Treatment process for improving dye leveling of polyester fabric for swimming trunks

A treatment process and level dyeing technology, which is applied in fiber treatment, fiber type, textiles and papermaking, etc., can solve the problems of general dyeing property and poor dyeing effect, so as to reduce dyeing unevenness, reduce unevenness, The effect of improving the uniformity of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

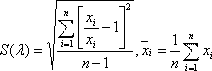

Image

Examples

Embodiment 1

[0020] A treatment process for improving the level dyeing of polyester fabrics for swimming trunks, comprising the following steps:

[0021] (1) Soak the polyester fabric in ethanol solution for 30 minutes, then filter it, and let it dry naturally in a cool and ventilated place;

[0022] (2) Fumigate the polyester fabric after the above treatment with water vapor for the first time, and the fumigation time is 5 minutes;

[0023] (3) Soak the polyester fabric after the above treatment in a sodium hydroxide solution with a mass fraction of 2.5% for 35 minutes, then add citric acid solution dropwise to the sodium hydroxide solution until the pH of the solution reaches 6.5, and then stop adding. Continue to soak for 10 minutes, then filter, wash with deionized water until neutral, and drain naturally in a cool and ventilated place;

[0024] (4) Fumigate the polyester fabric after the above treatment with water vapor for a second time, and the fumigation time is 3 minutes;

[002...

Embodiment 2

[0034] A treatment process for improving the level dyeing of polyester fabrics for swimming trunks, comprising the following steps:

[0035] (1) Soak the polyester fabric in ethanol solution for 40 minutes, then filter it, and let it dry naturally in a cool and ventilated place;

[0036] (2) Fumigate the polyester fabric after the above treatment with water vapor for the first time, and the fumigation time is 8 minutes;

[0037] (3) Soak the polyester fabric after the above treatment in a sodium hydroxide solution with a mass fraction of 3.0% for 38 minutes, then add a citric acid solution dropwise to the sodium hydroxide solution until the pH of the solution reaches 6.5, then stop adding. Continue to soak for 10 minutes, then filter, wash with deionized water until neutral, and drain naturally in a cool and ventilated place;

[0038] (4) Fumigate the polyester fabric after the above treatment with water vapor for a second time, and the fumigation time is 5 minutes;

[0039]...

Embodiment 3

[0048] A treatment process for improving the level dyeing of polyester fabrics for swimming trunks, comprising the following steps:

[0049] (1) Soak the polyester fabric in ethanol solution for 35 minutes, then filter it, and let it dry naturally in a cool and ventilated place;

[0050] (2) Fumigate the polyester fabric after the above treatment with water vapor for the first time, and the fumigation time is 6 minutes;

[0051] (3) Soak the polyester fabric after the above treatment in a sodium hydroxide solution with a mass fraction of 2.8% for 37 minutes, then add citric acid solution dropwise to the sodium hydroxide solution until the pH of the solution reaches 6.5, and then stop adding. Continue to soak for 10 minutes, then filter, wash with deionized water until neutral, and drain naturally in a cool and ventilated place;

[0052] (4) Fumigate the polyester fabric after the above treatment with water vapor for a second time, and the fumigation time is 4 minutes;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com