Keel structure and roof system

A roof system and keel technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of a single panel that is heavy, cannot meet the material requirements of rusty steel plates, and is difficult to bear the load of rusty steel plate materials, etc. , to achieve the effect of ensuring the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

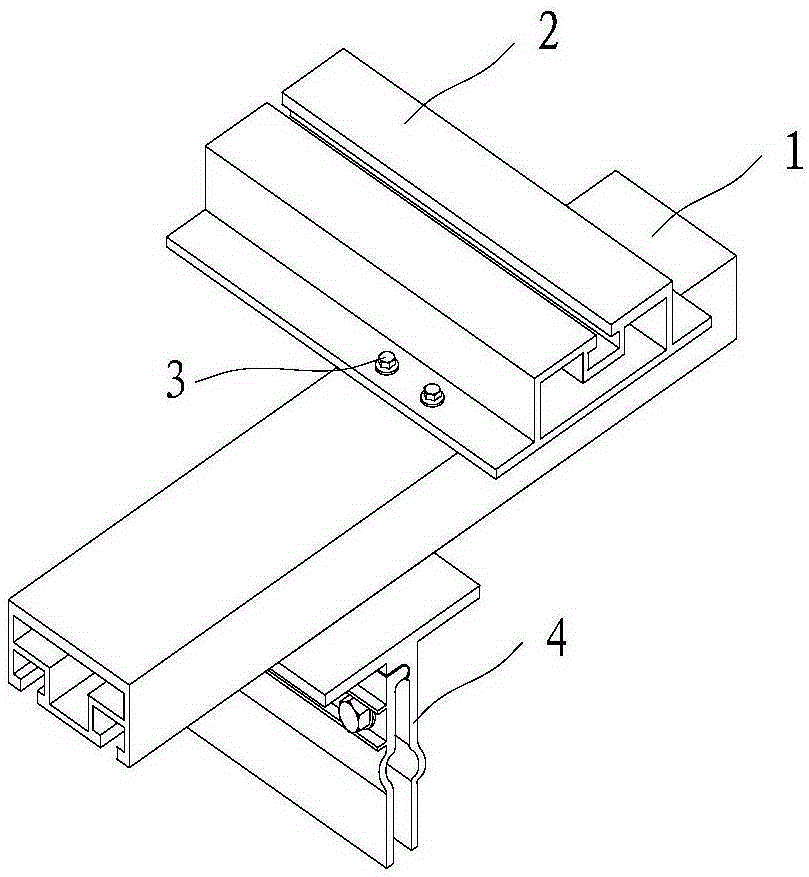

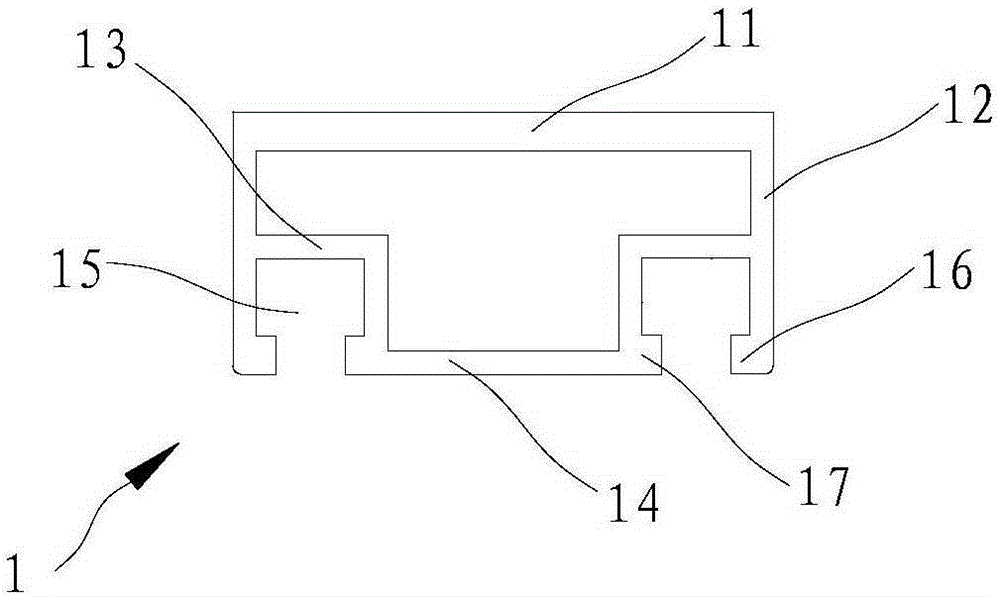

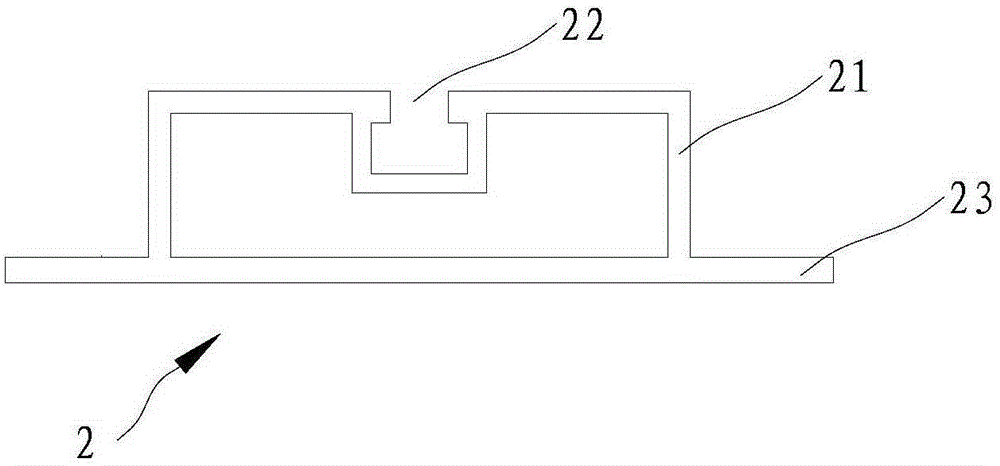

[0024] Such as figure 1 Shown is a schematic structural view of the keel structure of the preferred embodiment of the present invention, the keel structure includes a main keel 1, a secondary keel 2 fixedly installed on the main keel 1 by a first fastener 3 and a support for the main keel 1 The clamp 4; the first fastener 3 is a fastening bolt, and the fastening bolt is fixedly installed on the main keel 1 through the installation edge 23 on the secondary keel 2. The clamp 4 is installed under the main keel 1 . Preferably, the outer surfaces of the main keel 1 and the secondary keel 2 of the present invention are treated with fluorocarbon spraying. The keel structure treated with fluorocarbon spraying has excellent fading resistance, frost resistance, corrosion resistance to air pollution (acid rain, etc.), strong UV resistance, strong crack resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com