Recovery method of titanium oxydichloride waste liquid

A technology of titanium oxychloride and recovery method, which is applied in the preparation of titanium compounds, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of waste of titanium resources, increase the cost of wastewater treatment, etc., and improve the utilization rate. , Improve application value and economic value, improve the effect of whiteness and hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

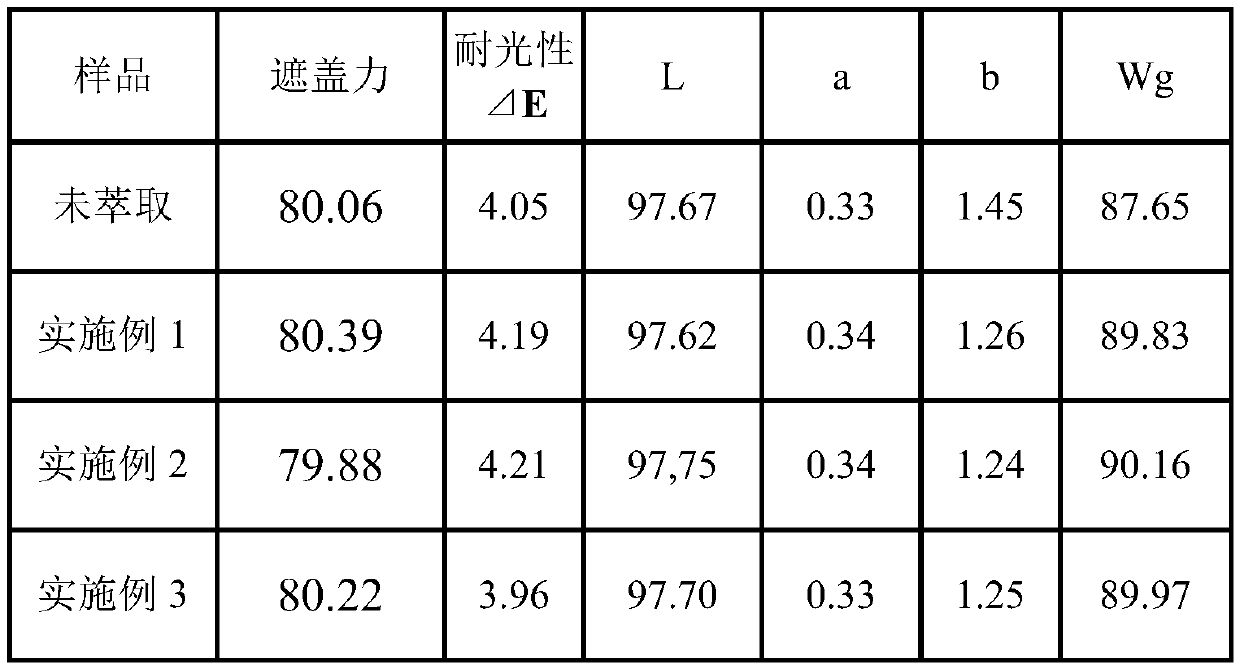

Embodiment 1

[0025] The tail gas produced during the preparation of titanium dioxide by the chlorination method is absorbed by hydrochloric acid to obtain a waste liquid of titanium dioxychloride. After analysis, the content of iron ions was 90.175ppm. In the case of stirring, continue to feed chlorine into the titanyl chloride waste liquid for 1 hour to fully oxidize the ferrous ions in the titanyl chloride waste liquid, and then use trioctyl decanyl tertiary amine extractant to extract , to obtain a titanyl chloride solution with an iron content of 2.385ppm and an organic extract phase containing ferric ions. Then, the organic extraction phase containing ferric ions is back-extracted with water, and ferric ions and hydrogen ions are extracted into water to obtain an acidic aqueous phase containing ferric ions and trioctyl tertiary amine extractant . During extraction, the volume ratio of organic extractant and titanyl chloride solution is 1:1, carry out 5 stages of extraction, the mixi...

Embodiment 2

[0027] The tail gas produced during the preparation of titanium dioxide by the chlorination method is absorbed by hydrochloric acid to obtain titanium dioxychloride waste liquid. Through analysis, wherein the content of iron ion is 88.335ppm, under the situation of stirring, continue to pass into chlorine gas 3h in this titanium oxychloride waste liquid, fully oxidize the divalent iron in the titanium oxychloride waste liquid, then use The tributyl phosphate extractant is used for extraction to obtain a titanium dioxychloride solution with an iron content of 2.067 ppm and an organic extract phase containing ferric ions. Then, the organic extract phase containing ferric ions is back-extracted with water, and the ferric ions and hydrogen ions are extracted into water to obtain an acidic aqueous phase containing ferric ions and a tributyl phosphate extractant. During the extraction, the volume ratio of the organic phase and the titanyl chloride solution is 1:3, and the 3-stage ex...

Embodiment 3

[0029] The tail gas produced during the preparation of titanium dioxide by the chlorination method is absorbed by hydrochloric acid to obtain a waste liquid of titanium dioxychloride. After analysis, the content of iron ions was 92.508ppm. In the case of stirring, continue to feed chlorine into the titanyl chloride waste liquid for 3h to fully oxidize the ferrous ions in the titanyl chloride waste liquid, and then use N,N-bis(1-methylheptyl base) hexanamide extractant for extraction to obtain a titanyl chloride solution with an iron content of 2.136 ppm and an organic extract phase containing ferric ions. The organic extraction phase containing ferric ions is then back-extracted with water, and ferric ions and hydrogen ions are extracted into water to obtain an acidic aqueous phase containing ferric ions and N, N-bis(1-formazan Heptyl) caproamide extractant. During the extraction, the volume ratio of the organic extractant and the titanyl chloride solution is 1: 5, and the 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com