Colored ageing-resistant butyl rubber self-adhesive waterproof coiled material and preparation method thereof

A self-adhesive waterproof membrane, butyl rubber technology, used in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of poor anti-aging performance, inability to achieve color, To the anti-aging effect and other issues, to achieve the effect of high strength, good anti-fading performance and strong anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

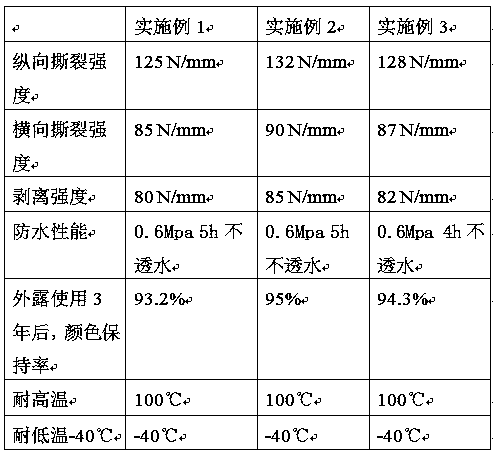

Embodiment 1

[0054] A colored anti-aging butyl rubber self-adhesive waterproof membrane, including a surface layer, a self-adhesive layer and an isolation layer.

[0055] Surface layer: anti-aging polyester film, anti-aging coating, non-woven fabric;

[0056] The anti-aging polyester film: a thickness of 0.1mm, an impermeability ≥ 2000mm, and an elongation at break of 78%;

[0057] The anti-aging coating: in parts by weight, raw materials include: 75 parts of polybutadiene latex, 8 parts of wollastonite powder, 10 parts of white carbon black, 38 parts of pentaerythritol oleate, fatty alcohol polyoxyethylene ether sodium sulfate 11 parts, 9 parts of mannitol, 6 parts of octyl dodecyl glucoside, 7 parts of ultraviolet absorber, 5 parts of silane coupling agent, 2.8 parts of pigment.

[0058] The ultraviolet absorber: the model is UV-326;

[0059] The silane coupling agent: the model is KH-550.

[0060] The non-woven fabric: needle-punched non-woven fabric with a thickness of 1.3mm, a mass...

Embodiment 2

[0066] Identical to the formula of a kind of colored anti-aging butyl rubber self-adhesive waterproof membrane described in Example 1, only change the following:

[0067] The anti-aging coating: in parts by weight, the raw materials include: 78 parts of polybutadiene latex, 9 parts of wollastonite powder, 7 parts of white carbon black, 35 parts of pentaerythritol oleate, fatty alcohol polyoxyethylene ether sodium sulfate 14 parts, 7 parts of mannitol, 8 parts of octyl dodecyl glucoside, 6 parts of ultraviolet absorber, 6.5 parts of silane coupling agent, 2.5 parts of pigment.

[0068]The ultraviolet absorber: the model is UV-326;

[0069] The silane coupling agent: the model is KH-550.

[0070] Described self-adhesive layer: raw material comprises main material and auxiliary material; The mass ratio of described main material and auxiliary material is 8:2;

[0071] The main material is butyl rubber;

[0072] The auxiliary materials are 26 parts of dimethyl adipate, 15 parts...

Embodiment 3

[0074] Identical to the formula of a kind of colored anti-aging butyl rubber self-adhesive waterproof membrane described in Example 1, only change the following:

[0075] The anti-aging coating: in parts by weight, the raw materials include: 70 parts of polybutadiene latex, 8 parts of wollastonite powder, 10 parts of white carbon black, 38 parts of pentaerythritol oleate, fatty alcohol polyoxyethylene ether sodium sulfate 11 parts, 9 parts of mannitol, 6 parts of octyl dodecyl glucoside, 7 parts of ultraviolet absorber, 5 parts of silane coupling agent, and 2 parts of pigment.

[0076] The ultraviolet absorber: the model is UV-326;

[0077] The silane coupling agent: the model is KH-550.

[0078] Described self-adhesive layer: raw material comprises main material and auxiliary material; The mass ratio of described main material and auxiliary material is 8:2;

[0079] The main material is butyl rubber;

[0080] The auxiliary materials are 20 parts of dimethyl adipate, 19 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com