Polyester resin composition and molded article using the same

A technology of polyester resin and composition, applied in the field of polyester resin composition, can solve the problems of reduced impact strength and moldability, reduced light stability, etc., and achieve the effects of excellent mechanical properties and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

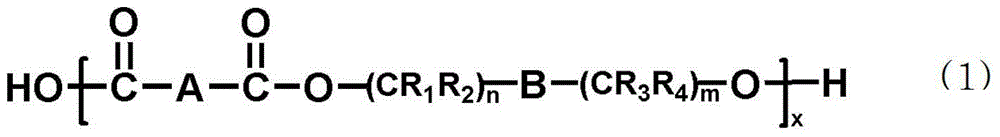

Method used

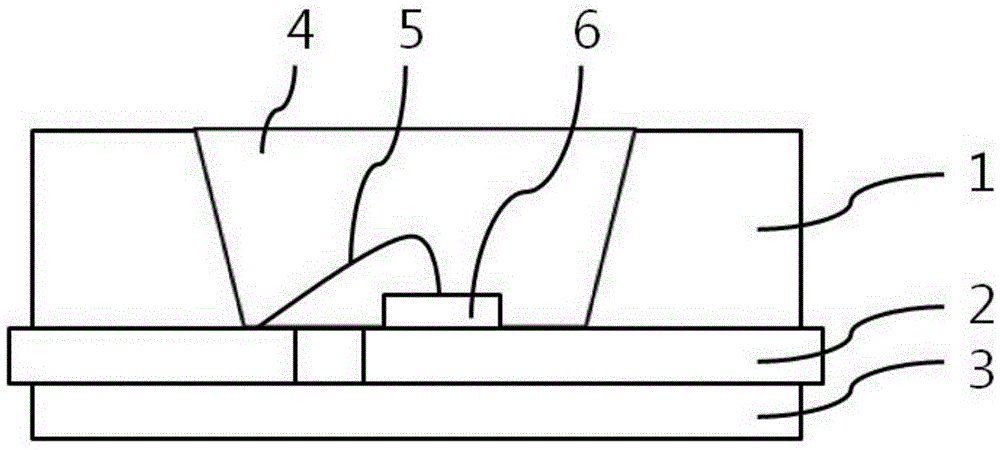

Image

Examples

Embodiment 1

[0132] As shown in Table 1, the (A) first polyester resin of 40wt%, the (B) second polyester resin of 10wt%, the (C) white pigment of 35wt% and the (D) inorganic filler of 15wt% were mixed, And dry blended to prepare a polyester resin composition. It was processed into pellets using a twin-screw extruder with Φ = 36 mm and a nozzle temperature of 250°C to 310°C. The prepared pellets were dried at 80°C for 4 hours, and the obtained samples were injection molded and evaluated for their physical properties, the results of which are shown in Table 2.

Embodiment 2 to 3

[0134] As shown in Table 1, the polyester resin composition was prepared in the same manner as in Example 1, except that (A) the first polyester resin, (B) the second polyester resin, (C ) white pigment and (D) content of inorganic filler. The measured physical properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com