Multi-colour figure film forming method

A coating film and pattern technology, which is applied in the field of multi-color pattern coating film formation, can solve the problem that the multi-color pattern coating film has insufficient anti-fading oil-based ink pollution resistance, the appearance of the multi-color pattern coating film is reduced, and the weather resistance performance is very different. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0085] 133 parts of resin solution of 60% solid content of oil-free polyester resin with a weight average molecular weight of 20,000 and a hydroxyl value of 15 mgKOH / g, and 20 parts of Cymel 303 (a low-nuclear body methylated melamine resin manufactured by Mitsui Cytec Co., Ltd.) , 90 parts of titanium dioxide pigment, 3 parts of silica micropowder with an average particle diameter of about 2 μm and 54 parts of mixed solvent A (Note 1) are mixed and dispersed to obtain 300 parts of white paint base, in which mixed with dodecyl 3.2 parts of a mixture of 1.0 parts of benzenesulfonic acid and 2.2 minutes of di-n-butylamine were further added to mixed solvent A and stirred uniformly to obtain White Paint-1 having a viscosity of 20 seconds measured at 25° C. with a Ford cup #4.

[0086] (Note 1) Mixed solvent A: Suwazo-Lu 1000 (high

[0087] Boiling point aromatic hydrocarbon solvent) / xylene / cyclohexanone=50 / 30 / 20 (weight ratio)

[0088]mixed solvents. Production examples 2 ...

manufacture example 2~11

[0089] The oil-free polyester resin solution was used in the same manner as in Production Example 1, and the compounding composition of Production Example 1 was changed as shown in the following Table 1, except that the compounding method of the sulfonic acid compound and the amine compound was as shown in the following Table 1. In the same manner as in Production Example 1, various paints having a viscosity of 20 seconds measured at 25° C. with a Ford cup #4 were obtained. The paints obtained in Production Examples 9 to 11 were used for comparison.

[0090] Manufacturing example

1

2

3

4

5

6

7

8

9

10

11

paint name

Material-1

Black painted

Material-2

blue paint

Material-3

Material-4

Black painted

Material-5

Material-6

Black painted

Material-7

blue paint

Material-8

whitewash

...

Embodiment 2

[0096] As paints, White Paint-4 obtained in Production Example 4 and Black Paint-5 obtained in Production Example 5 were used.

[0097] As the object to be coated, a galvanized steel sheet that has been coated with a KP color 8451 primer with a dry film thickness of about 5 μm and baked with a primer is further coated with a KP color 1573 white of about 18 μm. Enamel (polyester-melamine resin-based white paint manufactured by Kansai Pigment Co., Ltd.) and baked coated steel sheets (indicated by "coated object B" in Table 2 below).

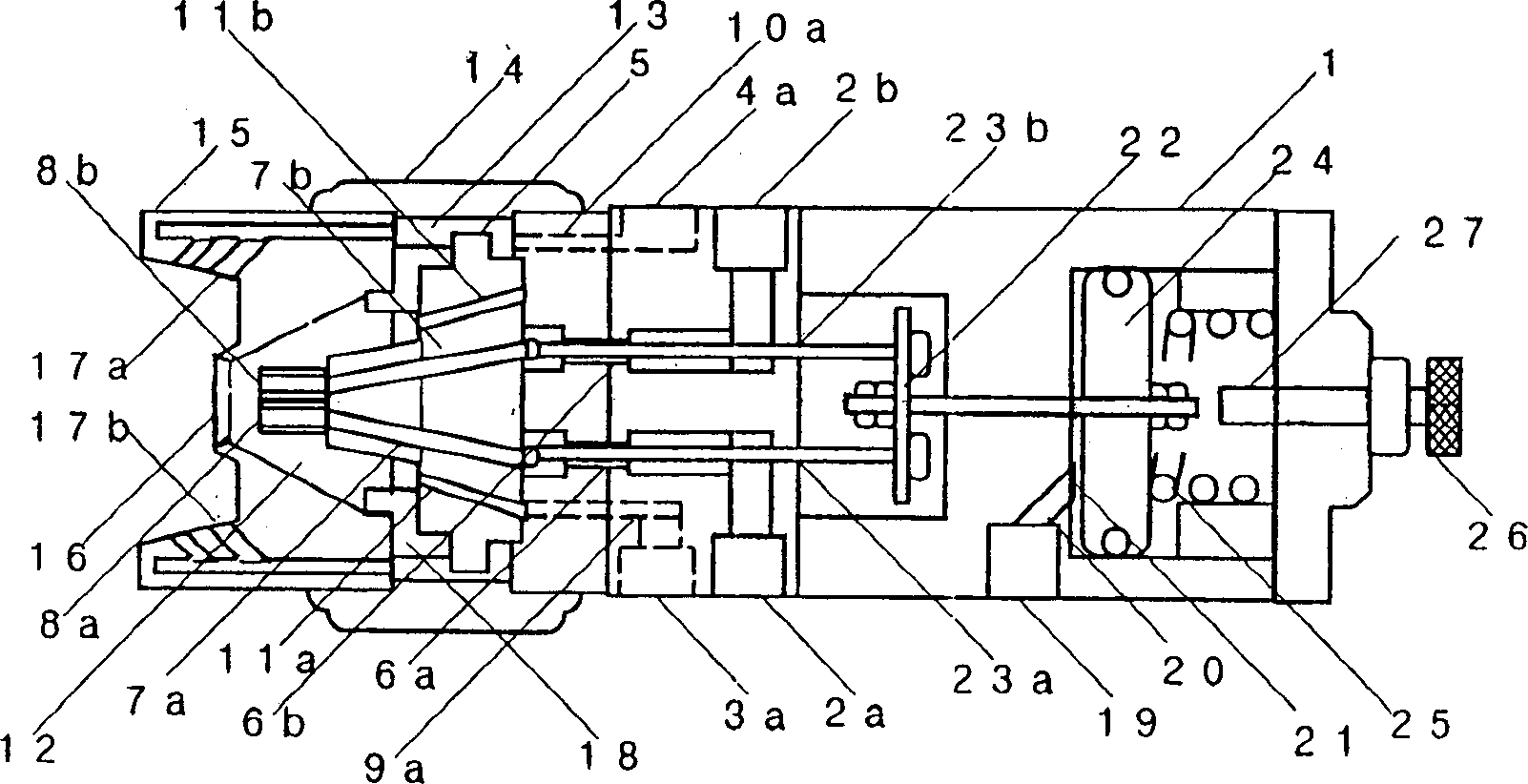

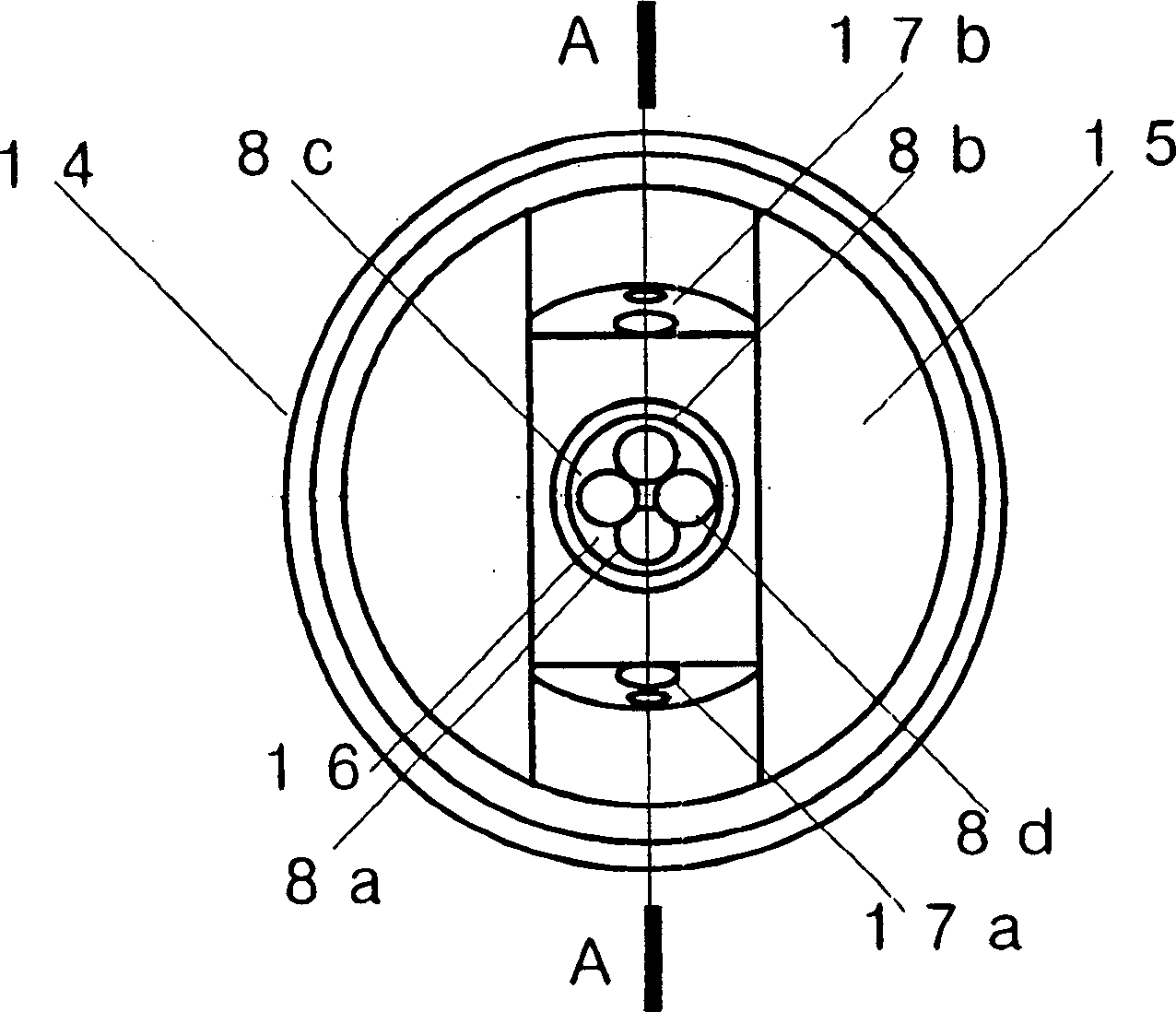

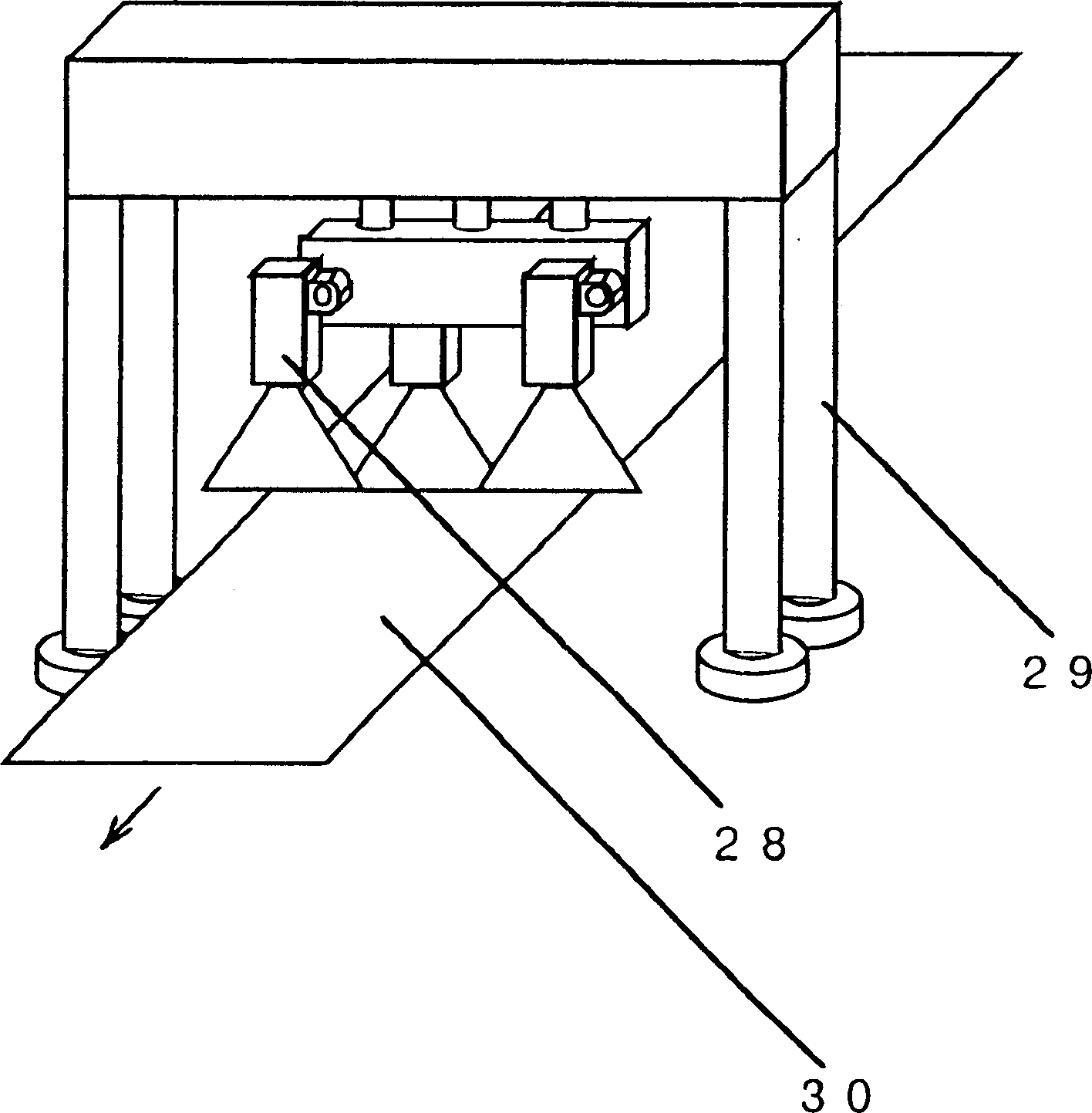

[0098] The moving speed (linear speed) of the object to be coated was set at 40 m / min. Except that the object to be coated B is used as the object to be coated, the width of the board is taken as 60 cm, and the four multi-nozzle guns are replaced by four two-head guns, the pattern coating is carried out in the same manner as in Example 1.

[0099] Each 2-head gun can alternately form a pattern coating film on the surface of the roller with white s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com