Nano light-cured anticorrosion spray-coating liquid

A technology of anti-corrosion spraying and nano-light, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of non-spraying, toxic epoxy resin coatings, long curing time, etc., to reduce construction costs, good fading resistance, Excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select raw materials according to weight ratio:

[0025] Epoxy Acrylic 53%

[0026] Trimethylolpropanoic acid resin 16.5%

[0027] Tripropylene glycol triacrylate 3.5%

[0028] N-Methylpyrrolidone 2.5%

[0029] Benzoin Dimethyl Ether 4%

[0030] Titanium nitride nanopowder 1.5%

[0031] Titanium dioxide 19%

[0032] Stir evenly under normal temperature and pressure to obtain a nano photocurable anti-corrosion spraying liquid.

[0033] Spray the spray liquid on a 100×100×3 (mm) iron plate, the thickness of the coating is 0.2mm, use sunlight to cure, and the curing time is 2 minutes. After testing, the results are as follows:

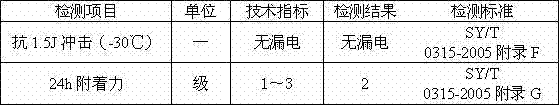

[0034] Coating Appearance: Smooth surface, no dark bubbles, pits, wrinkles, cracks, uniform color; -30 ℃ 1.5J impact resistance, 24h adhesion test results are shown in Table 1:

[0035] Table 1

[0036]

[0037] The test results of combustion performance, aging resistance and corrosion resistance are shown in Table 2:

[0038] Table 2 ...

Embodiment 2

[0044] Select raw materials according to weight ratio:

[0045] Epoxy Acrylic 50%

[0046] Trimethylolpropanoic acid resin 20%

[0047] Tripropylene glycol triacrylate 5%

[0048] N-Methylpyrrolidone 5%

[0049] Benzoin Dimethyl Ether 2%

[0050] Titanium nitride nanopowder 2%

[0051] Titanium dioxide 16%

[0052] Stir evenly under normal temperature and pressure to obtain a nano photocurable anti-corrosion spraying liquid. Spray the spray liquid on a 100×100×3mm iron plate with a coating thickness of 0.2mm, and cure it by sunlight for 10 minutes.

Embodiment 3

[0054] Select raw materials according to weight ratio:

[0055] Epoxy Acrylic 60%

[0056] Trimethylolpropanoic acid resin 15%

[0057] Tripropylene glycol triacrylate 3%

[0058] N-Methylpyrrolidone 2%

[0059] Benzoin Dimethyl Ether 2.5%

[0060] Titanium nitride nanopowder 0.5%

[0061] Titanium dioxide 17%

[0062] Stir evenly under normal temperature and pressure to obtain a nano photocurable anti-corrosion spraying liquid. The spray liquid was sprayed on a 100×100×3mm iron plate with a coating thickness of 0.2mm and cured by sunlight for 6 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com