Treatment method capable of improving dyeing performance of shell fabric for swinging trunks

A technology of dyeing performance and treatment method is applied in the treatment field of improving the dyeing performance of fabrics for swimming trunks, which can solve the problems of poor dyeing effect and general dyeing performance, and achieves remarkable effects, guarantees dyeing quality, and improves dyeing quality and dyeing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

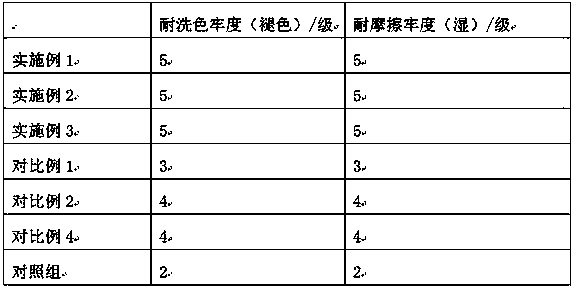

Embodiment 1

[0019] A treatment method for improving the dyeing performance of fabrics for swimming trunks, including the following steps:

[0020] (1) Preparation of pretreatment agent: mix oxalic acid and malonamide uniformly according to the mass ratio of 2:0.6 and add them to the reactor, pass in inert gas to remove the air in the reactor, and then heat to 42°C in a water bath and keep warm 15min, then add 0.3% glycolic acid by mass of oxalic acid, stir evenly, then adjust the pH of the mixed system to 5.3

[0021] , Heat to 68°C, heat preservation and react for 2.5 hours, then cool and discharge to obtain a mixed product, and dissolve the obtained mixed product in an organic solvent at a mass ratio of 1:10 to obtain a pretreatment agent;

[0022] (2) Acid-base treatment: soak the polyester fabric in 2.5% sodium hydroxide solution for 30 minutes, then add citric acid solution to the sodium hydroxide solution until the pH of the solution reaches 6.3, stop the dripping. Continue to soak for 12...

Embodiment 2

[0033] A treatment method for improving the dyeing performance of fabrics for swimming trunks, including the following steps:

[0034] (1) Preparation of pretreatment agent: mix oxalic acid and malonamide according to a mass ratio of 2: 0.9 and add them to the reaction kettle, pass inert gas to remove the air in the reaction kettle, and then heat to 42°C in a water bath and keep warm 15min, then add 0.5% glycolic acid by mass of oxalic acid. After stirring evenly, adjust the pH of the mixed system to 5.5, heat to 68°C, keep the temperature for 2.5 hours, and then cool and discharge to obtain the mixed product. 1:10 mass ratio is dissolved in organic solvent to obtain pretreatment agent;

[0035] (2) Acid-base treatment: soak the polyester fabric in a sodium hydroxide solution with a mass fraction of 2.9% for 35 minutes, and then add citric acid solution to the sodium hydroxide solution until the pH of the solution reaches 6.3, stop the dripping. Continue to soak for 12 minutes, th...

Embodiment 3

[0046] A treatment method for improving the dyeing performance of fabrics for swimming trunks, including the following steps:

[0047] (1) Preparation of pretreatment agent: mix oxalic acid and malonamide uniformly according to the mass ratio of 2:0.7 and add them to the reaction kettle. Inert gas is introduced to remove the air in the reaction kettle, and then the water bath is heated to 42°C and kept warm. After 15 minutes, add 0.4% glycolic acid by mass of oxalic acid. After stirring evenly, adjust the pH of the mixed system to 5.4, heat to 68°C, keep the temperature for 2.5 hours, and then cool and discharge to obtain the mixed product. 1:10 mass ratio is dissolved in organic solvent to obtain pretreatment agent;

[0048] (2) Acid-base treatment: soak the polyester fabric in a sodium hydroxide solution with a mass fraction of 2.6% for 32 minutes, and then add citric acid solution to the sodium hydroxide solution until the pH of the solution reaches 6.3, stop the dripping. Cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com