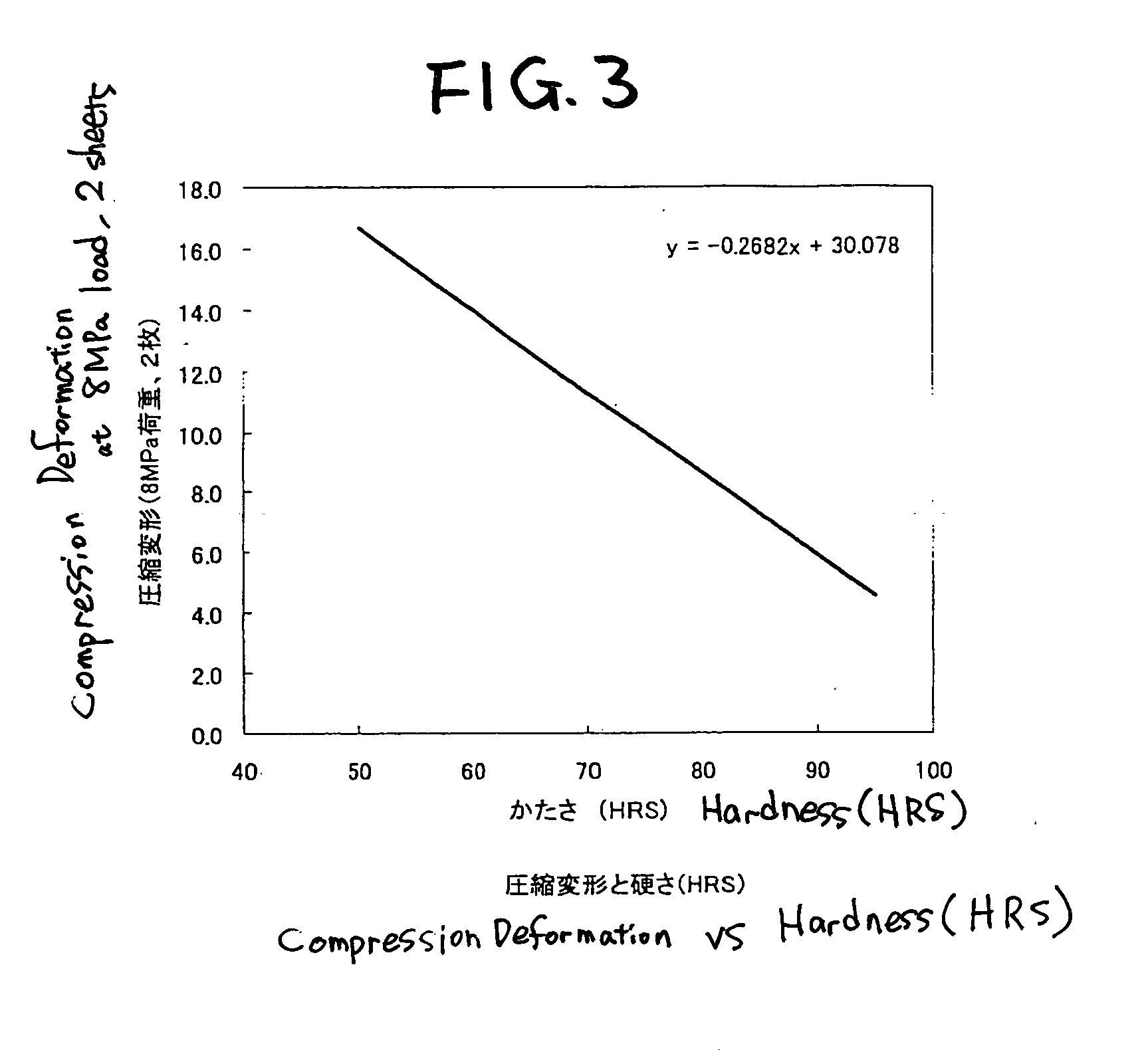

Friction material

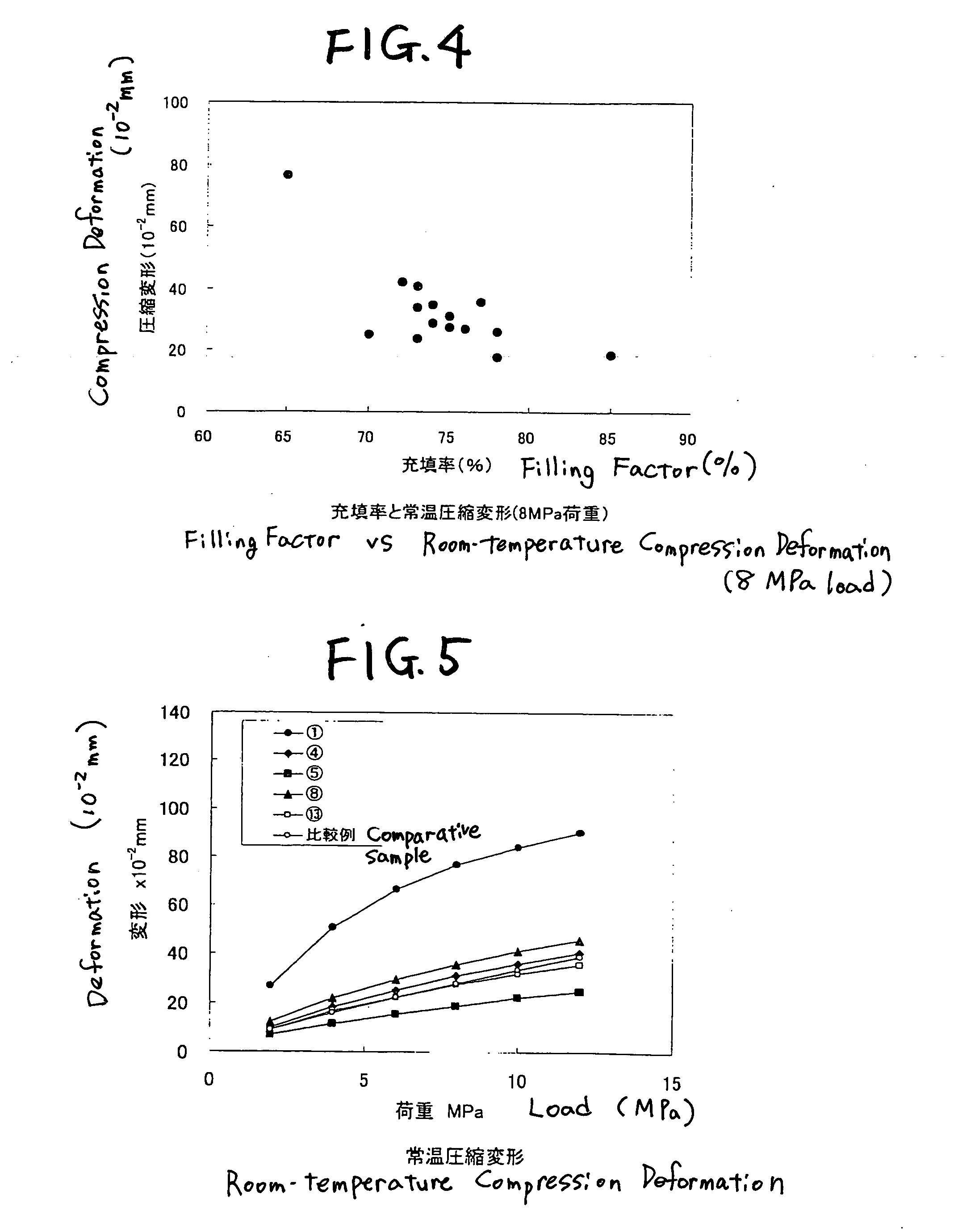

InactiveUS20070082974A1Maintain stable propertiesReduce speedMetal-working apparatusSpecial tyresCarbonizationRoom temperature

A friction material is provided with a baked carbonized organic material as the binder thereof. The friction material has a degree of compression deformation at room temperature of from 0.3 to 2.5% under a load of 4 MPa and from 1.0 to 4.5% under a load of 10 MPa. The compression deformation ratio of the degree of compression deformation at 300° C. to the degree of compression deformation at room temperature is from 1.0 to 1.5 under a load of from 1 to 10 MPa. The baking carbonization step comprises carbonizing an organic material in any atmosphere of vacuum, reducing gas or inert gas at a temperature of from 550° C. to 1300° C. with applying a load thereto.

Owner:AKEBONO BRAKE IND CO LTD

Nano light-cured anticorrosion spray-coating liquid

InactiveCN102391701ASave energyNo emissionsFireproof paintsAnti-corrosive paintsCrack resistanceUltraviolet

The invention discloses a nano light-cured anticorrosion spray-coating liquid relating to the field of treatment on surfaces of metal, concrete and wooden products. The nano light-cured anticorrosion spray-coating liquid consists of the following components in weight ratio: 50-60% of epoxy acrylate resin; 15-20% of trimethylolpropane acid resin; 3-5% of tripropylene glycol triacrylate triacrylic ester; 2-5% of N-methyl pyrrolidone; 2-4% of benzil dimethyl ketal; 0.5-2% of titanium nitride nano powder and 16-20% of titanium dioxide powder. The spray-coating liquid can be cured by sunshine or an ultraviolet lamp and is available for outdoor operation, wide in application range, non-toxic and odor-free, environment-friendly, simple in operation procedures, energy-saving and low in cost; and the formed layer has excellent resistance to corrosion, chemical and fading as well as remarkable adhesive property and has fireproofing property, good mechanical strength, dropping resistance, cracking resistance and pulverization.

Owner:阎善贵

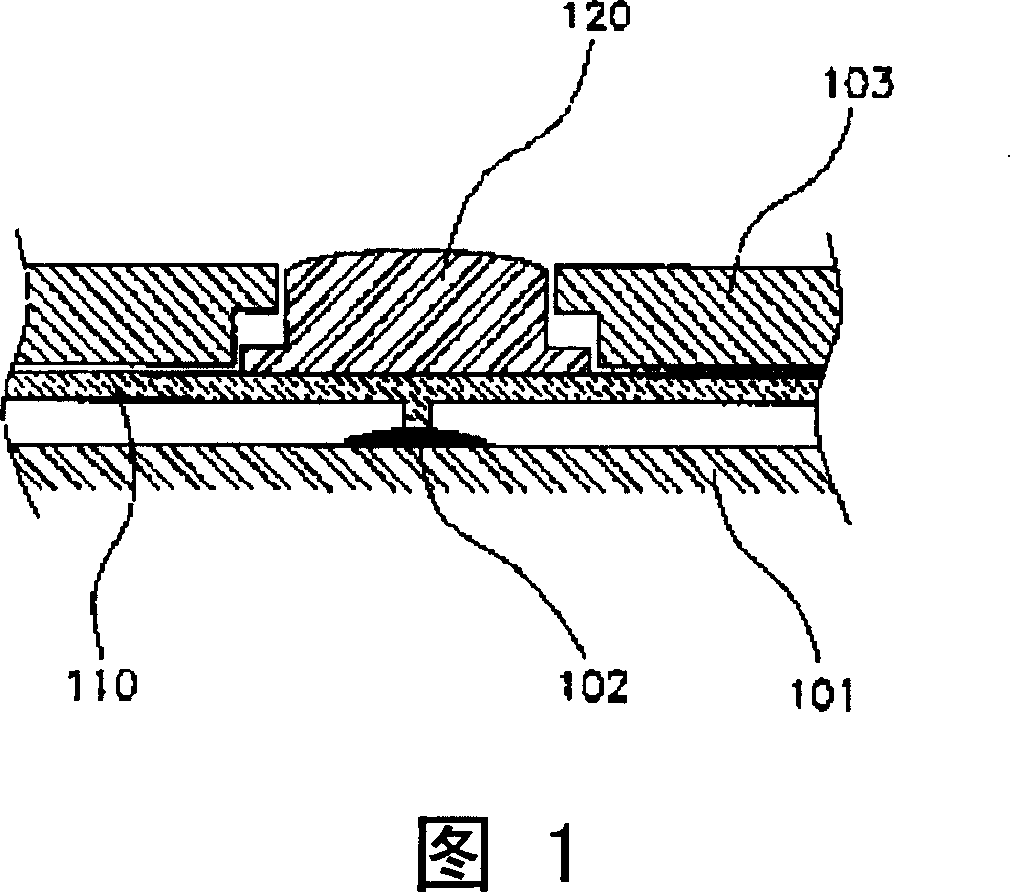

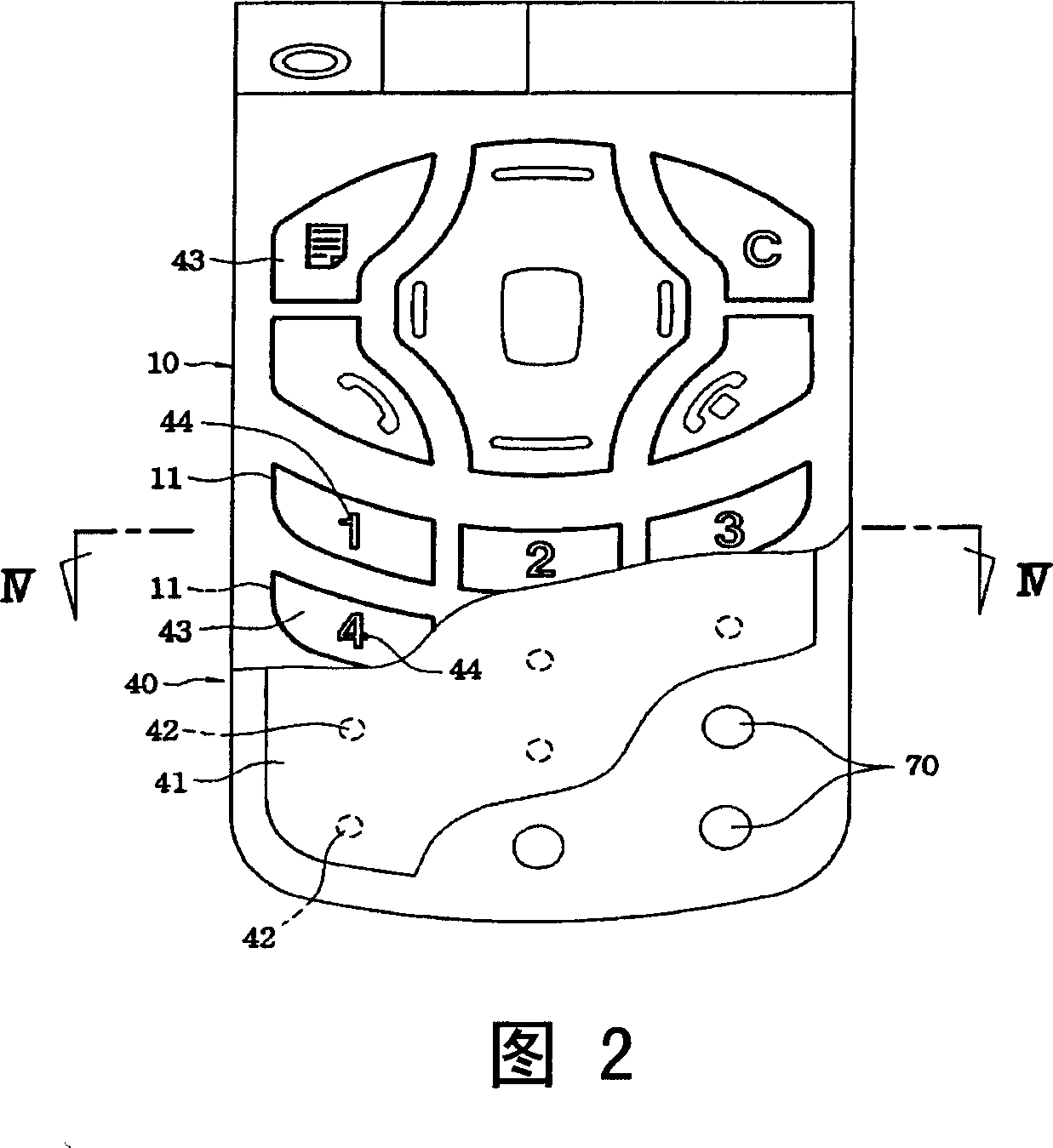

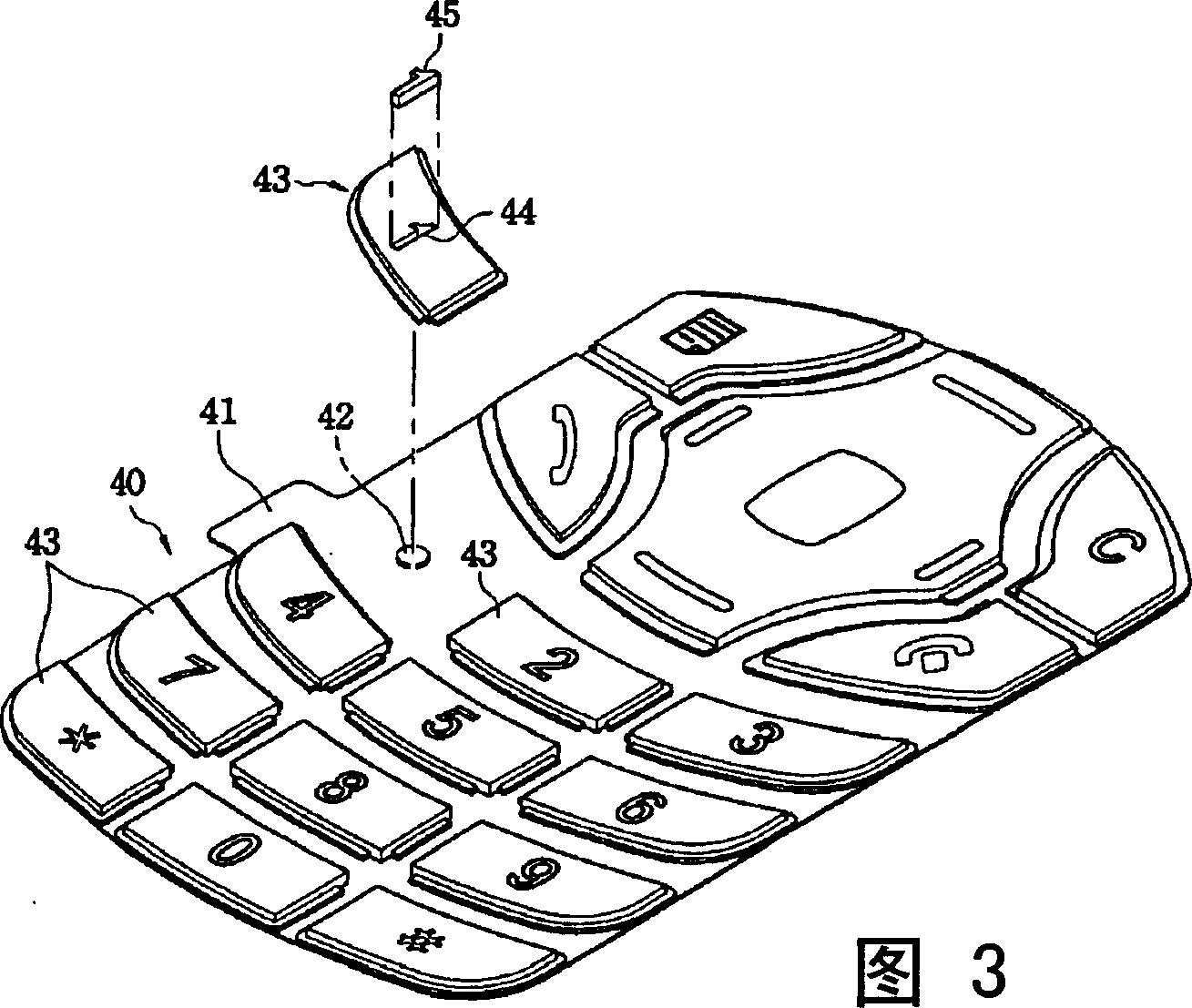

Metal keypad assembly for mobile phone and manufacturing method of keypad

InactiveCN1930858AIncrease interest in buying a mobile phoneNatural metallicElectric switchesTelephone set constructionsPolymer scienceAntioxidant

Disclosed herein are a composition for stabilizing Epigallocatechin gallate (EGCG) in water phase comprising 0.1-25.0% by weight of Epigallocatechin gallate, 0.1-5.0% by weight of a cationic polymer, an anionic polymer or a mixture thereof, 0.1-10.0% by weight of antioxidant in a remainder of water or the mixture of water and a hydrophilic solvent and a preparation method thereof. The composition is not easily decomposed in water phase as well as in external envionment consisting of temperature change, light effect etc. because the composition is stabilized by reacting with a cationic polymer or an anionic polymer.

Owner:SENSETECH

Spraying method applicable to aluminium profiles

InactiveCN102716850AImprove scratch resistanceImprove corrosion resistancePretreated surfacesCoatingsEngineeringPowder Spray

The invention provides a spraying method applicable to aluminium profiles. The spraying method comprises the following sequential steps of: oil removing, chromizing, water washing, pure-water washing, air drying, drying, upper hanging, trial spraying, powder spraying and lower hanging. The spraying method provided by the invention has the advantages and the positive effects that the spraying effect is good, and a spraying layer is stable and not easy to fall off.

Owner:TIANJIN YUDELONG ALUMINUM MFG

Polyester resin composition and molded article using the same

ActiveCN104877313AImprove mechanical propertiesExcellent fade resistanceSolid-state devicesSemiconductor devicesPolymer scienceColored white

A polyester resin composition comprises: (A) a first polyester resin having a melting temperature of greater than about 285° C.; (B) a second polyester resin having a melting temperature of less than or equal to about 285° C.; (C) a white pigment; and (D) an inorganic filler. The polyester resin composition may exhibit improved mechanical properties and discoloration resistance and can be used in a molded article, for example, as a LED reflector.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Printing and dyeing auxiliary for natural pigment dyeing

The invention discloses a printing and dyeing auxiliary for natural pigment dyeing. The printing and dyeing auxiliary is composed of the following components in parts by weight of 20 to 30 parts of coconut oil diethanolamide, 8 to 12 parts of octadecyl dimethyl benzyl amine chloride, 15 to 23 parts of sodium carboxymethylcellulose, 5 to 14 parts of sorbitan fatty acid ester, 5 to 9 parts of barium chloride, 6 to 8 parts of guar gum, 13 to 15 parts of polyethylene glycol laurate, 8 to 10 parts of polyalkyl acrylate, 8 to 10 parts of sodium dodecyl sulfate, 7 to 8 parts of polyalkyl acrylate, 6 to 7 parts of fatty alcohol, 5 to 7 parts of ethylene oxide, 2 to 3 parts of acetic acid and 9 to 24 parts of barium chloride. The printing and dyeing auxiliary for natural pigment dyeing has good effects of improving color fastness, protecting color and preventing fading through mutual combination of multiple components, can reduce the using amount of dye, is environment-friendly and non-toxic, effectively reduces the cost, can remarkably improve the color fastness of fabrics, and can be suitable for different types of fabrics.

Owner:JIANGSU SIXIN SURFACTANT TECH

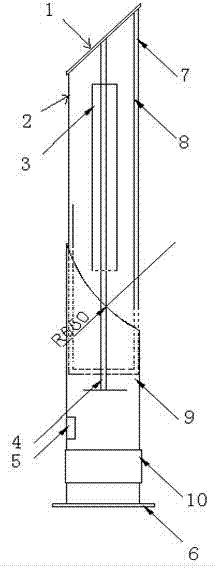

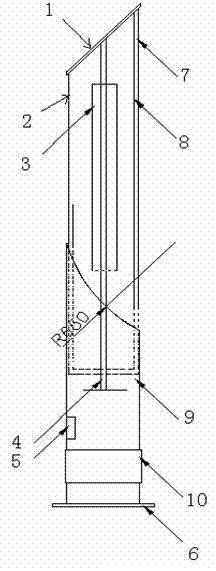

Cylindrical light box

The invention relates to a cylindrical light box, comprising a cylindrical cylinder body, wherein the top part and the bottom part of the cylindrical cylinder body are respectively provided with a top cover and a round chassis. The cylindrical cylinder body includes a transparent outer layer cylinder and an inner layer PVC board, wherein a fixed rack is installed in the cylindrical cylinder body and a lamp tool is arranged on the fixed rack. The lower part of the cylindrical cylinder body is provided with a junction box and the outside of the cylindrical cylinder body is wrapped with a cylindrical galvanized sheet. The cylindrical light box provided by the invention has the advantages of small area and space, visible all directions, corrosion resistance, aging resistance and long service life.

Owner:常州精石标识制造有限公司

Solubilized dyes for inks

This invention relates to an ink composition comprising a dye represented by Formula I: wherein R1 is independently a non-metallic substituent; s is 0, 1, 2, 3, or 4; R2 is hydrogen or a non-metallic substituent; R3 is a substituted or unsubstituted aromatic or heterocyclic group with the proviso that if R3 is a quinoline moiety, the azo group is not bonded to the 5, 6, 7 or 8 position of the quinoline ring; wherein the dye must bear at least one ionizable group that is capable of imparting water solubility to the dye. It also relates to dyes which comprise a specific subset of the above dyes.

Owner:EASTMAN KODAK CO

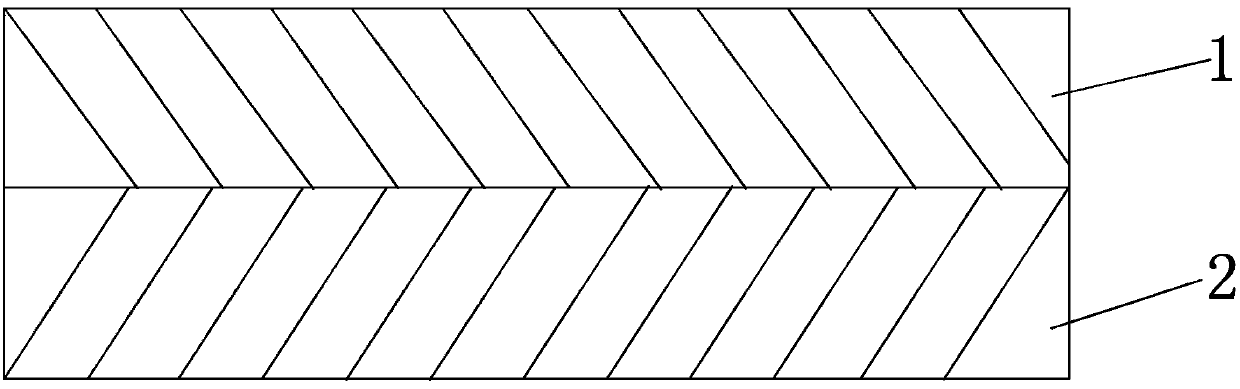

High-elasticity polyvinyl chloride fabric-art tablecloth

ActiveCN109591418AChange the boring and monotonous phenomenonCloth fits tightlyLamination ancillary operationsDomestic upholsteryYarnPolyvinyl chloride

The invention discloses high-elasticity polyvinyl chloride fabric-art tablecloth. The tablecloth comprises a PVC layer and a yarn layer, wherein the PVC layer is prepared through calendering, and theyarn layer is an environment-friendly degradable yarn layer; and the high-elasticity polyvinyl chloride fabric-art tablecloth is prepared by the steps of laminating double-surface embosses of the PVClayer and the yarn layer, printing, and reeling. The prepared high-elasticity polyvinyl chloride fabric-art tablecloth is high in flexibility, high in tear resistance and easy to clean, has anti-sliding performance and high elasticity and is relatively environment-friendly and relatively long in service life, and patterns and embosses can be printed on the prepared high-elasticity polyvinyl chloride fabric-art tablecloth.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Treatment process for improving dye leveling of polyester fabric for swimming trunks

The invention discloses a treatment process for improving dye leveling of a polyester fabric for swimming trunks and relates to the technical field of costume fabrics. The treatment process includes step (1) of immersing the polyester fabric with an ethanol solution; step (2) of using vapor to perform primary fumigation on the polyester fabric; step (3) of soaking the polyester fabric in a sodiumhydroxide solution, and then adding a citric acid solution dropwise; step (4) of adopting vapor to perform secondary fumigation on the polyester fabric; step (5) of adding the polyester fabric into clear water, adding methacrylic acid, trisodium phosphate, organic anhydride cyclodextrin and sodium alginate to the clear water, performing stirring, preserving the heat and standing, performing filtration, and performing vacuum drying to a constant weight. The polyester fabric treated by the method has better dye leveling, so that the dyeing quality of the treated polyester fabric is greatly ensured.

Owner:含山县海达服饰有限公司

A kind of high fade resistance polypropylene-graphene color masterbatch and preparation method thereof

The invention discloses a polypropylene-graphene color master batch with a high fading resistance and a preparation method thereof. The raw materials of the color master batch comprise graphene oxide, polypropylene, sodium sterate, acrylamide, an antioxidant, dibutyl phthalate, calcium silicate, a promoter, N,N-dimethylethanolamine and poly(ethyleneglycol p-phthalate). The preparation method comprises firstly adding graphene oxide into water to form a suspension, then successively adding acrylamide and ethanol into the suspension, performing stirring, adding dibutyl phthalate and N,N-dimethylethanolamine, performing heating for reaction, then adding the promoter, performing boiling, steaming an obtained mixture to dry, mixing the dried material, polypropylene, sodium stearate, the antioxidant, calcium silicate and poly(ethyleneglycol p-phthalate), performing grinding, and performing extrusion granulation on the ground material, so as to obtain the polypropylene-graphene color master batch with the high fading resistance. By modifying graphene, the heat resistance, light fastness and oxidation resistance of graphene are enhanced, and also the prepared color master batch is good in dispersibility, good in color reappearance and excellent in color fading resistance.

Owner:ZHEJIANG JINCAI NEW MATERIAL

A keel structure and roof system

ActiveCN105155782BGuaranteed stabilityExcellent fade resistanceRoof covering using slabs/sheetsKeel structureEngineering

The invention discloses a keel structure and a roofing system. The keel structure includes a main keel, a secondary keel fixed and installed on the main keel through a first fastener, and a fixture for supporting the main keel; the main keel comprises a horizontal plate and two Two upright plates are arranged in parallel on both sides of the horizontal plate, and the horizontal plate and the two upright plates together form a groove; the main keel also includes two protruding and extending from the upright plate into the groove and then detouring to the inside of the groove respectively. The circuit board is bent and arranged, and the two circuit boards are fixedly connected by a connecting plate; the end of the upright plate away from the horizontal plate is provided with a first hook portion, and the end of the circuit board away from the upright plate is provided with a second hook portion; the upright plate, The circuitous plate, the first hook portion and the second hook portion are jointly enclosed to form an installation groove; the clamp is installed below the main keel. The keel structure is especially suitable for supporting exterior decorative panels made of heavy materials such as rust steel plates.

Owner:CHINA STATE DECORATION GRP

Polyester resin composition with improved mechanical properties and fade resistance

ActiveCN104877313BImprove mechanical propertiesExcellent fade resistanceSolid-state devicesSemiconductor devicesPolymer scienceColored white

The present invention provides polyester resin compositions having improved mechanical properties and fading resistance. The present invention relates to a polyester resin composition comprising (A) a first polyester resin having a melting temperature greater than 285°C; (B) a melting temperature less than or equal to 285°C, and molded articles produced using the same The second polyester resin; (C) white pigment; and (D) inorganic filler. Accordingly, the present invention can provide a polyester resin composition having improved mechanical properties and discoloration resistance suitable for use as an LED reflector, and a molded article produced using the same.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Black porous polytetrafluoroethylene membrane, method for producing same, gas-permeable membrane and ventilation member using same

ActiveUS9616391B2Excellent fade resistanceLess subject to color fadingSemi-permeable membranesMembranesPermeationChemistry

Provided is a black porous polytetrafluoroethylene membrane including a porous polytetrafluoroethylene membrane dyed black. A whiteness of a principal face of the black porous polytetrafluoroethylene membrane as measured according to JIS L 1015 (Hunter method) is 18.0 to 23.0%, and the whiteness of the principal face falls within a range of 18.0 and 25.0% after heating at 350° C. for 1 minute. This black porous PTFE membrane is suitable as a gas-permeable membrane that blocks entry of water and / or dust and that allows permeation of gases; specifically, the black porous PTFE membrane is suitable, for example, as a waterproof sound-transmitting membrane, a waterproof gas-permeable membrane, and a dustproof gas-permeable membrane.

Owner:NITTO DENKO CORP

Wearable and abrasion resistant emulational artistic door with simulative wood grain

InactiveCN100557184CImprove surface propertiesExcellent abrasion and scratch resistanceNatural patternsDecorative surface effectsWater basedWear resistant

The invention is a wear-resistant and scratch-resistant wood grain simulation suit process door. It is characterized in that it is prepared according to the following process steps: kiln drying and moisture treatment of wood, wood and high-density fiberboard are made into door frames, honeycomb recycled paper is used as the base material, glue is applied on the base material, and multiple layers are used. The paper is cold-pressed into a certain thickness of honeycomb paper sound insulation material. The honeycomb paper sound insulation material is combined with the door frame to obtain a door blank. After sanding treatment, the wood grains such as walnut, mahogany, cherry wood or maple are printed on the front of the door blank. Then use a roller coater to apply the water-based primer, ink, transparent primer, and scratch-resistant transparent topcoat to the facade in sequence, so that the product facade can be decorated with wood grains such as walnut, mahogany, cherry or maple. noodle. In the surface finishing process of the present invention, no harmful substances such as solvents such as curing agents and diluents are used, natural wood is saved, and the paint film on the surface of the product has excellent surface properties, such as excellent wear resistance and scratch resistance, excellent anti-fading performance. and other performance.

Owner:昆明红塔木业有限公司

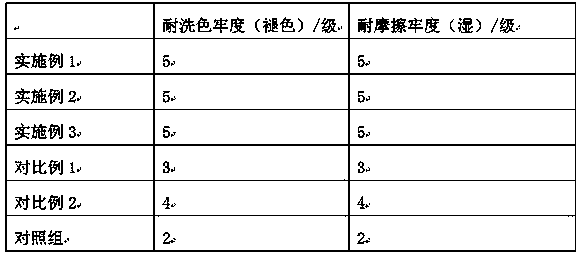

Treatment method for improving colour fastness of chinlon fabric used for swimming trunks

InactiveCN109056387AExcellent fade resistanceImprove wet rubbing fastnessDyeing processColour fastnessPre treatment

The invention discloses a treatment method for improving colour fastness of a chinlon fabric used for swimming trunks, and relates to the technical field of costume fabrics. The method comprises the following steps of (1) pre-treatment agent preparation, (2) chinlon fabric pre-treatment and (3) pre-treatment agent treatment. Chinlon treated through the method has better dyeing performance, and theswimming trunks prepared from the chinlon subjected to dyeing is fadeless and not stained when soaked in water for a long term, so that the service life of the swimming trunks is significantly prolonged.

Owner:含山县海达服饰有限公司

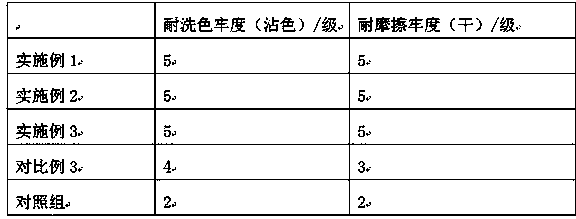

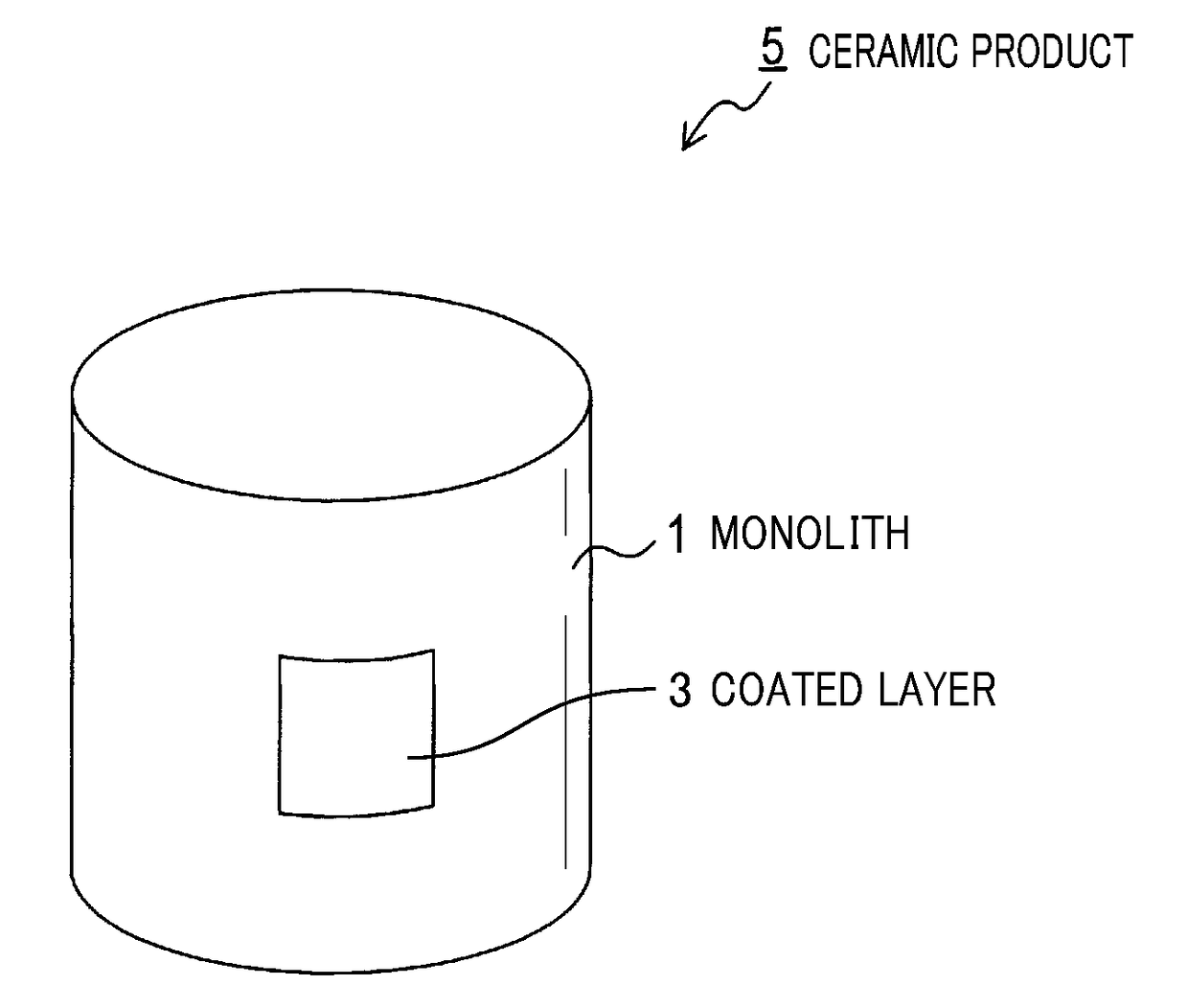

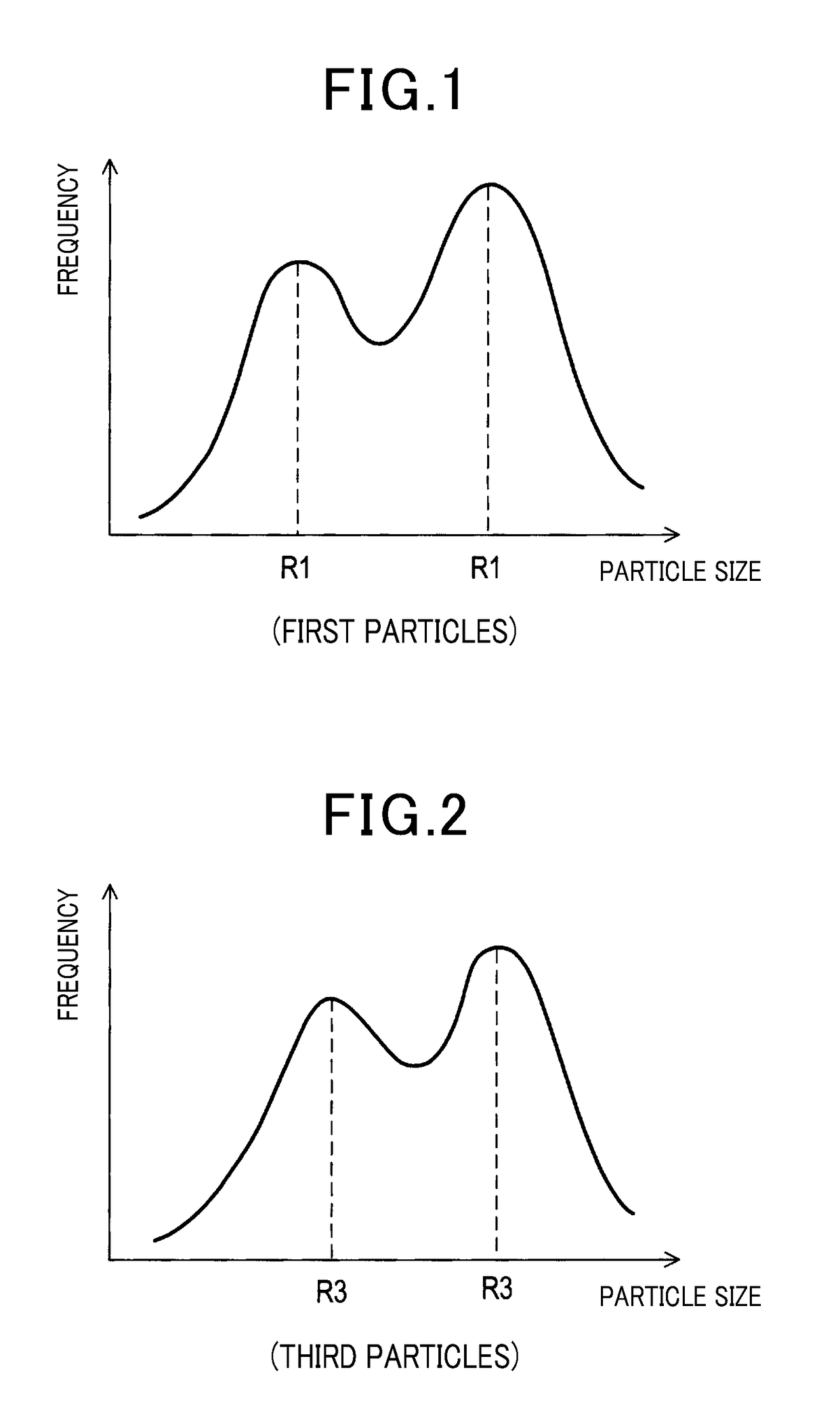

Outer peripheral coating member and ceramic product

ActiveUS20180118629A1Excellent fade resistanceHeterogenous catalyst chemical elementsSilencing apparatusPeak valueTitanium oxide

An outer peripheral coating member contains first particles containing titanium oxide, second particles containing zirconium oxide, third particles containing niobium oxide or aluminum oxide, and a dispersion medium. It is preferable for the first particles to have at least two peak values R1 in a distribution of particle sizes of the first particles. One of the peak values R1 is within a range of 1 to 50 nm, and the other peak value R1 is within a range of 100 to 500 nm.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com