Composition for ink acceptable layer, a recording medium and method for preparing recording medium

A technology for ink-receiving layers, recording media, applied in reproduction/marking methods, coatings, textiles, and papermaking, which can solve problems such as reduced compatibility and film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

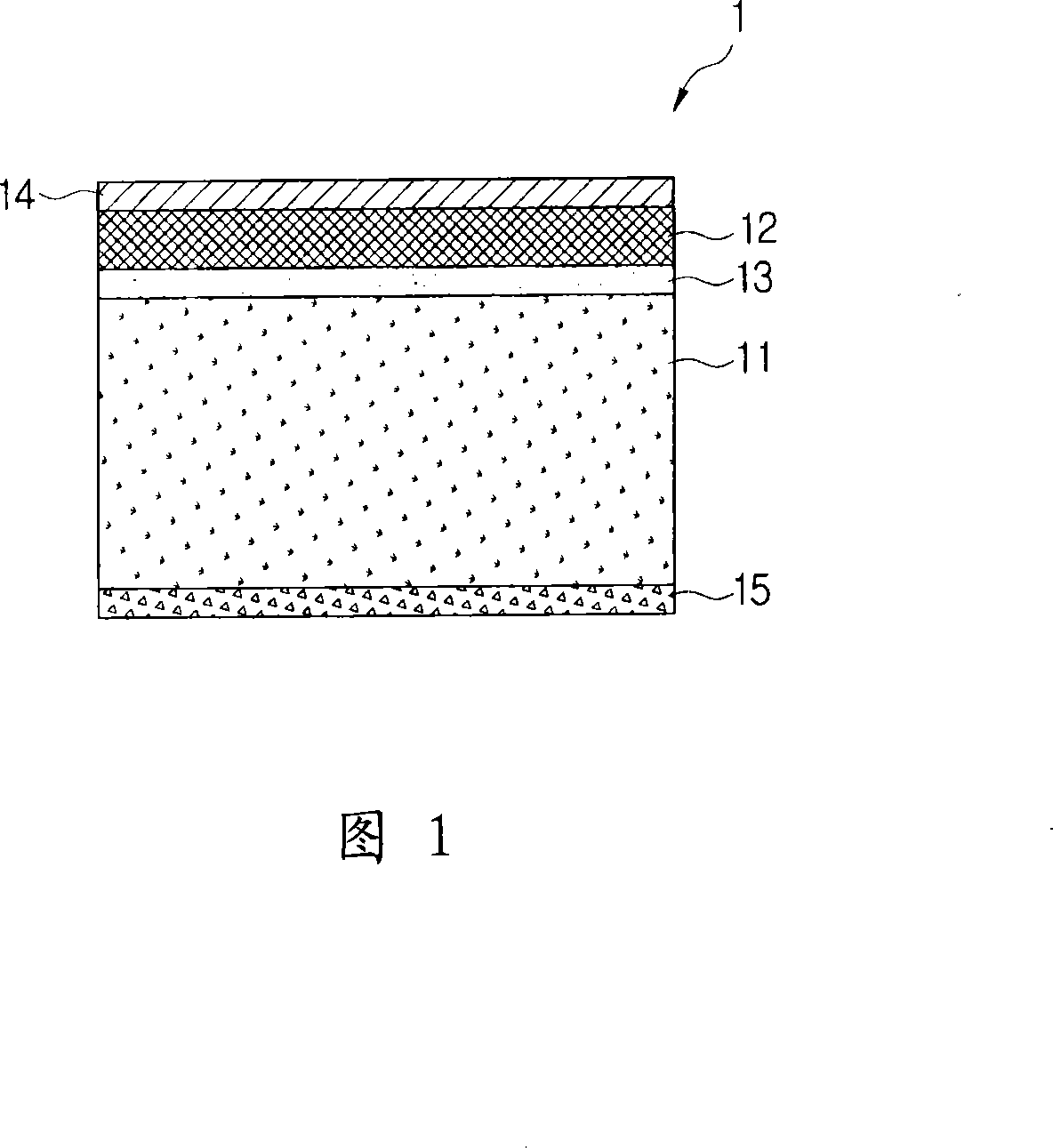

[0049] A composition for forming an ink-receiving layer of a recording medium of an image forming device according to an exemplary embodiment of the present invention includes a fixing agent, an inorganic filler, a binder, and a solvent.

[0050] The fixative is preferably a polymeric material, such as an acrylate cationic latex comprising an ultraviolet (UV)-absorbing component in a polymeric structure. As the cationic latex containing a UV-absorbing component, any component having a cationic-based polymeric structure containing a UV-absorbing component can be used as the UV-absorbing component.

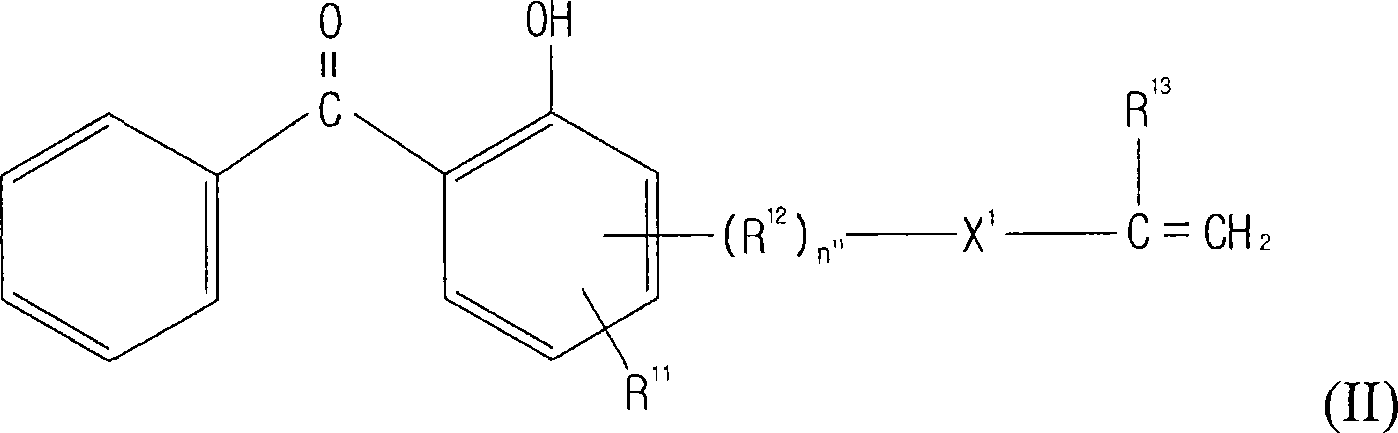

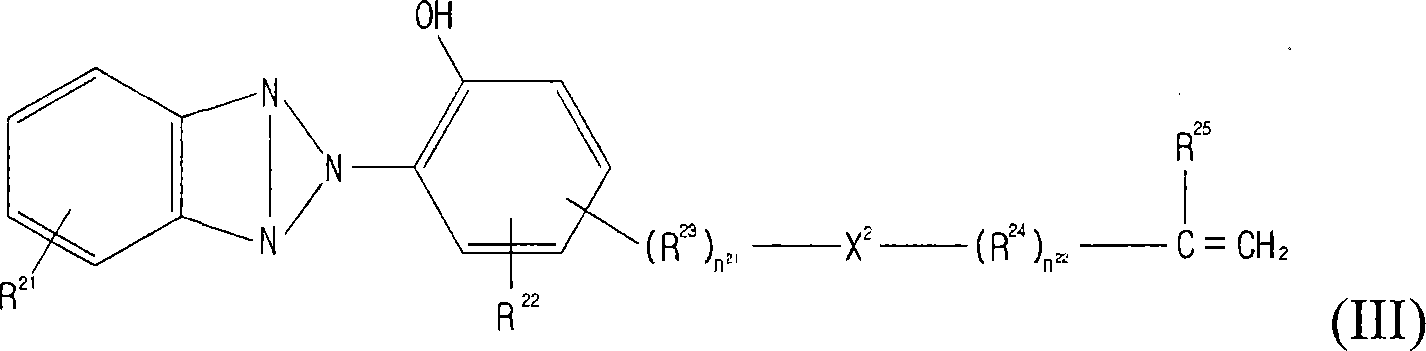

[0051] The cationic latex used as a fixing agent according to an exemplary embodiment of the present invention comprises a component unit having a cationic group, a component unit serving as a crosslinking agent during copolymerization, a component unit having no ionic character, and a component unit having an active UV-absorbing group. component units.

[0052] Generally, dyes use...

preparation Embodiment 1

[0129] 430 parts of distilled water, 80 parts of a 25% aqueous solution of dodecyltrimethylammonium chloride and 30 parts of 2-[2'-hydroxy-5'-(methacryloyloxy)phenyl]benzotriazole Add to shaker flask. The temperature of the resulting mixture was raised to 80°C, 40 parts of a 5% aqueous solution of 2,2'-azobis(2-amidinopropane)dihydrochloride was added thereto, and the resulting mixture was left to stand for 5 minutes. After 5 minutes, 16 parts of a 25% aqueous solution of dodecyltrimethylammonium chloride, 48 parts of 2,2'-azobis(2-amidinopropane) dihydrochloride were added thereto within 90 minutes, respectively. a 5% aqueous solution of compound and 186 parts of distilled water in water; and a monomer comprising 120 parts of dimethylaminopropyl acrylamidomethyl chloride, 200 parts of methyl methacrylate, 320 parts of butyl acrylate and 160 parts of styrene. The resulting mixture was kept stirring for 60 minutes until no longer changing.

[0130] The resulting mixture was t...

preparation Embodiment 2

[0132]590 parts of distilled water, 80 parts of a 25% aqueous solution of lauryltrimethylammonium chloride, and 240 parts of 2-hydroxy-4-acryloyl-oxybenzophenone were added to the shake flask. The temperature of the resulting mixture was raised to 80°C, 40 parts of a 5% aqueous solution of 2,2'-azobis(2-amidinopropane)dihydrochloride was added thereto, and the resulting mixture was left to stand for 5 minutes. After 5 minutes, 16 parts of a 25% aqueous solution of dodecyltrimethylammonium chloride, 48 parts of 2,2'-azobis(2-amidinopropane) dihydrochloride were added thereto within 90 minutes, respectively. a 5% aqueous solution of compound and 186 parts of distilled water in water; and a monomer comprising 120 parts of dimethylaminopropyl acrylamidomethyl chloride, 200 parts of methyl methacrylate, 320 parts of butyl acrylate and 160 parts of styrene. The resulting mixture was kept stirring for 60 minutes until no longer changing.

[0133] The resulting mixture was then coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com